Description

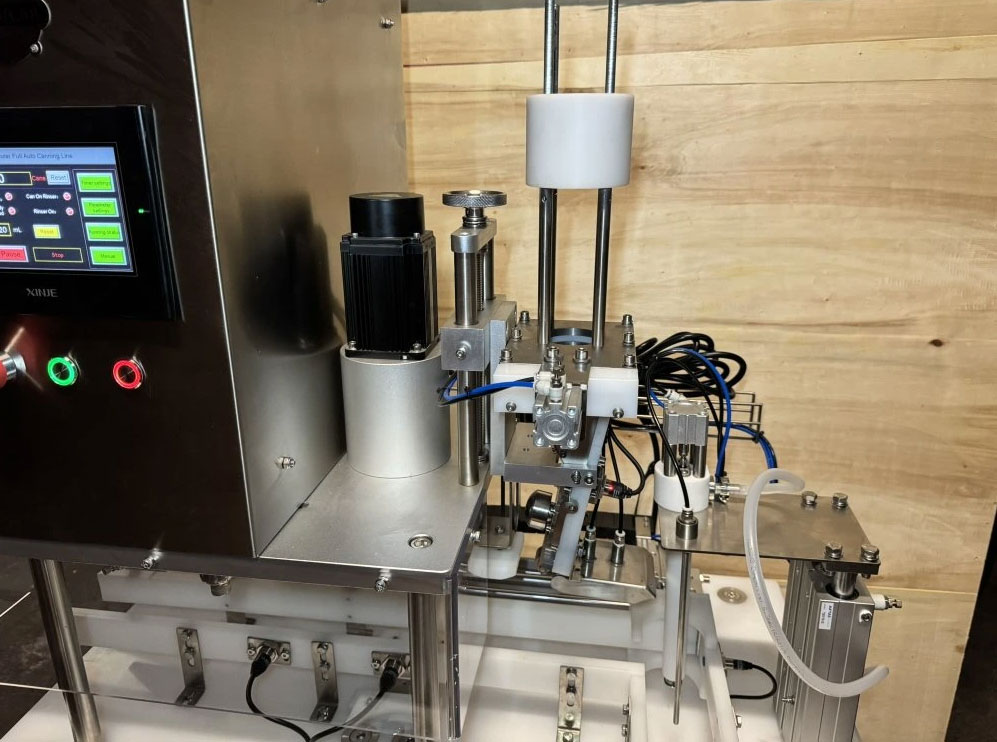

Compact machine designed to filling beer, cider or other similar beverages into aluminium cans and closing the cans with standard lids. This can filling line is able to fill and package beer into cans with speed up to 15 cans per minute (900 cans per hour) making this the highest output compact machine ever manufactured within this small dimensions.Easy to operate, the entire can filling and capping process can be handled by one operator. Simply fill the trays with cans and caps and remove the finished products from output side of the machine.

Compact machine designed to filling beer, cider or other similar beverages into aluminium cans and closing the cans with standard lids. This can filling line is able to fill and package beer into cans with speed up to 15 cans per minute (900 cans per hour) making this the highest output compact machine ever manufactured within this small dimensions.Easy to operate, the entire can filling and capping process can be handled by one operator. Simply fill the trays with cans and caps and remove the finished products from output side of the machine.

The cheapest compact fully automatic can filling line on the World

The Cannular brand of the KegLand company launched the manual can seaming machine at the start of 2019 that was affordable and accessible to home brewers worldwide. It gave home brewers and craft brewers the ability to get start their small scale filling into cans while still maintaining very low dissolved oxygen level, perfect can seam tightness and lock in beverage quality.

Since then the Cannular machines have become the worlds most popular can filling machines ever manufactured, selling worldwide in America, Europe, UK, New Zealand and Australia. On the back of this success KegLand then has further built the Cannular brand name to develop and deliver in world market a semi automatic can filli machine and now is delighted to bring out the Cannular Full Auto – the compact can filling machine, with capacity up to 15 cans per minute or 900 cans per hour.

In essence with the whole Cannular range it depends on fundamentally simple processes and when combined with modern engineering provide an elegantly simple solution to small scale packaging the beverages.

The Cannular Fully Auto can filling line will suit a small to medium sized brewery filling into cans in volumes from 1000L and up to 5000L on one batch.

