Description

The tunnel pasteurizer BTP-1200P with capacity 1200 bottles or cans per hour is intended to pasteurize beverage product inside cans or bottles to desired temperature, which should assure proper microbiological stability of the beverage produced(heat treatment process).

FIELDS OF USE

- Beer and beverage industry

- Vegetable and fruit processing

- Ketchup and sauces

- Jams

- Liquid food

Description of the construction :

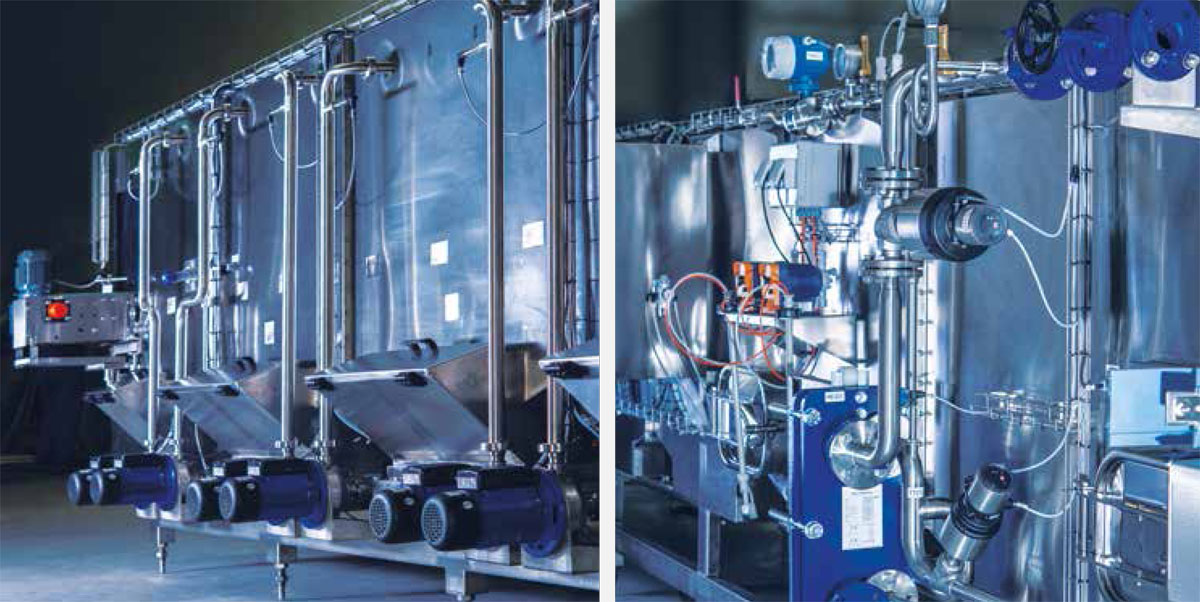

Construction of the machine is made completely from stainless steel AISI 304. This means that there are no parts from cast or iron or carbon steel. Result of this important fact is construction, which enables long life period of machine and corresponds to standards in food production industry. The machine is designed as monolith.

** The photo is symbolic (an actual pasteurizer can be in different design)

The machine is placed on multiple (height adjustable) legs, enabling adequate distribution of load and overcoming potential differences in floor heights.

The machine is placed on multiple (height adjustable) legs, enabling adequate distribution of load and overcoming potential differences in floor heights.

Important construction feature is also fully sanitary execution. Construction is completely welded. This means that practically all parts in contact with spraying water are waterproof (there is no point that would be only point welded). Also, from the outside surfaces majority of welds is continuously welded which provides lower possibility of impurities load.

Construction is designed (especially on inside but also on outside) in a way that where possible, all surfaces are inclined, so there is no possibility that water would be held and microorganisms would have chance to develop. This way we provide that the machine inside space stays longer intact and will be still without bad influence of smell, molds etc. On the outside, also roof of the pasteurizer is inclined, as well as top of the water tanks. This ensures that after external cleaning of machine all potential water residuals drip to the floor.

