Description

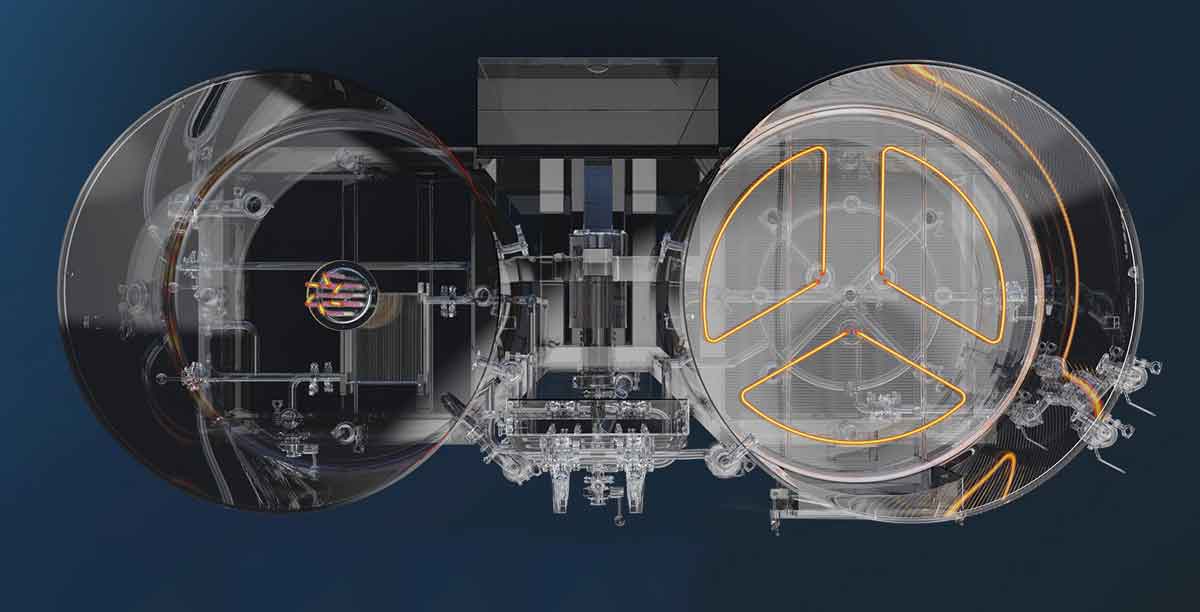

BREWTRION BT-400 is a compact wort brew machine

with production capacity of 410 liters per batch and three special tanks

This professional wort brew machine is designed and engineered in USA. The brewhouse with capacity 400 liters of wort ( 3.5 bbl) is the central spot for a start-up brewery, brewery pub, or the perfect pilot system for a larger production brewery.

