Description

Automatic CIP system for the cleaning, sanitizing of the stainless steel kegs and for the filling of carbonated beverages into the kegs

… with the automatic rotation of the keg between the cleaning and the filling cycle

The KCA-25AR is a multifunction machine that includes a device for automatic rinsing of stainless steel kegs and the automatic isobaric filling of carbonated beverages like beer, lemonade, wine or cider into kegs. The equipment is designed for the filling and rinsing of kegs with beer, cider, wine and for other beverages, using by computer control operated valves and a pump. The machine is equipped with one tank for storage, heating and dosing of the alcalic sanitizing solution during the CIP cycle.

Operating capacity :

- up to 10 pcs of kegs per hour : all rinsing, sanitizing cycles and the filling cycle

- up to 25 pcs of kegs per hour : only rinsing and sanitizing cycles without the filling

The actual capacity of the machine depends on how dirty the kegs are and how long time it has been since they were used. For more dirty kegs, it is necessary to set longer times for individual washing cycles and this reduces the capacity in the number of kegs per hour. If the drink foams more, the time required to fill the kegs also increases (in this case, we recommend lowering the temperature of the drink in the source tank).

The machine is designed for cleaning and filling kegs with a volume from 15 to 50 liters.

The working performance is :

- Two cycles : the rinsing cycle & the sanitation cycle : the maximal performance 25 kegs per hour ( with volume of 50 liters).

- Three cycles : the rinsing cycle & the sanitation cycle & the filling cycle : the maximal performance 10 kegs per hour ( with volume of 50 liters).

The device is controlled by a PLC – it is possible to individually change the time of each cycle. Inserting of kegs is manual, removing of kegs after finalizing of filling cycle is manual. The computer opens and closes all valves, switches on the pump and controls a temperature of the sanitizing solution automatically as well. The machine is equipped with an integrated reservoir for the alcalic sanitizing solution.

Sterilized compressed air is needed for flushing inner space of the keg, which can contain of the rest of water or sanitizing solutions.

We recomment to use an external hot steam-generator as optional accessories to ensuring perfect sterilization of the inner walls of the kegs and shorter cleaning and sanitation cycle.

Material is stainless steel AISI 304.

Description of the keg sanitizing and filling cycle :

Description of the keg sanitizing and filling cycle :

1. Dropping the rest of beverage from the keg using sterile pressure air

2. Relief of excess pressure from the keg

3. Rinsing of the keg with cold water

4. Rinsing of the keg with an acidic sanitizing solution

5. Rinsing of the keg with cold water

6. Steam sterilization of the keg (if an external steam generator is attached)

7. Filling and pressurizing the keg with carbon dioxide

8. Conterpressure filling the keg with a beverage (In the case of choosing mode keg sanitation + filling)

Determination of the product

- The KCA-25AR machine is used in the sanitation and filling of kegs with beer and other types of beverages

- The KCA-25AR machine is not intended for explosive atmospheres – it does not contain EX certification.

- Sanitizing solution – 3% sodium hydroxide solution (NaOH)

- The working substance to be filled into the kegs is beer, cider, lemonades, sparkling wine or other carbonated or non-carbonated drinks.

Permissible dimensions of filling kegs :

The unit is able to fix and rotate kegs of the following parameters :

