Description

Compact machine designed to automatic filling of non-carbonated or carbonated beverages (beer, cider, kombucha, sparkling wine, sparkling water) into aluminium cans.

This can filling machine is able to fill beer into cans with speed up to 25 cans (150 ml up to 500 ml) per minute (1500 cans per hour).

You can fill all types of cans quickly and easily with this compact machine.

Carbonated beverages like beer, cider, sprakling wine, kombucha or sparkling water should go to the machine as cold as possible, at between 2.1 to 2.6 vols CO2 (4.1 – 5.1 grams of CO2 /liter). Maximum temperature of 2°C is optimal.

Can height and filling height are adjustable. The 7” waterproof touchscreen is used to set all filling parameters: CO2 pre-purge time, filling time and pressure, etc.

Suitable for all types of aluminium cans, both slimline and standard sizes (with capacity of 150 ml up to 500 ml).

How the machine works :

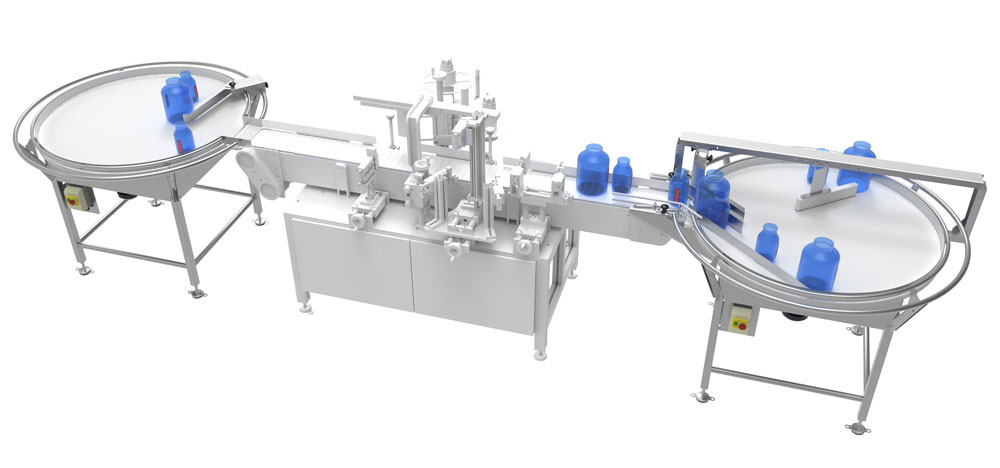

Cans are fed into the machine by either a depalletiser or loading onto the conveyor by hand. Place empty cans on the infeed rotary table, let the machine work and take off the full cans with seamed lids from the collection table. Everything in between is fully automatic. Optionally you can order the machine with a depalletiser, can lowerator, labelling unit and the date/batch coder (ink jet printer).

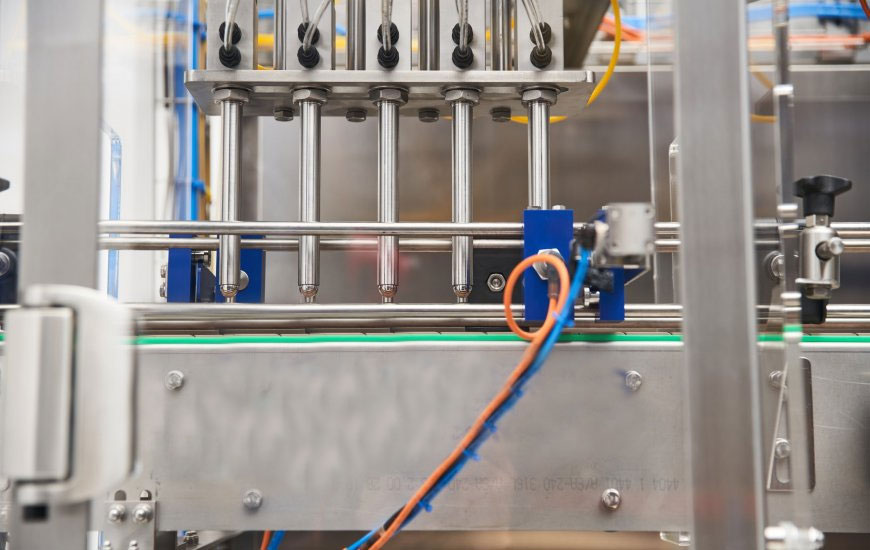

The cans are transferred on the conveyor underneath the filling valves. The cans are held in position and the valves are lowered into the cans. The CO2 purges the cans to remove all the oxygen and then the valves are opened to allow the beverage to flow into the cans.

