Description

CCT-SNP-300 is the simplified non-pressure cylindrically-conical fermentation tank with usable volume 300 liters and total volume 354 liters for fermentation (not suitable for maturation, storage, filtering, bottling, filling into kegs) of beer, cider, wine and other beverages. Made of stainless food steel DIN 1.4301 (AISI 304). Maximal pressure 0 bar, noninsulated, with water (or glycol) cooling channels.

Dimensions

| Usable volume [liters] | 300 |

| Total volume [liters] | 354 |

| Cylindrical part – volume [liters] | 276 |

| Conical part – volume [liters] | 77 |

| Total height [mm] | 1824 |

| Total diameter [mm] | 800 |

| Weight of empty tank [kg] | 184 |

| Weight of full tank [kg] | 538 |

Standard properties, design and equipment

| Maximal allowed overpressure | 0 bar |

| PED 2014/68/EU certificate | no |

| GUM / GOST certificate | no |

| Inner surface – plates | 2B |

| Inner surface – roughness | Ra<0.8μm |

| Outer surface – plates | 2B |

| Outer surface – welds | natural |

| Cooling channels in the cylindrical part | yes |

| Cooling channels in the conical part | no |

| Insulation of the tank | surcharge |

| Outer jacket | no |

| Top manhole | DN400 |

| Clear product drain outlet + butterfly valve | DN25 |

| Complete content drain outlet + butterfly valve | DN25 |

| Rotary sanitation sprayball + CO2 input | yes |

| Sampling valve | DN10 |

| Manometer | no |

| Temperature measuring-welded threaded connector | DN10 |

| Automatic temperature control system | surcharge |

| Independent safety overpressure valve | no |

| Underpressure – ovepressure valve | 0.1/0.5 bar |

| Fermentation lock and bung for fermentation vessel | yes |

| Overpressure setting mechanism [range] | no |

| Product level indicator | surcharge |

| Carbonization stone | no |

| Height-adjustable legs and feet [pcs] | 3 |

| Usable for the fermentation process | yes |

| Usable for the maturation process | no |

| Usable for the storage of the finished product | no |

| Usable for the non-pressure product flotation | yes |

| Usable for the product clearing under pressure | no |

| Usable for the product filtration under pressure | no |

| Usable for manual filling of the product into kegs | no |

| Usable for manual filling of the product into bottles | no |

| Usable for machinery filling of the product into kegs | no |

| Usable for machinery filling of the product into bottles | no |

Optional equipment (for surcharge)

| Clear product drain outlet with adjustable level inside tank – adjustable only with empty tank | € 327 |

| Clear product drain outlet with adjustable level inside tank – adjustable with full tank – rotation arm | € 650 |

| Inner surface gloss 2R | € 865 |

| Insulation 50 mm – Mirelon foam is glued on the cylinder and cone part (88% of CCT surface) | € 682 |

| Side manhole instead top one | no |

| Product level indicator | € 196 |

| Carbonization stone (sintered stainless steel) | no |

| GUM / GOST certificate | no |

How to choose the right type of CCT ?

