Description

Industrial brewery BREWORX OPPIDUM 6005A-15000 with the wort brew machine BREWORX OPPIDUM 6000 allows the production from 6000 to 36000 liters of beer per day (from one to six batches per day). This configuration of the brewery includes set of fermenters with production capacity up to 1 500 000 liters of beer produced using the on surface fermentation method or 900 000 liters of beer produced using the under bottom fermentation method per year. Industrial design and powerful equipment of the brewhouse OPPIDUM predetermines this brewery for beer producers with requirement for high production capacity .

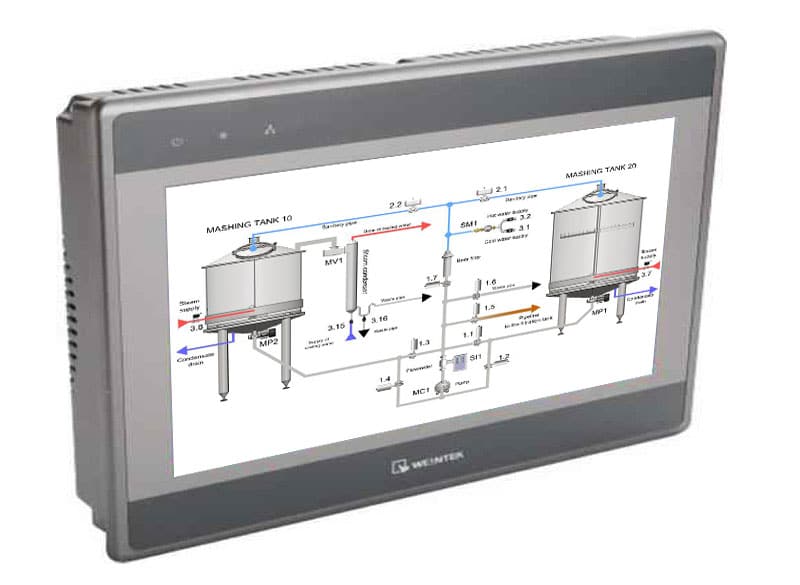

Automatic control of the wort production process, beer fermentation process, beer maturation process, media processing.

Technical parameters :

Production capacity – daily :

- 6000 liters of beer wort per day – one batch for 24 hour – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 12000 liters of beer wort per day – two batches within 24 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 18000 liters of beer wort per day – three batches for 24 hour – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 24000 liters of beer wort per day – four batches within 24 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 30000 liters of beer wort per day – five batches for 24 hour – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 36000 liters of beer wort per day – six batches for 24 hour – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

Production capacity – yearly :

- Beer produced using the on surface fermentation method ……… 1 500 000 liters per year

- Beer produced using the under bottom fermentation method …. 900 000 liters per year

Raw material :

- Classical raw materials : Malt + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

- Beer concentrates : Malt extract + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

- CO2 in pressure bottles (cylindres)

- Washing and sanitizing agents

Control system :

- Brewhouse – boiling equipment :

- valves and claps – computer automatic control

- temperatures – computer automatic control

- motors, pumps – computer automatic control

- timing – computer automatic control

- Tanks – fermentation, maturation, bright beer :

- temperatures – computer automatic control

- timing – computer automatic control

- Media – hot water, ice water, wort cooling, glycol tank :

- temperatures – computer automatic control

- timing – computer automatic control

Required space for building :

- Floor area min : from 360 to 550 m2

- Room height min : 12 m

Electrical connection :

- Electrical socket : 400V 3ph / 50 Hz

- Electrical consumption : 100 kW

Brewhouse heating system :

- Gas steam-generator

Cooling system :

- Cooling of wort : Drink treated cold water + Ice cooling water (with glycol)

- Cooling of tanks : Ice cooling water (with glycol)

BREWORX OPPIDUM – the modern brew and fermentation system for production beer

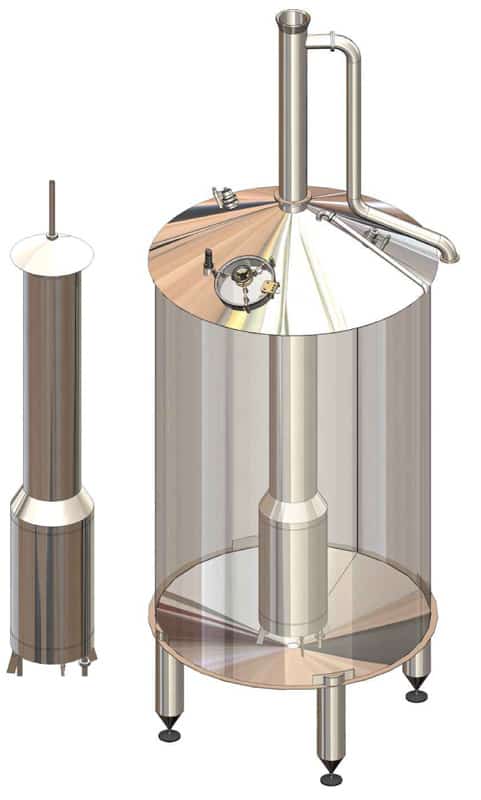

I. Wort brew system

The wort brew machine OPPIDUM 6000 is a powerful professional compact equipment with industrial design which includes all necessary equipment to produce 6900 liters of wort in one batch from malt (or malt extract or wort concentrate), hops and water. The compact machine for preparation of wort includes six special vessels to maximize of production capacity. Thanks to parallel production method this machine is able to produce from one to six batches of wort per day – (from 6900 up to 41400 liters of wort per day). The wort production machine is the main functional component of the brewery BREWORX OPPIDUM 6000 . It is a food machine whose primary function is the production of wort. The wort is an intermediate product which is result of a first phase during production beer. The next phase of the production cycle is fermentation and maturation of this wort in fermentation tanks. The resulting product of this production process is a tasty refreshing low-alcoholic beverage – beer.

AC – Automatic control system – wort brew machine equipped with a computer support – the automatically controlled process of infusion or decoction – fully automatized management of the entire processes of production wort.

The wort brew machine BREWORX OPPIDUM 6000 includes in standard version :

- mash kettle tank 6000 liters – vessel for mixing of grinded malt grains with warm water and splitting starch to form a sugar solution

- mash kettle tank 4000 liters – vessel for boiling and for cleave the starch to form a sugar solution

- filtration tank 8500 liters – (wort filtration tank) – vessel with a special sieve for filtering of wort

- wort storage tank 7200 liters – vessel for temporary storage of hot wort and keeping its temperature

- wort boiling tank tank 9000 liters – vessel for boiling of wort with hops

- whirlpool tank 7500 liters – for centrifugal separation of hop dregs from wort

- laboratory sink for tests of wort

- control panel with all control elements

- platform with stairs

- all needed pipes and wires connections

- all needed mechanically and automatically controlled valves and armatures

- electric switchboard cabinet

- industrial computer for control of wort brewing process (only version with automatic control system)

Options and properties

Two kinds of a raw material for production of wort :

- Classical raw materials : Malt + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

- Beer concentrates : Malt extract + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

Six production capacities of the brewhouse :

- 6900 liters of wort per day – one batch during 12 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 13800 liters of wort per day – two batches during 24 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 20700 liters of wort per day – three batches during 24 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 27600 liters of wort per day – four batches during 24 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 34500 liters of wort per day – five batches during 24 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 41400 liters of wort per day – six batches during 26 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

Practical design :

- SC : Stainless steel / C-shape – all tanks are fully made of stainless steel AISI 304, arrangement of containers into the C-shaped

- BLMS – Brewlock quick door-lock system – simple BLMS system allows very quick locking and unlocking of all upper doors of the tanks by only one hand (with the glass door design)

Powerful heating system :

- SH – Steam heating – the heating of the tank kettles is performed by hot steam produced by the steam-generator. Heating by hot steam significantly speeds up the boiling process. This is the best and very safety system for the heating of wort without danger caramelization of malt. This system requires a connection of the brewhouse to electric, gas or pellet steam-generator that is not included in the wort brew machine (see an optional accessories).

