Description

Fully equipped set for the cold extraction of hops in 4000-liters of beer and optionally also final carbonization of beer before filling of finalized beer into bottles, kegs, petainers etc.

Fully equipped set for the cold extraction of hops in 4000-liters of beer and optionally also final carbonization of beer before filling of finalized beer into bottles, kegs, petainers etc.

Make your own strongly bitter beer Pale Ale, India Pale Ale, prepared by original traditional recipes, using the professional equipment made in the CZECH BREWERY SYSTEM !

I. Basic set – extraction of hops into cold beer

The basic set includes :

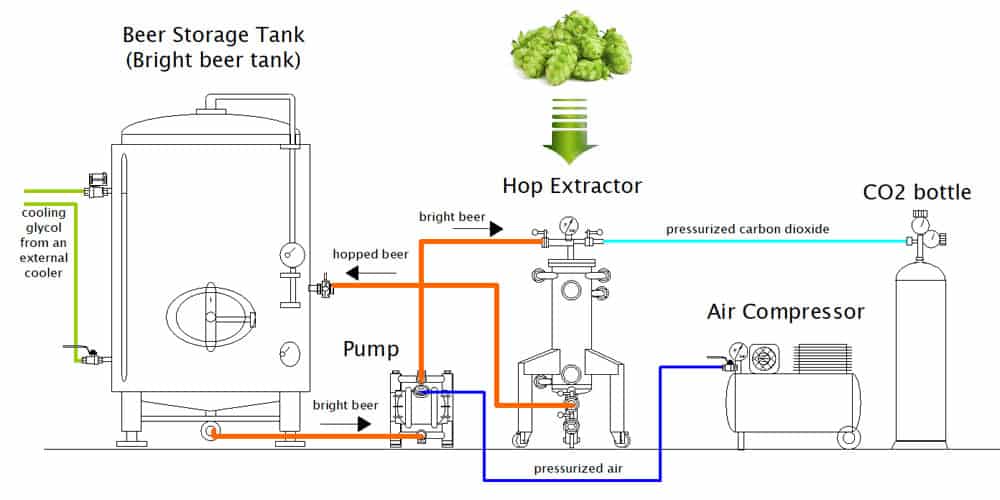

- Beer storage tank BBTVI-4000C : The cylindrical storage tank for final work with purified beverage (called also serving tank, filling tank, service tank, storage tank, BBT – bright beer tank) with a vertical construction and an insulated double steel jacket. The vessel is cooling by ice water or glycol that circulates in the cooling channels inside the cooling jacket. The tank has usable volume 4000 liters. The beer tank has to be cooled by glycol. We suppose the tank will be added to your current external glycol cooling system in your brewery.

- Hops extractor HX-60 : is an equipment for extraction of aromatic active substances from hops into cold beer (dry hopping) – an infusion of hops extracts to finalized cold beer after finalizing the beer fermentation process. This equipment is used in the production of strongly bitter beer types, such as IPA (India Pale Ale). The capacity of the hops tank is 60 liters.

- Pneumatic diagphragm pump : Special diaphragm pump for circulation of beer throuhg entire system. The pump is connected between the beer tank and Hops extractor , it is powered by pressured air (no electrical power connection). This type of pump is very friendly to beer and does not cause undesirable changes of its taste. Compressed air is never in contact with beer – therefore there is not needed to use the pump with a food friendly certificate..

- Hose set – All hoses needed to connection between the beer tank, hops extractor , diaphragm pump. This set does not include any hoses needed to connection of air compressor, pressure bottles with carbodioxide (needed for use of the carbonization candle) and hoses needed to transportation beer to/from the beer storage tank.

Optionally :

- Air compressor : Optional accessory. The air compressor is required to drive a diaphragm pump. It is possible to use any other air compressor available in the brewery instead, therefore it may not be included in the set.

- Reduction valve for CO2 pressure bottle : Optional accessory. We recommend to add this reduction valve if any other one is not available in your brewery. Pressurized carbon dioxide is necessary technical gas in all breweries to pushing of beer from tanks to other tanks, from filling beer into bottles or kegs, for filtering beer etc.