Next important construction feature is minimized water tanks below each zone enabling that minimum amount of water is at all times inside pasteurizer. Consequently, minimum amount of water goes to drain every time water inside pasteurizer needs to be replaced.

In concrete case single deck pasteurizer is foreseen for the project task. Construction of pasteurizer is designed on a way that multiple top and side manholes are available for easy approach to the inside for supervision and maintenance.

Top of the pasteurizer is covered with removable covers for inspection and maintenance reason.

** The photo is symbolic (an actual pasteurizer can be in different design)

Each pool has its own door for cleaning the tunnel and one central outlet for water. All pools are equipped with double mechanical filter sieves in order to prevent any dirt particles in the water to travel to the nozzles and to block them.

On the inlet and outlet of pasteurizer inspection doors made from stainless steel are installed.

Conveying system of the pasteurizer :

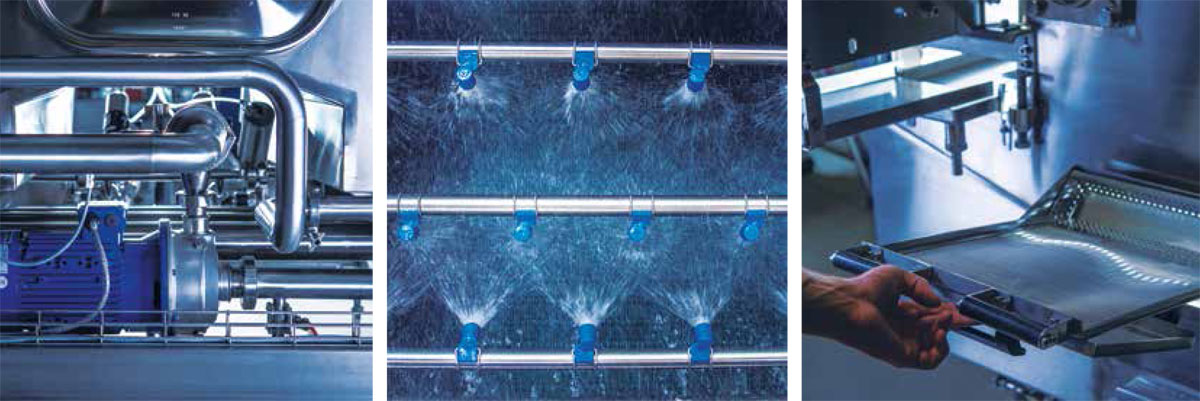

The tunnel pasteurizer is equipped with 1 independent main transporting belt. Width of transporting belt is approximaly 1180 mm.

Composing parts of pasteurizer are also in-feed and discharge conveyor (app. 1.500 mm from in-feed or discharge of pasteurizer), with electro motor drive together with frequency controller.

Main belt is running on supporting guides (wear stripes). Construction is indicated on below photo – parallel per module further different modules has displaced wear stripes (looking from the perspective of “neighbour” modules) in order to prevent cans or bottles from falling. With this it is assured that platform is adequate and that in every position, cans or bottles stand stable and there is no possibility of falling inside the pasteurizer.

Pumps and nozzle system :

The tunnel pasteurizer is equipped with suitable number of pools (10) and centrifugal pumps which transport water to nozzles. Pumps (parts in contact with water are from stainless steel) are protected from dry work with level probes in pools.

Main pumps are designed to assure flow of approx. 6,5 m3/h. Supporting pumps could have different flow depending from the purpose.

Spraying with process water inside pasteurizer is preformed trough register of nozzles which is placed on the top of the machine. Nozzles are producing fine fog of water that assures adequate transfer of heat energy. Nozzles are from plastic material.

Used type of nozzles is very simple to maintain due to easy system of fixing on the distribution pipes.

Nozzles are side (tangential) mounted on each spraying bar. This reduces possibility of blocking.