- Professional design, small scale

- Energy-efficient machine thanks to the internal combinated heating system

- User-friendly touch controllers on the valve system

- Easy removal of waste grains

- Ergononomic handling thanks to gas spring assisted lids

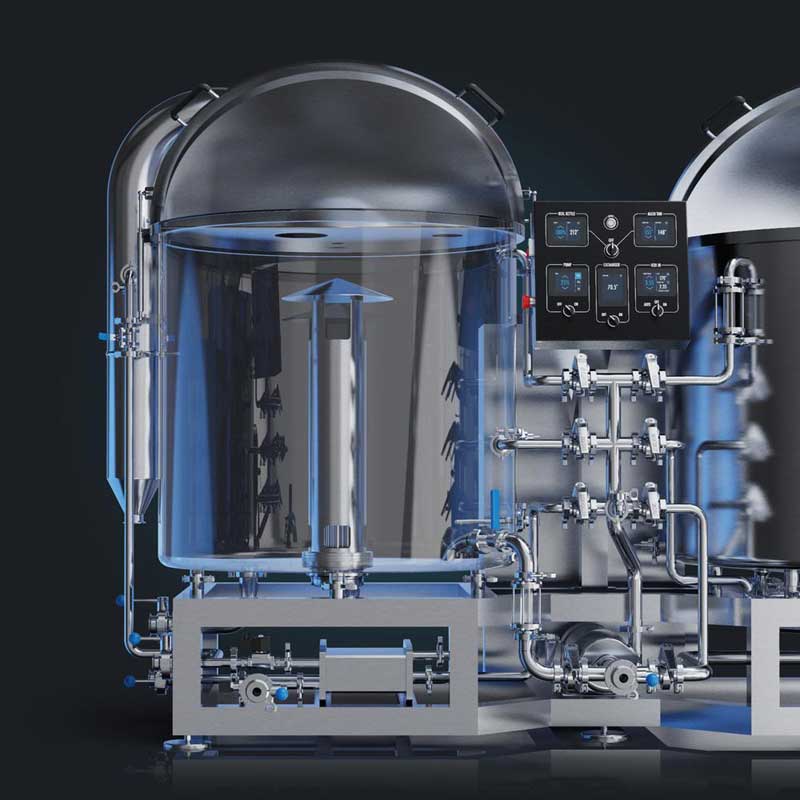

Heating and temperature control system

The heating, measure and control system based on simple computer enable the brewer precise control over each step, temperature and phase of the beer production process. At the core of that objective are independent heating elements for each vessel, allowing the user to choose the perfect temperatures for each step and to sustain the optimal temperature in the boil tanks. The computer always precisiously regulates temperature via the proportional heat control system.