Scheme of the basic set CHS – the recommended connections and all needed equipment for the cold extraction of hops into beer

II. Extended set – extraction of hops into cold beer + carbonation of beer

The extended set includes :

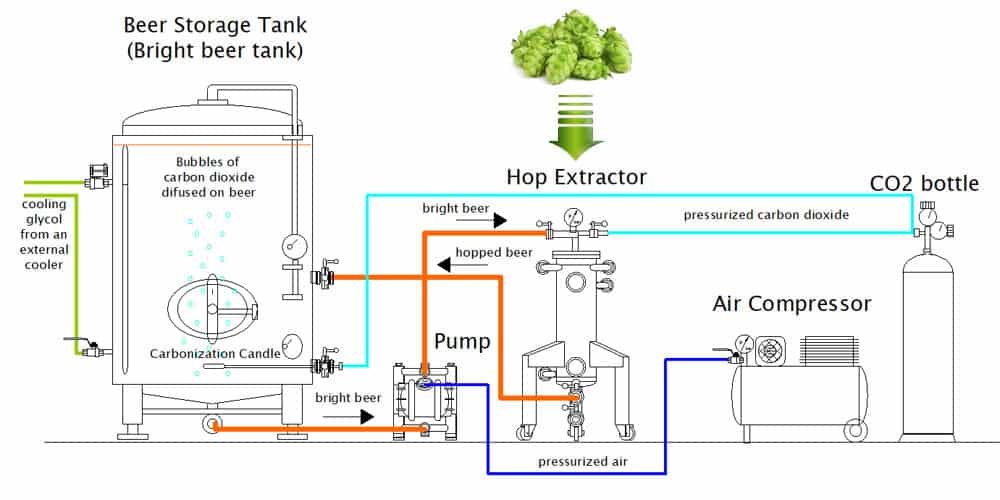

- Beer storage tank BBTVI-4000C : The cylindrical storage tank for final work with purified beverage (called also serving tank, filling tank, service tank, storage tank, BBT – bright beer tank) with a vertical construction and an insulated double steel jacket. The vessel is cooling by ice water or glycol that circulates in the cooling channels inside the cooling jacket. The tank has usable volume 4000 liters. The beer tank has to be cooled by glycol. We suppose the tank will be added to your current external glycol cooling system in your brewery.

- Hops extractor HX-60 : is an equipment for extraction of aromatic active substances from hops into cold beer (dry hopping) – an infusion of hops extracts to finalized cold beer after finalizing the beer fermentation process. This equipment is used in the production of strongly bitter beer types, such as IPA (India Pale Ale). The capacity of the hops tank is 60 liters.

- Pneumatic diagphragm pump : Special diaphragm pump for circulation of beer throuhg entire system. The pump is connected between the beer tank and Hops extractor , it is powered by pressured air (no electrical power connection). This type of pump is very friendly to beer and does not cause undesirable changes of its taste. Compressed air is never in contact with beer – therefore there is not needed to use the pump with a food friendly certificate..

- Hose set – All hoses needed to connection between the beer tank, hops extractor , diaphragm pump. This set does not include any hoses needed to connection of air compressor, pressure bottles with carbodioxide (needed for use of the carbonization candle) and hoses needed to transportation beer to/from the beer storage tank.

- Carbonization candle – Saturation candle for beverage tanks is designed for the saturation of the beer by sterilized compressed carbon dioxide before filling beer into packages when the beer is in the tank under pressure.

- Extended hose set – Hose and connectors to connection between the carbonization candle connected in the beer storage tank and the pressure bottle with carbon dioxide.

Optionally :

- Air compressor : Optional accessory. The air compressor is required to drive a diaphragm pump. It is possible to use any other air compressor available in the brewery instead, therefore it may not be included in the set.

- Reduction valve for CO2 pressure bottle : Optional accessory. We recommend to add this reduction valve if any other one is not available in your brewery. Pressurized carbon dioxide is necessary technical gas in all breweries to pushing of beer from tanks to other tanks, from filling beer into bottles or kegs, for filtering beer etc.

Scheme of the extended set CHS – the recommended connections and all needed equipment for the cold extraction of hops into beer and the carbonization of beer in the same beer tank

III. Full set – extraction of hops into cold beer + carbonation of beer + filling beer into bottles + filling beer into kegs + CIP cleaning and sanitizing system

The full set includes :