Automatic control system for automatization of entire wort production process :

- AC – Automatic control system – wort brew machine equipped with a computer support – the automatically controlled process of infusion or decoction – fully automatized management of the entire processes of production wort.

Why only the automatic control system for this wort brew machine is available ?

The OPPIDUM machine produces several batches of wort at the same time. This is extremelly demanding of attention, concentration and speed of brewer work as well as rapid and concurrent monitoring and evaluation of rapidly changing data from many sensors . Only sophistical system with a computer and many electronic sensors of the automatic control system are able to provide the properly timing of all brewing phases, the right temperatures in the right time, the right speed of pumps and motors, without damage of wort, it all controlled continuously during up to six paralelly worked production processes.

There are also other good reasons why use the automatic control system :

There are also other good reasons why use the automatic control system :

- Elimination of human errors – machine accurately and timely perform necessary tasks

- Costs saving for owner – only one worker is necessary for manipulating in the brewery

- Minimization the number of error conditions in the brewery – everything is still under control of the computer

- Monitoring and registration– all statuses and operations of the wort production process are stored in the computer memory

- Minimization of requirements – this system does not require extremelly attention of human operator – There is always ensured an early reaction of machine

- Stable quality of beer – standard manufacturing procedures are always observed in order to ensure always the same maximum possible quality of beer

- Six pre-programmed recipes – for production of the most known types of beer : Pils, Lager, Black, Weissenbeer, Ale, Special

- Manual brewing mode – for production of all other different types of beer that pre-programed system does not know

- Special sanitation mode – for automatic cleaning, sanitizing and sterilization of all tanks, pipes, armatures and other brewery equipment

Technical specification

This type of the stainless steel wort boiling machine OPPIDUM 6000 consists of:

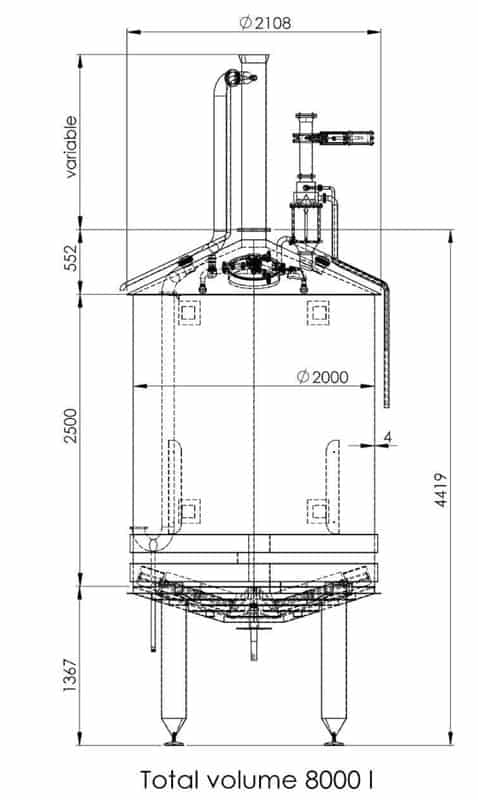

1. Mash kettle 8000 liters

Vertical, double-walled stainless steel vessel with a spherical or conical upper bottom, designed for mixing malt meal with warm water and splitting starch to form a sugar solution. Internal surface of tank: Cold rolling to a thickness of 4 mm and hot-rolling from a thickness of 5 mm, surface treatment 2B, seams polished to Ra<0.3 micrometers. Maximal ovepressure in the tank 0.3 bar.

Vertical, double-walled stainless steel vessel with a spherical or conical upper bottom, designed for mixing malt meal with warm water and splitting starch to form a sugar solution. Internal surface of tank: Cold rolling to a thickness of 4 mm and hot-rolling from a thickness of 5 mm, surface treatment 2B, seams polished to Ra<0.3 micrometers. Maximal ovepressure in the tank 0.3 bar.

Usable capacity 8 000 liters

Usable capacity 8 000 liters- Dimensions Ø 2 110 mm, height 4 419 mm

- Steam-heated bottom area 1.54 m2

- Steam-heated cylindrical area 3.60 m2

- Steam valve ASCO jucomatik DN 15

- Steam condensate discharge DN 15

- Maximal steam overpressure 6.5 bar

- Four-arm agitator with gearbox LBC 130/50, output power 850 Nm

- Motor Siemens 2.2 kW 400V 50Hz

- Lighting 24V 100W 1440 lm IP65

- Service manhole with a glassed door Ø 440 mm / glass 8mm

- Hopper for crushed malt DN 100

- 2 pcs of Sanitary rotating shower DN 20 for cleaning of the tank

- 1pc of Sanitary shower for cleaning of glass manhole

- Agitator – rotation speed 29 /min , 2 pcs of blades

- Double jacketed bottom with a slope of 12° , heating area 3.60 m2 50 mm entrance

- External jacketing stainless steel 1.5 mm

- Top cover in stainless steel, welded seams and polished to Ra 0.1-0.3

- Steam outlet to the central air exchanger DN 100

- Wort pipes DN 65

- Saniary pipes DN 40

- Steam pipes DN 15

- Adjustable feet DN 150 4pcs

- Pre-masher – a special chamber to spraying of malt grist by water before before its pouring into the mashing tank.

- Insulation plasticized cotton wool : upper cover 50mm / cylindrical jacket 50mm / steam bottom 50mm

- Signal light: red / green – open door signaling / fault / process error

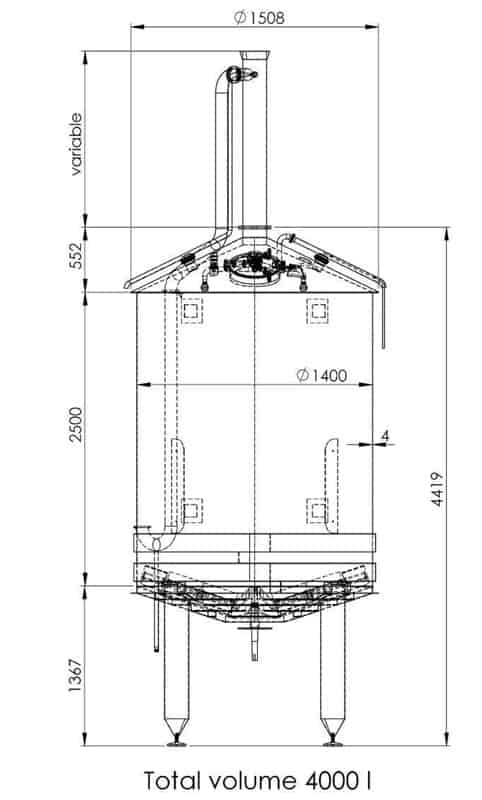

2. Mash kettle 4000 liters

Vertical, double-walled stainless steel vessel with a spherical or conical upper bottom, designed to cleave the starch to form a sugar solution.

Vertical, double-walled stainless steel vessel with a spherical or conical upper bottom, designed to cleave the starch to form a sugar solution.