Standard distance from nozzle registers and main belt is 400 mm.

Instrumentation, controlling and automation :

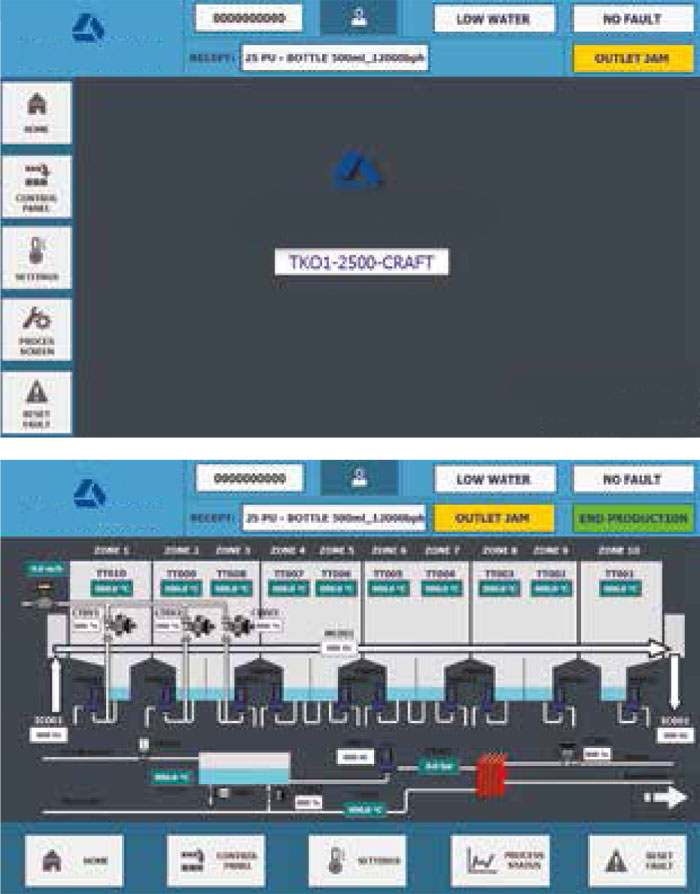

Tunnel pasteurizer is equipped with multiple safety providing elements as well as quality and up-to-date software which enable simple control of all pasteurizer’s functions.

Offered machine has installed following measuring and regulating equipment:

- Automatic water level correction (water tanks have installed level probes and in case of too low water level, water is being dosed automatically)

- Automatic temperature regulation (system is equipped with regulating system at steam / hot water inlet which feeds pasteurizer with steam/hot water water accordingly to actual needs)

- Automatic control of can over load on the main belt (inductive sensor installed on outside conveyors switches off the feeding conveyor in case of too big pressure)

- Controlling and management of tunnel pasteurizer is executed through PLC computer and a touch panel. Electrical control cabinet is supplied in stainless steel execution and it is of IP 65 rate.

The control panel is installed on main electrical cabinet and is based on the Siemens industrial computing system.

The pasteurizer is equiped with our own developed software. Software is designed on a way that enables automatic control and overview of complete pasteurization process. Process parameters are visualized and displayed on user friendly interface. Software also logs and visualizes all process alarms.

Software is protected by password for various levels (administrator, operator, and maintenance).

Standard part of our software is also so called “boiling out” program, enabling periodical complete machine sanitation. This program enables thermal sterilization of complete system. Details about temperatures and durations are to be agreed with a customer.

During start up two recipes are foreseen to be commissioned. Any additional recipes are subject of additional cost.

Materials used, quality and standards the components :

- Tunnel construction and construction pipes are made from AISI 304 material.

- Pipeline seals are of EPDM material

- Guides profile is polyethylene UHMWPE placed on stainless steel guides.

- All gaskets (that are not defined differently) are EPDM material, on steam graphite.

