Description

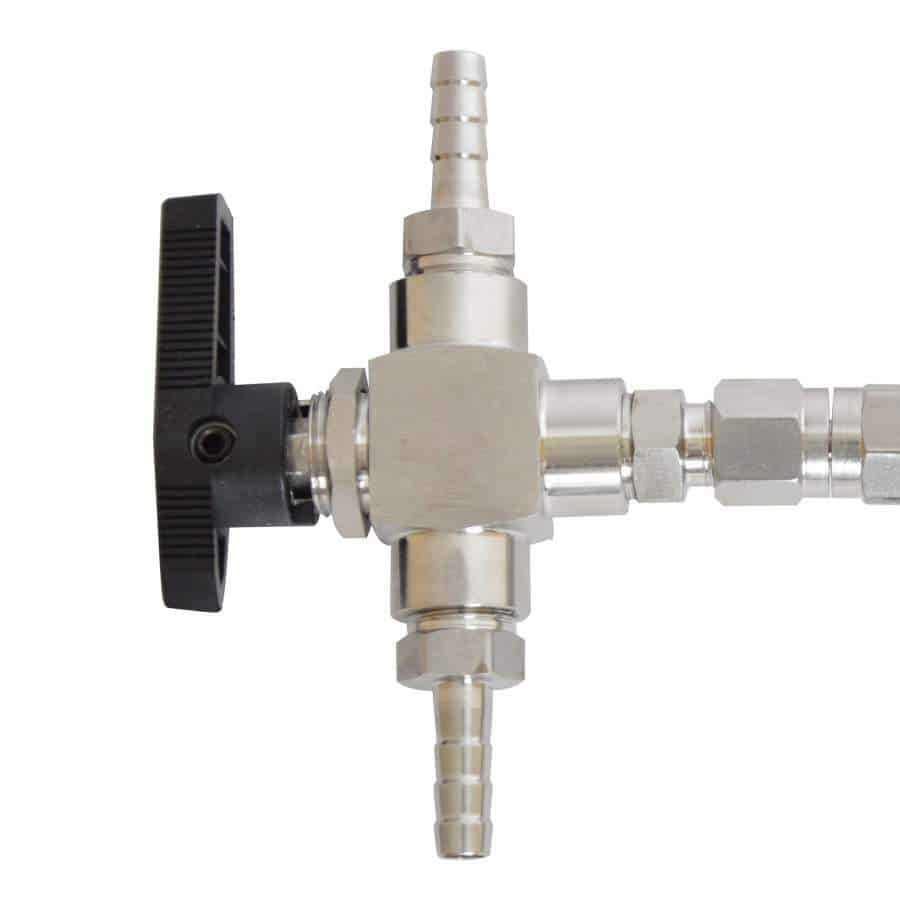

A simple manual isobaric filling mechanism for easy filling of bottles – Manual stainless steel counter pressure filler. The filling needle set contains of one three-way valve, pressure relief valve, hose adapters and needle and has a simple design. It is suitable for filling sparkling wines, soft drinks, beer, etc., (any kind of bottle such as glass or PET). It is made from stainless steel AISI 304 and an acetal food grade plastic.

The bottles filling capacity depends on: the quality and pressure of beverage, size of bottles, the ambient temperature, the beverage temperature, the pressure of carbon dioxide, and on user’s experiences.

CHARACTERISTICS:

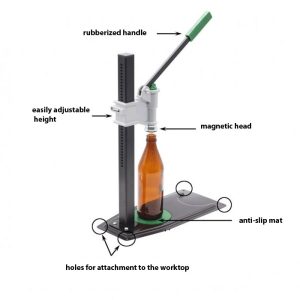

- Manual isobaric system for the filling of bottles with one universal stainless steel filling head.

- Stainless steel valve (with three possible positions) to filling bottles with carbon dioxide, to filling bottles with a beverage and the close.

- Stainless steel adjustable pressure valve for fine-tuning fill speeds.

- Beverage and carbon dioxide gas piping with resistant stainless steel forging.

- Attachable to any source of carbonated liquid, gas and cleaning solution that uses many standard fittings.

- Versatile equipment for use with many different bottle sizes.

- All parts of the unit can be easily disassembled for maintenance work or cleaning.

The equipment has two hose ends with a diameter of 3/8 inch for the feed hose line. One for gas and one for liquid. A user has to connect the piping, clamps and fittings with the output from a pressure tank with a beverage and also with the carbon dioxide bottle.

The counter pressure filling needle allows you to fill glass or PET bottles from a pressure keg with minimal foaming and CO2 loss. This prevents sediment in the bottle from bottle conditioning. Full Stainless construction with a silicone bung to sealing on the bottle neck. The filling needle has 7mm hose adapters on the inlets and three-way release valve that suits beer hose lines with internal diameter of 5 or 6 mm. The cone seal suits bottles with an internal neck diameter between 14 – 20 mm. Bottles need to be at least 22 cm high.

Hoses, clamps, gas pressure splitter and coupler to suit the kegs are not included.

Three way valve at the top of the counter pressure filler: Connect your CO2 hose from the regulator on one side and the beer line hose from the keg to the other side.

Valve has 3 positions : CO2 input / Beer input / Closed.

Cleaning after and before use :

After use we recommend to let run a peroxide based cleaning solution through the filling needle (such as PBW or Chemipro Oxi ) and then rinse it out with drinking water. Before the next use rinse the needle again with a phosphoric acid based sanitizer (e.g. Star San).

How to connect the bottle filling needle to beverage hoses :

You need to orders also :

Code |

Photo |

Description |

| DMA-G14M-H060 |  |

DMfit quick coupler/adapter : BSPP 1/4″ male thread | hose (flexi pipe) D=6.0mm (1/4″) |

| DMA-G14M-H080 |  |

DMfit quick coupler/adapter : BSPP 1/4″ male thread | hose (flexi pipe) D=8.0mm (5/16″) |

| DMA-G14M-H095 |  |

DMfit quick coupler/adapter : BSPP 1/4″ male thread | hose (flexi pipe) D=9.5mm (3/8″) |

Optional accessory :

-

1 pcs of silicone plugs to filling glass bottles – diameter 17/22mm, inner hole 9mm …… 10 Eur

-

1 pcs of silicone plugs to filling PET bottles – diameter 21/27mm, inner hole 9mm …… 10 Eur

The bottle filling unit is delivered with one silicone plug with diameters 17/22 mm, inner hole 9mm (recommended for standard glass beer bottles) … without a surcharge.

![]()

Reviews

There are no reviews yet.