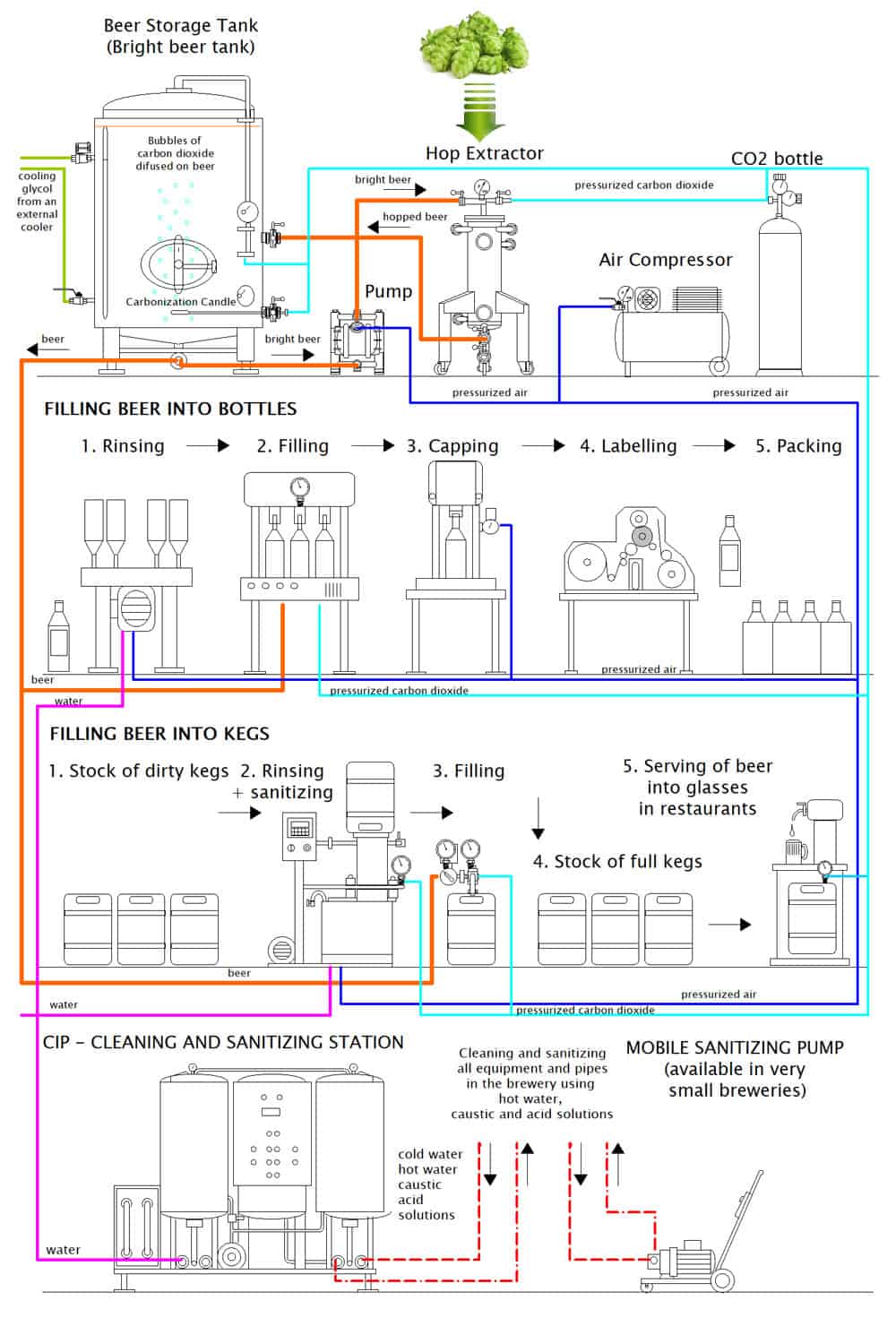

- Beer storage tank BBTVI-4000C : The cylindrical storage tank for final work with purified beverage (called also serving tank, filling tank, service tank, storage tank, BBT – bright beer tank) with a vertical construction and an insulated double steel jacket. The vessel is cooling by ice water or glycol that circulates in the cooling channels inside the cooling jacket. The tank has usable volume 4000 liters. The beer tank has to be cooled by glycol. We suppose the tank will be added to your current external glycol cooling system in your brewery.

- Hops extractor HX-60 : is an equipment for extraction of aromatic active substances from hops into cold beer (dry hopping) – an infusion of hops extracts to finalized cold beer after finalizing the beer fermentation process. This equipment is used in the production of strongly bitter beer types, such as IPA (India Pale Ale). The capacity of the hops tank is 60 liters.

