Description

Manual blowing machine for two glass bottles

The bottle blowing machine allows to blowe wet glass bottles and jars from inside, with sterile air (with 4bar minimum pressure) to dry them after their rinsing before the filling beverage into the bottles.

Can be used with bottles of various shapes – range of volumes from 0.2 litres up to 2 litres.

Maximal bottle diameter: 120 mm.

Minimal bottle diameter: 30 mm.

Maximal bottle height: 400 mm.

Minimal bottle height: 180 mm.

Productivity … depending on the operator experiences : 200 up to 600 bottles/hour.

Air consumption … under pressure 2bar = 1 liter/bottle ( The air compressor is not included).

Filtering assembly … mechanical air filter with 0.45 microns cartridge.

Main properties :

- Productivity … depending on the operator experiences : 200 up to 600 bottles/hour.

- Connection for sterile pressurized air (3-4 bar) from an external air compressor (consumption approx. 1 litre/bottle)

- Connection for neutral gas (2 bar) from an external pressure cylinder (consumption approx. 2 litres/bottle)

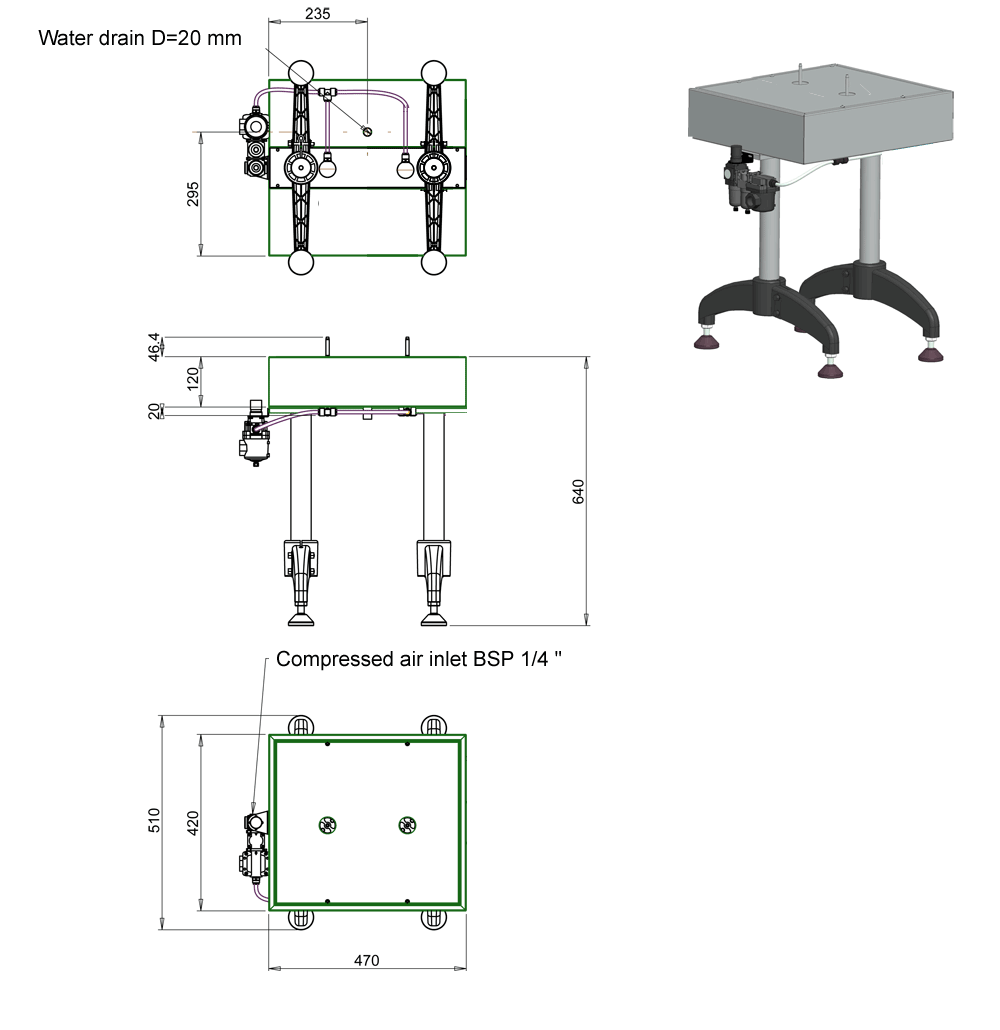

- Dimensions: width 51 cm, length 54 cm, height 65 cm, weight 25 kg.

- Made to EC standards.

How the machine works :

Connection on media

The machine must be connected compressed air (or nitrogen) supply with a pressure of 2 bar.

Used water drains under the machine to the floors.

Drying the bottles :

The operator places two bottles upside down on the two blow nozzles in the center of the workbench and presses the bottle against the nozzles to start drying the bottles with pressure air (or nitrogen). The bottle is blowed as long as pressure is applied to the bottle.

DESCRIPTION AND DIMENSIONS :

Optional accessories :

- Air compressor 2-3 hp with 100L air tank : ACO-6M Air compressor 6 m3/hour with filtration & pressure tank

Reviews

There are no reviews yet.