Description

MFCS-2000 microfiltration station serves to filter beer or cider and thereby extend the consumption period. The microfiltration device is always used as secondary beverage filtration. Microfiltering station must always be classified as a second filter device after a primary filtration. Its absolute effect on beverage stabilization replaces pasteurization.

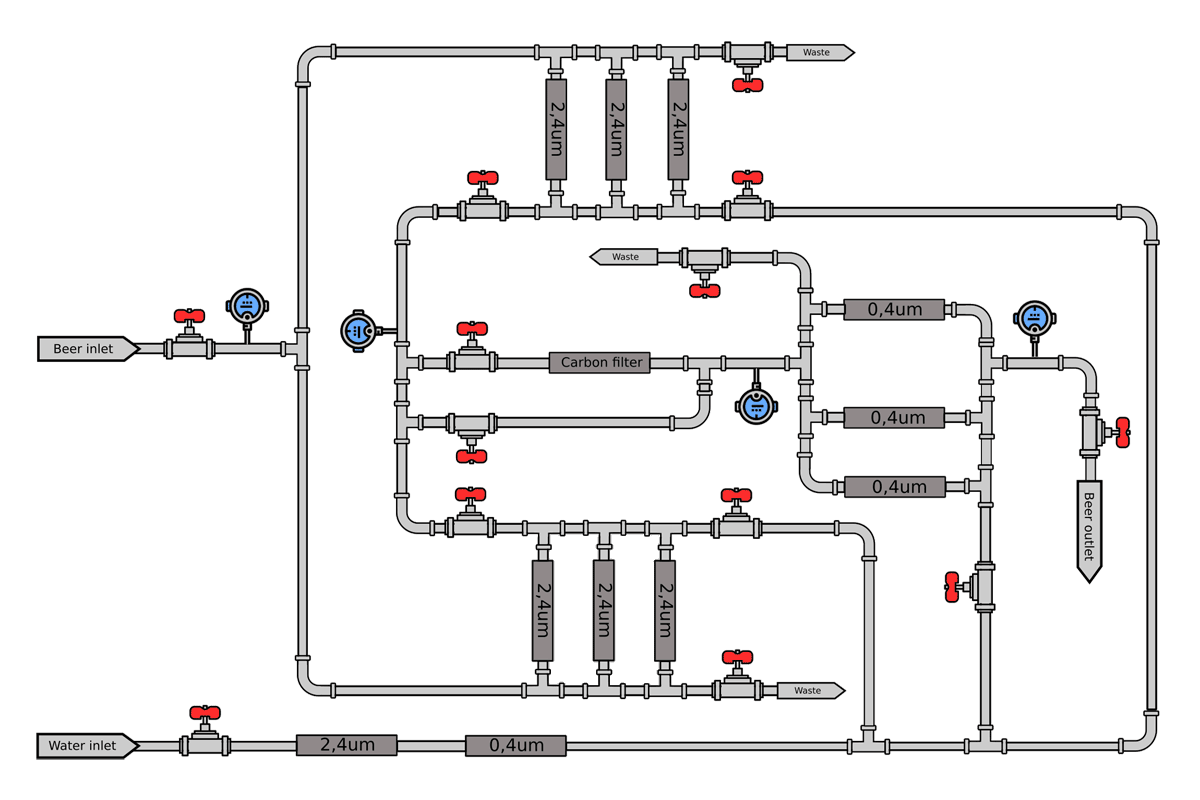

The microfiltration is composed of filtration stainless steel vessels in which two types of special polypropylene microfiltration candles with a permeable surface are located at the microfiltration level of 2.4 microns (10pcs) and 0.45 microns (5pcs).

The entire microfilter is stored on a stainless steel frame made of material of class 1.4301 (AISI 304)

The special polypropylene microfilter meets all requirements for food production in the EU (1935/2004 / EC) and USA (CFR Title 21)

Price of the microfiltration station includes one set of the filtration elements (no-name deep filtration candles).