Components used:

- Pumps: LOWARA

- Electro components: SCHNEIDER ELECTRICS

- PLC computer: SIEMENS

- Touch control panel: SIEMENS

- Measuring and regulating equipment: E&H

- Cable trays from stainless steel shape G and U, net without top cover

- All stainless steel is purchased in Europe with certificates according to EN 10204

NOTE:

Adding any chemicals into the water of tunnel pasteurizer must comply with the resistance of these materials and has to be guaranteed from the local chemical distributor!

Dynamic active PU control

Dynamic PU (number of pasterization units) control enables that in no case product is over pasteurized. System’s platform is virtual deviation of pasteurizer to multiple rows which enables us to always monitor in which position are cans inside pasteurizer. In case of stoppage the system reacts on a way that main belt inside pasteurizer is stopped and cooling of cans in overheating and holding zones starts with intention to reduce product temperature below PU cut off point (for beer is calculated at 70ׄ°C). Our software is monitoring the duration of stoppage for the whole time and on a basis of wide range of heat transfer coefficients we know exactly how much time we need to cool in order to cool down product below PU cut off temperature and after stoppage is dismissed, we know exactly how much time we need to re-establish temperature regime that was in function before stoppage and to start of the main belt again.

Important matter is that dynamic active PU control does not end here. For every stoppage it is normal that product receives more PU than planned in balanced conditions. This means that for further process temperature SET points of next temperature zones are lowered in order to reach defined PU (inside agreed tolerances). This is happening also in case of multiple stoppages following one after another and in no case, product can exit over pasteurized (of course also under-pasteurization is not possible).

With technology of dynamic active PU control we can provide perfect pasteurization process with minimum impact to product organoleptic characteristics.

Standard process:

• Automatic control and regulation of PU is based on precise software which calculates (and monitors the exact position of cans inside the pasteurizer) current amount of received pasterization units.

• In case of stoppage on the line, pasteurizer starts cooling in required zones (overheating and holding zones) with goal of reducing product temperature below PU set point. This is obtained in order to prevent overdosing with PU’s.

• When stoppage on the line is dismissed, software again recalculates necessary temperature of spraying water in order to reach regime before stoppage occurred.

• Necessary temperature regime is projected on the basis of received samples, filled with an individual beverage product. In our laboratory pasteurizer all monitoring will be done prior to start of manufacturing of suitable system.

E&H registrator

E&H registrator RSG series RSH offers paperless recording, visualization and monitoring of all the crucial process values at the same time.

It is foreseen that module is mounted on the pasteurizer electro cabinet. All data that is recorded, is archived on SD card and can be used further on.

Ecograph offers a possibility of ethernet connection to local computer, enabling the transfer of recorded data for purposes of monitoring of the curtail parameters in real time.

Local computer and Ethernet connection are not in scope of supply and their ensure is a customer’s obligation.

Dosing of chemicals

In order to preserve the process water that is stored inside to tunnel for as long as possible and in the meantime reduce chance of cans corrosion, we offer an option of pre-installed system for dosing of chemicals – biocide & anticorrosive chemical solutions.

The dosing is of the two chemicals is done by two separate pumps, and is done directly in-line with support of a flow meter. The exact quantity of the chemicals dosed in to the water can be set on the pumps, while the dosing is then executed automatically. Along with the pumps a floating level switch is also suppled (if the chemicals level in the cannisters gets low, the machine signals an alarm).

System is foreseen for dosing biocide solution at 80 ppm and anticorrosive solution at 25 ppm . If different concentrations of chemicals are required, this should be agreed at the beginning of the project.

Note: if customer decides to install his own hardware for dosing of chemicals it is necessary to follow instructions of a producer regarding type of chemicals and their concentrations. In opposite case machine elements can be damaged.

UPS

UPS

UPS provides emergency power to a machine when the input power source or mains power fails or is disrupted. It ensures that CPU and HMI stay powered, so all crucial parameters are not lost. This is especially beneficial in case of pasteurizers with active PU control, where production can be restarted much more precisely with exact PU values.

