Description

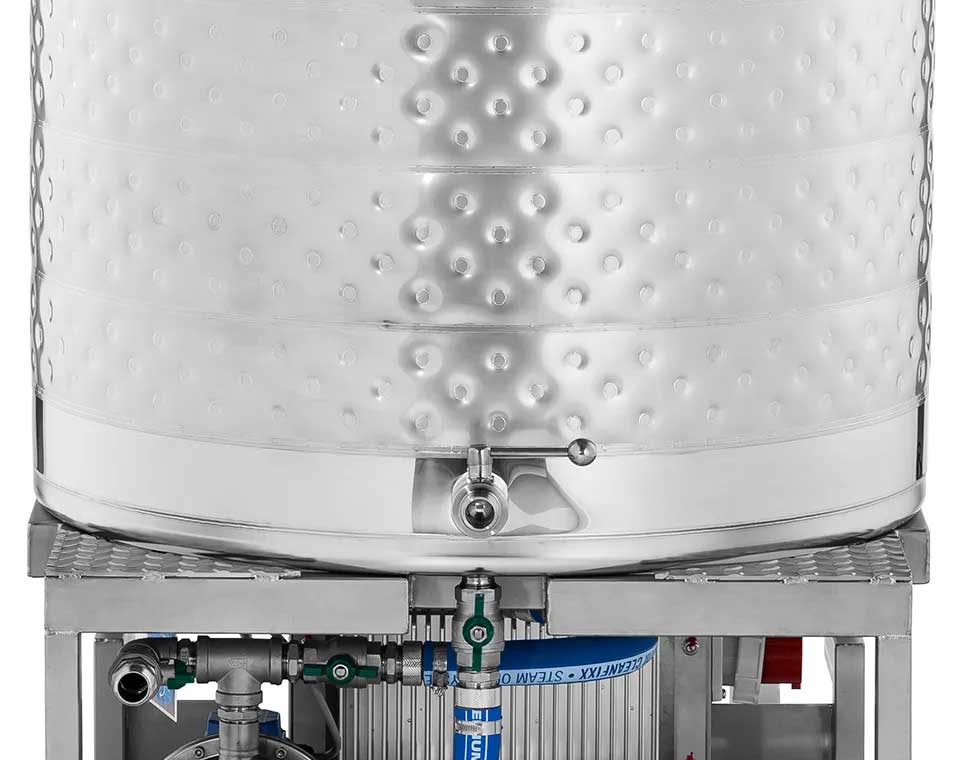

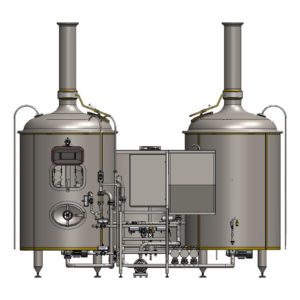

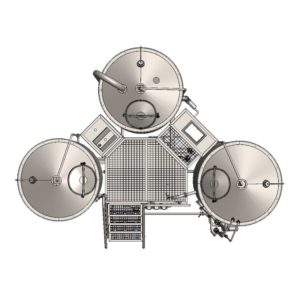

The medium-size wort brew machine that is intended for easy preparation 1100L of beer wort in one batch using the infusion brewing method. Practical and easy beer production device to use for all home brewers. Our brew machine BREWMASTER BM-1000 with use of some simplified wort fermentors permits to prepare a good hand crafted beer, using fresh products according to any kind of recipe. The wort brew machine is produced of stainless steel. Maximal malt quantity 225 kg per batch. The wort brew machine is fully produced of stainless steel AISI 304.

1100 liters of produced wort is sufficient volume to produce around 1000 liters of beer after finish the fermentation and maturation process.