- Usable capacity 4 000 liters

- Dimensions Ø 2 110 mm, height 4 419 mm

- Steam-heated bottom area 3.48 m2

- Steam-heated cylindrical area 1.50 m2

- Steam valve ASCO jucomatik DN 15

- Steam condensate discharge DN 25

- Maximal steam overpressure 6.5 bar

- Agitator – rotation speed 29 /min , 2 pcs of blades

- Gearbox 130/50, output power 850 Nm, input power 2.2 kW

- Motor Siemens 2.2 kW 400V 50Hz

- Lighting 12V 35W 1440 lm

- Service manhole with a glassed door Ø 440 mm

- 2 pcs of Sanitary rotating shower DN 20 for cleaning of the tank

- 1pc of Sanitary shower for cleaning of glass manhole

- External jacketing stainless steel 1.5 mm

- Top cover in stainless steel, welded seams and polished to Ra 0.1-0.3

- Adjustable feet DN 150 4pcs

- Insulation plasticized cotton wool : upper cover 50mm / cylindrical jacket 50mm / steam bottom 50mm

- Signal light: red / green – open door signaling / fault / process error

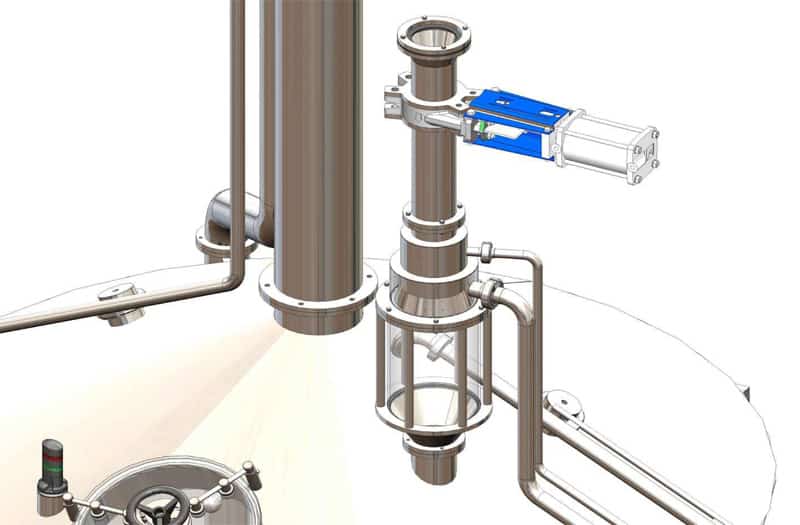

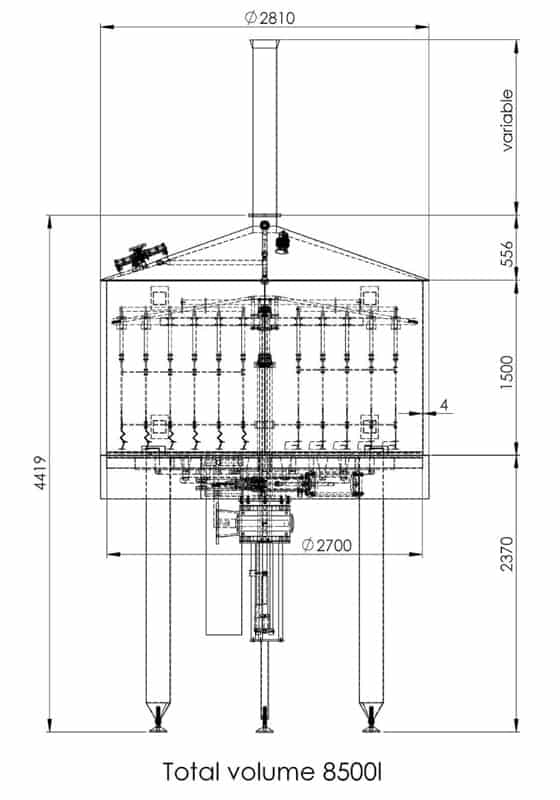

3. Filtering tank (wort filtration tank)

Stainless steel vessel with a special sieve for filtering of wort, with a spherical or conical upper bottom. Filtering pipe and collector – Output pipeline is located below the reactive bottom, pipe diameter DN 80. Lautering reducers from the bottom 80/40 are driven into a circular pipe with a diameter of 80 mm.

Vacuum sensor. PICK pneumatic pressure sensor from SICK. Material AISI 316L. Pressure range -1bar to 1 bar. Output voltage 0-10V. The filtering system works on

the principle of calculating the hydrostatic pressure by volume in the take – off and hydrostatic pressure measured by a tachometer located in a circular pipeline below the reactive bottom of the tank. The system evaluates the difference that passes the PID controller information. The PLC controls the pump speed and the required flow rate so that the filter layer is not drawn to the bottom of the vessel. This system automatically secures the maximum rate of filtering.

We recommend : BH-OPT-ELS60 Electric lift of the knife-stirrer in the filtering tank … see the options bellow.

The special customization of the wort brew machines Oppidum 6000 – the electric lift of the knife-stirrer in the filtering tank (wort filtration tank). This customization of the wort brew machine allows you very variable setting position of the knife-stirrer inside the filtering tank. This is useful during filtration of wort through the malt grain sediment when some stronger beer types are produced. The lifting of the knife-stirrer ensures you to speed up the process of souring wort. This is important to avoid excessive oxidation of the wort during the filtering process.

The lifting mechanism is ensured by the electric actuator. Operator of the wort brew machine can change a position of the knife-stirrer in any position as he needs at the moment. The lifting of the knife stirrer is solved by system of fixed shafts of 35mm diameter located in the main hollow rotary shaft. The lifting mechanism is located underneath the gearbox at the bottom parts of the tank. The maximum allowable pressure is 800kg. Stroke of the stirrer is up to 200 mm. Positions of the knife stirrer secures the positioner that is part of the electric actuator. Output voltage of the positioner is 0-10V. Display of the position of the knife stirrer is on the LCD monitor. Lifting time is 40 sec.

The wet malt grains ejection from the tank is solved by a lower ejection fitted with a pneumatic sliding flap for the movement of the malt grains that is ensured by the reverse movement of the knife stirrer. Pneumatic sliding flap is made from material AISI 304 DN 250. The wet malt grains are taken by the screw conveyor transporting the waste material out from the brewery to a lorry car or waste vessel which is prepared under the conveyor.

- Usable capacity 8 500 liters

- Dimensions Ø 2 810 mm, height 4 419 mm

- Filtration bottom 8 segments with 18% permeability (cutted holes 0.6 – 4mm / 80mm)

- Nozzles for rinsing under the sieve 6 pcs

- Stirrer 2 arms, 10 blades

- Gearbox LBC 130/100 820 Nm 2200 W

- Service manhole with a glassed door Ø 550 mm

- Lighting 12V 35W 1440 lm IP65

- Mechanical temperature indicator 0-120ºC stainless steel

- 4pcs of the Sanitary rotating showers DN 25

- Three-way setting valve with sight glass DN 80

- Inlet pipes DN 65

- Outlet pipes under the sieve DN 80

- Brewer’s grains discharge 420*540

- Deaeration pipe serves to remove overpressure and vacuum during the lautering process

- Equipment for automatic grains discharge

- Insulation plasticized cotton wool : upper cover 50mm / cylindrical jacket 50mm / steam bottom 50mm

- External jacketing stainless steel 1 mm

- Top cover in stainless steel

- Adjustable feet DN 150 4pcs

- Signal light: red / green – open door signaling / fault / process error

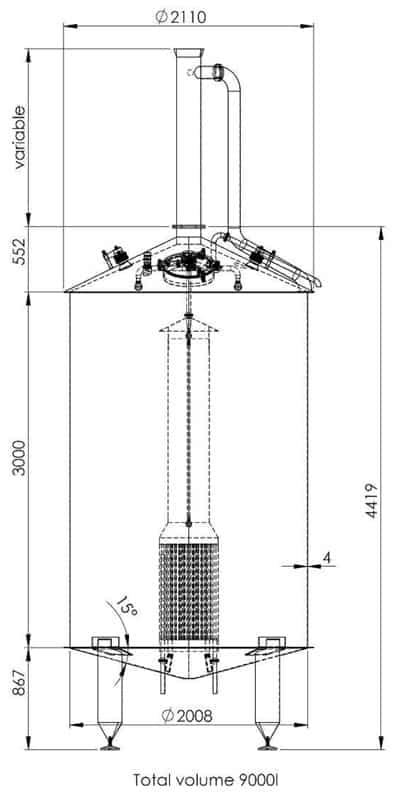

4. Wort kettle – the new high effective heating system with the turbine

Vertical, stainless steel tank with a spherical or conical upper bottom. Steam heating is secured by special turbine, located inside the container. Spiraly heating area 6.2 m2.

