Description

Automatic chamber batch pasteurizer for pasteurization beverage products in sales containers (cans, glass bottles, etc.). Its hourly capacity depends on a container type and foreseen temperature regime and its duration. Once temperature regime on the computer is set, pasteurization (or any other heat-treatment) the all cycle is automatically controlled.

Operation capacity for the mostly used beverage containers :

- 330 ml glass bottles (longneck) with diameter of 60,9 mm: approximally 204 bottles per batch

- 500 ml glass bottles with diameter of 70,0 mm: approximally 144 bottles per batch

- Cans with diameter of 58.0 mm: approximally 216 cans per batch

- Cans with diameter of 66.3 mm: approximally 144 cans per batch

Main parameters :

| Type of product | Beer, cider, wine, juice, water, jam etc. |

| Type of containers | Glass bottles, aluminium cans etc. |

| Capacity of each batch | Depends on shape and dimensions of a container. Examples :

|

| Total hour capacity | Depends on required temperature regime (is defined differently for each product) |

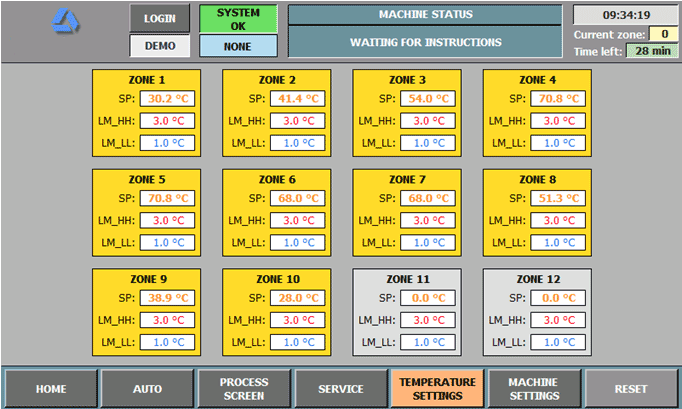

| Control system | Fully automatic (times and temperatures are defined by a customer for each product and batch capacity) |

Description and features :

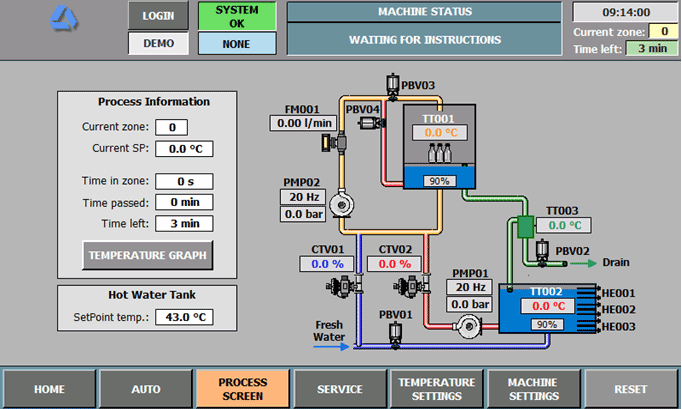

For heating, electrical heater is used, while cooling source is fresh water (with temperature approx. 15°C), which is dosed directly on suction side of main circulating pump. Heat transfer is executed by water – spraying with water inside the batch pasteurizer is performed trough register of nozzles, which are located above each basket.

On this type of batch pasteurizer, we have foreseen using a so called “hot water preparation system”. Using this system enables us precise and fast changes between temperature zones and slightly lowers overall water consumption.

Hot water, that is used for heating of the product is being pre-heated and stored in so called “hot water tank”. Water heating is executed by means of electrical heater. Set point temperature of hot water is determined automatically (it is calculated based on spraying temperatures in the recipe).

Hot water is then stored in hot water tank (that is thermally insulated), until it is dosed (by means of regulating valve) on suction side of main circulating pump. Tank itself is equipped with temperature & level probe, opening for cleaning purposes and air vent.

The pasteurizer includes two stainless steel circulating pumps (including frequency converters for flow control) from which one is used for beforementioned hot water circulation and dosing, while the other one serves as main circulating pump for process water.

Located under the baskets is so called water recovery pool, which’s minimized – only minimum amount of water needed for operation is in the pool. Consequently, minimum amount of water goes to drain, every time water inside batch pasteurizer needs to be replaced. Water collection pool is equipped with manhole for cleaning of pasteurizer.

Complete construction is made from stainless steel AISI 304 and is thermally isolated. Baskets with product are placed on two pull-out trays on the front side of the machine.