Condensate removal armature

In scope of basic equipment, machine is supplied with manual shut-off valve, steam cleaning piece and pressure gauge on steam pipeline. As an optional upgrade we are offering you additional armature on condensate pipeline, which offers easy and simple connection in single point, while simultaneously offering practical maintenance.  Condensate removal is foreseen by simple steam trap, active condensate pump (if required) is not included in scope of supply.

Condensate removal is foreseen by simple steam trap, active condensate pump (if required) is not included in scope of supply.

Scope of supply includes:

- Ball float steam trap (1 pc)

- Thermostatic steam trap (1 pc)

- Non-return valve (2 pcs)

- Manual ball valves (4 pcs)

- Additional piping material

Steam pressure reduction equipment

If pressure of steam on site is higher than 3,0 barg, steam pressure reduction equipment is required. In scope of supply, we are offering you:

• Steam pressure reducing valve (1 pc)

• Safety valve (1 pc)

• Additional piping material.

DIMENSIONS

- Gross width: 2.776 mm

- Length: 7.170 mm

- Height: up to 2.300 mm

- Treatment surface: 8 m2

Technical parameters

| Product: | Carbonated beverages (beer, cider, sparkling beer, carbonated water etc.) |

| Purpose: | To pasteurize product inside the glass bottles and to assure microbiologically stabil product. |

| Capacity: | Up to 1.200 bottles per hour (valid for 330 ml cylindrical bottles with diameter 55mm) |

| Filling temperature: | It is considered that a product enters the pasteurizer with temperature approx. 2°C . |

| Foreseen temperature regime : | – inlet temp.: T1 = 2ºC – pasteurizing temperature Tp = 74.ºC* – outlet temp.: T2 = 20-30ºCAbove stated temperatures represent average temperature measured directly on the inlet and outlet of the tunnel after product is mixed, before temperature probe is inserted in the centre of the container. * at PU level = 4 Formula used for calculation of PU = t x 1,259 Tp-80 t = holding time on pasteurization temperature Tp = temperature of pasteurization T cut-off = 74°C |

| Process time : |

– holding on pasteurizing temperature: app. 25,3 min – total cycle: app. 128.0 min |

| Installed electric power : |

P = app. 12 kW Voltage supply: 3Ph, 400V± 5% / 50Hz± 2% Net system: TN-S |

| Required heat energy | Will be provided after confirmation of temperature regime. |

| Compressed air : | Consumption and conditions :

ca 300-500 l/h Requirement for the quality control of air hight solids |

| Softened water : | Normal production (only for topping up the system for the water that evaporates and is taken out heat from the pasteurizer):Consumption and conditions : p = 2-3 barg Q = approx. 900 l/hRequired quality of water is: • Soft water – total water hardness 4-6°dH • pH > 7 • Without particles • Conductivity ≥ 50 mS/cm • Temperature approx. 15°C • Max amount of chlorine dioxide 0,2 ppmConsumption during stoppages and at the end of production is different. |

| Dimensions : | – gross width: 2.200 mm – belt width: 1.180 mm – length: 7.170 mm – height: up to 2.300 mm – treatment surface: 7 m2Pasteurizer is of monolith construction.Dimensions stated above are general dimensions. Exact dimensions will be accordingly to provided layout of the machine. |

| Conveyors / belt : | 1. main belt single lane belt – 1.180 mm wide2. feeding belt conveyor: multi – row conveyor (length: 1,5 m);

3. exit belt conveyor: multi – row conveyor (length: 1,5 m); |

Price list :

| DESCRIPTION | PRICE IN EURO |

| Tunnel pasteurizer 1200 bottles per hour | € 145 000,- |

| OPTIONS |

|

| Dynamic PU control | € 11000,- |

| E&H registrator | € 2760,- |

| UPS | € 1200,- |

| Dosing of chemicals | € 7475,- |

| Condensate removal armature | € 3105,- |

| Steam pressure reduction | € 4552,- |

| Remote maintenance | € 1400,- |

Optional services :

I. Installation work on the place …. € 7200 / 7 + 2 days

The price is valid for all countries of the European Union. The price includes seven days work (+ two days travelling) of two specialists on the place – assembling and start up of the equipment.