The volume of beer is controlled using volumetric flow valves for the most accurate fill level. Once the fill level has been reached, the cans travel on the conveyor through the gassing tunnel to keep oxygen out of the can until the can is under the seaming unit.

The machine utilises a built in sophisticated pressure monitoring system to fill by time to within +/- 2ml. The machine monitors the source tank pressure and is able to maintain a consistent top pressure by automatically topping up with CO2 as required.

The lid is collected by the can while simultaneously a final jet of CO2 is placed underneath the lid.

The can is seamed with a lid and then it is pushed through the rinser to remove any excess liquid from the can.

Finally, the can passes through the air knives which blow the water down the can body to leave a clean, sealed can at the end of the conveyor.

Main features :

- Compact filler for aluminium cans

- EHDEG compliant can filling line

- Equipped with 5 filling heads for standard cans 150 up to 500 ml

- Maximal dimensions of the cans : 71 mm in diameter and 230 mm high

- Output capacity : up to 1500 cans per hour

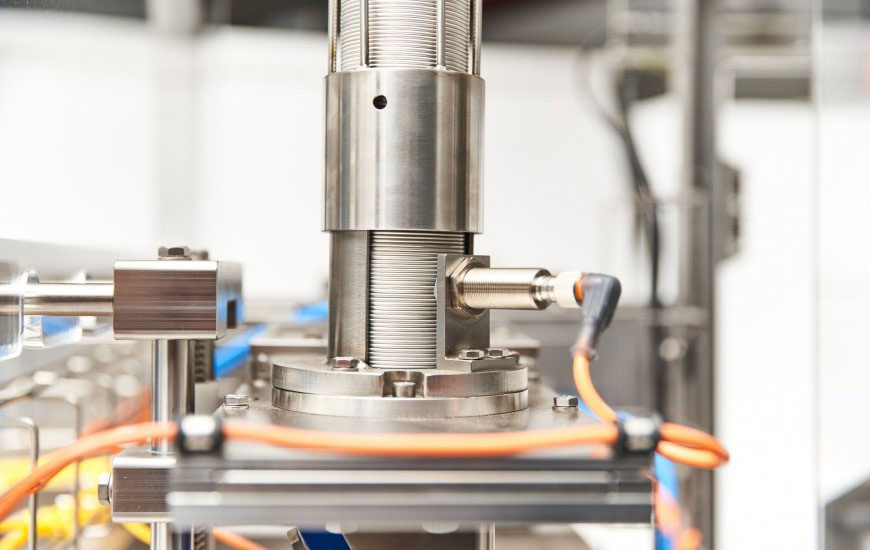

- Quick and easy height adjustment of seaming heads and the lid dispenser

- Fully automatic pre-purge and filling with unique sensor technology

- Foam creation technology for minimal oxygen pickup

- Disolved oxygen level is less than 20 ppb

- Stainless steel frame

- Stainless steel AISI 316L valves with EPDM seals

- 7” waterproof touchscreen LCD

- PLC controller : Siemens Simatic S7 with lifetime updates of software

- Beverage input: TriClamp 1.5” (DN40)

- Compressed air input: 10 mm hose push in connector (John Guest) / BSP threaded pipe 3/8″ / 10 bar max./ 6 bar min. / Maximal consumption of 150L min

- Carbon dioxide input: 10 mm hose push in connector (John Guest) / BSP threaded pipe 3/8″

- Power supply : 3-phase 380 ~ 420 V / 50-60Hz, current consumption 16A max.