BREWMASTER BM-1000 produces up to 1000 liters of hopped wort per one batch

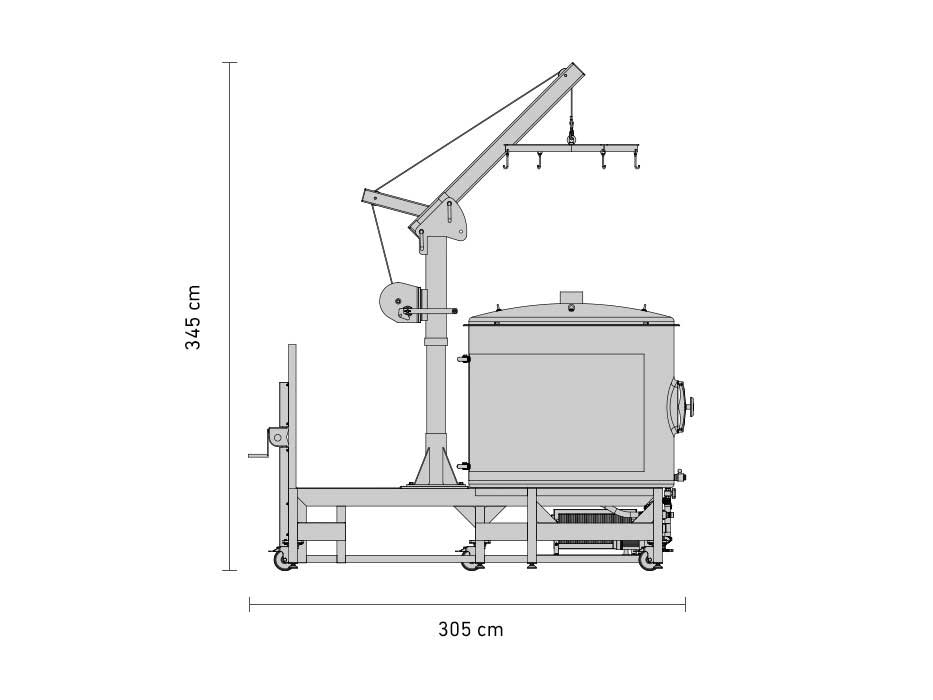

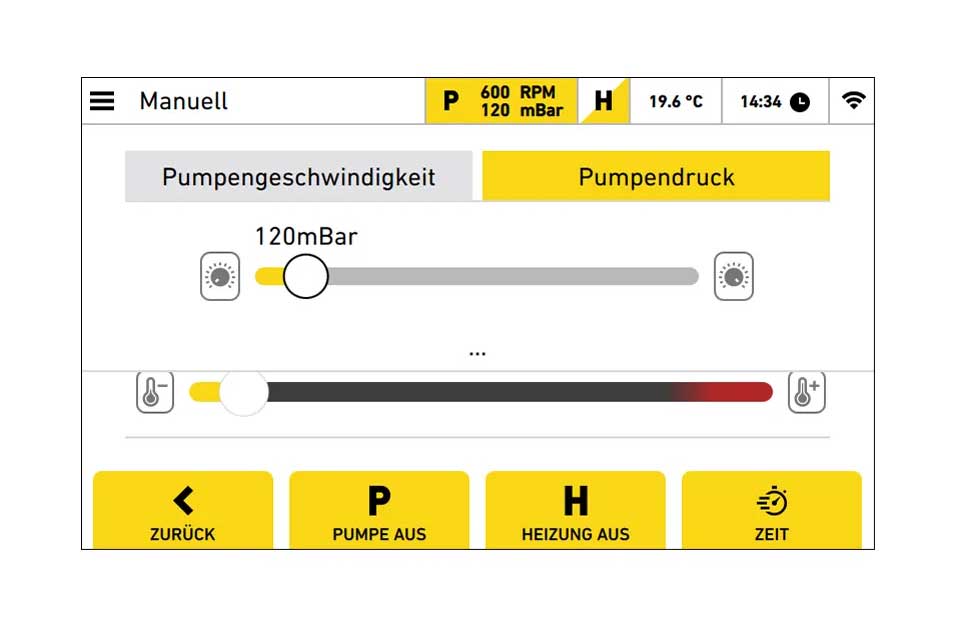

The fully automatic wort brewing control system takes over the brewing process according to individually adjusted recipes and runs through all brewing phases with exact times and temperatures. The filtering of pure wort out from rest malt grains is done easily and quickly by lifting the inner basket with the malt sieve using the lifting device integrated. This way you can carry out the wort filtering process easily and quickly.