The price does not include : transports costs and accomodation of the workers. Will becalculated individualy.

II. Installation work ensured by customer (with our remote assistance) …. € 850 / day

Do you want to save your money ? Are you technically skilled and not afraid of challenges? Do your country’s hygienic restrictive regulations not allow a visit of a specialized technician from a foreign country? Don’t be afraid to use the remote assistance service.

How is the installation of the filling line by our customer, using our remote assistance?

1.) The customer positiones all the machines and connects them to power guided by our checklist.

2.) Once photos were sent of the completion of the preliminary phase we proceeds with the start up and commissioning.

3.) First we connects the PLC of the machine via internet to our service console in our factory — this allows our service manager to view and control your PLC on a remote screen, as if he was in front of the machine in person.

4.) We then organise a Microsoft Teams conference call, with one your worker holding the camera, and the others working around the our technician´s instructions.

5.) After only 3-5 days setting up and configuring, first full glass bottles or cans will leave your filling line.

General sales conditions :

This document is subject to final confirmation after receipt of samples of the bottles, labels, caps, capsules and information on all raw materials to be processed. Following conditions are applicable unless otherwise stated in the above document.

1. General Principles

These terms and conditions of sale shall be applied unless otherwise specified in an agreement written by the seller and the customer (herein referred as the “Buyer”). When a Buyer sends an order, it implies full acceptance of these Conditions of Sale and supersedes any previous offers, correspondence and quotations between the Parties.

2. Sales Contract

The Seller shall be bound to abide solely by the terms specifically set forth in the present document. The Parties are bound to respect the terms of the Conditions of Sale only after the Seller has accepted the Buyer’s order in writing, in the form of a confirmation of receipt of the order.

3. Prices

Prices are “EX-WORKS”, VAT is not included. The quoted prices do not include shipping, insurance or packing. These items will be calculated separately.

Prices are established on the basis of economic and financial conditions as of the date of the quotation.

Prices are quoted for Products only and do not include technical data, or patent or proprietary rights.

4. Delivery

4.1. Delivery terms shall be calculated as of the date of the confirmation of the receipt of the order.

Delivery time is subject to receipt of the payment to deposit account, samples necessary for the construction of the equipment and technical details. In any event, if the order is suspended, after that date, for any of the following reasons such as non-payment of invoices, lack of approval of drawings, non receipt of samples or prototypes, transfer of export or import licenses, credit facilities, etc., the delivery date shall be considered as of the date said conditions are fulfilled.

4.2. The delivery date indicated by the Seller shall be considered an estimate. Unless specifically agreed otherwise by the Seller and Buyer, missing the delivery date shall not be cause for cancellation of the order or entitle the Buyer to any indemnification.

5. Force Majeure

Any conditions of force Majeure shall be cause for the Seller to suspend its commitments until said conditions shall cease to exist. The following conditions shall be considered force Majeure to the terms and conditions of sale: any unforeseeable circumstance the effects of which could not be reasonably prevented by the Seller and which are of such nature as to prevent the Seller from fulfilling its obligations.

The following conditions constitute force Majeure : fire, flood, interruption or delay in transportation, shortcomings on the part of a supplier or subcontractor, strikes of any kind, machine breakdowns, epidemy, goverment restrictions etc.

6. Insurance and Transportation

The goods shall be shipped at the buyer’s risk. The buyer shall be responsible for inspecting the goods upon arrival and, if necessary, advise the shipper of any damages. Upon receipt of specific instructions from the Buyer, shipments may be insured by the Seller who will then bill the buyer for the insurance costs.

