Description

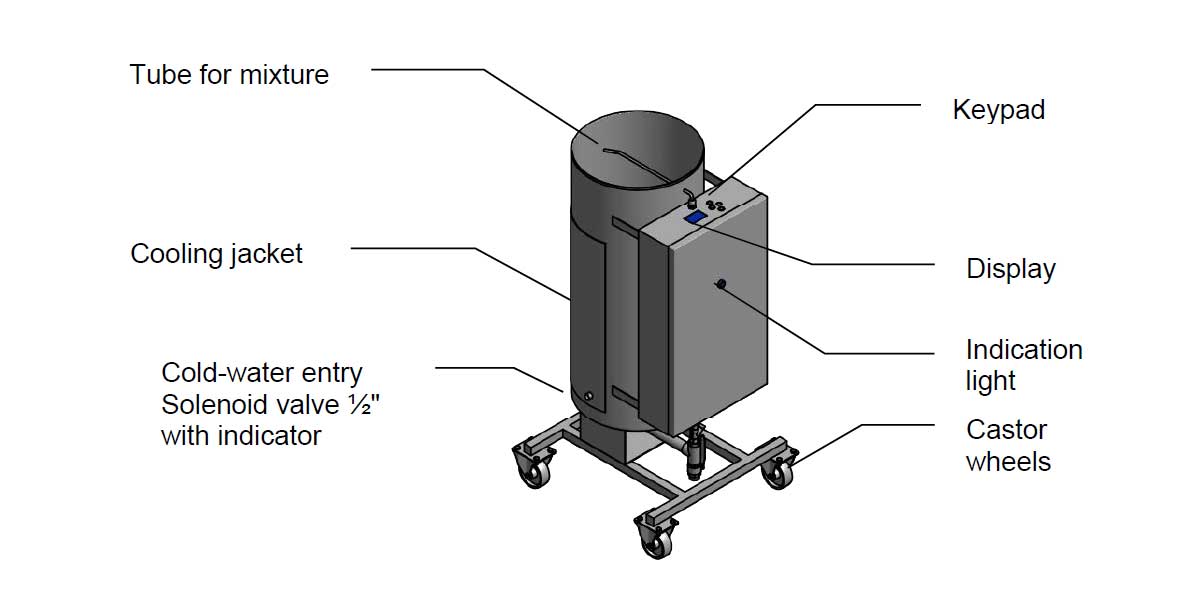

The compact mobile yeast propagation station YEAST-BOOSTER-2110 provides reliable assistance by optimal re-activation and propagation of yeast that are used for the fermentation of beer, cider or wine. For a good yeast propagation you need a controlled temperature, gentle heating and cooling, a careful nutrition management and an effective oxygenation of the yeast-cells along the duration of the process. All these are performed automatically by the YEAST-BOOSTER-2110 mobile station for dry yeast activation up to 2 kg per batch. Volume of the yeast regeneration tank is 110 liters.

In the start-phase, the water inside the tank of the Yeast-Booster will be heated up to 38,5°C (default). Upon reaching this temperature, the YEAST-BOOSTER signals start of the next phase – dosing yeast to the mixture. The first phase of propagation process the yeast begins. The yeast will be circulated gently through a membrane pump to break up the lumps, and slowly cooled down to the target temperature. Oxygen is added to the mixture during this circulation. Additionally, every 15 minutes the YEAST-BOOSTER will draw fresh must or wort from the target tank as nutrition for the yeast and adding to the mixture in order to reach the desired required mixture concentration. This circulation and adding of must or wort are done slowly, to avoid big temperature changes in the mixture and ensure a good yeast cells health throughout the process. Once this phase is complete, the yeast mixture is overpumped into the target tank. The YEAST-BOOSTER is then ready to start another yeast culture propagation or launch the yeast cleaning cycle.

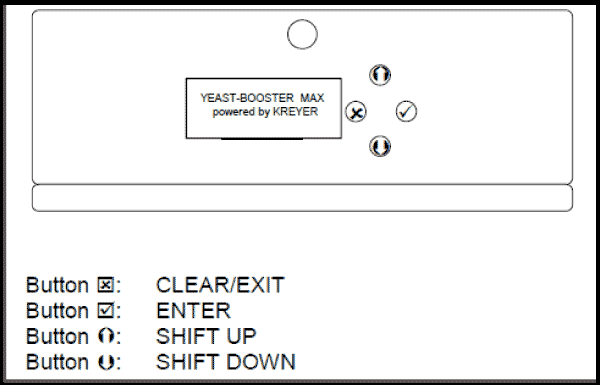

The YEAST-BOOSTER is controlled by a processor. All the required parameters can be set in the menu: start temperature, target temperature, start yeast concentration, target yeast concentration, timer. The menu language and the display lighting contrast can also be easily changed.

