Description

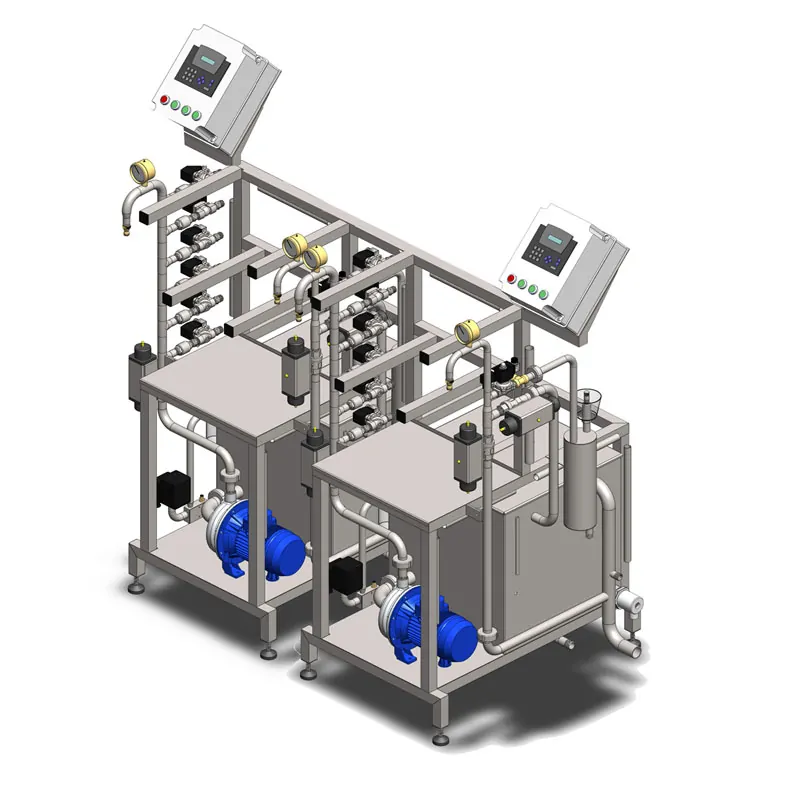

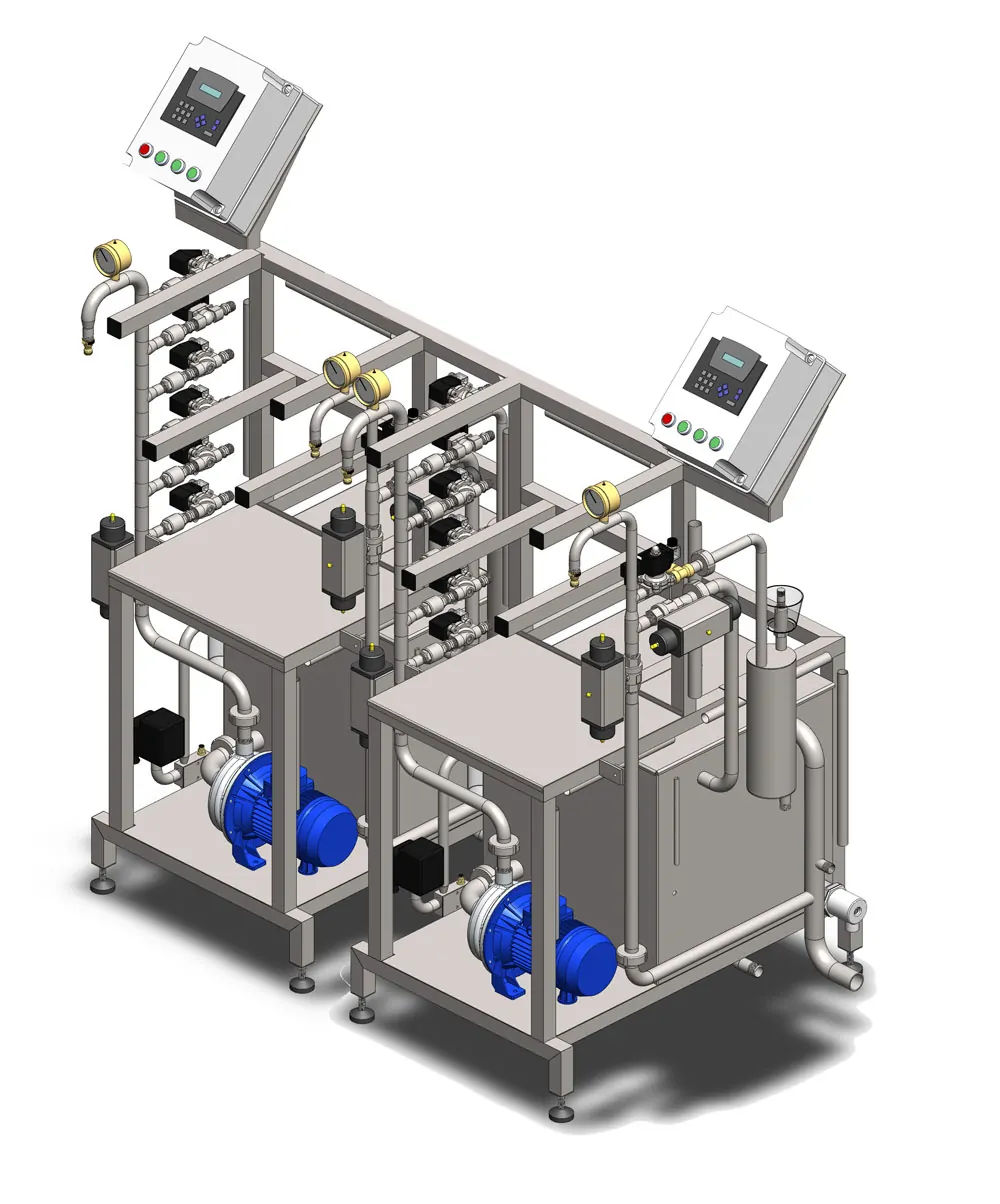

Automatic CIP system for the cleaning, sanitizing of the stainless steel kegs and for the filling of carbonated beverages into the kegs

… with two keg positions and two different sanitizing solutions

The KCA-40D is a multifunction machine that includes a device for automatic rinsing of stainless steel kegs and the automatic isobaric filling of carbonated beverages like beer, lemonade, wine or cider into kegs. The equipment is designed for the filling and rinsing of kegs with beer, cider, wine and for other beverages, using by computer control operated valves and a pump. In comparation with the KCA-50 machine the KCA-40D machine includes two tanks and two pumps to sanitation of kegs using both alcalic and acid sanitizing solutions (two tanks on each machine = total is four tanks).

All operations are performed automatically (washing, sanitizing and filling the kegs), but between washing and filling the keg it is necessary to turn the keg manually after the sound signal. The station is equipped with solenoid valves.

Operating capacity :

- up to 16 pcs of kegs per hour : all rinsing, sanitizing cycles and the filling cycle

- up to 40 pcs of kegs per hour : only rinsing and sanitizing cycles without the filling

The actual capacity of the machine depends on how dirty the kegs are and how long time it has been since they were used. For more dirty kegs, it is necessary to set longer times for individual washing cycles and this reduces the capacity in the number of kegs per hour. If the drink foams more, the time required to fill the kegs also increases (in this case, we recommend lowering the temperature of the drink in the source tank).

The machine is designed for cleaning and filling kegs with a volume from 15 to 50 liters.

The working performance is :

- Two cycles : the rinsing cycle & the sanitation cycle : the maximal performance 40 kegs per hour ( with volume of 50 liters).

- Three cycles : the rinsing cycle & the sanitation cycle & the filling cycle : the maximal performance 16 kegs per hour ( with volume of 50 liters).

The device is controlled by a PLC – it is possible to individually change the time of each cycle. Inserting of kegs is manual, removing of kegs after finalizing of filling cycle is manual. The computer opens and closes all valves, switches on the pump and controls a temperature of the sanitizing solution automatically as well. The machine is equipped with an integrated reservoir for the alcalic sanitizing solution.

Two positions for paralel cleaning, sanitizing and filling of steel kegs.