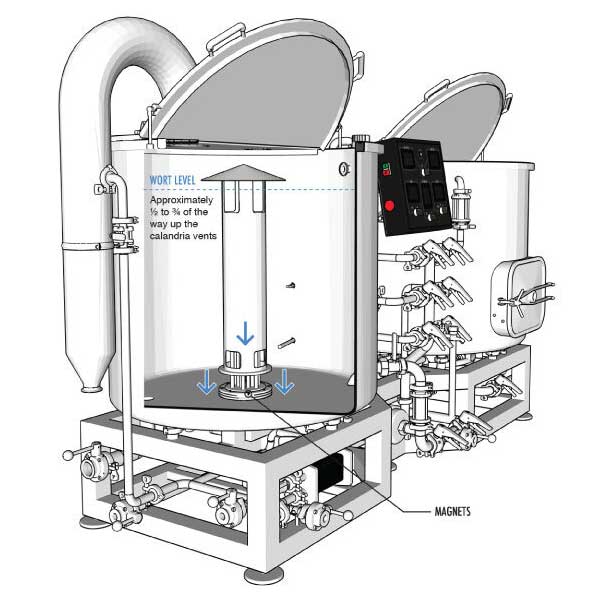

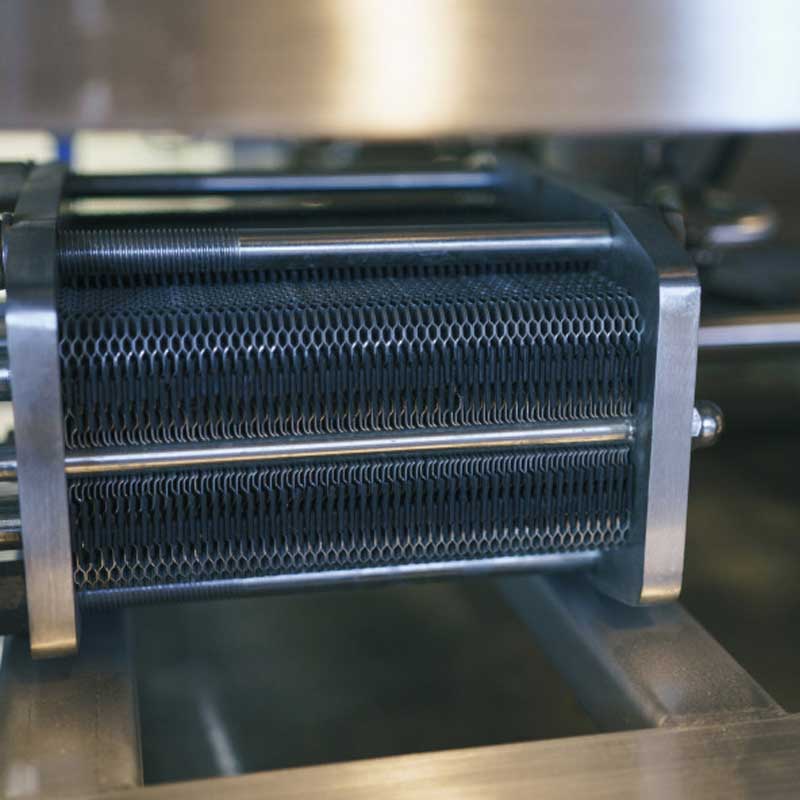

Patented internal heater

External wort heaters are widely used in large scale professional brewhouses. Therefore the wort heater integrated to this brewhouse vastly improves the efficiency of a brewhouse by requiring less energy to achieve an effective boil. Patented internal wort heater takes the essential elements of an external wort heater and places them directly in the wort boiling tank. The natural convection of the liquid removes the need for the additional pump. Version 2.0 of our popular internal wort heater incorporates magnets mounted into the base of the shell to allow for easy removal and cleaning of the heater.