Main properties :

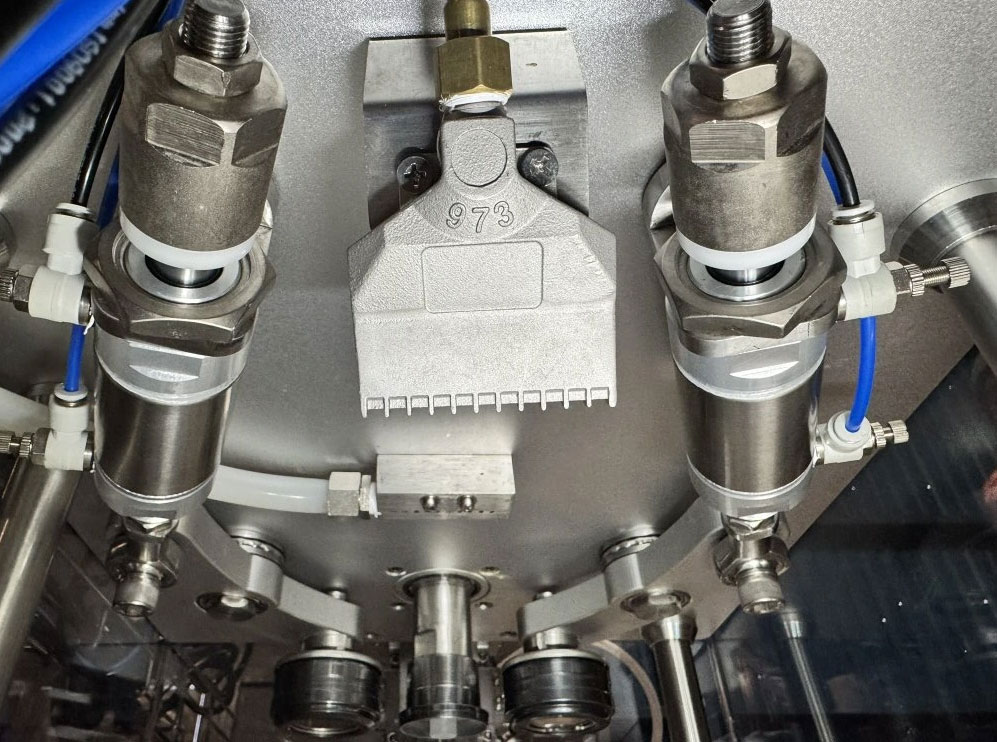

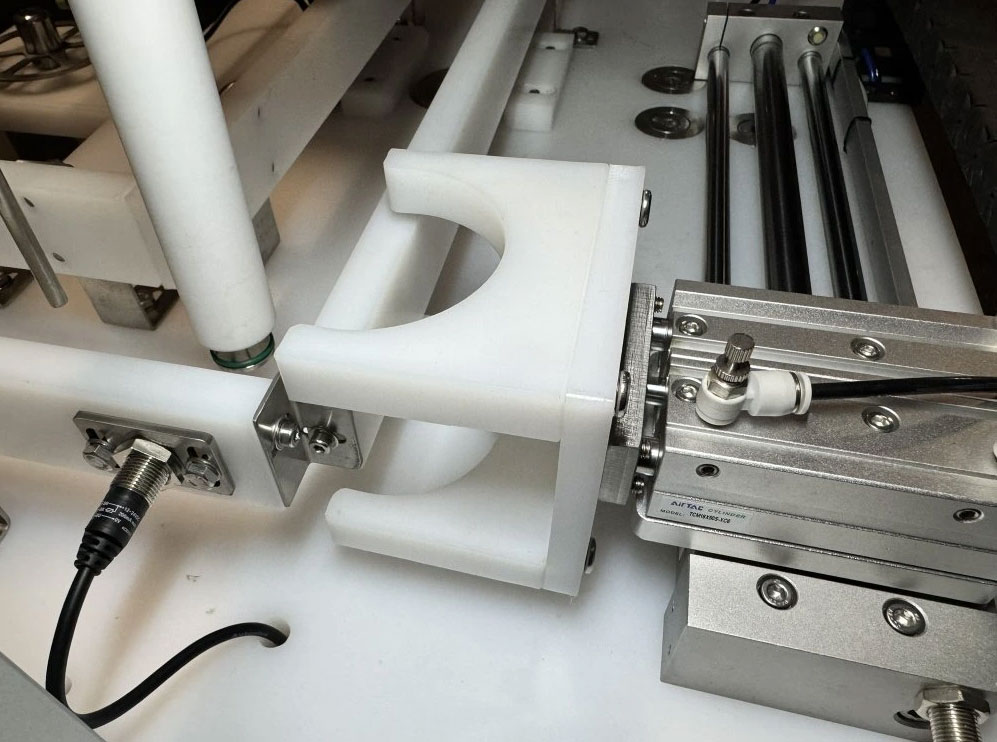

- Supplied as standard with both chucks (B64 for 202 B64-lids, CDL for CDL-lids) that suits 202 can bodies.