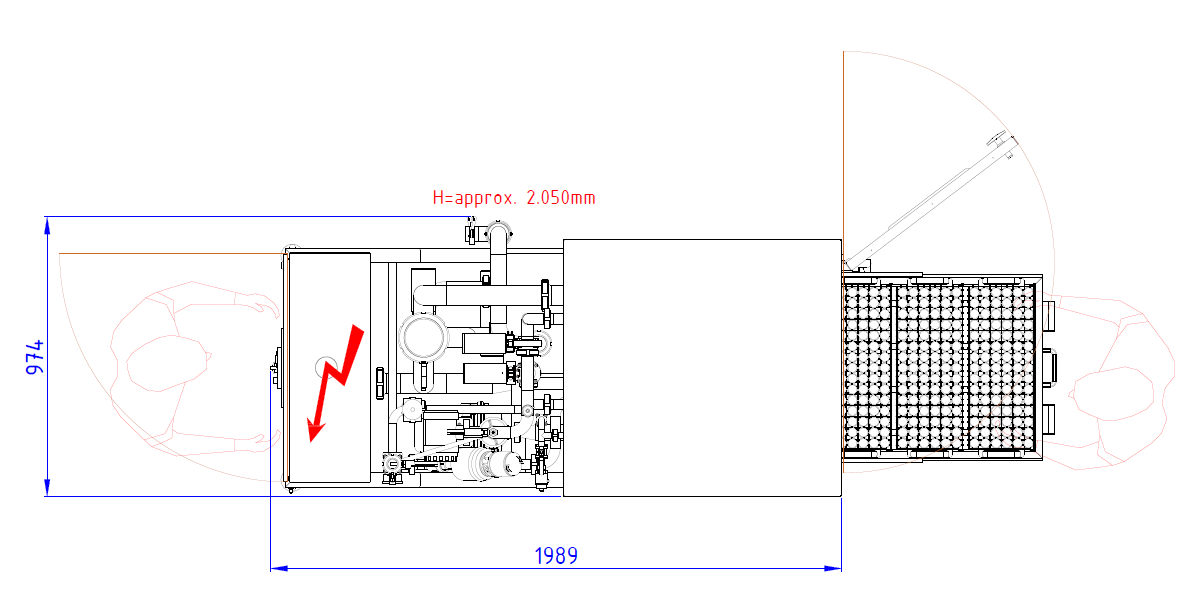

Machine dimensions :

Approximate dimensions of the machine are length 2.000 mm, depth 1.000 mm, height h = 2.050 mm.

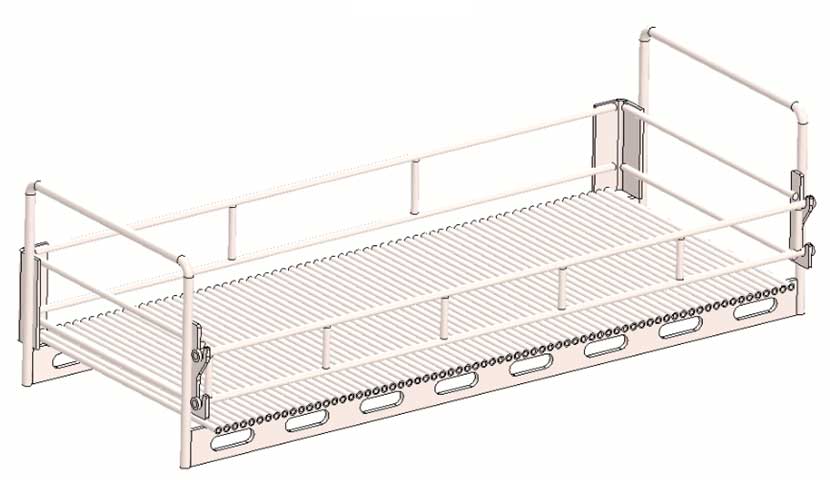

Carrying baskets for containers with a product :

Carrying baskets for product are made of stainless steel (approx. dimensions 600 x 240 mm – for exact basket dimensions please see the attached drawing). Height of the inserted containers is limited to approx. 170 mm (we can offer a modified construction that enables higher containers for an upcharge). In this case we have foreseen three baskets per each deck, so six baskets in total are in machine during heat-treatment proces. Both pull-out trays are mounted on telescopic guides, that enable the baskets to be pulled out of the pasteurizer for loading/unloading of the containers (loading and unloading is done manually). In total, machine is supplied with six baskets, set six additional baskets are offered as an optional equipment to be achieved maximal operation capacity (the primary set of baskets with the containers is pasteurized inside the machine while the operator loads new containers in the secondary set of baskets outside ).