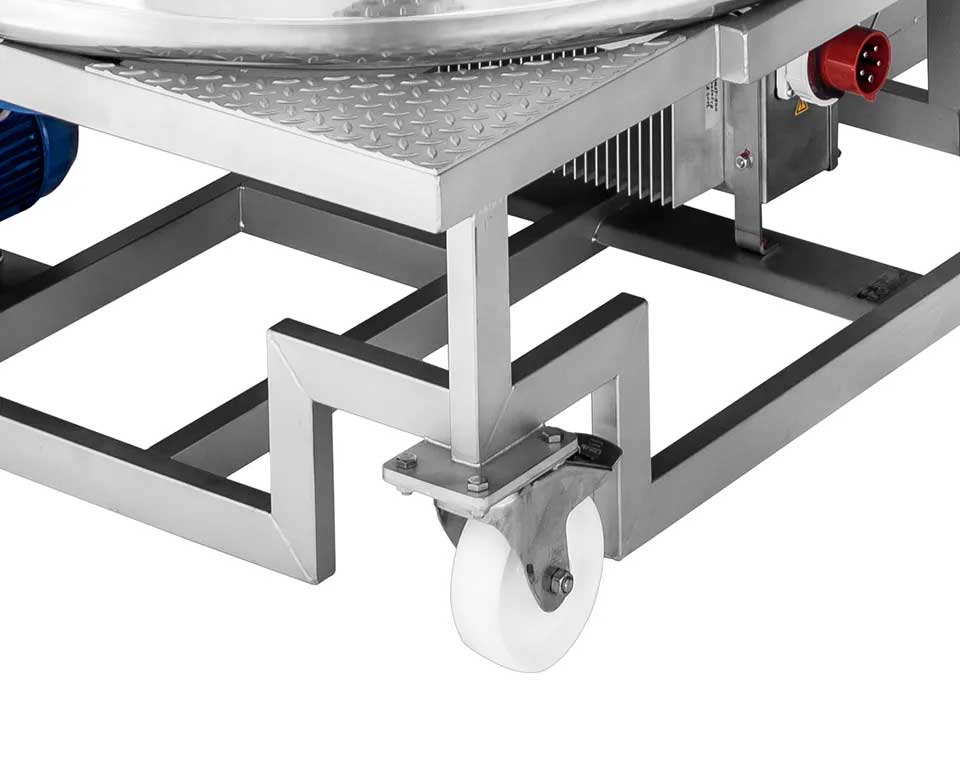

In addition, this brewing device is mobile, easy movable , and its space requirement is minimal. This makes it ideal for smaller restaurants, pubs, events or home-brewing beer communities. The low purchase cost and a low price per produced litre of beer ensure a quick costs return.

Description of the BM-1000 BREWMASTER brewhouse :

The wort mashing-boiling / The wort filtering

Technical details

- PLC programmer which allows to check, regulate and program automatically any desired times, pump activities and temperatures, following recipe choosed. In support of that, we can supply also a WiFi Interface which helps you to program the PLC directly from your PC computer.

- Moto-reducer in the lower part.

- Thanks to a modular wort brewing system, good organoleptic qualities, and thanks to the newest patented system, you will got a better extraction of sugar from wort than with other brewing systems.

- Twelve heating elements for the heating, easy maintaining and a practical wire-filter, a winch module to easy lift and positioning the wort filter without any effort, four turning wheels (of which n. 2 with brake) for an easy transport of the machine in a room.