Secondary microfiltration = substitute for pasteurization (called “cold pasteurization”)

Benefits of the microfiltration :

– Lower acquisition costs

– Lower operating costs

– Flavor of beer is not negativelly affected by pasteurization

Microfiltration station MFCS can be equipped with different levels of guaranteed filtrate quality – according the type of the choosed terminal filter elements:

A) Elements Prepor NG:

- Absolute capturing of yeast

- Reduction of bacteria

B) Elements Bevpor PH:

- Absolute capturing of yeast

- Absolute interception of bacteria that harmful to beer

C) Elements PF-PES B:

- Absolute capturing of yeast

- Reduction of bacteria

Technical specification

The microfiltration station assembly consists of 15 membrane filtration candle elements :

- FMS prefilter – 8pcs of filtering candle elements 2,40 μm

- FMS final filter – 4pcs of filtering elements 0,45 μm

- CIP water & sanitary section – 3pcs of water microfiltration elements 1.0 μm

Optional version with the carbon filter (16 candle filters)

(the additional housing for the 16th filtration elements is optionally for surcharge 1/16 of standard price of the filter)

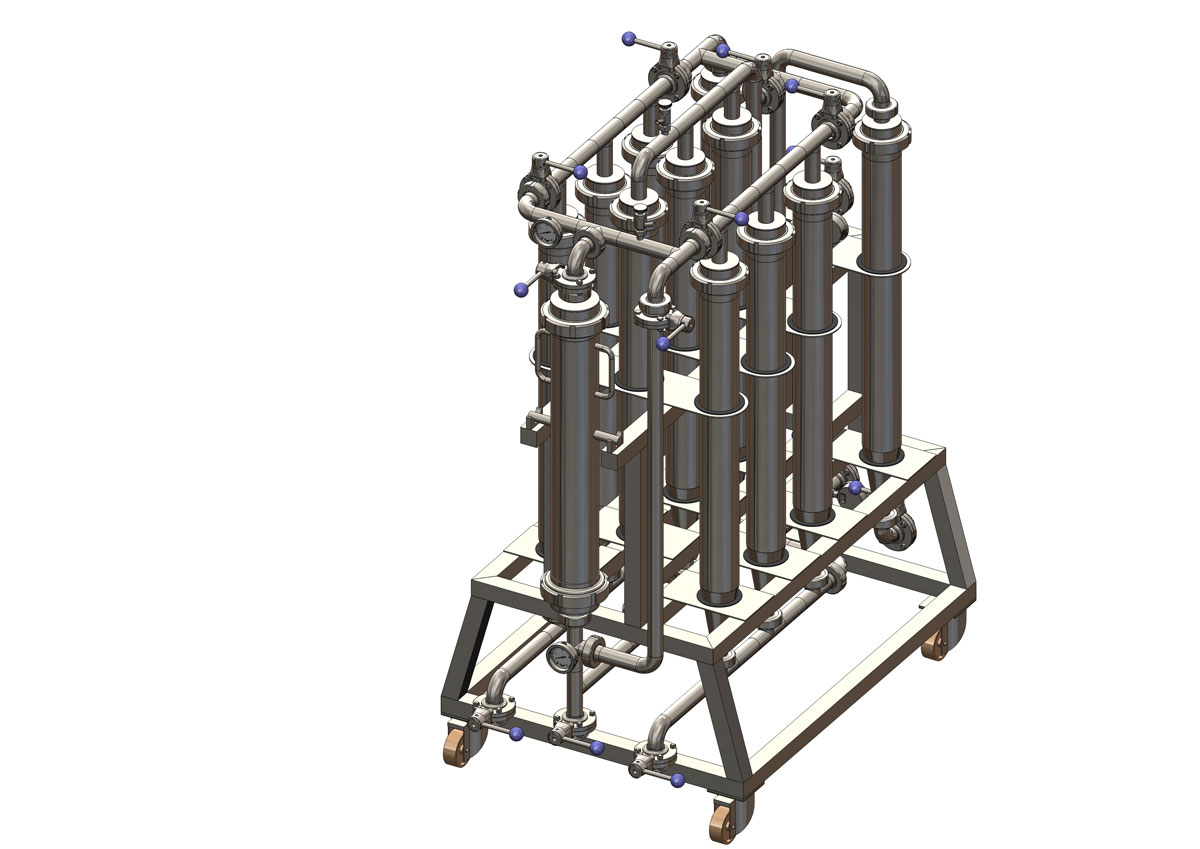

These two pictures show the MFCS-1000 version with less filtration candles…

1. Product section – microfiltering set 12x FMS

Filter assembly consists of 9 candle filters

- FMS prefilter – 8pcs of filtering candle elements 2,40 μm

- FMS final filter – 4pcs of filtering elements 0,45 μm

Filter set is mounted on a common frame and connected by pipes with fittings

Construction of filters:

- Input / Output socket with clamp fitting

- Material – stainless steel AISI 304

- Surface external : grinding + polishing

- Surface internal : polishing

2. Water & sanitary section – CIP with water filtration unit – 3x FMS

CIP section – to achieve maximum purity of the terminal filters and microfilters and other equipment associated with the filling process.

Technical parameters :

- FMS prefilter – 8pcs of filtering candle elements 2,40 μm

- FMS final filter – 4pcs of filtering elements 0,45 μm

- CIP water & sanitary section – 3pcs of water microfiltration elements

Maximum filtering performance with fitting and filtration elements:

- Prepor NG ….. 2000 liters per hour

- Bevpor PH ….. 1200 liters per hour

Filtration elements (consumable filtration material) :

A1) Beer – complete capturing of yeast, bacteria reduction

Pre-filtration element PEPLYN Plus 3 mic. (1st filtration level)

Final filtration element Prepor NG (2nd filtration level)

Pre-filtration element PP100 T 30/3 P7 2.40 µm (1st filtration level)

Final filtration element PF-PES B 0.45 µm (2nd filtration level)

A2) Beer – absolute yeast capturing , absolute interception of bacterias that harmful to beer

Pre-filtration element Prepor NG (1st filtration level)

Final filtration element Bevpor PH (2nd filtration level)

B) Water – complete capturing of yeast, bacteria reduction

Pre-filtration element Prepor PP (1st filtration level)

Final filtration element Bevpor PH (2nd filtration level)

Pre-filtration element PP100 T 30/3 P7 2.40 µm (1st filtration level)

Final filtration element PF-PES B 0.45 µm (2nd filtration level)

CIP process – sanitizing of the microfiltration station

For the sanitation of the microfiltration station an external CIP station is needed.

Cleaning and sanitizing process of the microfiltration unit :

1. An external CIP unit, for circulating sanitary solutions, and water has to be connected to the microfiltration station.

2. Circulation of alkalic sanitizing solution in the direction of filtration.

3. Flushing against the direction of filtration with water, draining used water into the sewer.

4. Circulation of acidic sanitizing solution in the direction of filtration.

5. Flushing against the direction of filtration with water, draining used water into the sewer.

6. Using a pump on the CIP unit, flood all filter cartridges of the MF filter with the ENOL solution.

7. Regeneration of filtration cartridges for a maximum of 12 hours.

8. Flushing against the direction of filtration with water, draining used water into the sewer.

9. The microfilter is now ready for further filtration cycle.

The CIP station must allow:

- Preparation (heating and mixing) of sanitizing solutions

- Controlled circulation of sanitizing solutions inside the sanitized or disinfected equipment, piping, etc.

- Using filtered, microbiologically pure water for the last irrigations

Efficiency (aggression) of the cleaning sanitizing process depends on:

- Concentration of sanitizing solution

- Temperature of sanitizing solution

- Kinetic intensity acting on the surface

- Application time of sanitation solution

Basic recommended equipment of the CIP sanitizing station to use with the microfiltration station :

- Storage vessel for the sanitizing solutions with controlled heating

- Water filter set – for constant source of filtered water for flushing filter elements and preparation of sanitizing solutions

- Sanitation circulating pump fitted with a control valve

- Product pump fitted with a control valve

- Armature piping connections

- CIP station is connected with the microfiltration station with hoses

- Wiring in stainless steel cabinet

- Other accessories (according to the needs of specific applications)

We recommend to use any of the CIP station we produce : Our CIP stations

Reviews

There are no reviews yet.