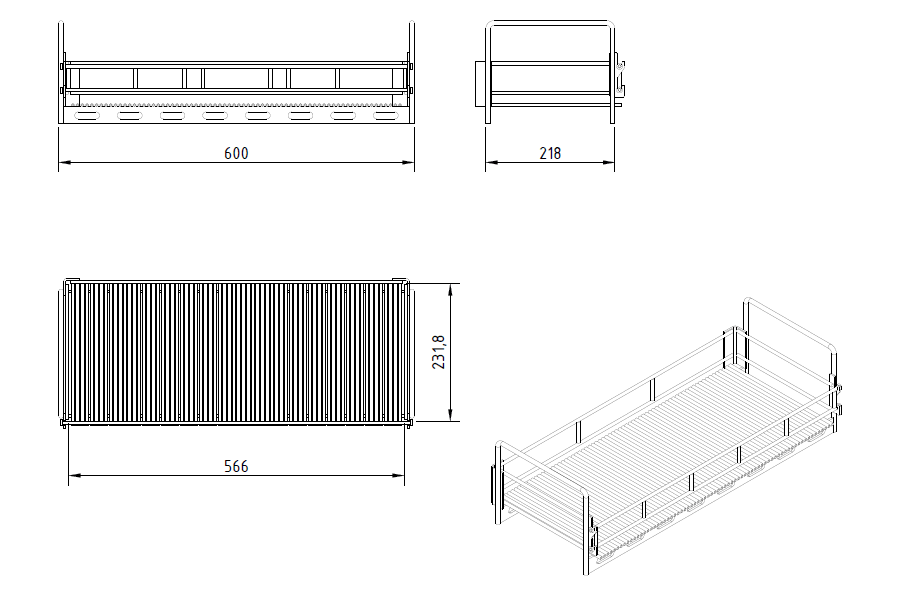

Dimensions of the carrying basket :

Cleaning the machine :

Cleaning of the batch pasteurizer is manual.

*Please note: Adding any chemicals into the water of batch pasteurizer must comply with the resistance of all inbuild materials and has to be guaranteed from the local chemical distributor

The pasteurizer has a manual outlet valve for purpose of draining the water from the pasteurizer. There is also an additional drainage point between water pool under the basket and hot water tank.

Electric equipment :

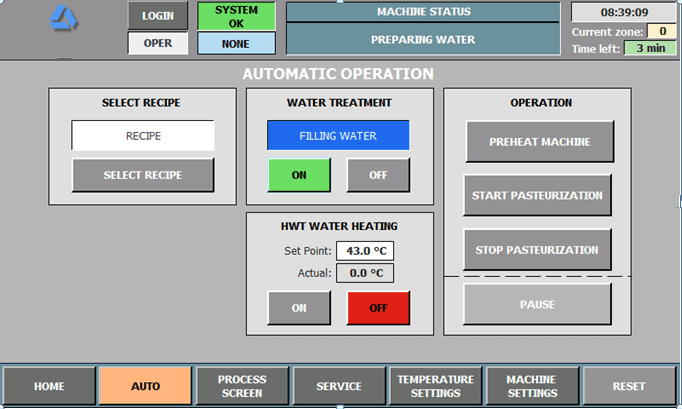

Electrical cabinet (made in stainless steel) is located on a machine’s construction and includes 9-inch touch LCD control panel for setting all parameters and monitoring of fully automatic operation.

The machine is equipped with modem for remote access. With modem we can provide you remote assistance (troubleshooting, creation of new recipes, …) eliminating costs connected with on-site visit (cost of hotel, meals, plane tickets, internal transfers…). Please note, that price of service of remote assistance is not included in the price and is a subject of additional agreement.

