Description

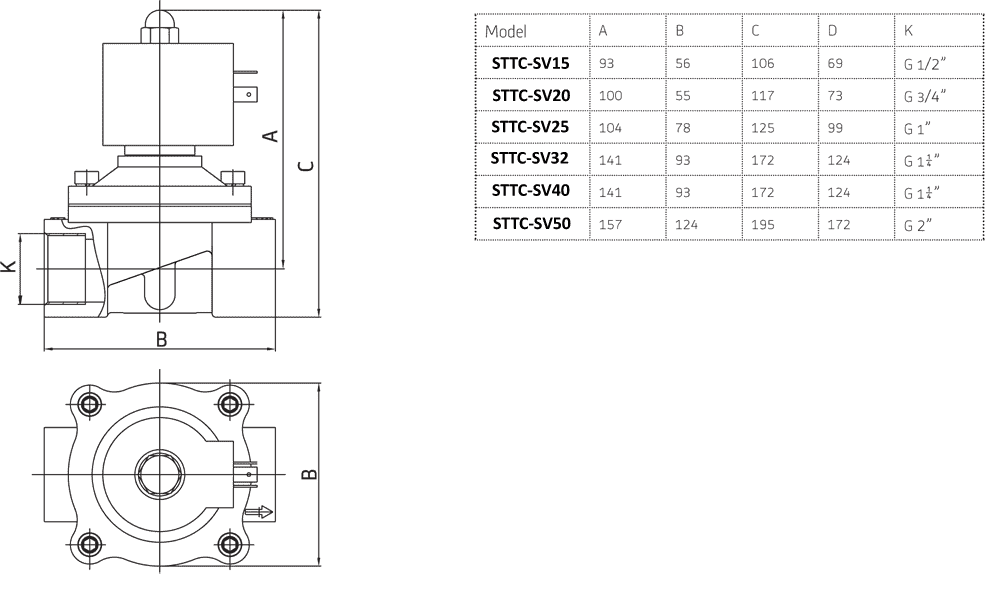

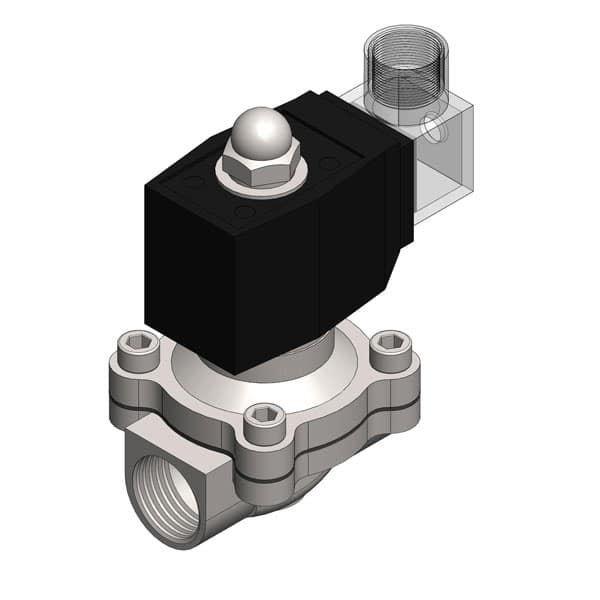

STTC-SV15-24VS is a 24V (AC 50Hz/60Hz) solenoid valve made of stainless steel for the STTC-FF178F single tank temperature controller. It is intended to a quick opening and closing of the coolant pipe way. Each the solenoid valve is connected to one STTC-CB100 connection box. Inner diameter of the pipe DN15 (G 1/2″). Designed in Germany.

Electromagnetic valves two-way Serie: STTC-SV15-24VS (for water/glycol use)

Usage:

– these valves are designed for two-positioned flow of cold or hot liquids and gaseous media

Technical dates:

– working voltage ……………………………………………………. 24V AC 50Hz/60Hz ±10%

– normal position (when is not under voltage) ……………….. closed valve

– working position (when is under voltage) ………………….. opened valve

– nominal pressure(max. pressure) for water ………………. 10 bar(1 MPa)

– working pressure range(differential pressure) ………… according to type of media 0-10 bar, 0-1 MPa

– maximum switching frequency …………………………….. 60 switching/min

– medium ……………………………………………………. gas, liquids based on water solutions, oil

– ambient temperature …………………………………………from -20 to +40°C

– medium temperature ………………………………………….FPM from -20 to +85°C

– maximum viscosity of medium ………………………………. 20cSt(mm2/s)

– pipe connection …………………………………………….. DN 15 = G 1/2”

– electric connection …………………………………………. ISO 4400, IP65

– material of body ……………………………………………. stainless steel

Function description:

This type od electromagnetic solenoid valve is normally closed without supply voltage. Under these conditions, the membrane abuts on the polished valve seat and closes the flow of the medium. If a voltage is applied to the coil terminal, it will create the electromagnetic force field that pulls the core into the core. This will pull the membrane and open the overflow channel.

The membrane is elastically(by means of a tension spring) connected to the core´s coil, which allows full functionality even at zero pressure. To easier opening and closing of the membrane is further provided with a slit and a drain passage that allow outflow of the medium above the membrane.

When disconnected, the coil´s core is pulled by the spring back from the coil, membrane lands back on the valve saddle and the pressure will equalize above and under the membrane and come to full closure.

Mounting and installation:

These valves can be mounted to the clean pipeline in any position, with horizontal pipeline we recommend to rotate the coil above the valve. The flow direction must be in the direction of the arrow marked on the valve.

Electromagnetic coil must not be used for catching torque when installing the body valve into the pipe (DO NOT USE AS A LEVER VALVE). The electromagnetic coil may not be energized when it is dismounted from the core of the body valve. If this happens the coils burns rapidly!

The electromagnetic coil may be connected to a different voltage than what is stated on the label or on the valve spool.

Terminal in the coil connector has two clips for connection of control voltage and one for the connection of protective conductor. The coil connector has a bushing PG11 with option 4×90°. The coil on the valve can be freely rotated 360°.

If the medium contains mechanical impurities, it is necessary to put in front of the valve mesh filter (fineness of 0.2 mm).

Before installing the valve, you should check and clean the threads. If you use a sealing tape, paste or spray to seal thread, make sure that the materials do not get into the valve.

When the coil is energized for longer time it has a higher operating temperature, therefore, it should not be installed in the immediate proximity of easily flammable materials and in places where it could be dangerous to health.

ELECTRICAL CONNECTIONS:

– the electromagnetic coil has three electrical contacts

– bottom(separate) is designed to earthing, it has an earth symbol

– the other two(in one level they are designed to connect el. cables – phase and zero conductor), you can connect them freely. Eg. phase to left, zero conductor to right(or the other way around)

– to each el. valve is supplied connector with LED indication of turning on

– the connection on the connector is compatible with the connection of the coil contacts

Service and maintenance

These valves are designed for continuous operation. The coil´s life is rated on 20 000 hours and 1,5 million cycles. If the valve is used in normal conditions(temperature, media), it does not require any maintenance. It is performed only in case of a failure – leak or malfunction.

Malfunction can be caused by interruption of the coil´s winding(short-circuit), mechanical damage of the core, membrane and seal. The identified causes can be cleared by changing a set of spare parts, spare coil.

Replacement can be performed only when the valve is not pressurized by a media and the coil is without voltage.

Reviews

There are no reviews yet.