Vertical, stainless steel tank with a spherical or conical upper bottom. Steam heating is secured by special turbine, located inside the container. Spiraly heating area 6.2 m2.

The container is designed to cook wort and dosing of hops using a PLC controlled hop hopper system. The container is made of AISI 304 material of thickness 4mm.

Outer and inner surface is polished Ramin = 0.8μm.

Maximum achievable overpressure in container 0.3 Bar

Heat control and dosing of hops using PLC available in modes : Manual / Semi Automatic / Automatic

- Usable capacity 9 000 liters

- Dimensions Ø 2 110 mm, height 4 419 mm

- Steam-heated bottom area 6.20 m2

- Steam valve ASCO jucomatik DN 15

- Steam condensate discharge DN 25

- Input wort pipes DN 65

- Output wort pipes DN 65

- Sanitizing pipes DN 40

- Lighting 12V 35W 1440 lm IP65

- Service manhole with a glassed door Ø 440 mm

- 2 pcs of the Sanitary rotating shower DN 20

- Steam outgoing pipe DN 100, 3x spraying device

- Insulation 50 mm plasticized cotton,

- External jacketing stainless steel 1 mm

- Top cover in stainless steel

- Insulation plasticized cotton wool : upper cover 50mm / cylindrical jacket 50mm / steam bottom 50mm

- Adjustable feet DN 150 4pcs

- Signal light: red / green – open door signaling / fault / process error

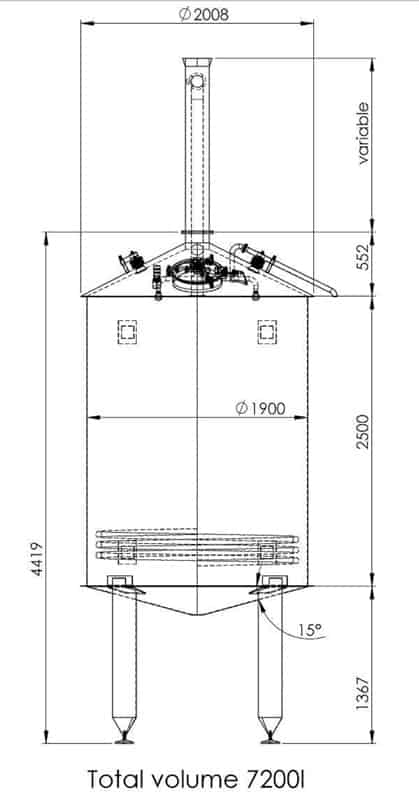

5. Wort storage tank

Vertical, stainless steel tank with a spherical or conical upper bottom for storage of wort and keeping its temperature. Steam heating is secured by coil, located inside the container.

Vertical, stainless steel tank with a spherical or conical upper bottom for storage of wort and keeping its temperature. Steam heating is secured by coil, located inside the container.

The container is designed to collect the filtered wort and then reheat before pumping it into the wort boiling tank. The container is made of AISI 304 material of thickness 4mm. External i

the inner surface is polished to Ra min = 0.8μm

- Usable capacity 7 200 liters

- Dimensions Ø 2 008 mm, height 4 419 mm

- Steam-heated cylindrical area 2.30 m2

- Steam valve ASCO jucomatik DN 15

- Steam condensate discharge DN 25

- Input wort pipes DN 65

- Input sanitizing pipes DN 40

- Lighting 12V 35W 1440 lm IP65

- Service manhole with a glassed door Ø 440 mm

- 2 pcs of the Sanitary rotating shower DN 20

- Steam outgoing pipe DN 100, 3x spraying device

- Insulation plasticized cotton wool : upper cover 50mm / cylindrical jacket 50mm / steam bottom 50mm

- External jacketing stainless steel 1 mm

- Top cover in stainless steel

- Adjustable feet DN 150 4pcs

- Signal light: red / green – open door signaling / fault / process error

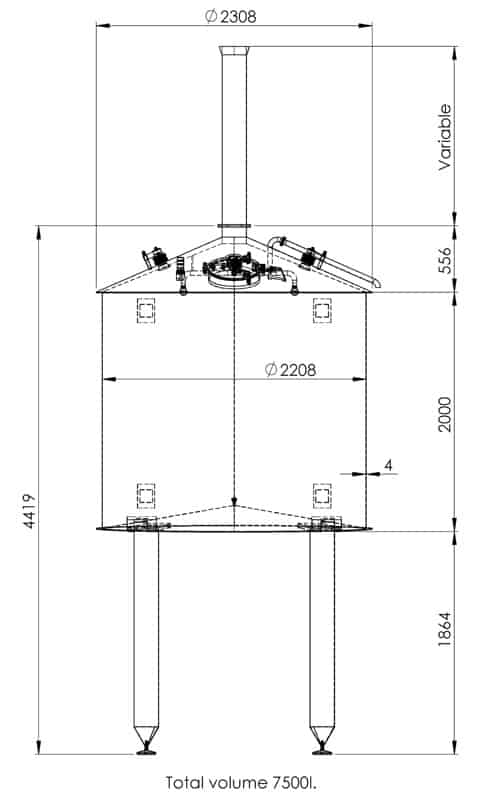

6. Whirlpool tank

The vessel is designed to separate sludge and clusters of proteins from the wort produced. The outer and outer surfaces are polished with a maximum roughness of Ra min = 0.8μm. This vessel has a bottom with a gradient towards the perimeter – this option will allow you to get full volume the wort with almost a zero-loss.

The vessel is designed to separate sludge and clusters of proteins from the wort produced. The outer and outer surfaces are polished with a maximum roughness of Ra min = 0.8μm. This vessel has a bottom with a gradient towards the perimeter – this option will allow you to get full volume the wort with almost a zero-loss.

- Usable capacity 7 500 liters

- Dimensions Ø 2 308 mm, height 4 419 mm

- Service manhole with a glassed door Ø 440 mm

- 2x Sanitary rotating shower DN 60

- Wort pipeline DN 65

- Outgoing wort pipeline DN 50

- Draining pipe DN 65

- Tangential nozzle DN 32

- Filling level indicator DN 40

- Venting pipe 1x DN 65

- Lighting 12V 35W 1440 lm IP65

- Insulation plasticized cotton wool : upper cover 50mm / cylindrical jacket 50mm / steam bottom 50mm

- External jacketing stainless steel 1 mm

- Adjustable feet DN 150 4pcs

- Signal light: red / green – open door signaling / fault / process error

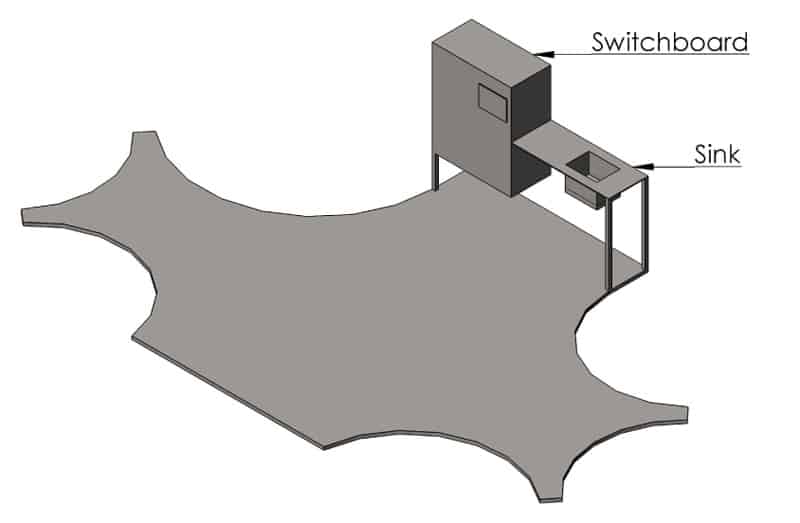

Service platform

The frame and construction of the service platform is made of AISI 304. The frame is firmly connected to the individual containers that it uses as a supporting element. The frame is used also to fix the containers. Floor of the construction is a galvanized floor grid as a variant of a transparent floor, or an anti-slip stainless steel sheet with a perforation for easy drainage.