Other electric components :

1. Pumps: LOWARA

2. Electric components: SCHNEIDER ELECTRICS

3. PLC commander: SIEMENS

4. OP panel: SIEMENS

5. Pneumatics: SMC

6. Level and PT 100 probes: ENDRESS HAUSER

7. Cable trays: shapes G&U, mesh, without top covers, made from stainless steel

Measure and control system:

| PLC commander Siemens S7 1500 & 9” colour touch screen panel for simple management of complete system.

|

| Automatic temperature regulation. |

| Pneumatic regulating valve on heating, for precise regulation of heating. |

| Pneumatic regulating valve on cooling for precise regulation of cooling.

|

| Both pumps are equipped with frequency converters. |

| Temperature, pressure and level probes. |

| Manometers and thermometers. |

| Other armatures and valves to complete the system.

|

| Machine is equipped with external signal light with buzzer, that can alert the operator in case of any alarms. |

| All electronic components are installed inside electrical cabinet |

| Completely pre-wired and tested in our workshop |

Material :

Batch pasteurizer construction and pipelines are made from AISI 304 material.

All gaskets (that are not defined differently) are made from EPDM material.

Technical requirements for energy and media :

| Installed electric power | Power consumption = approx. 26 kW

Voltage supply: 3F/N/PE/~, 50Hz Net voltage: 400 Volt Voltage variation: ±5% maximum Frequency variation: ±2% maximum Net system: TN-S |

| Compressed air | Consumption = approx. 70-150 l/h

Pressure = 6-8 barg

Quality control of air high solids (air filtration and drying)

oil content, oil free max. 25 mg/m3 / oil (quality class 3) |

| Softened water | Pressure = 2 – 3 barg

Fresh water consumption depends on recipe used! Water, that would otherwise go to drain (during zone changes) can also be collected and stored for future use (equipment for collection and storage of water is not included)

Required quality of water are:

Permitted value of chlorine dioxide is max 0,2 ppm |

Price offer :

| Batch pasteurizer

|

On demand |

| Packing | On demand |

| Total price | On demand |

Optional accessories :

| E& H registrator

Registrator (with Ethernet connection), enabling export of data from batch pasteurizer to remote computer (which has installed suitable software for transfer and archive of data) – remote computer is not scope of supply. Manufacturer: Endress + Hauser. Data is transferred and archived in table format.

|

On demand |

| 6 additional baskets

In total, machine is supplied with 6 baskets, but 6 additional baskets are offered as an option – this way operator can prepare 6 baskets, while the other 6 baskets are being in the machine with pasteurization program running.

|

On demand |

Commercial terms :

| Delivery conditions |

Loaded on truck.

Price will be calculated individually. |

| Delivery time |

To be agreed. Usually 3-4 months. |

| Payment | 40% advance payment when is ordered

60% before delivery based on FAT protocol documents |

| Packing | Equipment will be packed onto wooden platform and protected by thermo shrink film. |

| Start up and commissioning |

The system will be completely pre-installed and tested in workshop. After successful test, system will be prepared for transportation and loaded on the truck. These costs are included in our offer.

Transportation itself, offloading and installation of the system on site are not included. The connection of the energetic connections is also not included in our offer. |

| Items exculded from the price |

The following items are specifically excluded from this offer:

– transport and unloading the equipment from truck, – energetic connections (electric, water, air, cooling agents…), – any equipment outside of the limit of supply, – insulation of pipelines, – installation (mechanical or electrical), commissioning/start-up on site (system will be completely pre-installed and tested in workshop, so only energetic connections and armature need to be connected), – training (machine will be equipped with instructions for use and maintenance), – any other civil works, except the engineering as described above, – grounding and its measurements – E&H registrator (offered as an option) – cost services via remote access – air conditioning of electrical cabinet – UPS (recommended) – ON/OFF switches for pump motors, – preparation/upload of any recipes – electrical wiring beyond the individual machines and main switch boards, – system to collect drainage/overflow water, – Haffmans Redpost device (or any similar testing device), – any consumable materials, e.g. utilities, chemicals, lubricants, etc. in connection with the production, – foundations, drainage, – any taxes, social burdens or other duties to be paid outside Czech Republic.

Also excluded are any other items of equipment, material or services not specifically mentioned as having been included, or which we elsewhere in this document stated to be excluded!

|

| Technical documentation |

In English language, delivered with the machine at the takeover: 1 set (1 x print + 1 x USB). |

| Guarantee | We guarantee the use of the specified material and skilful workmanship. The equipment delivered is covered by a normal manufacturer’s guarantee for workmanship and materials.

Any defective materials will be made good by repair or replacement at our expense during a period of 12 months from start-up, however max. 14 months after dispatchment of the equipment from our company. On-site maintenance and repairment services are excluded.

Supplier in no case is responsible for eventual loss of buyer’s income, which is affected from direct or indirect damages. |

Reviews

There are no reviews yet.