Sterilized compressed air is needed for flushing inner space of the keg, which can contain of the rest of water or sanitizing solutions.

We recommend to use an external hot steam-generator as optional accessories to ensuring perfect sterilization of the inner walls of the kegs and shorter cleaning and sanitation cycle.

Material is stainless steel AISI 304.

The device operates in the following cycles:

- An emptying the keg (automatic)

- A depressurization the keg (automatic)

- Flushing the keg with cold water (automatic)

- Flushing the keg with alcalic sanitizing solution (automatic)

- Flushing the keg with hot water (automatic)

- Flushing the keg with acid sanitizing solution (automatic)

- Flushing the keg with hot water (automatic)

- Steam sterilization of inside of the keg – it requires an external source of steam (automatic)

- Filling the keg with carbon dioxide gas (automatic)

- Rotation of the keg 180 degrees (manually in the SA version, automatically in the FA version)

- illing the keg with beer (semi-automatic)

Sterilized compressed air is needed for flushing inner space of the keg, which can contain of the rest of water or sanitizing solutions.

We recomment to use an external hot steam-generator as optional accessories to ensuring perfect sterilization of the inner walls of the barrels and shorter cleaning and sanitation cycle.

The first connection :

1. DO NOT CONNECT THE MACHINE TO THE POWER SUPPLY until you succesfully progress to the step 6. The spiral heater will be burned down (will be destroyed) if the steps are not followed in exact order.

We do not hold the warranty in case you burn down the heating spiral.

2. Connect media according to the description on the device.

3. Fill the rear tank with sanitizing solution (6% solution of caustic).

4. Connect the KCA-40D unit to the air distribution system – minimal pressure 4bar.

5. Set the air pressure on reducing valve on range between 2.0bar up to 2.5bar.

6. Set the carbon dioxide pressure to 2bar using the CO2 reducing valve.

7. Connect KCA-40D unit to the power supply 3ph 400V/50Hz .

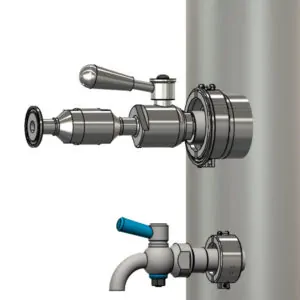

That’s how the filling valve looks – all types A, D, G, M, S, U are available according to requirement of the customer :

Description of keg rinsing and filling step by step:

This description is valid only for the manual mode. The KCA-40D machine provides all steps automatically excluding steps from 16 to 17 – manual filling of the keg.

1. All valves are closed

2. Connect the filling coupler on the keg

3. Overturn the keg and place it on the KCA-40D unit

4. Open valve 1.8 (waste) and valve 1.2 (air). The rest of content in the keg is drained.

5. Valve 1.8 (waste) remains opened, close valve 1.2 (air) and open valve 1.4 (cold water).

That is the first rinse of the keg. Time of rinse will vary depending on total volume and degree of pollution of the keg.

6. Close valve 1.4 (cold water), valve 1.8 (waste) remains open.

7. Valve 1.8 (waste) remains open, open valve 1.2 (air). Water is forced out of the keg by air. Time may vary depending on the total volume of keg.

8. Close all valves. Open valve 1.7 (caustic), turn on the pump. The caustic sanitation of keg is in progress. Time may vary depending on the total volume of keg. The valve 1.2 (air) may be opened to improve the scattering of sanitation solution.

9. Turn off the pump and open valve 1.2 (air). Cycle of returning the caustic to caustic tank runs.

10. Close all valves.

11. Open valve 1.8 (waste), open valve 1.3 (hot water). Rinse until the keg is completely deprived of caustic (usage of pH meter is recomended). The valve 1.2 (air) may be opened to improve the scattering of hot water.

12. Close valve 1.3 (hot water), valve 1.8 (waste) remains open, open valve 1.2 (air). Hot water is forced out of the keg by air. Time may vary depending on the total volume of keg.

13. Close all valves. Open valve 1.1 (CO2) and open valve 1.8 (waste). Air is forced out of the keg by CO2 gas. Time may vary depending on the total volume of keg.