7. Installation & Setting up

In case that assembly and start-up operations are requested, the Seller will guarantee the execution of the plant assembling and start-up in the lowest possible time, at prices indicated in the standard tariff unless otherwise specified in the present document. Seller´s technicians will start assembling work after a communication with the Buyer who confirms that the machines arrived on site in good condition, that the eventual preparing operations have been carried out and that all rooms and relative utilities in place have been finished in accordation with the Seller´s requirements (building works, piping and electric nets). It is understood that at technician/s arrival the necessary manual labour, all lifting and movement means will be at disposal as well as the necessary work-shop equipment and needed tools.

The Buyer will prepare and ensure :

• the area provided for the installation and the appropriate access routes free from stored materials or equipment;

• the necessary mains supply requirements such as water, steam, inert gas, product, electrical connections, compressed air, etc. available at the specified predetermined user points.

• the necessary handling equipment (forklifts, cranes, etc.) to discharge, to allow site positioning and handling of equipment and materials on site and the necessary personnel dedicated to such tasks.

• placing the products and all required raw materials on site in sufficient quantity for conducting the necessary equipment tests.

If the installation is not carried out or will be prolonged, due to delays whether attributable to the Buyer, then the Seller will charge the Buyer the costs related to technicians’ time at an hourly rate prescribed in our intervention tariff, and also the cost of expenses incurred for travel, food and lodging.

Furthermore, the Buyer’s staff, appointed to control and maintain the equipment, must co-operate with the Seller’s technicians for the assembling operations and to receive training.

Installation, start up and commissioning of the equipment are at the expense of the Buyer who will be charged the cost of technical assistance provided at our standard rates and terms and conditions (details provided on request and may vary depending on the country of destination).

During the commissioning of the system, the technical personnel of the Seller will carry out various routine tests on the equipment which may cause a certain amount of product loss. The Seller will not be held responsible for such losses and will not be liable for any claim of compensation.

8. Conditions for Acceptance on the part of the Buyer

8.1. Product features shall be those published in the most recent edition of the manufacturer’s specifications, unless other features are specifically agreed upon between the Seller and the Buyer.

8.2. The output capacity of the Products described in the present document result from an average calculation carried out with similar product characteristics or as a result of a theoretical calculation, unless otherwise specified. The Seller will advise the Buyer about the real effective capacity after having trialled the Product with the sample Products supplied by the Buyer. In the case that product samples are not supplied by the Buyer, the Seller shall not be responsible for properties different from the values stated in the offer.

8.3. The Seller’s goods are subject to tests and inspections in the factory where they are manufactured. The Buyer is entitled to request that the goods be inspected in his presence. If the Buyer cannot attend said inspections after having been given the agreed, advance notice of the date by the Seller, the Seller may send the

Buyer the inspection report that the Buyer will accept without discussion.

8.4. In order to be accepted to the provisions of this paragraph, all claims regarding the goods supplies shall be prepared according to the instructions provided by the Seller and contained in the documents sent with the goods.

8.5. No goods may be returned without prior authorisation from the Seller.

8.6. When a return of goods is accepted by the Seller, the Seller shall have the option to repair or replace the item(s) or to issue a credit note for the items acknowledged to be defective. In any event, the Buyer shall not be authorised to consider the return of goods, to suspend any payments due to the Seller, nor to cancel all or any part of any still pending order.

9. Payment Terms

Payments to the Seller covering price of the goods and related services supplied shall be effected according to the conditions set forth on the present quotation or order confirmation and the invoice. In the event the purchaser does not pay an invoice or part of it, the Seller shall be entitled, without prejudice to its other rights, to suspend all deliveries, irrespectively of the terms of the order(s) until full payment is received.

