Flotation is most suitable way to achieve the pure fruit juice via continuous purging process. On using the method, the fruit juice is firstly pressure saturated with gas or air, and then the pressure is quickly released. The released air or gas creates small bubbles in the beverage, which bound the solid particles and these particles then flow upward. Therefore a compact mud cake is created on the surface of the juice.

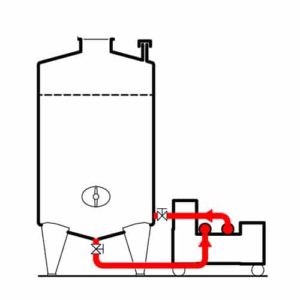

By the flotation process, the fruit juice or must is clarified under pressure after having been pumped with a flotation-gas (commonly air or Nitrogen). The tiny gas-bubbles tie the most solid particles, and then float them up to the top of the tank, to form a floated ‘cake’ of solid particles. The fruit juice which is left beneath becomes very cleared this way and is then pumped out from the bottom of the tank.

The flotation is an opposite process than sedimentation.

The MFE flotation unit are available in 6 sizes, with capacities between 6.000 and 50.000 l/h, dependent on the model type. The larger models ( MFE 150, 200, 350 and 500) are mounted on a stainless steel carriage with wheels and brakes. The control panel of the bigger MFE machines is set on the frame-handle at a convenient height.