The frame and construction of the service platform is made of AISI 304. The frame is firmly connected to the individual containers that it uses as a supporting element. The frame is used also to fix the containers. Floor of the construction is a galvanized floor grid as a variant of a transparent floor, or an anti-slip stainless steel sheet with a perforation for easy drainage.

Equipment platform:

The central electro-switchboard, which houses an automated system for managing all processes

- PLC with the touch screen

- Wash-basin

- Work desk

- Laboratory holder for saccharometers

- Equipment for cooling laboratory samples

- Lockable cabinet for storage of all laboratory aids and tools

- Railing

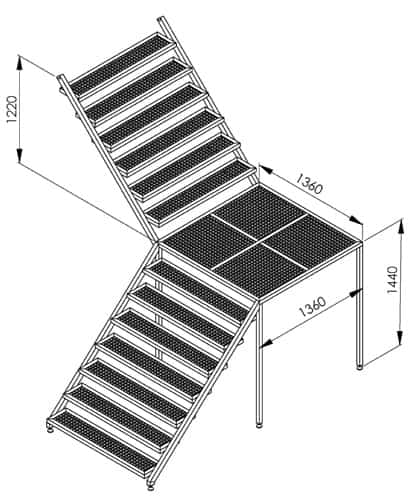

Stairs and auxiliary platform

The frame and construction is made of AISI 304.

Floor of the construction is made of a galvanized floor grate as a variant of a transparent floor, or an anti-slip stainless steel sheet with a perforation for easy water drainage.

The handrail of the stairs is made of AISI 304 with a diameter of 40 mm

Main and auxiliary piping, fittings, pumps, sensors, flowmeters

Piping systems

Piping systems

- The main piping system is made of AISI 304 DN 65, th. 2 mm.

- Connecting fittings are DIN 11851, AISI 304 DN 65.

- Auxiliary piping for water distribution, sanitation and dosing are made of material AISI 304 DN 40

- Connection fittings, food fitting DIN 11851, material AISI 304 DN 40.

Valves and pneumatic actuators

- The main pipe fittings are made of AISI 316 material

- Flap valve DN65 with vertical single-acting stainless steel drive.

- Fittings of the auxiliary pipline is made of AISI 316 material.

- Ball valves DN 40s are controlled by a single-acting AT101U S09B.

- Pneumatic slanted valves DN 25 and DN 32 are made of AISI 316 material.

Pumps

- Pump of the boiling set : Ebara DWO 300 fitted with SIC-SIC / Installed power 3.0 kW

- Pump of the filtering set : Ebara DWO 200 Perforated Pump With SIC-SIC Seal / Installed power input of 2.2kW

- Pump of the wort outgoing set : Ebara DWCH 50 / Installed power input of 2.2kW

(It is possible to replace these pumps with pumps PACKO Type NP 60 – at extra cost of approx. 1700 euro per piece)

Sensors

- The wort boiling set contains sensors of empty pipes.

- Sensors of the SLICK LFV 200 type are mounted on the suction of each pump (3 pieces).

Flowmeters

- Flowmeter of the wort boiling set – Comac cal Flow 38

- Flowmeter of the filtering set – Comac cal Flow 38 DN 32

- Flowmeter for transport of wort – Comac cal Flow 38 DN 50

Dosage of hops

The device serves for automatic dosing of hops into the wort boiler using the pump located on the main pipeline.

Material AISI 304, th. 2.5 mm

Working pressure 4 bar, test pressure 6.5 bar

Electric installation

- Main switch 3x 25A with central stop button

- Motor starter 3x 2,5-4A

- 1x Frequency converter Fronic mini 1.5 kW

- 2x Frequency converter Fronic mini 0.75 kW

- Digital temperature regulator of mash kettle Dixel XR20D

- Digital regulator of wort output temperature Dixel XR20D

- Circuit breaker 6A 230V

- Circuit breaker 10A 230V

- Circuit breaker 4A 230V

- Plastic DIN switchboard, 36 modules

- Wiring

- 5*1,5 18 m

- 5*2,5 10 m

- 3*1 48 m

Connections:

- Wort discharge pipe DN 32

- Cold water supply DN 32

- Hot water supply DN 32

- Drain line DN 60

- Electro 5*2,5 18 000 W

Auxiliaries:

- Wash basin with combined lever taps assembly

- Cooling device for samples

- Flow meter DN 32 of water supply

- Water filter

Main technical data:

- Length … 10500mm

- Width … 8000mm

- Height above chimney flange … 4500mm

- Platform height … 2700mm

- Minimum room height … 5500mm

- Recommended room height … 6000mm

Transport

This equipment is usually shipped in assembled state with exception for stainless steel covers, steamer for steam condensation, steps of service bridge and electric switchboard.

Warranty:

- Boiling equipment OPPIDUM 36 months

- Pump 24 months

- Electrical components 24 months

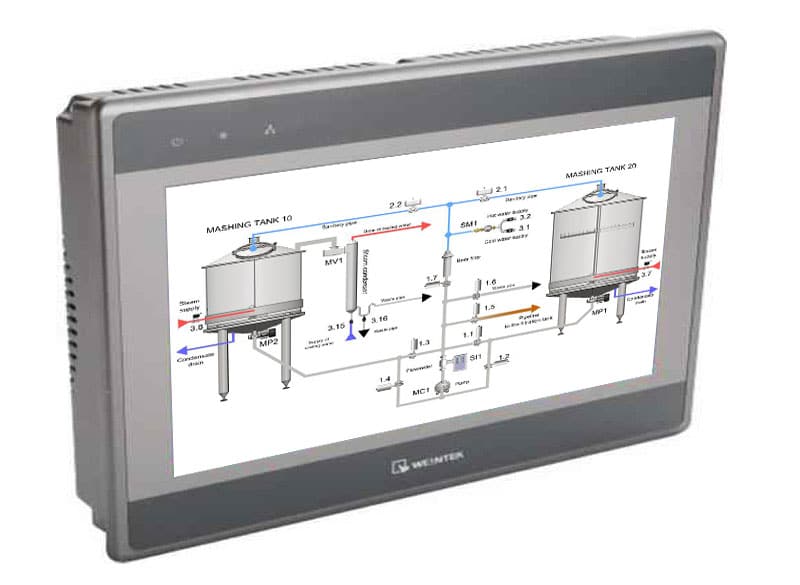

The automatic control system for the OPPIDUM – technical description

The BHAC4 is an automatic control system for the OPPIDUM wort preparation machines with computer support and most operations controlled automatically – according to a specified program from a central control panel.

The BHAC4 is an automatic control system for the OPPIDUM wort preparation machines with computer support and most operations controlled automatically – according to a specified program from a central control panel.

The brewing automation system allows you to operate in modes

1. Manual mode

2. Semi-automatic mode

3. Automatic mode,

All modes can be controlled from the touch panel, located in the cabinet on the operator platform, or by remote control from the control room.

In each mode, you can go back and forth during the process to another mode.

In automateic mode, you can stop the process and adjust the mode during the process, or by manual access to the process, depending on the access level.