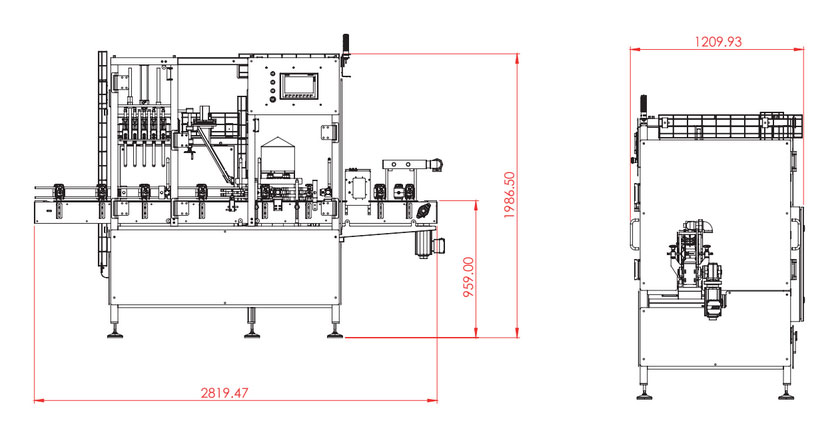

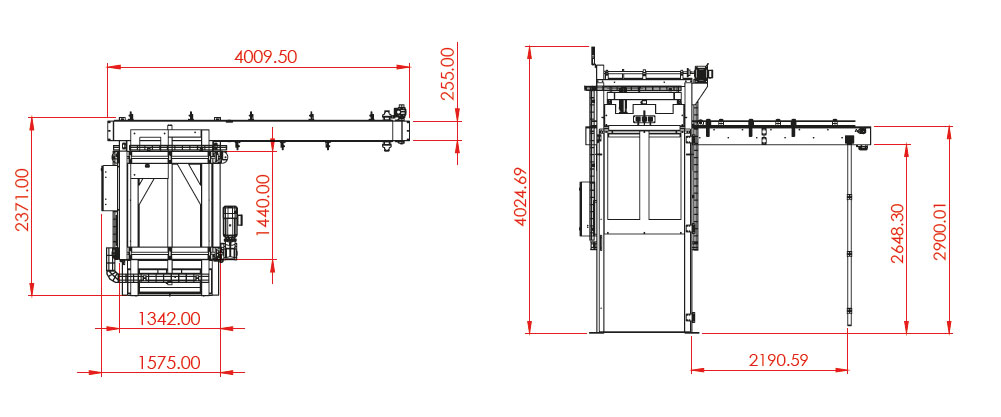

- Dimensions: 2860 x 1200 x 2000 mm (W x D x H)

- Net weight : 500 kg

- Transporting dimensions: wooden pallet 2900 x 1300 x 2200 mm (W x D x H) / 600 kg

- Delivery period is approximately 2-4 months (according to current saturation of our production capacity)

Dimensions :

Configurator :

Code |

Description |

Price |

| CFS-25INFA | Compact fully-automatic can filling and capping machine – up to 1500 cans per hour | On demand |

| Optional equipment : | ||

| CFS-RIFT | Rotary can infeed table (for manual loading the empty cans) | On demand |

| CFS-RCCT | Rotary can collection table (for manual unloading the full cans) | On demand |

| AWLM-PL501 | Automatic can labelling machine (for wraparound self-adhesive labels) | On demand |

| CIJ-AX150I | Continuous inkjet printer (date/batch/QR coder) | On demand |

| CFS-DEP6000 | Automatic depalletiser | On demand |

| CFS-LOW6000 | Automatic lowerator (can conveyor between the depalletiser and the filling machine) | On demand |

| CFS-INDS | Integrated nitrogen dosing system | On demand |

Recommended example configurations :

Version |

Description |

Price |

| CFS-25INFA-C1 | Compact fully-automatic can filling and capping machine (without other accessories) | On demand |

| CFS-25INFA-C2 | Compact fully-automatic can filling and capping machine + infeed table + collection table | On demand |

| CFS-25INFA-C3 | Compact fully-automatic can filling and capping machine + labelling unit + printing unit | On demand |

| CFS-25INFA-C4 | Compact fully-automatic can filling and capping machine + depalletiser + lowerator | On demand |

| CFS-25INFA-C5 | Compact fully-automatic can filling and capping machine + depalletiser + lowerator + infeed table + collection table | On demand |

| CFS-25INFA-C6 | Compact fully-automatic can filling and capping machine + depalletiser + lowerator + labelling unit + printing unit + infeed table + collection table | On demand |