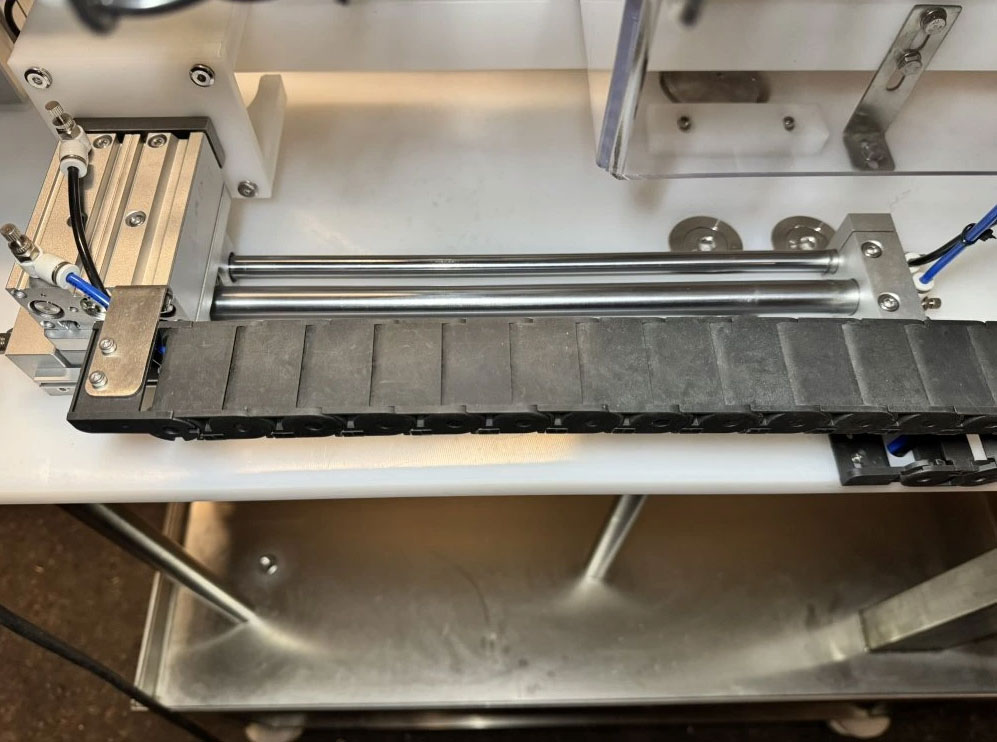

- Compact size of the machine

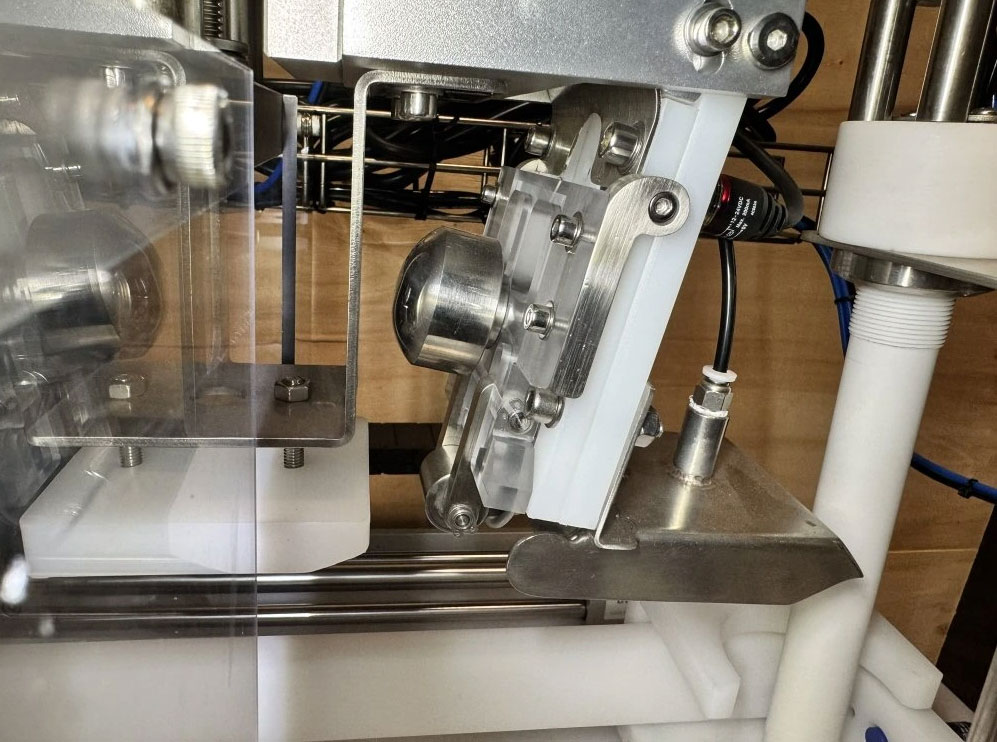

- Easy and quick maintenance adjusting

- The compact footprint means this canning line is almost the size of a standard pallet so it can be stowed into pallet racking or wheeled out of the way easily.