MITSUBISHI PLC Specifications:

- L61P power supply

- L6ADP-R4 card for serial communication RS 485

- Processor L02CPU-P

- Output card LY42PT1P

- L60RD8 card for connection of temperature sensors PT100

- Analog output card L60DA4

- Control panel: WEINTEK MT8150XE

- Remote control: VIPA TM-C VPN router WAN / LAN 900-2C510

Control panel :

How looks the automatic control panel ? This is a main menu. Choose one from several beer types or other functions, fill stackes by all required raw materials, then click and let the computer to brew your beer :

Special functions :

- CIP function – the special mode ensures cleaning, sanitization and sterilization of the brewhouse, wort pipes and optionally also other devices in the brewery

Technical specification and functions

The control unit is developed on PC platform with an operating system and control programme.

In the price of the automatization of the boiling equipment is contained a complete assembly of hardware included the pneumatic actuators and the installation elements of the boiling equipment. The automatization also contains the operation system including the licence and software for an automatic production of wort using this machine.

The software enables to change the recipes for brewing more different kinds of beer directly via the control panel or by installation via USB port. Software and boiling equipment are both designed to brew all of the world known beers in decoction way or in infusion way as well. Also at decoction way, it is possible to brew on one or two mashing cycles.

Process sequences as times, speed of pumps, timing of all phases, temperature measuring and control etc.

Individual volumes of water refilling or the overflow volumes, temperatures and flow rate of each media can operator set himself after entering the user password on the third level.

Automatic control of the wort production machine with controlling the most of steps and operations by computer – according to a specified program from a central control panel ( touch screen ) . An human operator selects a recipe and starts a program that controls all production processes. The operator checks the progress of all procedures and performs laboratory tests , solves non-standard conditions and ensure the preparation of raw materials for the wort production process .

Manual operations before start of brewing :

- Preparation of malt using a mill machine (milled malt grist)

- Mixing of malt – sprinkling malt grist into warm water (mashing proces)

Automatical operations :

- Heating of tanks and timing (precise temperature gradients and time control all phases according to selected recipe)

- Decoction or infusion brew process including control of all pumps

- Filtering of wort (Lautering wort process)

- Boiling of wort with hops + dosing of hops (automatic adding of hops into wort during boiling)

- Whirpooling (separation of wort from hops using a centrifugal rotation)

- Cooling of young beer and saturation of wort with air

- Throwing out of rests malt from the filtration tank

- Sanitisation of all pipes (CIP process)

The control programme operates in Czech, Russian and English language. We can customize the program also for other languages.

Hardware and software description

Automatized beer brewing process is custom-built to exactly match the requirements of a particular type of boiling equipment and also the user´s requirements.

Automatic includes the following items:

1st Hardware

-

- Pneumatic valves and flaps including the actuators

- Flowmeter with digital output

- PLC control systém

- Touch panel for operator control

- instalation and connection of the automation components.

2nd Software

- Original operation system

- Support for setting custom lengths and work sequences

- Preprogrammed recipies for several beer types

10° light beer (Czech light lager beer)

11° dark beer (Czech black lager beer)

12° light beer (Traditional Czech lager type Pilsen)

13° weissenbeer (Beer made of wheat malt)

14° special beer (Stronger lager beer)

Hardware description :

Automatic control system

– 1pc PLC Tecomat Foxtrot CP 10006 13x AI/DI, 10x RO, 2x AO, 2x SSR, SD/MMC slot, Ethernet, WebServer

– 1pc IB 1301 12x DI 24V DC (4 x DI High Speed)

– 5pc IR 1401 12x DO 24V DC (transistor outputs 0,5A)

Display and communication system of automatization

Display and communication system of automatization

– 3 pc display operation panels Weintek CMT-IV5

- screen resolution 1024×768

- screen diagonal 9,7“ capacit TFT

- brightness 350 cd/m²

- 500:1 contratst ration

- support for multi-touch

- 1 Ghz RISC Cortex A9 processor

- 512 MB Flash, 1GB RAM

- Ethernet communication port

- 24 VDC power supply

- Degree of protection IP65

- external dimensions 257,2×199,7×32,7mm (LxWxH)

- weight 760g

- working temperature 0 ~ +50°C

– 1 pc vizualization server Weintek SMT – SVR

1 pc vizualization server Weintek SMT – SVR

- ARTEX A8 RISC processor

- 256 MB flash memory, 256 MB RAM

- inputs/outputs – USB2.0- Serial port- SD card- Ethernet

- 24 VDC power supply

- Degree of protection IP65

- External dimensions 130x115x24mm (LxWxH)

- Weight 180g

- Working temperatre -20 ~ +55°C

Pneumatic valves

– screw-thread size

- G 1/2“ (DN15)

- G3/4“ (DN20)

- G 1 1/4“ (DN32)

–  PTFE seal

PTFE seal

– working temperature -30 ~ +180°C

– min. and max. pressure 0 ~ 16 bar

– min. and max. working pressure 6 ~ 8 bar

– weight and dimensions are variable depending the type of the valve/flap

– material – body – stainless steel no. 1.4408

– pneumatic actuator – aluminum body

– 14 pcs of pneumatic valves

Pneumatic flaps

– screw-thread size 2“ – brightness flaps DN50

– sealing VMQ – Silicon

– max. working temperature 100°C

– steam sanitation max. temperature 130°C

– working pressure max. 10 bar

– valve and actuator are made of stainless steel 1.4301

– 24 pcs of pneumatic flaps

Electromagnetic valves

Water

Water

– screw-thread size – G 1/2“ (DN15)

– G 3/4“ (DN20)

– max. pressure 16 bar

– ambient temperature -20 ~ +65°C

– temperature of medium -20 ~ +120

– material: stainless steel AISI304

Steam

– screw-thread size G 1/2“ (DN15)

– max. pressure 25 bar

– ambient temperature -20 ~ +65°C

– temperature of medium +5 ~ +185°C

– material: stainless steel AISI304

In Oppidum brewhouses are 16 pcs of water and steam electro-magnetic valves

Electrical installation is carried out according to standard ČSN EN 60204-1, the degree of protection IP 65

Software and description of available program modes

Available operations

– The PLC programe is devided into processes

– The measuring processes are: – temperature measurement – impuls counting of data from the flowmeters ( induction , impulse)

– Another process is responsible on the basis of data received from the operator panel to run different processes according to the selected recipe

– Infusion

– Method of one boiling cycle of malt mash per batch

– Method of two boiling cycles of malt mash per batch

– Other possible processes and brewing methods

– Back-flush of pipes,, pumps and tanks

– Sanitation of all important parts of the machine

Access modes

– For vizualization is used the operator panel with touch panel

– User is able to work in four available modes with different access rights.

User mode

– Allowed only monitor the progress of the brewing process

Extend user mode

– User mode + the possibility of switching valves, motors, pumps and pausing the automatic process

Admin mode

– Extending user rights + the possibility of starting the automatic brewing and changing the procedures parametres

Programming mode

– Full setting of all programm parameters and constants

Manual control mode

– The operator panel is used for remote control of valves, dampers, mixers and pumps

Automatic control mode

– Possibility of setting up the parametres of individuals recipes and starting the automatic process

– Operator panel displays the name of the beer, the type of cooking, monitoring of the actual step either with countdown timer, or with deduction liters or with reached temperature

– On the panel the current statuses of all important elements in each step are visualized – valves, motors, pumps, sensors

– Process is possible to suspend or interrupt everytime by human operator

Extending of possibilities

– Customization of all hardware and software equipment according to individual costumer requests and the available technology

Price of the wort brew system Oppidum 6000 includes :

1. Brewhouse Oppidum 6000

– main wort brew machine that is described on this site. The set includes all tanks, pumps, pipe system, electric system, support construction, service platform and stairs.

2. Automatic control system

– All hardware, technical equipment and software designed to operation of the brewhouse in all three available modes : manual / semi-automatic / full automatic.