The YEAST-BOOSTER is the ideal unit for brewers, alcoholic cider, wine and champagne producers who are looking for a reliable and automatic assistant for reach and keep optimal yeast mixture. This not only saves time but also costs. Correct temperature control, mixing of the yeast culture and a controlled yeast propagation phase with sufficient nutrition and oxygenation minimize ‘killing’ of yeast cells, and allows to reach remarkably reduced amounts of dead cells in the yeast solution which results and saving costs. The optimal yeast propagation helps avoid slow start of the fermentation process and reach optimal beverage fermentation results.

Where to place the YEAST-BOOSTER

Attention : The yeast storage tank is not equipped by hermetic lid. Therefore it is good solution to put this equipment in a separate room, which is separate from the other production rooms. This is to avoid possible infection of yeast by other organisms.

Characteristics / Advantages

- Beginning of the fermentation with optimally revitalized yeast at the desired temperature

- Automatic process, saving work and time

- Less yeast needed, significantly reducing yeast-purchase costs

- Helps avoid stop fermentations by good yeast preparation

- Secure, simple and easy-to-use automated device

- Solenoid valves for automatic temperature control

- Integrated temperature control

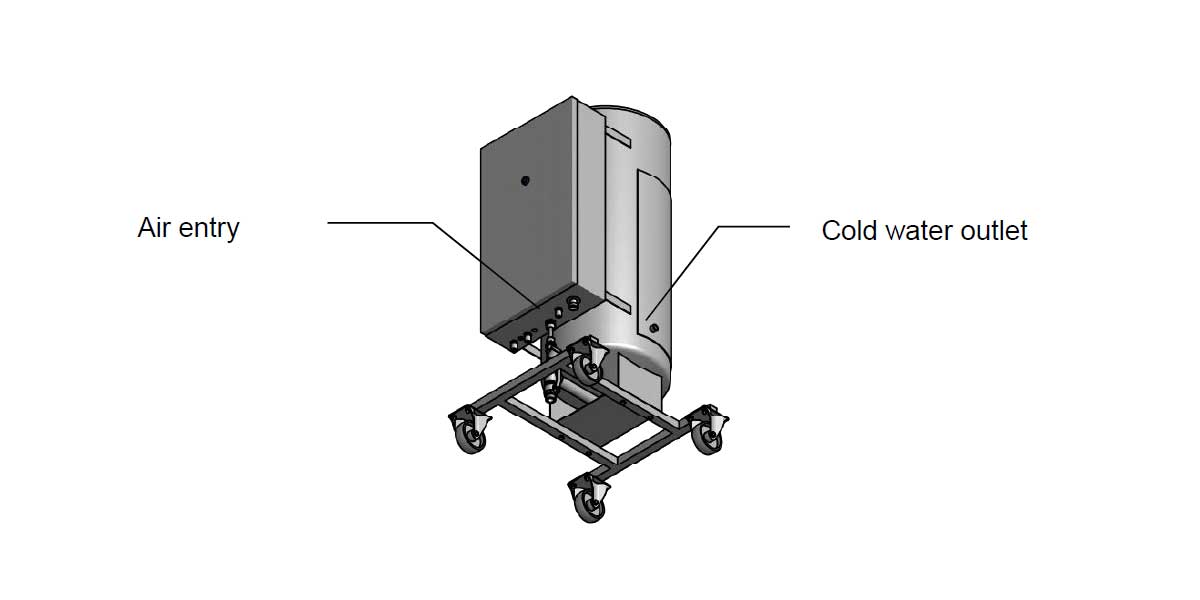

- Integrated cooling through cooling jacket for feeding over the existing cooling system of the brewery (winery, cideria)

- Automatic electric heating system

- Fully automatic yeast nutrition management

- Control cabinet with a circulation membrane pump and integrated Oxygenation element

Technical Characteristics

- For dry yeast activation up to 2kg yeast per batch

- Electric connection: 230V / 1Ph / 50/60 Hz

- Power consumption:

- Standby mode: 0,2 kW

- Ferm mode: 0,7 kW

- Heating mode: 0,65 kW

- With single pipe serving for pumping water and must or beer wort in and out of the container, as well as pumping yeast mixture into the target tank and also cleansing at the end of the process

Cleaning of the YEAST-BOOSTER machine

Cleaning the YBMS machine is essential to maintain healthy batches of yeast cells. The beer yeast are very sensitive to bacteria infection. Therefor strict and careful cleaning of the YBMS unit is very important to receiving good results and effective operation.