- maximum height 600mm

- minimum height 250mm

- maximum diameter 400mm

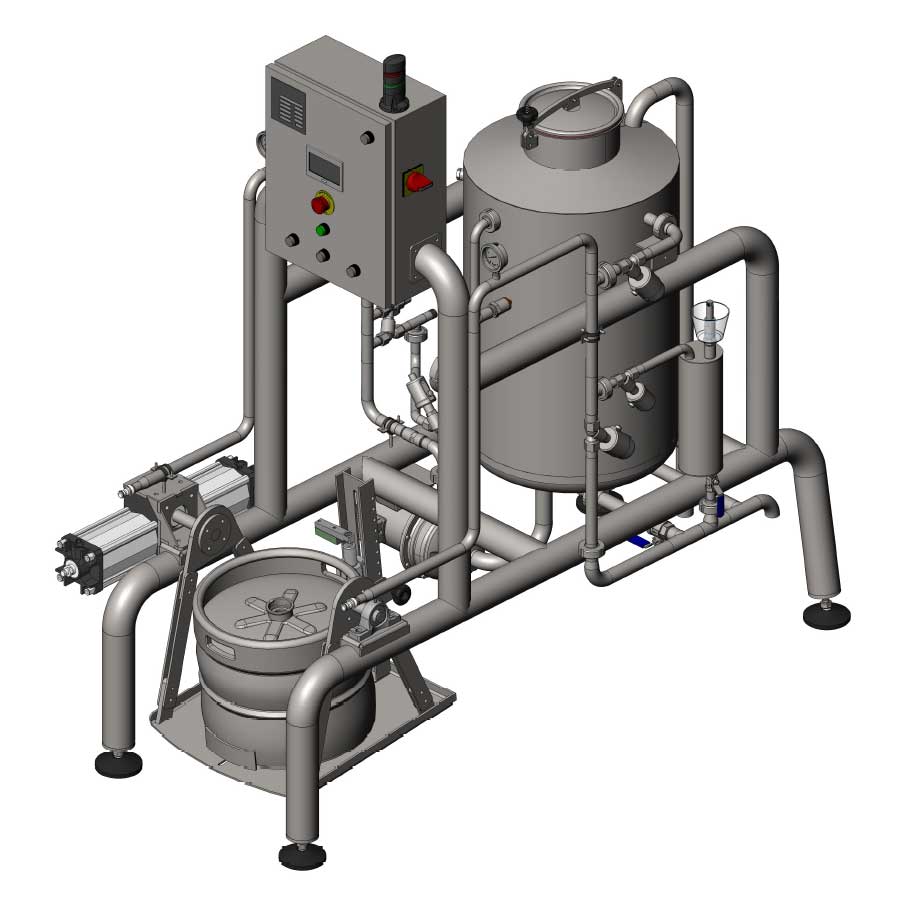

Main parts and connections :

| Code | Description |

| PoP | Suction pipeline – dring inlet |

| HrV | Pressure adjustable valve with the plastic cup |

| ZP | Foam collection container |

| NKK | Waste draining outlet |

| PP | Pressure piston (for automatic keg rotation) |

| RP | Rotary platform (for the keg) |

| FS | Keg fixation (for safe fixation of the keg) |

| Code | Code in the program | Valve type | Medium / use |

| valve 1.1 | Y1.1 | Pneumatic valve | Cold water inlet |

| valve 1.2 | Y1.2 | Pneumatic valve | Hot water inlet |

| valve 1.3 | Y1.3 | Pneumatic valve | Carbon dioxide inlet |

| valve 1.4 | Y1.4 | Pneumatic valve | Compressed air inlet |

| valve 1.5 | Y1.5 | Pneumatic valve | Beverage inlet |

| valve 1.6 | Y1.6 | Pneumatic valve | Hot steam inlet |

| valve 1.7 | Y1.7 | Pneumatic valve | Lye / Alkalic solution return |

| valve 1.8 | Y1.8 | Pneumatic valve | Waste outlet |

| valve 1.10 | Y1.10 | Pneumatic valve | Beverage / Filling into keg |

| valve 1.11 | Y1.11 | Pneumatic valve | Refilling the lye container with water |

| valve M2.1 | Manual valve | Draining the lye container | |

| valve M2.2 | Manual valve | Foam / Draining the foam collection container |

Control panel, indication and control elements :

| Code | Description |

| L | Type label |

| DD | Touch display |

| SS | Signal light |

| KP | Traffic light (current status indicator) |

| HV | Main switch |

| CS | Central STOP button |

| KT1 | Control button 1 (function depends on current program step) |

| KT2 | Control button 2 (function depends on current program step) |

| KT2 | Control button 3 (function depends on current program step) |

| KT3 | Control button 4 (function depends on current program step) |

How the machine works :

The device operates in the following cycles:

- Emptying the keg (automatic)

- Depressurization the keg (automatic)

- Flushing the keg with cold water (automatic)

- Flushing the keg with sanitizing solution (automatic)

- Flushing the keg with hot water (automatic)

- Steam sterilization of inside of the keg – it requires an external steam generator (automatic)

- Filling the keg with carbon dioxide gas (automatic)

- Rotation of the keg 180 degrees (automatic)

- Filling the keg with beer (automatic) – only if this step is allowed in the setting

Sterilized compressed air is needed for flushing inner space of the keg, which can contain of the rest of water or sanitizing solutions.