10. Title

Notwithstanding the effected delivery to the purchaser, the goods shall remain the property of the Seller until full payment is received. In the event that the purchaser does not effect payment by the established date, the Seller may repossess back already the delivered goods. In any event, as specifically stipulated, the purchaser shall be responsible for all damages and losses that may occur after delivery.

11. Warranty

The Seller engages to try solving all eventual defects coming from designing, production and assembling defects, guaranteeing the regular running of the supplied equipment for a period of 12 months from the date of shipment, if not agreed different time.

The warranty does not include normal wear and tear , and break downs due to an incorrect or improper use, to lack of diligent maintenance and to the non observance of technical descriptions as well as instructions indicated on the hand books which will be supplied to the Buyer. Warranty is limited to mechanical parts which are not subject to wear and does not include electric and electronic components, as per international guarantee regulations. Defective parts under guarantee must be returned to the Seller for examination and assessment of the defect, for the Buyer´s costs.

Replacement of damaged parts will occur after the manufacturer’s examination and confirmation of the damage of the returned defective component.

Replacing the components with non original parts by the Buyer or his customer shall invalidate the warranty unless such replacement has been specifically permitted by the Seller in writing. Spare parts supplied under guarantee are delivered free of charge EX-WORKS. All expenses for shipment of such parts from EX-WORKS to destination, including our technician’s travel, food and lodge are at customer charge. The Seller’s own technician labour for installation of spare parts under guarantee is free of charge. Any intervention carried out on the Seller’s equipment by the Buyer or by third party technical personnel are only for customer’s charge and responsibility. Modifications or interventions on the equipment may invalidate the guarantee terms unless explicitly authorised by the Seller.

12. Transfers

By virtue of this document, any transfer by the purchaser of any contract without prior makes agreement from the Seller shall render the contract null and void and shall relieve the Seller of any future obligations.

13. Court of Jurisdiction and Applicable Laws

In the event of judicial proceedings, the rights, obligations and claims of both parties will be decided by a court in a European country and city chosen by the Seller, irrespectively of the agreed upon terms of sale and payment, as well as warranty problems or in the event of multiple defendants.

The agreement and any difference or dispute arising out of it or related to it shall be governed, construed and interpreted in accordance with the Laws of Czech Republic. If any dispute, difference in opinions or question shall arise between the Parties under or in connection with the Contract, including any dispute on the validity of the Contract, such dispute, difference or question shall be finally settled by arbitration under the Rules of Arbitration of the Ministry of commerce of Czech Republic as in force and effect at the date hereof by one or more arbitrators appointed in accordance with the said Rules. The language to be used in the arbitrate proceedings shall be English. The seat of arbitration shall be Opava, Czech Republic. The decision of the arbitrators shall be final and conclusive and shall be binding on the Parties.

14. Compliance with Safety Regulations

The Equipment is built according to the European CE regulations. It is the duty of the Purchaser to inspect all Products and to provide proper safety devices to safeguard the operators from harm and to ensure compliance with all Safety Regulations. By accepting the “Order Confirmation”, the Purchaser acknowledges and agrees that the goods may not include or require the necessary safety equipment to permit safe operation or comply with Local, State, Federal, Industry and/or other applicable Safety Standards or requirements which may be different from the CE regulations. Before placing the equipment in operation the Buyer agrees to utilise such safety equipment and will give operators such instructions and/or warnings as necessary to permit safe operation and to comply with Local, State, Federal, Industry and/or other applicable Safety Standards or requirements. Purchaser further agrees to indemnify and hold Seller and their officers, employees harmless from any and all liability which may be imposed upon Seller and any and all costs, including attorney fees, incurred as a result of any claim made against Seller for injury arised out with the Products, that was caused or contributed to by purchaser’s or user’s failure to provide safety equipment and/or instructions and/or warnings necessary to operate this Products safely.

15. Instruction manuals:

The instruction manuals, assembly manuals, operation manusls, maintenance manuals are supplied exclusively in English language.

Reviews

There are no reviews yet.