- Twelve heating coils: 4 x 3.000 W + 8 x 2.725 W output

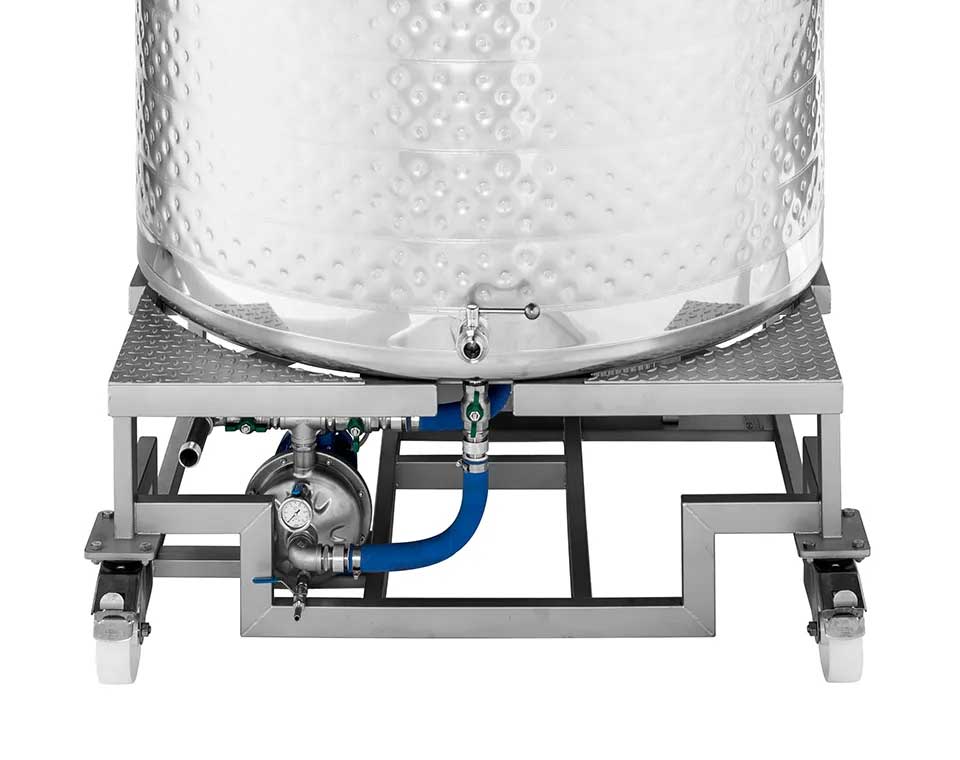

- Pump: 370 W

- Power supply connection: 400V /3-phase (fuse protection min. 63 A with star, min. 125 A with delta)

- Total power consumption: 34.2 kW

- Wort cooling: Ensured using the double-jacket with 2.56 m2 surface area and with ice water that circulates through it. The wort cooling process takes approximately 2 h (Cooling down of wort from 95°C to 25°C). For shorter cooling time some extra external cooling device is necessary.

- The pump and tangential inlet ensures easy separation of wort from hops using the whirlpooling effect.

- Max. malt quantity: 225 kg

Weight : 980 kg

Pipe connections :

- Wort output : BSP 1″ male

- Cooling water input: BSP 1″ male

- Cooling water output: BSP 1″ male

Benefits :

- Very easy to use, clean and maintain.

- In support of the brewing unit, we can supply a wide range of accessories (hop filters, passive or cooled cylindric and conic fermentation tanks, cooling heat exchangers, ..) which will guide you into a brewing of perfect your own beers !

- It is an ideal solution for small craft breweries, pubs, agritourisms, catering institutes and for any activities which wants to offer their own craft beer to their customers.