- Pneumatic diagphragm pump : Special diaphragm pump for circulation of beer throuhg entire system. The pump is connected between the beer tank and Hops extractor , it is powered by pressured air (no electrical power connection). This type of pump is very friendly to beer and does not cause undesirable changes of its taste. Compressed air is never in contact with beer – therefore there is not needed to use the pump with a food friendly certificate..

- Hose set – All hoses needed to connection between the beer tank, hops extractor , diaphragm pump. This set does not include any hoses needed to connection of air compressor, pressure bottles with carbon dioxide (needed for use of the carbonization candle) and hoses needed to transportation beer to/from the beer storage tank.

- Carbonization candle – Saturation candle for beverage tanks is designed for the saturation of the beer by sterilized compressed carbon dioxide before filling beer into packages when the beer is in the tank under pressure.

- Extended hose set – Hose and connectors to connection between the carbonization candle connected in the beer storage tank and the pressure bottle with carbon dioxide.

… and also the special recommended accessories :

Equipment to filling of beer into bottles :

- Equipment to blowing and rinsing of dirty empty bottles – Machine for the preparation of pure bottles before their filling by beer.

- Equipment to filling beer into bottles – Machine for isobaric filling beer from the beer storage tank to bottles under pressure.

- Equipment to closing of bottles – Machine for closing of bottles by crown caps (pneumatic system powered by pressurized air)

- Equipment to labelling of bottles – Machine for the gluing of prepared etikets to surface of bottles. The paper etikets must be pre-printed in rolls on any laser printer that is not in this set. The roll with all etikets must be compatible with this machine.

Equipment to filling of beer into kegs :

- Special valve to manual filling of beer into kegs – Special filling head to safe manual isobaric filling process that is usable for filling of beer into petainers or pure sanitized steel kegs.

- Equipment to rinsing of dirty empty kegs – Special professional powerfull machine to rinsing, sanitizing, cleaning of kegs and filling beer into kegs (that are designed for reuse).

Equipment to cleaning and sanitizing of all equipment in the brewery

- CIP mobile pump – Simple solution for the smallest breweries. The pump ensures the circulation of sanitizing solutions through the beer storage tank and all pipes.

- CIP cleaning and sanitizing station – The professional machine to cleaning and sanitizing all tanks and pipes. The CIP station should be available in each good brewery.

Optional accessories :

- Air compressor : Optional accessory. The air compressor is required to drive a diaphragm pump, blowing of bottles and kegs, powering of the bottle crown capper and it also cooperates with many other machines in the brewery. It is possible to use any other air compressor available in the brewery instead, therefore it may not be included in the set.

- Reduction valve for CO2 pressure bottle : Optional accessory. We recommend to add this reduction valve if any other one is not available in your brewery. Pressurized carbon dioxide is necessary technical gas in all breweries to pushing of beer from tanks to other tanks, from filling beer into bottles or kegs, for filtering beer etc.

Scheme of the full set CHS – the recommended connections and all needed equipment for the cold extraction of hops into beer + the carbonization of beer in the same beer tank + filling of beer into bottles + filling of beer into kegs + cleaning and sanitizing equipment

Why to use the hop extractor?

- It emphasizes the aroma of hops in beer

- Sensitive and careful dissolution of hop pellets (type 45 and 90) in the cold beer

- Optimal extraction and increase in the proportion of essential oils in finished beer

- Fixed period of the extraction of hops

- Without heating, absence of agitators

- Excellent separation of extracted substances – it does not cause problems during a filtration

How does it work:

- Firstly, open a top lid of the device (unscrew all screws).

- Fill with: hop pellets (20% of the total volume of the hop extractor) and close the top lid, tighten all screws of the lid.

- Connect a beer tank and the device with the membrane pump according to the picture above.

- Push air out – start to fill the device with beer and open the top CO2 inlet. The air will be pushed out through the opened valve. Close the top part when the device is full of beer.

- If the pressure in the tank of the device is too low, refill CO2 into the tank from the CO2 bottle.

- Open all valves in the circle. (Input and output: the device, input and output of the beer tank).

- Turn on the membrane pump (2 – 6 hours). The time of the extraction of hops depends on a volume of the beer tank.

- Push all beer – start to fill the device with CO2 and open a bottom HG outlet. Beer will be pushed out through the opened valve.

- Close all valves in the circle. (Input and output: the device, input and output of the beer tank)

- Reconnect the system, clean and disinfect the device, pump and hose.

- If the pressure in the tank is too low, refill CO2 into the tank from the CO2 bottle.

- Your beer is now ready.

Reviews

There are no reviews yet.