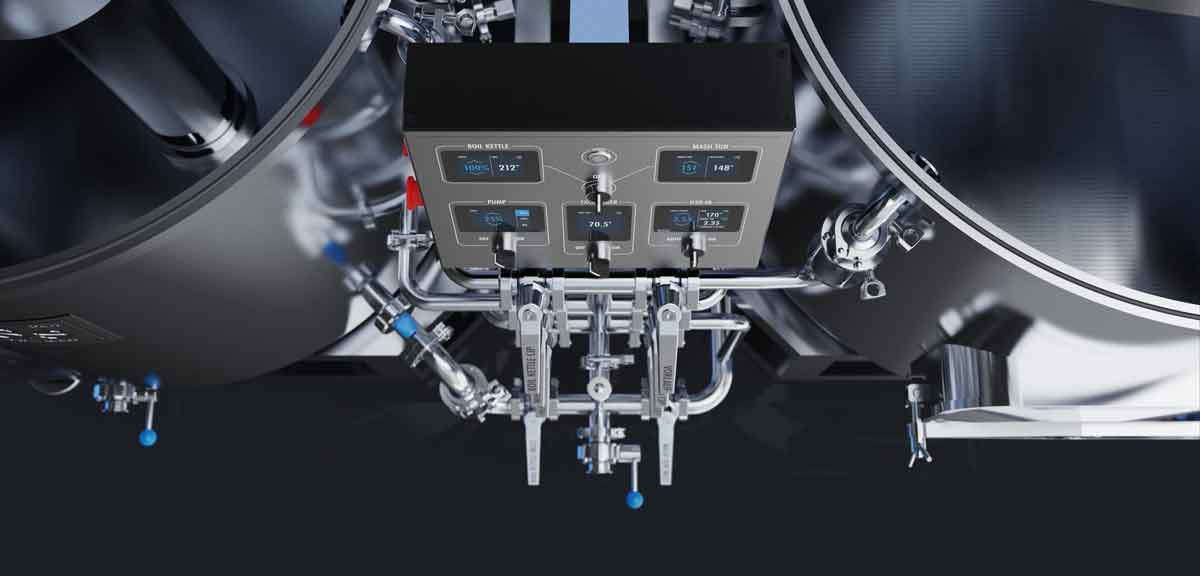

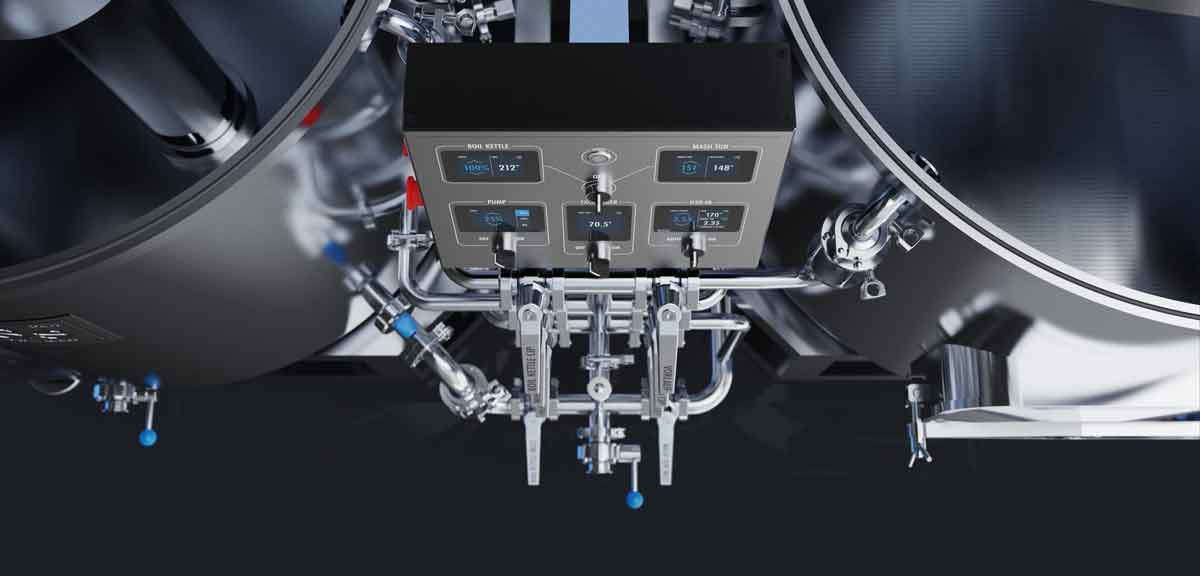

Touch controls & Professional valve tree

A fundamental design element for all Brewtrion Brewhouses has always been centralized control system. Having all the process-significant valves on a centralized tree allows for quick and accurate adjustments of all parameters during your brew.. The 3.5 of the control panel incorporates our reimagined user interface. The new control panel design incorporates touch controllers and the ability to automate some key functions. The result is a brewhouse with a much higher degree of precision and operating comfort than ever before.

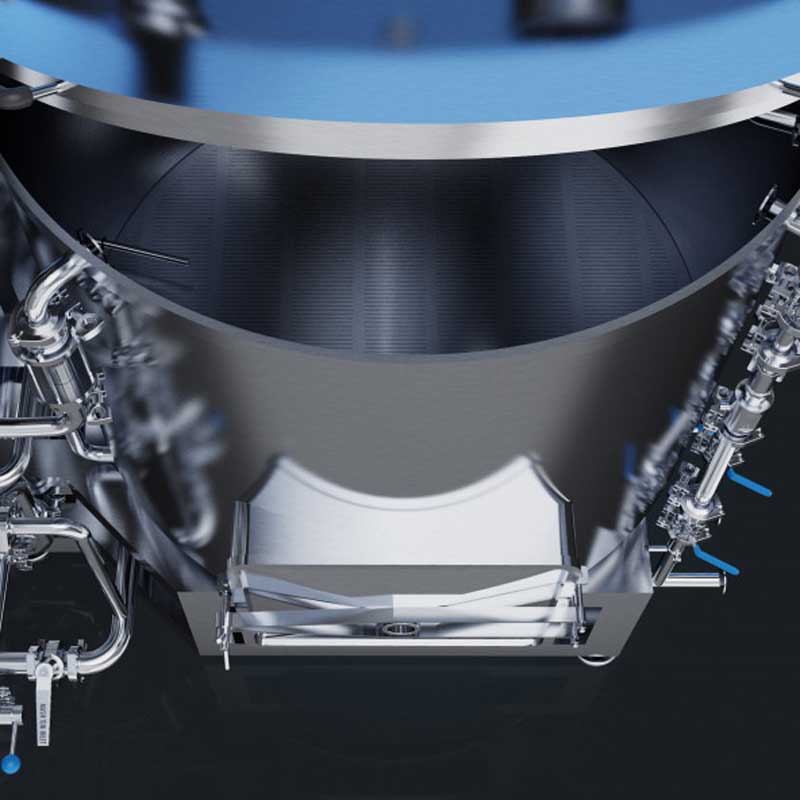

False bottom with wort sieve and grain output door

In none of our professional brewhouses will you find a punched false bottom. This is valid for this small brewhouse as well. The precisious milled sieve (false bottom) allows for a faster wort filtration, clearer run-off, and mitigates the risk of a stuck malt sparge. The grain-output door above the sieve allows for quick and easy clean-up of the filtration tank. No more hassle scooping grain from the top of a mashing tank.