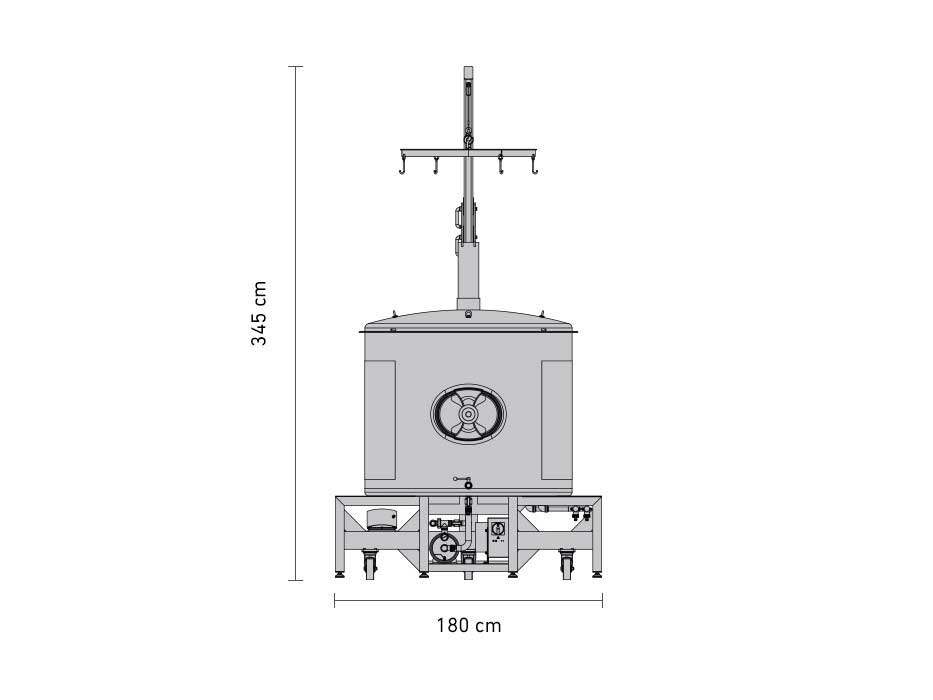

Dimensions

- Length: 305 cm

- Width: 180 cm

- Height: 345 cm

- Wooden crate: 310 x 190 x 195 cm (length x width x height)

- Shipping weight: 980 kg

Practical design and very comfortable operation :

Wort brewing process :

Programming – Depending on the recipe, the BM-1000 brewing system is programmed with the appropriate brewing times and temperatures. The brewing process starts by switching over to automatic control. The control system guides the user through the step by step and executes all four brewing phases automaticaly.

Mixing and heating of malt mash – Depending on the recipe and method, you poure water into the BREWMASTER machine and heat it up to 38 °C. Then put the malt basket with the sieve in its working position. Pour required amount of malt between the sieve inserts. The malt basket is fixed with bracket and drawbar.

Mash brewing – The pump switches on automaticaly. During the malt in water circulation process, he starch is extracted from the malt. The four wort brewing phases are executed according to recipe is selected. For example as follows:

- Protein phase : 55 °C, approximately 5 min

- Maltose phase : 63 °C, approximately 30 min

- First sacharidation phase : 72 °C, approximately 20 min

- Second sacharidation phase : 78 °C, approximately 10 min

Filtering – At the end of the four mashing phases an acoustic signal sounds. The subsequent wort filtering process is easy executed by simply removing the malt basket from the BREWMASTER machine. This is done by means of the integrated lifting device. Allow to filtrate the wort through malt a few minutes. Then shortly sparge the malt in the basket by hot water to achieve a better yield and remove the malt basket.

Boiling the wort with hops – The wort is boiled for 80 minutes with hops , with opened lid. Hops being added several times during the boiling. Using a special sieve you can easy to separate hops pellets from wort. The evaporated water is to be replaced by adding fresh brewing water. The original wort viskosity can be finally adjusted by adding or leaving out water. Scale on the wort brew machine serves as a level meter. At the end of the boiling phase, an acoustic signal sounds again.