- Process automation: Filling, CO₂ flushing, and can sealing in one device

- Possibility of adapting to different can sizes and detailed calibration of the double seam

- Equipped with adjustable feet and wheels with brake for easy movement and stability during operation

- High capacity: Up to 15 cans per minute (when using 330 ml cans at low carbonation level)

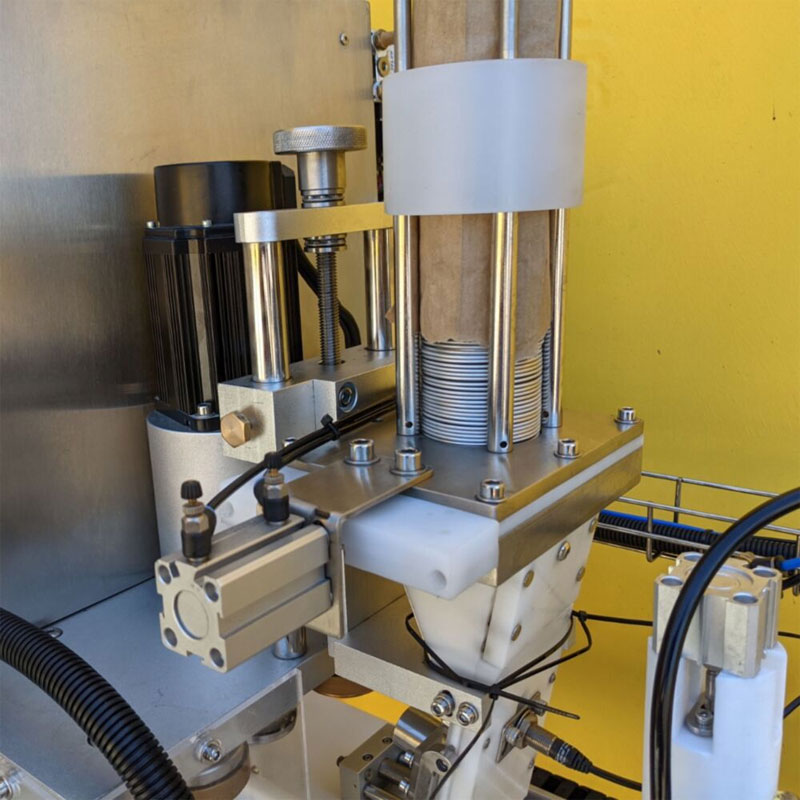

- Clamping head: Cr12MoV clamping heads with titanium coating, which ensures long life and minimal maintenance

- All parts that come into contact with water or beverages are made of high-quality materials such as nylon, Teflon and AISI 304 stainless steel