Key Features:

- 24 kW boil element in the mashing tank

- 2 kW wort heater

- 18 kW heater under false bottom with RIMS elements

- Proportional heating control with touch controls and dynamic adjustability

- Tangential inlet in the whirl tank

- Steam condensate stack

- LED lights in the lids

- Stainless hard pipping throughout with the valve tree

- Fully assembled and ready to brew

Other features:

- Nitrogen spring assisted lids

- Special sampling valve

- Dedicated CIP port

- Sparging ring in the filtering tank

- Fully sanitable hard piping with the patented valve tree

- Milled filtration sieve (false bottom) with grain-output door for easy removal of used grains

- On frame mounted sanitary pumps and plate heat exchanger for wort cooling

- Adjustable feet

- Modular mounted electrical service panels

Specifications:

- Final wort batch volume … 400-410 l (3.5 bbl)

- Heating system : 24 kW electric heating elements + 18 kW sub false bottom RIMS elements

- Foam space … 20% height of the tanks

- Wall thickness … 2.5 mm

- Inner surface finish … 2B ; matte appearance and bright defect-free finish

- 1.5″ inlet piping / 1″ outlet piping

- Butterfly valves, pipe sight glass, and TC gaskets … 1”

- Heat exchanger surface area … 2 m²

- Power supply : 3ph 380-400 V / 50 A (If you are unsure, check with your utility provider to verify the type of electrical service that is available at your location.)

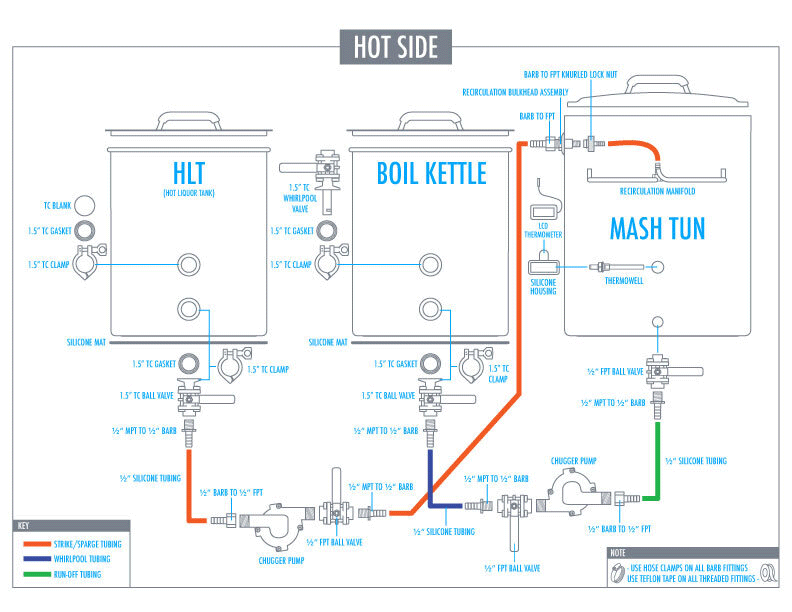

Hot side flow diagram :

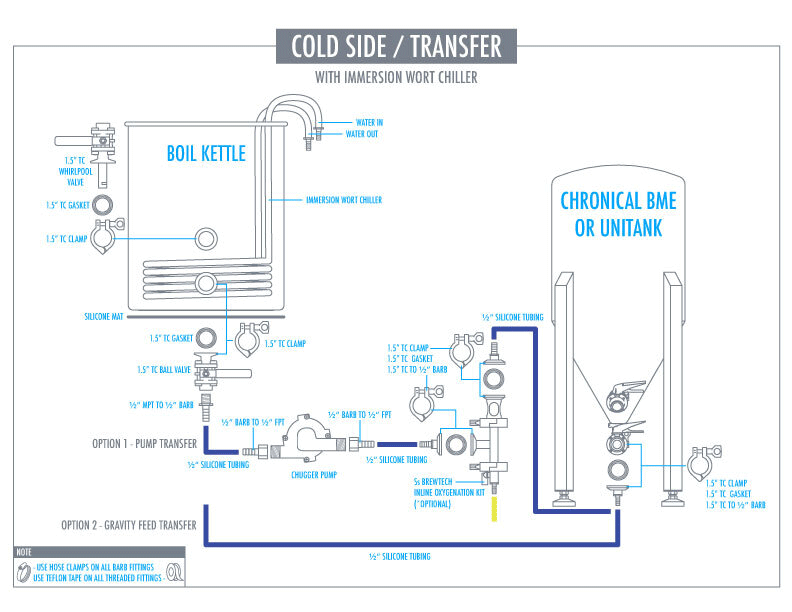

Cold side flow diagram (with immersion wort chiller) :

