Description

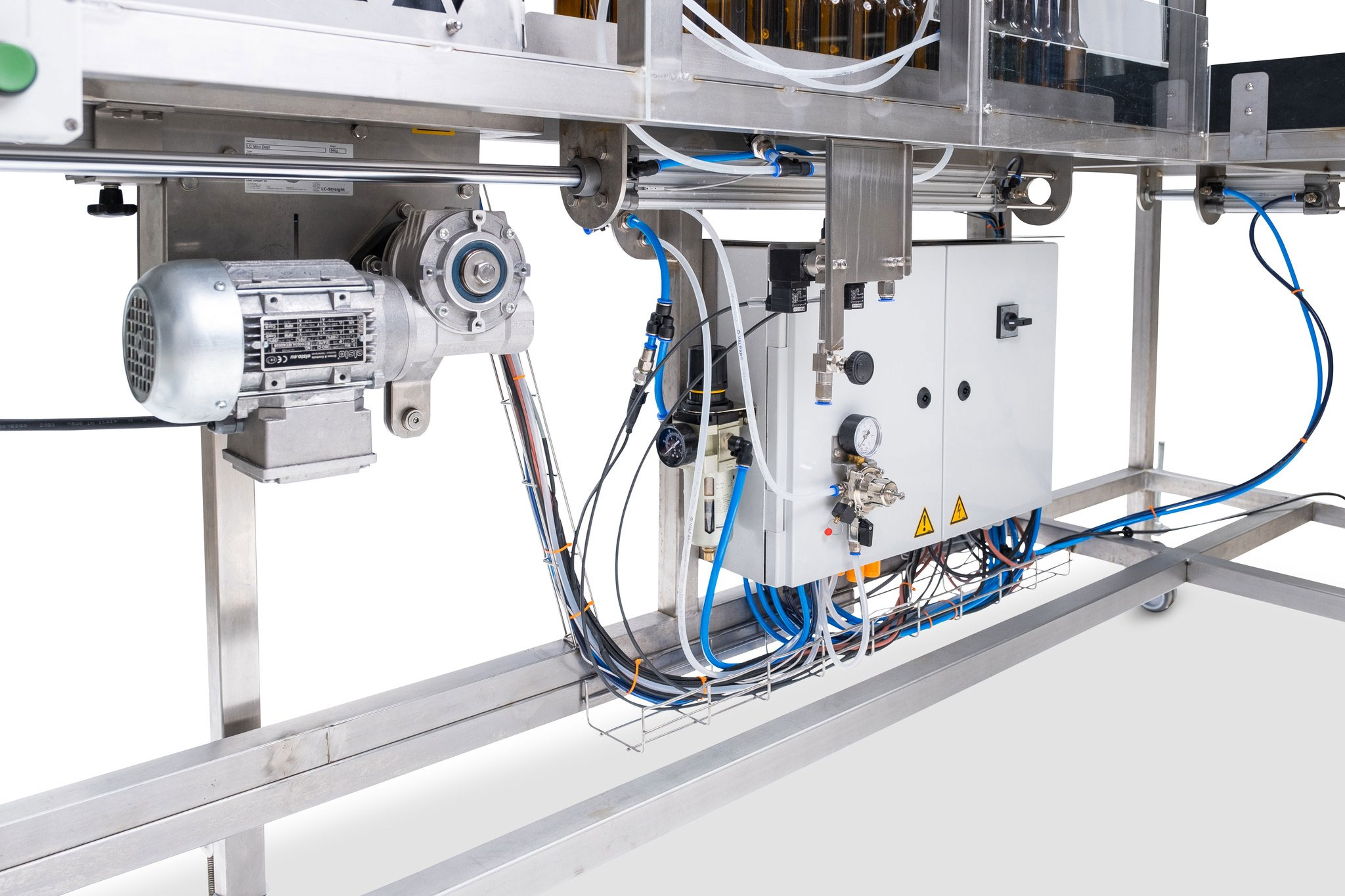

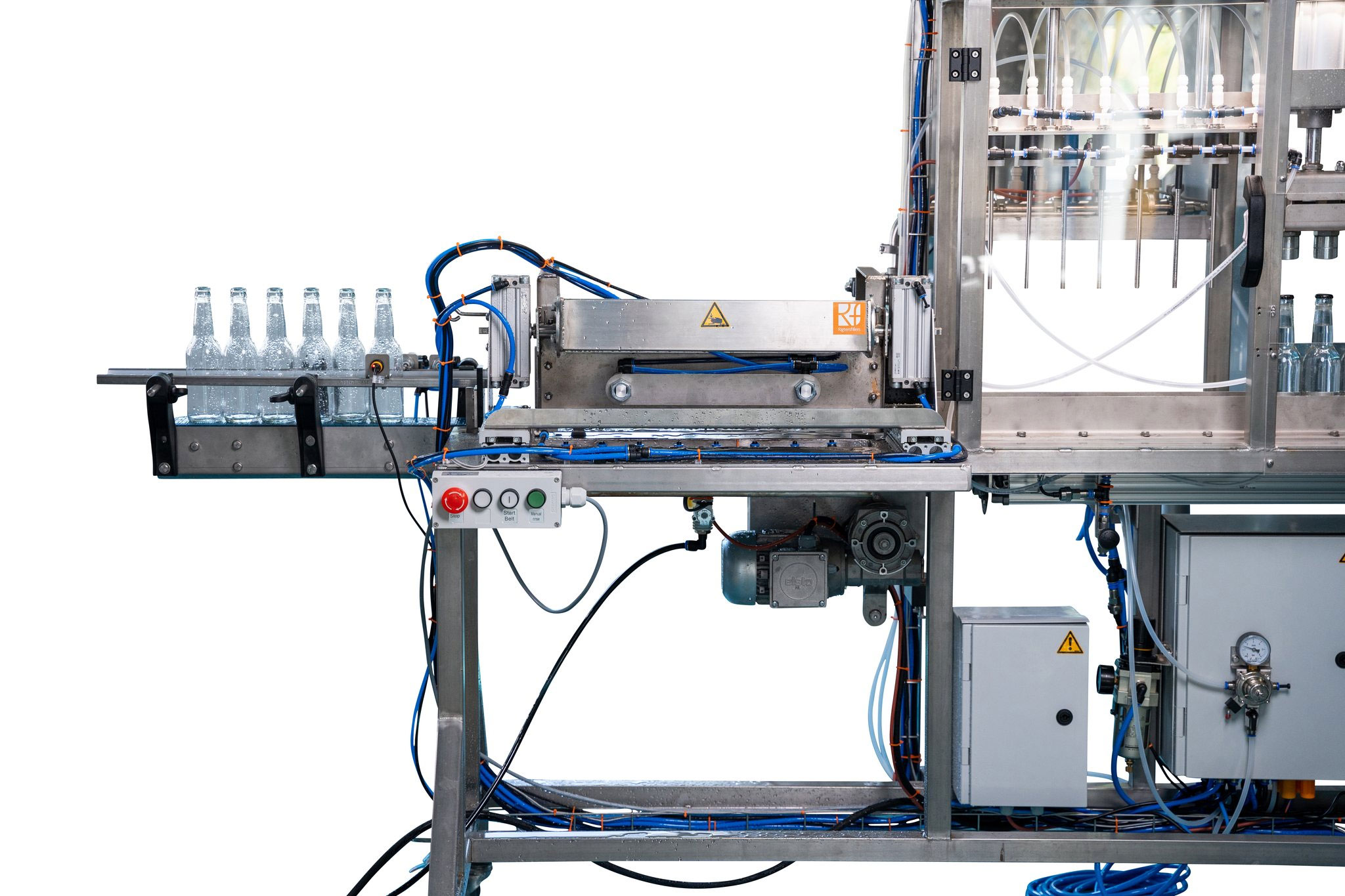

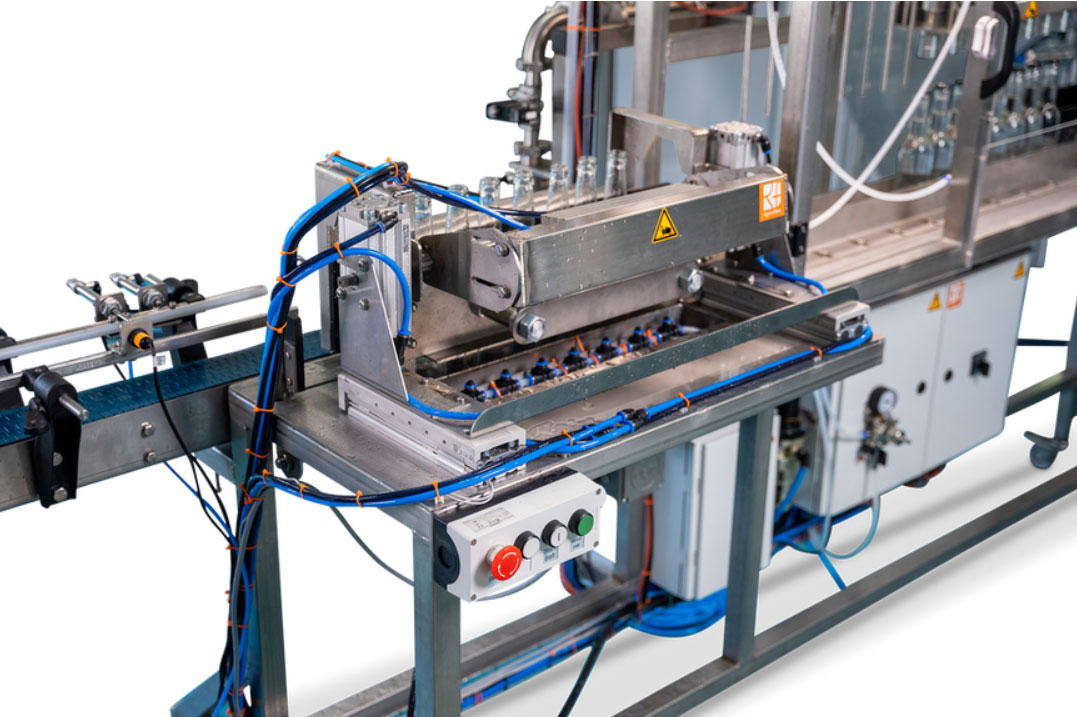

Semi-automatic or fully-automatic eight-head filling machine for one format of glass bottles with the filling capacity up to 1800-2200 bottles per hour. We offer this machine as a semi-automatic (in the basic version) or a fully-automatic (in the completelly equipped version) bottle filling system with fully automatic bottle rinser, depaletizer and the bottle capping unit (but the crown caps are always inserted manually into the machine).

These machines are made for 1 bottle format (usually 0.33L). The format of the bottles is defined by a customer when the machine is ordered.

Output capacity is up to 1800 bottles per hour in the basic semi-automatic version or up to 2200 bottles per hour in the fully equipped automatic version.

We are an authorized sales partner of the European producer.

Technical specifications :

- Dimensions in the basic version : 1200 x 600 x 2200mm (W x D x H)

- Dimensions in the fully equipped version : 3000 x 800 x 2200mm (W x D x H)