| Type of CCT | CCT-SNP | CCT-SLP | CCT-SHP |

|---|---|---|---|

| Maximal adjustable pressure in the tank | 0.0 bar | 1.2 bar | 2.5 bar |

| Usable for the fermentation process | yes | yes | yes |

| Usable for the maturation process | no | yes | yes |

| Usable for the storage of the finished product | no | yes | yes |

| Usable for the non-pressure product flotation | yes | yes | yes |

| Usable for the product clearing under pressure | no | yes | yes |

| Usable for the product filtration under pressure | no | no | yes |

| Usable for manual filling of the product into kegs | no | yes | yes |

| Usable for manual filling of the product into bottles | no | yes | yes |

| Usable for machinery filling of the product into kegs | no | no | yes |

| Usable for machinery filling of the product into bottles | no | no | yes |

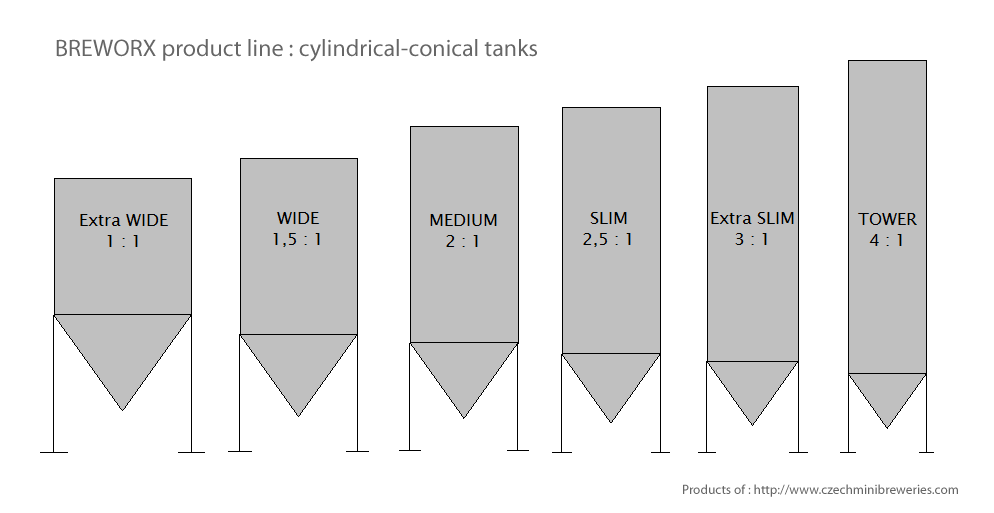

Do you need other dimensions of the CCT tank?

Optionaly we can produce the CCT tank also with other ratio of dimensions :

Prices of nonstandard dimensions … on request.

We recommend to buy also :

1. The cooling system for CCT tanks

Choose a suitable system for cooling your CKT tanks. If you you’re not sure that the choosed cooling system is suitable for you, we’ll be happy to advise you.

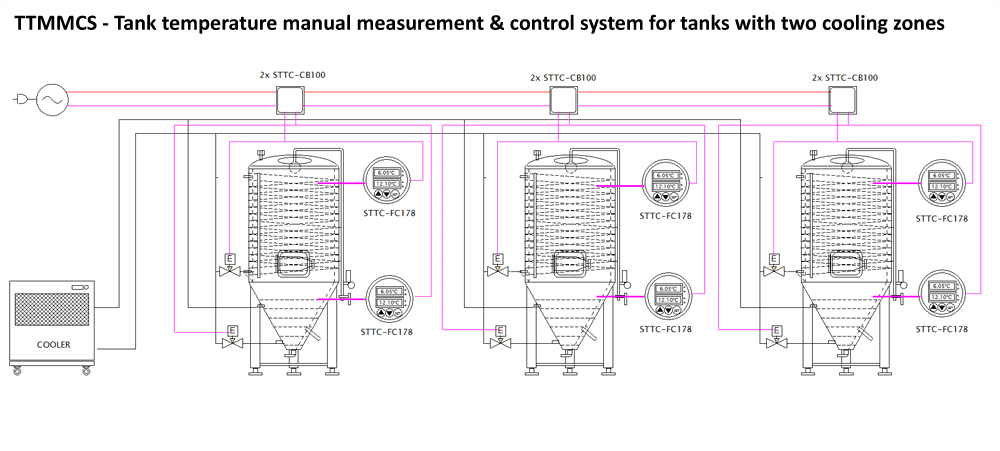

2. The temperature control system for CCT tanks

The tank temperature control system for manual control or automatic control of temperatures in the fermentation and maturation process is recomended accessory for each cct tank.

3. The CIP cleaning and sanitizing station

The CIP station is very recommended equipment for easy cleaning (by cold and hot water) and sanitizing (by acid and hydroxide) of the tank and all pipes and hoses that are in contact with the product. There is not possible to produce a good beverages without professional care of perfect cleanliness of the production equipment.

4. Fruit juice flotation equipment

The special machine for easy removing of solids and sludges from the pressed fruit juice or wine using the flotation process. Necessary equipment for get clear beverage before fermentation process. The flotation process is not using during beer production.

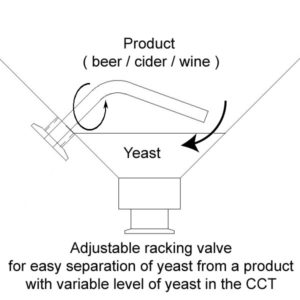

5. Our best tip : Adjustable pure product drain valve for CCT – the special equipment for preventing loss of the product

We recommend to use our new adjustable pure product drain valve system for easy separation of yeast from the product (beer, cider, wine …) without loss of product residues.

This system allows the precise height setting of the outlet pipe suction hole just above the actual level of yeast in the tank.

No more product loss – no unusable residues in the tanks.

Your price : 650 Eur surcharge

Our recommendation:

If you are comparing our prices with competitors, please always make sure that any other manufacturer guarantees the same quality as our company offers.