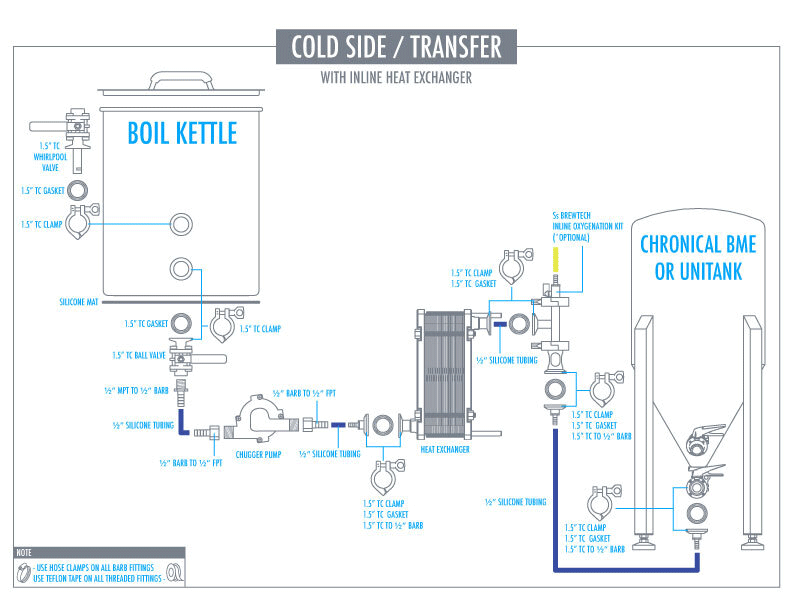

Cold side flow diagram (with inline heat exchanger) :

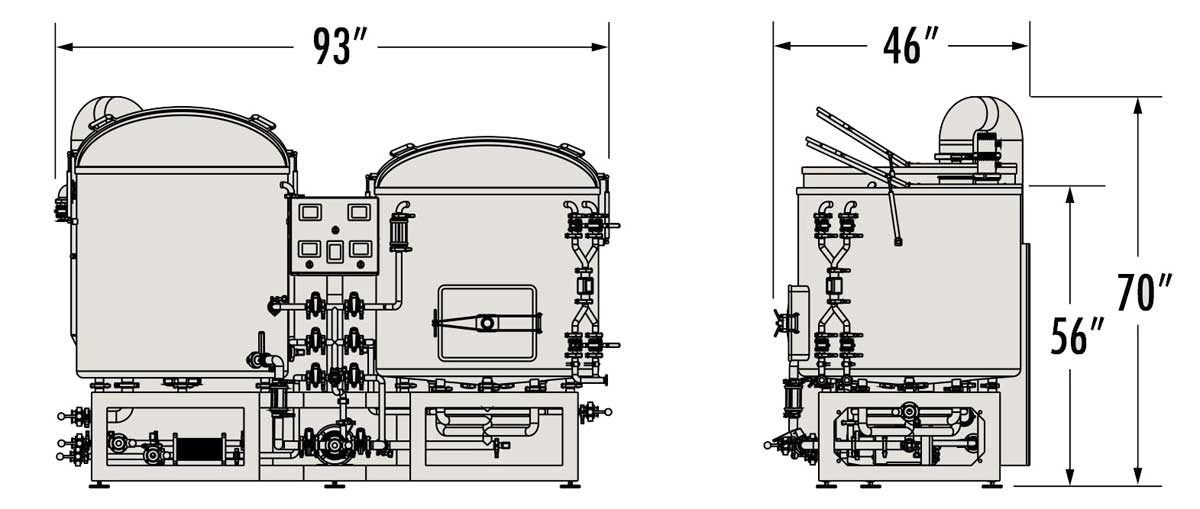

Dimensions:

- Measurements (w x h x d): 2.36 x 1.78 x 1.17 m (93″ x 70″ x 46″)

- Height: 1.560 m (56″) to top of the tanks

This product is made in China, designed and certified in USA. This version is designed and certified especially for European market. Will be delivered with the CE certificate.

Warranty 6 months. On-site services are not included.

The lead time of the equipment is from 18 to 19 weeks.

Reviews

There are no reviews yet.