- Weight in the basic version : 320 KG

- Weight in the basic version : 650 KG

- Stainless steel frame

- Wheels and height adjustable feet

- Working height 905 – 1050 mm

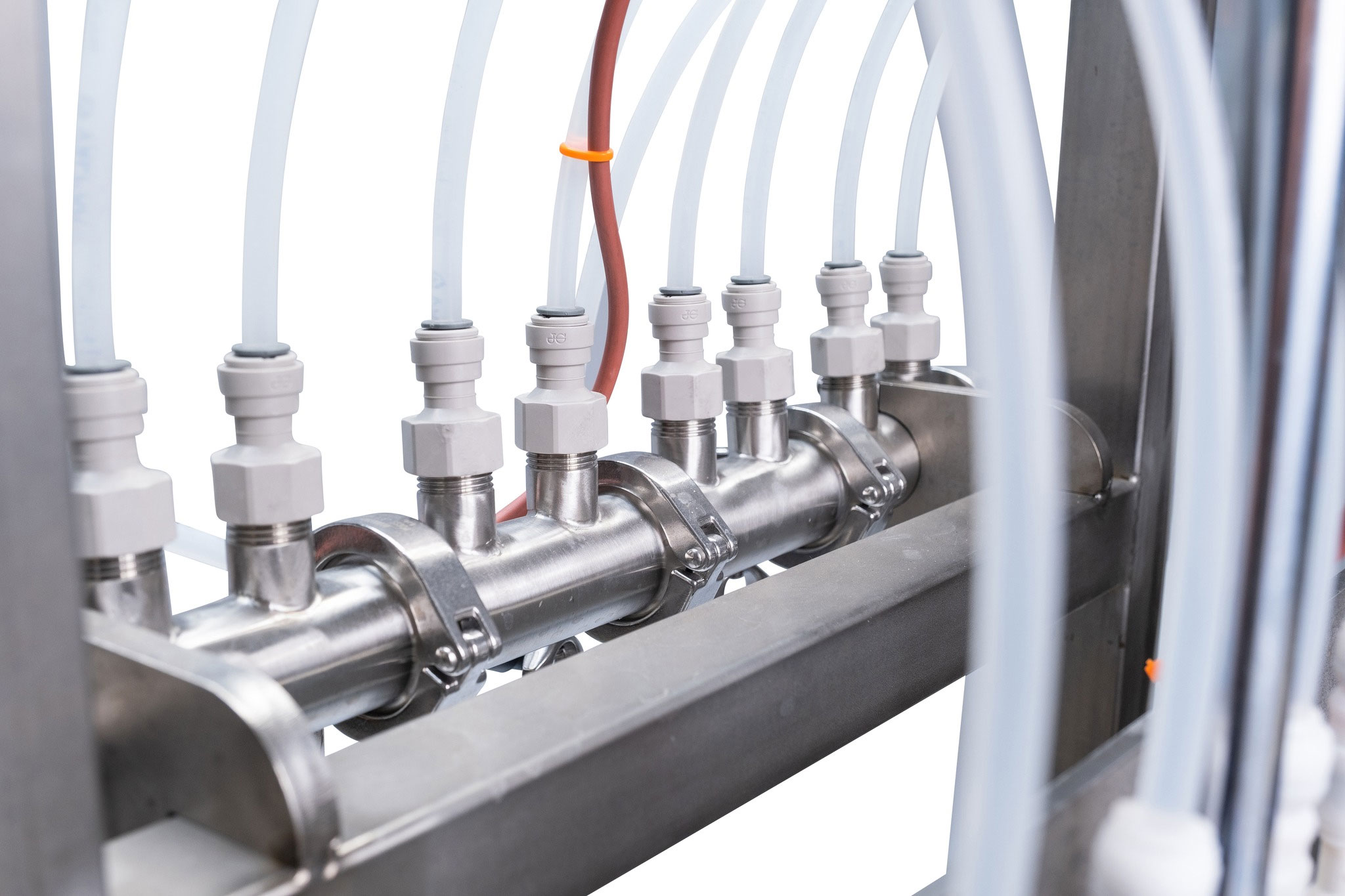

- Stainless valves with EPDM seal

- 10” waterproof touchscreen

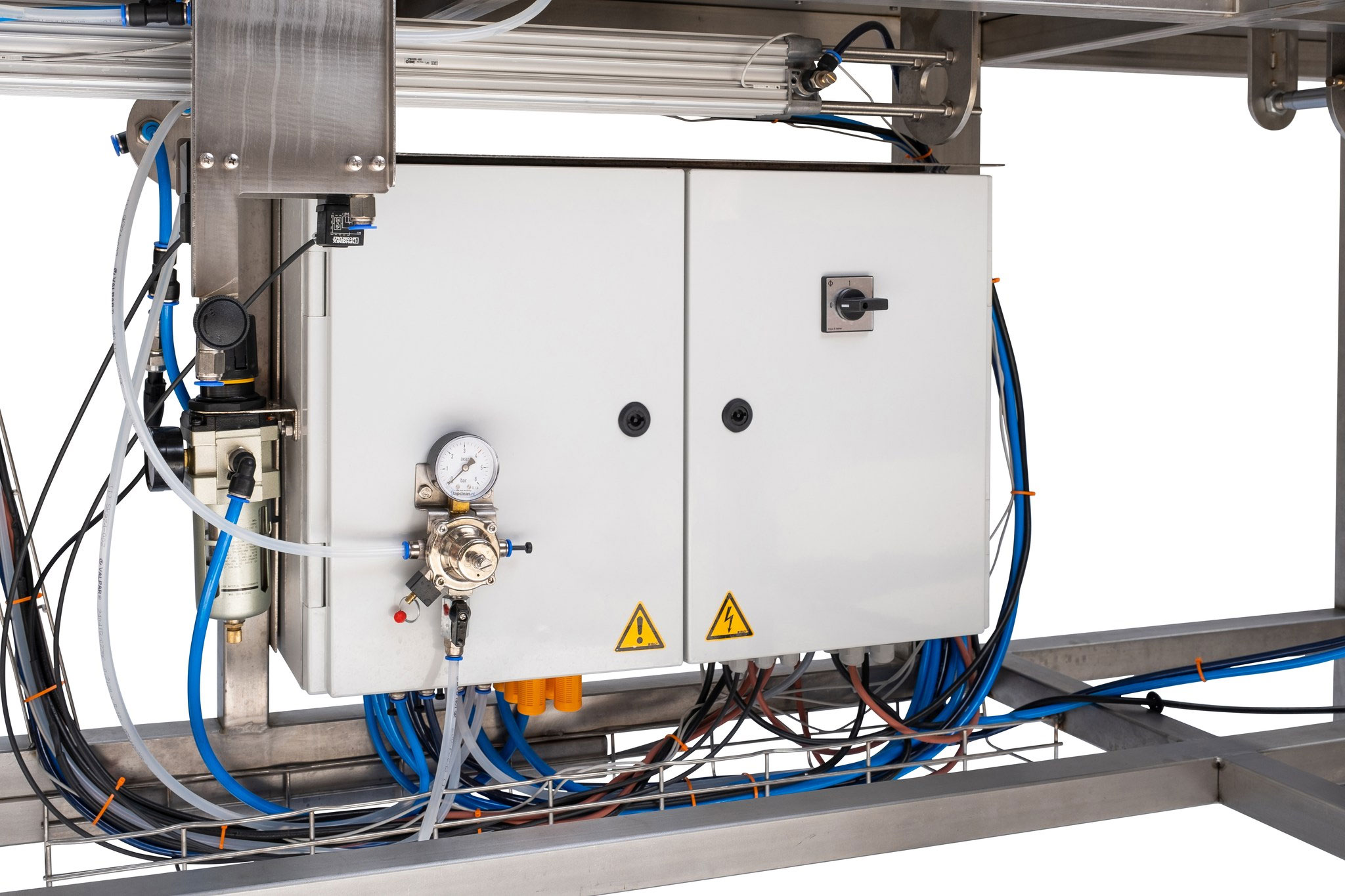

- The Arduino PRO PLC controller with lifetime updates

- Power supply : 3phase 400V / 50 @ 4A maximal input power

- Beverage input : DIN 32676 (TriClamp) 1,5” / DN40

- Compressed air input : BSP 3/8″ male

- Water input: BSP 1/4″ male

- CO2 input: BSP 1/4″ male

- Air consumption : 400L/min. at 8 bar

- Number of the bottle/can rinsing positions : 8

- Number of the bottle/can filling heads : 6

- Number of the bottle/can capping heads : 6

- Output capacity : 1800-2200 bottles/cans per hour (depends on foamicity of a beverage and equipment of the filling system)