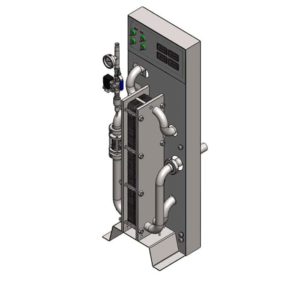

Wort cooling – After end of the boiling the wort with hops, the wort is cooled as soon as possible to the fermentation temperature by a special wort cooler integrated in the machine or using the cooling double jackets of the fermenting tank cooled with cold water and water cooler.

Beer fermentation/maturation process :

Immediately after end of the boiling of the wort the temperature of the wort is brought to the level of the fermentation temperature by a wort cooler or by a double jacket; the wort is also mixed with yeast and fermented in a suitably large fermentation tank (optional accessory).

Primary beer fermentation and secondary beer fermentation ( maturation )

For both the beer fermenation and maturation you can use the stainless steel fermentors fully equipped for semi-professional the beer production process.

>> Pressure tanks for the beer fermentation and maturation …

>> Complete sets with one fermentor for the secondary beer fermentation …

>> Complete sets with more fermentors for the secondary beer fermentation …

Consuming :

After several weeks of conditioning beer in bottles or in a pressure beer maturation tank (optional accessory), the well cooled beer can be consumed.

Available accessories :

1. SBT2 : Set of brewing tools for BREWMASTER breweries

Set of brewing tools for BREWMASTER . This set includes :

- Hydrometer and sampling plastic cylinder – Hydrometer is a basic measurement tool for measuring the percentage of alcohol in the beer produced. This set includes a noncalibrated hydrometer with temperature correction and support plastic cylinder.

- Large shovel – for handy removing malt from the wort-boiling machine after the wort filtration process.

- Cleaning set – set of tools for easy cleaning of the wort-boiling machine, tanks and hoses.

- Malt barrel – the plastic vessel for easy collecting of the milled malt under the malt milling machine

- Wooden mash paddle – for handy occasional mixing of wort during the brewing process

2. BMTM-100 Termo-sleeve for the BREWMASTER BM-100

BMTM-1000 Termo-sleeve is a recommended accessory for the BREWMASTER BM-1000 wort brew machine. This accessory is intended for insulation of the boiling vessel to speed up heating, speed of each brew batch and saving energy. The termo-sleeve is also very recommended for use when is requirement for more than one brew cycle per day – in this case we recommend to use the fermentation-maturation tanks with volume equal total volume of daily produced wort.

3. MM-283EWR : Mill of malt grains

Machine for fine squeezing of malt grains without damaging the outer parts of grain, with production capacity from 60 to 80 kg per hour.

4. FUIC-SLP1C-2x1000CCT Compact fermentation unit 2×1000/1200 liters 1.2 bar

with two pieces of 1000/1200 liters Cylindrical-conical tanks (CCT) and one independent compact water/glycol chiller

5. CFSCT1-2xCCT1000SLP : Complete fermentation set with 2xCCT-SLP 1200 liters

The complete beer fermentation set. This set CFSCT1-2xCCT1000SLP includes all equipment necessary for professional production of beer using the fermentation and maturation of wort using the fermentation and maturation process in two cylindrically-conical low-pressure fermenters. This set is also designed for the production of cider from fruit or carbonized wine.

The set CFSCT1-2xCCT1000SLP consists of :

- 2 pcs of the CCT-SLP-1000DE simplified non-insulated cylindrical-conical tank 1000 liters (total capacity 1200 liters) with one cooling zone – the special container for both fermentation and maturation of beer (cider, wine) under pressure max. 1.2 bar

- 1pc of the compact water/glycol chiller 2300 W with four independent digital temperature regulators, four temperature sensors, foru pumps

- Hoses and fittings to connection between cooler and tank.

- Installation manual

Reviews

There are no reviews yet.