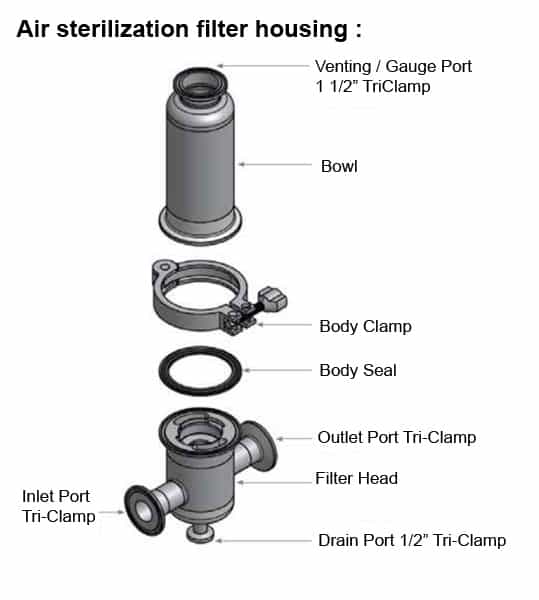

3. Air sterilization station

DEMI HBA 5 ” – The sterilization air filter for food processing technologies

- Operating temperature: max. 150 ° C

- operating pressure: max. 10 bar (g)

- Dangerous gases / vapors max. 10/5 bar (g)

- The construction material is high quality stainless steel AISI 316L. All welds are fully welded, free from cracks and inflammations.

- The filters are supplied with threaded connection, FDA silicone sealant, FDA PTFE sealing vent and drainage and base coat:

– inner surface: welded, stained and passivated

– outer surface: polished 0.8 μm Ra (32 μln Ra)

– output up to 100 M3 / hr

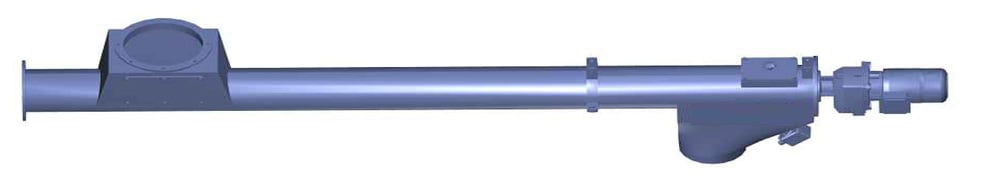

4. Brewer´s malt grain discharging conveyor

Transport of wet used brewer’s grains from the filtering tank out of the building to the lorry vehicle.

The spiral stainless steel conveyor is used to transport wet malt grains from the filter tank to prepared containers or trucks, which are prepared outside the brewery building.

The conveyor is made of AISI 302 and AISI 304 and is fitted with a Nord engine. At the output of the conveyor there is a level sensor.

DN32 threaded neck for easier drainage of surplus water is located at the lowest point of the conveyor.

Parameters:

- Overall length 7,900 mm

- Shipping length 7000 mm

- Inlet diameter 300 mm

- Output diameter 249 mm

- Power 8,6 m3 / hour

- Gearbox Nord with 400V engine

- 7 900 mm stainless steel pipe diameter 219.1 * 2.0 mm (AISI 304)

- 7 900 mm stainless steel robust spiral RLN 200 * 200 * 61 * 10 mm (AISI 304)

- 1 piece of stainless steel feed hopper with inspection hole and connection fitting with a 300 mm diameter flange (AISI 304)

- 1 piece of stainless steel outlet with socket diameter 249 mm (AISI 304)

- 1 pc of 24-volt flow sensor located in the conveyor outlet – safety design

- 1 piece of Nord gearbox with Nord engine located at the drop, food oil filling

- 1 piece of stainless steel sleeve for conveyor suspension (AISI 304)

- Color of RAL 1015 drive (changeable on request)

Optional accessories and upgrades

| Recommended options and additional equipment for improvement of the wort brew machine Breworx Oppidum 6000 | Prices (EUR) |

|---|---|

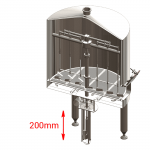

| ELS : Electric lift of the knife-stirrer in the filtering tank (lifting up to 200mm)This customization of the wort brew machine allows you very variable setting position of the knife-stirrer inside the filtering tank. This is useful during filtration of wort through the malt grain sediment when some stronger beer types are produced. The lifting of the knife-stirrer ensures you to speed up the process of souring wort. This is important to avoid excessive oxidation of the wort during the filtering process. | ELS : Electric lift of the knife-stirrer in the filtering tank (lifting up to 200mm)This customization of the wort brew machine allows you very variable setting position of the knife-stirrer inside the filtering tank. This is useful during filtration of wort through the malt grain sediment when some stronger beer types are produced. The lifting of the knife-stirrer ensures you to speed up the process of souring wort. This is important to avoid excessive oxidation of the wort during the filtering process. |

11458 |

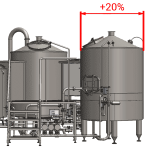

| EFT : Enlarged filtering tanks to production of stronger beer types with EPM (plato) higher than 15°The special customization – the filtration tank with diameter by 20% larger than standard version of the (wort filtration tank). This customization of the wort brew machine allows production of beer types with EPM (Plato) from 12 to 17 (Our brew machines with the standard filtering tank are optimalized for production beer types with EPM (Plato) from 10 to 15). According to customer´s requirements we can produce the wort brew machines with more larger diameters as well (the price will be calculated individually). | EFT : Enlarged filtering tanks to production of stronger beer types with EPM (plato) higher than 15°The special customization – the filtration tank with diameter by 20% larger than standard version of the (wort filtration tank). This customization of the wort brew machine allows production of beer types with EPM (Plato) from 12 to 17 (Our brew machines with the standard filtering tank are optimalized for production beer types with EPM (Plato) from 10 to 15). According to customer´s requirements we can produce the wort brew machines with more larger diameters as well (the price will be calculated individually). |

7596 |

| WSF : Wire sieve to acceleration process filtering of wortSpecial wire sieve to filtering wort during the wort brew process has by 30% bigger filtering area in comparation with the classic filtering sieves where the holes are cut using a profiled knife. The main benefit is faster filtering of wort through the malt sediment layer. This is useful during filtration of wort through the malt grain sediment when some stronger beer types are produced. It is important to avoid excessive oxidation of the wort during the filtering process. | WSF : Wire sieve to acceleration process filtering of wortSpecial wire sieve to filtering wort during the wort brew process has by 30% bigger filtering area in comparation with the classic filtering sieves where the holes are cut using a profiled knife. The main benefit is faster filtering of wort through the malt sediment layer. This is useful during filtration of wort through the malt grain sediment when some stronger beer types are produced. It is important to avoid excessive oxidation of the wort during the filtering process. |

2500 |

| WMP-100 : Waste processing system for used extracted malt 100hlSystems for processing of used extracted malt and hops and their preparation for the transport out of the brewery. The WMP-100 Waste processing system for used extracted malt consists of : 1. Primary screw conveyor with the hopper – Stainless steel conveyor for the transport of used malt from the filtration tank of the wort brew machine out ofthe building. / 2. Main malt-waste storage hopper – Stainless steel conical container for temporary storage of used malt before its transport to farmers. / 3. Secondary screw conveyor with the hopper – Stainless steel conveyor with capacity 100 hl for the transport of the stored used malt from the main hopper to prepared truck or trailer. / 4. Electric and pipe system with central control panel and switchbox. / 5. Support construction – Stainless steel pipe contruction for the installation of all parts of the system, with ladder, water jet for cleaning of the hopper and connection parts. | WMP-100 : Waste processing system for used extracted malt 100hlSystems for processing of used extracted malt and hops and their preparation for the transport out of the brewery. The WMP-100 Waste processing system for used extracted malt consists of : 1. Primary screw conveyor with the hopper – Stainless steel conveyor for the transport of used malt from the filtration tank of the wort brew machine out ofthe building. / 2. Main malt-waste storage hopper – Stainless steel conical container for temporary storage of used malt before its transport to farmers. / 3. Secondary screw conveyor with the hopper – Stainless steel conveyor with capacity 100 hl for the transport of the stored used malt from the main hopper to prepared truck or trailer. / 4. Electric and pipe system with central control panel and switchbox. / 5. Support construction – Stainless steel pipe contruction for the installation of all parts of the system, with ladder, water jet for cleaning of the hopper and connection parts. |