Optional equipment :

Rotary tables for the loading and unloading the cans

CFS-RIFT : Rotary can infeed table (for manual loading the empty cans) | CFS-RCCT : Rotary can collection table (for manual unloading the full cans)

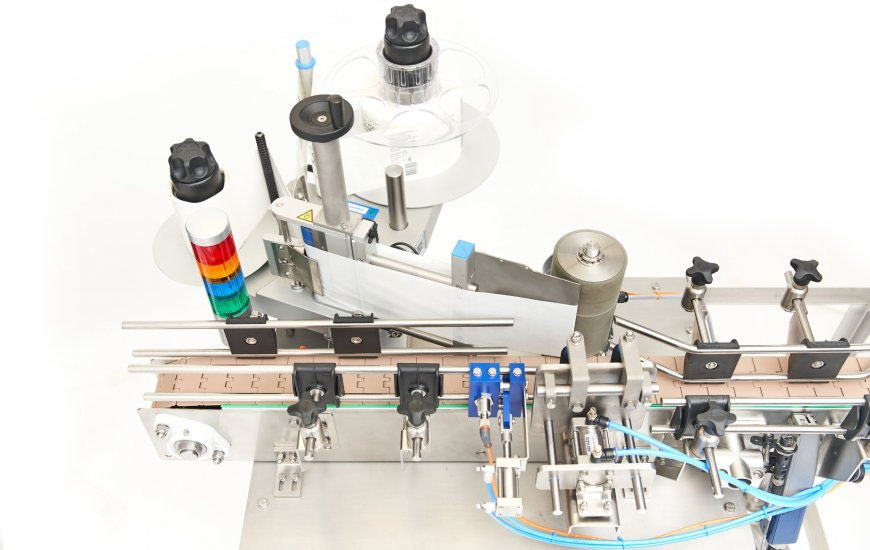

AWLM-PL501 : Automatic can labelling machine (for wraparound self-adhesive labels)

Fully automated, inline, wraparound labelling system.

The AWLM-PL501 is a high-quality, versatile and affordable can labelling machine with an operator-friendly control system for ease of use.

This vertical wrap around labeller can provide accurate and secure labelling of aluminium cans, reducing the need for manual involvement. It has a basic mechanical construction that allows it to perform at high speeds with stability.

The AWLM-PL501 is built of stainless steel and anodised aluminium and treated to guard against the effects of harsher environments. This durability translates into a solid choice for labelling machine longevity. It is dependable, reliable and easy to maintain.

CIJ-AX150I : Continuous inkjet printer (date/batch/QR coder)

The CIJ-AX150I continuous ink jet (CIJ) printer can print high quality codes on virtually any surface and product; whether flat, round, uneven or moving.

The CIJ-AX150I is compatible with Industry 4.0 standards.

Connecting to Domino Cloud enables remote diagnostics and 24/7 visibility of your printers’ performance. The integrated touchscreen user interface provides a class-leading user experience.

Domino’s service-free ink system with i-Pulse printhead technology utilising Domino-developed inks provides clear, readable text, graphics and barcodes while ensuring regulatory compliance.

CFS-DEP6000 : Automatic depalletiser

The depalletiser is a fully automated machine for transferring standard or slim beverage cans from supplier pallets to the canning line. It is fully integrated

with the canning line and uses a Siemens S7-1200 PLC for the control system and a Siemens HMI.

For optimum hygiene, the depalletiser is manufactured from food grade AISI 304 stainless steel. This ensures robustness and a high level of cleanliness, as well as the safe use of cleaning agents. A food grade grease is specified for machine lubrication.

The safety interlock system ensures the operator cannot come into contact with any moving parts of the depalletiser.

CFS-LOW6000 : Automatic can lowerator

The automatic lowerator is a special can conveyor between the depalletiser and the filling machine …