- Bottle format : All cylindric bottles with diameter 59.5 – 61.6 mm, long neck

Optional equipment and services :

| Item code : | Description : | Price : |

| ABF-MDEP | Mini depaletizer | Price on demand |

| ABF-LDEP | Large depaletizer (for a full pallet layer including the bottle lift) | Price on demand |

| ABF-MRIN | Manual bottle rinser | Price on demand |

| ABF-ARIN | Automatic bottle rinser | Price on demand |

| ABF-PTNP | Simple packing table without the packing system | Price on demand |

| ABF-PTPS | Packing table with the packing system | Price on demand |

| ABF-BWAH | Big wheels with adjustable height | Price on demand |

| ABF-PKEU | Packing for shipping (Europe) – price depends on configuration | Price on demand |

| ABF-PKWD | Packing for shipping (Out of Europe) – price depends on configuration | Price on demand |

| ABF-SHEU | Shipping cost (Europe) – price depends on configuration and destination | Price on demand |

| ABF-SHWD | Shipping cost (Out of Europe) – price depends on configuration, destination, kind of shipping | Price on demand |

How the machine works :

The ABF8 machine can be equipped according to the wishes of the customer.

In the basic configuration (semi-automatic version) is equipped with :

– Bottle input conveyor (the bottles are manually loaded by an human operator)

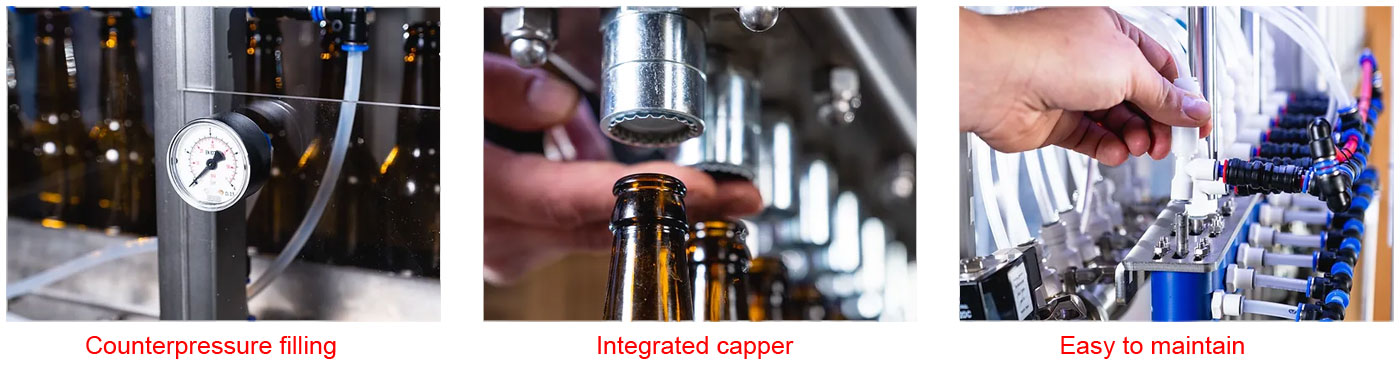

– 8-head counter-pressure filling unit

– 8-head capping unit (the crown caps are inserted manually into the machine)

To this can be added an empty bottle loading system with a small or large depalitizer which can be combined with a fully automatic rinser. At the end of the machine the bottles can be moved to a labeling machine or you can add a packing table.

The isobaric bottle filling is always fully automatic with our sensor technology.

Capping the bottles can be done only semi-automatically where a user manually adds 8 bottle caps before the capping the bottles.

Mini depaletizer :

Manual bottle rinser :

Automatic bottle rinser :

Delivery time : 4-6 months after the order.

Videos :

ABF8-2200 : Automatic counter-pressure bottle filling machine

ABF-ARIN : Automatic bottle rinsing unit

ABF-LDEP : Large depaletizer (for a full pallet layer including the bottle lift) / ABF-PTAB : Packing table with the packing system