59850 |

| Fully-welded outer stainless steel jacket without rivets and with glossy outer surface | 49800 |

| PID control of the hot steam heating of the kettle + three-phase steam heating (for accelerating of the wort brew cycle) | 5460 |

| GSG : BR-GSG-1500 Boiler room with the Gas steam-generator 1500kg/hr – heating of the wort brew machineFully equipped boiler room with the automatic gas steam-generator, available power 1048 kW. Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 16 bar. The machine complies with EU Directive 97/23 EC (PED) and Module H1, CE | GSG : BR-GSG-1500 Boiler room with the Gas steam-generator 1500kg/hr – heating of the wort brew machineFully equipped boiler room with the automatic gas steam-generator, available power 1048 kW. Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 16 bar. The machine complies with EU Directive 97/23 EC (PED) and Module H1, CE |

80352 |

| MSS : MSS-2×40 Malt storage silo 2x40m3The MSS-40 malt storage silo is fully equipped system for storage and dose malt for medium-large breweries. The system consists of these subsystems : | MSS : MSS-2×40 Malt storage silo 2x40m3The MSS-40 malt storage silo is fully equipped system for storage and dose malt for medium-large breweries. The system consists of these subsystems :Basket for incoming malt, Bucket conveyor for malt above the both silos, Distribution pipe manifolds with flap above both malt silos, Silos for storage malt … 2x 40 m3, Automatic control system, Steel construction, connection elements, pipe and electric system. |

151570 |

II. Beer bermentation system

We produce minibreweries BREWORX OPPIDUM in modern variant of the main fermentation and arrangement of the tank storage.

Microbreweries BREWORX OPPIDUM CF

Microbreweries BREWORX OPPIDUM CF

Fermentation and maturation in sealed cylindrical-conical tanks is an effective and modern way of producing beer, which is highly resistant to contamination of fermenting beverages with unwanted organisms. Precision control of the fermentation and maturation leads to permanent results of constant quality and sensory characteristics of the beer. This scheme of brewery is particularly suitable for the production beer types using upper yeast, but it is possible to produce all types of bottom-fermented beer too.

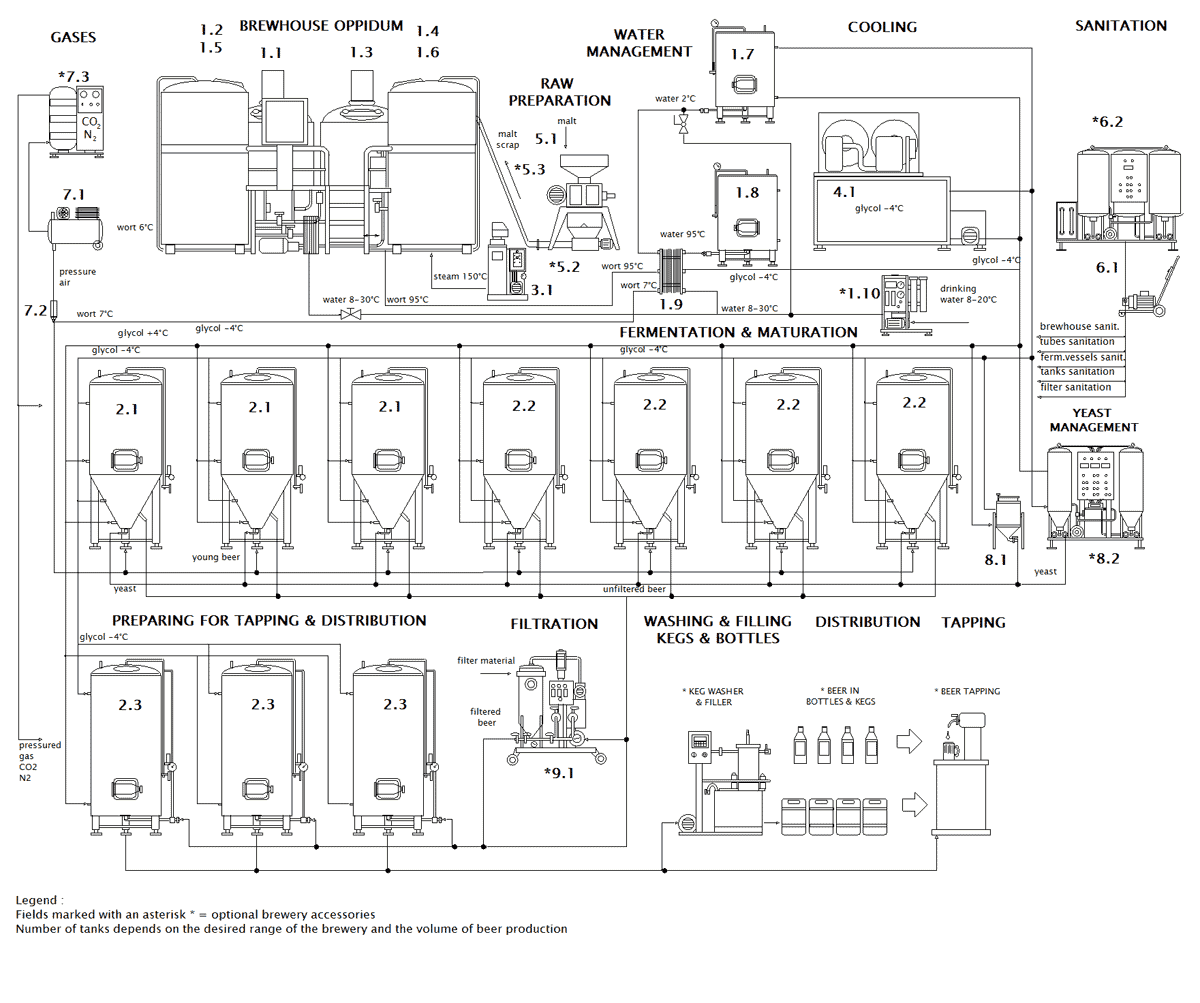

Drawing of brewery BREWORX OPPIDUM CF (closed fermentation):

1. Brewhouse: 1.1 Brewhouse: Mash kettle primary, 1.2 Brewhouse: Mash kettle secondary, 1.3 Brewhouse: Lauter tun, 1.4 Brewhouse: Wort storage tank, 1.5 Brewhouse: Wort kettle, 1.6 Brewhouse: Whirlpool, 1.7 Hot water tank (boiler), 1.8 Ice treated water tank, 1.9 Wort heat exchanger , 1.10 Water treatment, 2. Fermentation: 2.1 Fermentation , 2.2 Maturation tanks, 2.3 Serving tanks, 3. Hot steam-generator, 4. Cooling: 4.1 Glycol Cooling Unit + Ice cooling water tank, 4.2 Plate heat exchanger for cooling the wort / hot water production, 4.3 Plate heat exchanger for ice water cooling, 6. Sanitation: 6.1 Mobile CIP pump, 6.2 * CIP station, 7. Production of industrial gases: 7.1 Compressor, 7.2 Wort aeration stone, 7.3 Beer pushing inert gas, 8. Yeast management: 8.1 Yeast tank, 8.2 * Propagation station for growing yeast strains, 9. Beer filtration: 9.1 * Primary and secondary filter, 10. Bottling and salling of beer: 10.1 * KEG Washing and Filling maschine, 10.2 * Distribution and sales of beer * 10.3 Tapping of beer.

Reviews

There are no reviews yet.