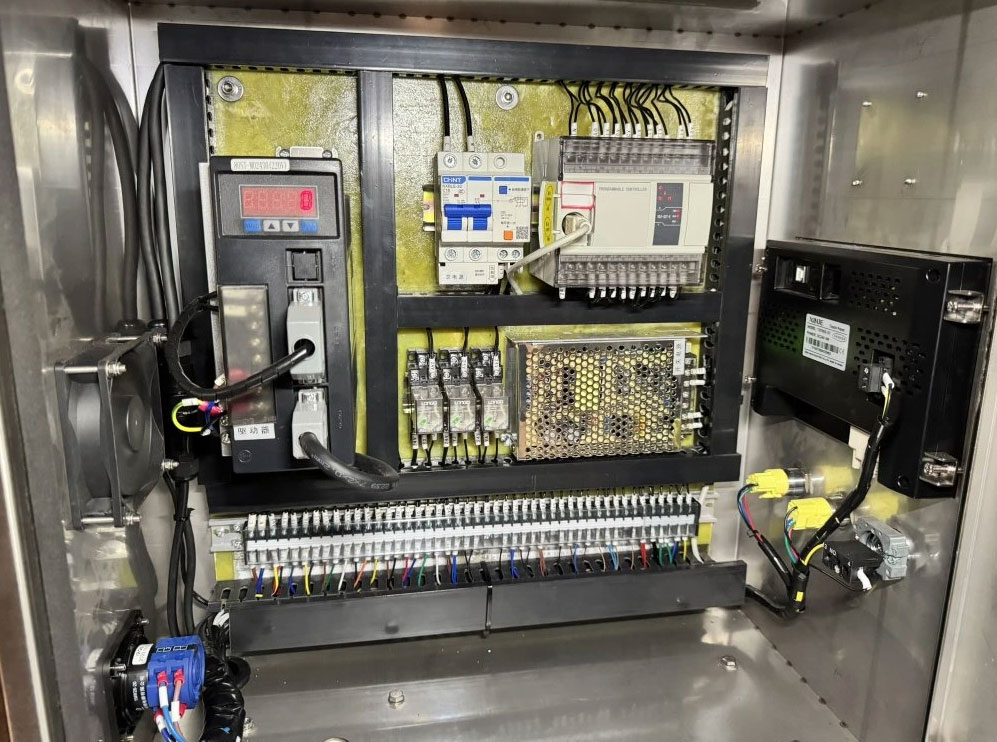

- Clear control with the option of manual and automatic mode

- Eco-friendly choice – cans are more environmentally friendly than plastic.

Technical specifications :

- Power supply : Single Phase 230V / 50Hz

- Operating Air Pressure: 100 psi (7 bar)

- CO₂ Flush: Recommended Pressure 3 psi (0.2 bar)

- Disinfectant Rinse: Maximum Pressure 15 psi (1 bar)

Dimensions for transport :

- Wooden pallet : 120 x 85 x 215 (h) cm / 330kg

Main advantages :

Empty can rinsing

The built-in empty can rinsing system ensures thorough removal of dirt, dust and possible contaminants from the can before filling.

Flushing of the can with CO₂ before filling

The Cannular is equipped with a food-grade carbon dioxide (CO₂) can flushing system that minimizes the oxygen content in cans before filling, thereby extending the shelf life of beverages.

Rinsing filled and sealed cans

The device includes an outlet for connecting a disinfectant or rinsing agent, which ensures thorough cleaning of closed cans from any beverage residues or foam.

Integrated can dryer

The built-in dryer (Airblade system) effectively removes residual moisture from the surface of the cans after rinsing. The cans are ready for labeling, packaging or storage immediately after passing through the dryer.

Compact Size

The compact footprint means this can filling line is almost the size of a standard pallet so it can be stowed into pallet racking or move it out on wheels easily.

Hardened chuck

The chucks on this machine are made from chrome steel Cr12MoV which is then coated with Titanium. This steel grade has superior hardness so it can last an extremely long time without needing to re-tune the machine or change the chuck. The hardness is 58-62 dH. manufactured if requested.

Washdown of the machine

As the machine is fairly compact its setup and wash down is extremely simple. The whole operating deck can be washed down with a hose and the chassis is mounted with oversized drip tray to catch stray drips from the filling process. The drain pipe can also be connected to sewerage so cleaning in place (CIP) can be implemented. All wet areas are made from nylon, teflon and AISI 304 stainless steel.

Maintenance of the machine

The machine is made with European pneumatics elements, electronic controllers, flow sensors and industrial grade PLC you can be confident that all components are build to last transport to the distance and they are designed to handle millions of cans before requiring an overhaul. We recommend that tolerances are checked on the rolls and chuck every 100000 cans and lubricate some of the pnuematics. Fortunately, all spare parts are supplied by KegLand so you know you will not wait too long for replacement parts if you need them. No major overhauls will be required until well over 1 milliion cans have gone through this machine. Even when that time comes the maintenance procedures are relatively straight forward and easy. Every filling unit is backed by KegLand’s legendary customer service.

Low labour cost

As this machine is relatively small and simple to run only one operator can load cans and lids into the respective hoppers and also package cans from the output of the machine. You need not more operators. Larger more complicated machines often require several operators.

Easy setup before the first useIt is important that you develop an in-depth understanding of how to setup, adjust and trouble-shoot this machine to optimise the canning process. There is a detailed start up manual and also the installation video below which guides you through the initial setup of the machine which would need to be made to get this machine in operation correctly.

Recommendations for use:

Cool your beverage to 2-4°C before filling to minimize foaming.

For maximum efficiency, we recommend using a flow-through chiller to pre-cool beverages (e.g. CIMF-4500 : Compact flow-through chiller 0.5 kW for 4 beverage lines with a pump) .

Adjust the device settings to the size of the cans and the desired filling parameters.

Quick start manual

Quick start manual to download is here

Videos :

Introduction of the Cannular Fully Auto can filling machine :

How to set up the Cannular Fully Auto can filling machine before the first use :