After the yeast suspension is ready after revitalization in the Yeast Booster are necessary to be done these steps:

- Pump the yeast suspension into the target tank using the command: ‘Empty’.

- Rinse the suction pipe with water by putting the hose into a fresh water bucket and use the command ‘Fill’.

- Rinse the tank thoroughly to remove all residue of foam.

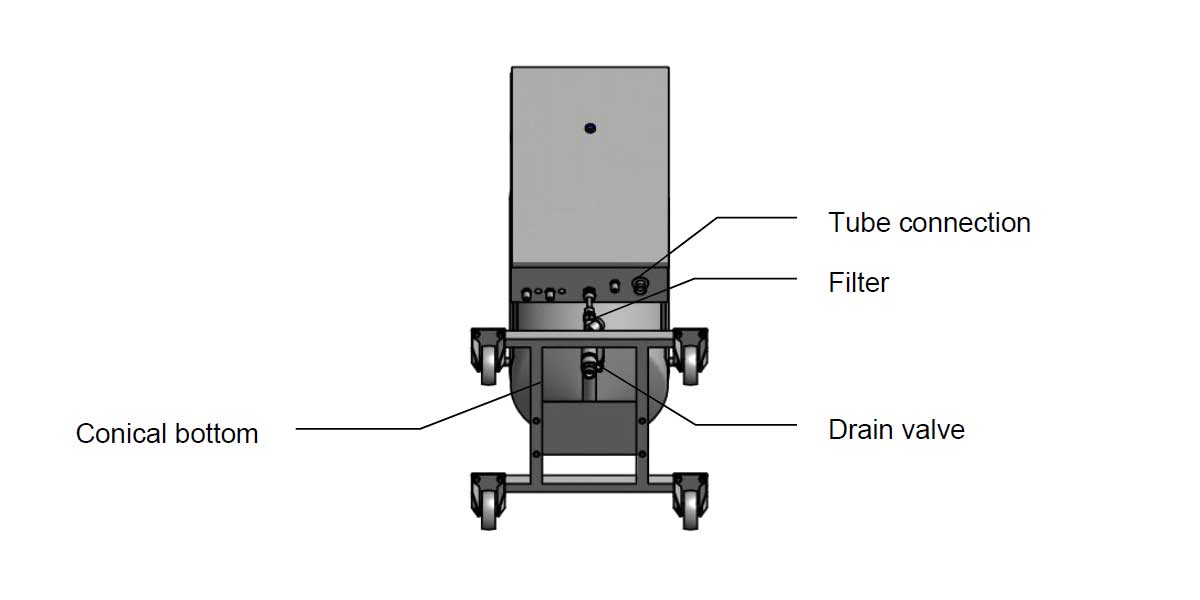

- Remove the filter (on top of the draining pipe) and wash out remains of suspension, clean thoroughly.

- Replace the filter.

- Fill the tank with about 10 lt water and activate the ‘Cleaning’ cycle.

- Drain out the turbid water and repeat this step with additional 10lt water.

- By tenacious turbidity, use warm water or use the heating function of the YBMS machine to heat up to 40°C.

- Fill about 150gr NaOH, mix it in the water, , and re-activate a ‘Cleaning’ cycle. When finished, drain the water.

- Repeat the process with 200gr citric acid to neutralize the caustic residues.

- Rinse with fresh water.

- Make sure that the water after last rinsing is clean.

- Rinse and drain the tank. Activate shortly the command ‘Fill’ to get rid of all remaining water at the bottom of the container and valves. With the open ball valve and a short start of the machine, you suck the remaining water out of the system.

- Disconnect the pipe and open the ball-valve to let all rest water drain out of the unit.

Download the datasheet

Reviews

There are no reviews yet.