14. Close valve 1.8 (waste), valve 1.1 (CO2) remains open. Fill the keg with CO2 until the inner pressure is 1.8 bar. The inner pressure is controlled by pressure regulator.

15. Close all valves.

16. Put the keg on the floor, open valve 1.6 (beer) and open valve 1.9 (outlet of CO2 from keg). Keg is being filled by beer, filling speed is controlled by pressure regulator. When he beer foam starts flowing from pressure regulator, the keg is full. In the FA version the rotation of the keg is provided automaticaly.

17. Keg is sanitized now, filled with beer and ready to be shipped to your customer.

Filling of the 50L beer keg takes from 1 to 4 minutes – the time depends on the chosen overpressure in the keg and in the beer storage tank, temperature of beer, beer type and other physic influences.

Technical description :

| Maximum performance : rinsing & sanitation | 40 | |

| Maximum performance : rinsing & sanitation & filling | 16 | |

| Volume of kegs maximum [ liters ] | 50 | |

| Inserting and removing kegs | manually | |

| Pneumatic connection – pressure sterile air | min. 4bar | |

| Electric connection | 3x400V /50Hz 32A | |

| Heating | 2x 2.2 kW | |

| Pump | 4x 750 W | |

| Control panel | 230V / 50Hz | |

| Alcalic solution tank with dosing | 2x 50 liters | |

| Acid solution tank with dosing | 2x 50 liters | |

| Switching between modes : washing – filling | auto | |

| Sterilisation mode with hot steam (optionally) | external steam | |

| Width / mm / | 1800 | |

| Depth / mm / | 1200 | |

| Height / mm / | 1900 | |

| Weight /kg/ | 300 | |

| Average delivery time / months / (after first advance payment) | 2 | |

| Material | AISI 304 |

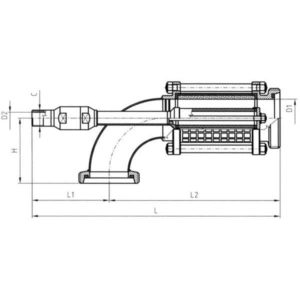

Available filling heads for this machine :

Description of all pipe and hose connections that are available on the KCA-25 machine.

| Type of input part | Automatic electromagnetic / pneumatic valve | JohnGuest connector |

|---|---|---|

| Picture |  |  |

| Connection type | Inner thread | Socket for plastic hose |

| Steam input | G 1/2" | |

| Hot water input | G 1/2" | |

| Cold water input | G 1/2" | |

| Compressed air input | JG 3/8" | |

| CO2 gas input | JG 3/8" | |

| Beer input | JG 1/2" |

Optional equipment :

Recommended set of spare parts … price € 1194,-

The set includes :

- 2 pcs x electric heating spiral …. € 82,- / pc

- 2 pcs x gasket for EBARA CDX pump … € 120,- / pc

- 1 pc x solenoid or pneumatic valve (according to the ordered version) …. € 270,- / pc

- 2 sets x hoses and couplings …. € 120,- / set

- 2 sets x filling head for kegs …. € 140,- / set

ESG-16MWT : Electric steam-generator compact 16kg/hr (on the stainless steel frame, with water treatment)

Electric and automatic steam-generator, available power from 7 kW to 15 kW. Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable between 0.5 and 7 bar. This steam-generator is available with a single group of heaters (three elements) or with two independent sets of heaters (six elements). The steam-generator shell is manufactured in accordance to the current PED regulations. The water treatment system (for automatic water softening) and electric switchboard cabinet is included in this set. All system is mounted on the stainless steam frame. Easy installation – without electrician works – it is needed only to plug on the electric power socket on the wall.

ACO-18-150B : Oil-free air compressor 18m3/hour with air tank 150L and basic filter 5µm

The Oil-free Air Compressor with the pressure air tank 150 liters, one-level air filtration 5µm, production capacity 18 m3 per hour

The air compressor is designed for use with all equipment that do not require absolute purity of the pressure air but cannot be contamined with oil – powering the pneumatic control valves, blowing the liquids from the pipes and vessels before their sanitizing etc.

The Compressor consists of a oil-free compressor with electromotor, pressure vessel, one-level air filter with filtration element 5µm.