We recomment to use an external hot steam-generator as optional accessories to ensuring perfect sterilization of the inner walls of the barrels and shorter cleaning and sanitation cycle.

Software :

The program allows several modes :

- Sanitation / filling – automatic process of the keg chemical sanitation with filling the keg

- Sanitation – automatic keg chemical sanitation process without filling the keg

- Filling – automatic filling the keg without sanitation

- Disinfection – chemical disinfection of the filling valve and the foam collectioning reservoir

Language : English, Czech. Other languages available for individual demand for a surcharge

Media and connections :

Connections to pipelines :

- Steam – thread G1/2″

- Beer – thread G1/2″ / hose 12/7×9.5mm

- CO2 – thread G1/2″ / hose 12/7×9.5mm

- Compressed air – thread G1/2″ / hose 9.5×6.7mm

- Hot water – thread G1/2″ / hose 12/7×9.5mm

- Cold water – thread G1/2″ / hose 12/7×9.5mm

The connection to the pipelines can only be carried out by persons who are familiar with the properties and function of the pressure vessel and are also familiar with the relevant regulations for its operation

Input media

- Hot steam

- minimum pressure 3 bar

- maximum pressure 5 bar

- maximum temperature 160°C

Cold water

- minimum pressure 2,5 bar

- maximum pressure 4 bar

- recommended temperature 8-12°C

Hot water

- minimum pressure 2,5 bar

- maximum pressure 4 bar

- recommended temperature 80°C

Pressure air

- minimum pressure 6 bar

- maximum pressure 8 bar

- must not be contaminated by

– humidity – dry air

– solid particles (oil)

– microorganisms (sterility) - (Only oil-free air compressor with very fine air filtration and air dryer can be uses … see recommended air compressor and filtration bellow)

Carbon dioxide CO2

- recommended pressure : from 0.5 bar up to 1.0 bar

(From the pressure bottle with carbon dioxide)

Beverage product

- Beer, cider, wine, juice, lemonade etc (beverage to be filled into kegs)

- minimum pressure 2 bar

- maximum pressure 3 bar

Sanitizing chemical solution :

- As a sanitizing solution, we recommend using a NaOH alkalic solution with a maximum concentration of 3%

- The total volume of the tank is 150 l

- The filling volume is 125 liters – calculate the concentration on this volume (in the factory settings, the heating temperature of the sanitation solution is set to 60°C, if necessary, this value can be changed in the control application settings)

Electrical connection

- Power supply 3+PEN, 50Hz, 400V, TN-S

- Installed input power 4.7kVA

- Control voltage 24 VDC

- The filling unit is fitted with a CYKY5x2.5 connection cable in length 5m, the end of a plug socket 400V 16A

- The connection to the electrical network can only be carried out by persons who are familiar with the characteristics and function of the pressure vessel and are also familiar with the relevant regulations for its operation

Available keg couplers – the filling heads :

That’s how the filling valve looks – all types A, D, G, M, S, U are available according to requirement of the customer :

Technical parameters :

| Maximum performance : rinsing & sanitation (depends on many parameters – steam yes/no, keg contamination level etc. ) | 15-25 | |

| Maximum performance : rinsing & sanitation & filling (depends on many parameters – temperature, foaming, beverage type etc.) | 8-10 | |

| Volume of kegs maximum [ liters ] | 10 / 20 / 30 / 50 | |

| Inserting and removing kegs | manually | |

| Pneumatic connection – pressure sterile air | min. 4bar | |

| Electrical connection | 3x400V /50Hz 16A | |

| Heating | 2x 2.2 kW | |

| Pump | 750 W | |

| Control panel | 230V / 50Hz | |

| Alkalic solution tank with dosing | 1x 150 liters | |

| Acidic solution tank with dosing | no (on demand) | |

| Switching between modes : washing – filling | auto | |

| Sterilisation mode with hot steam (optionally) | external steam | |

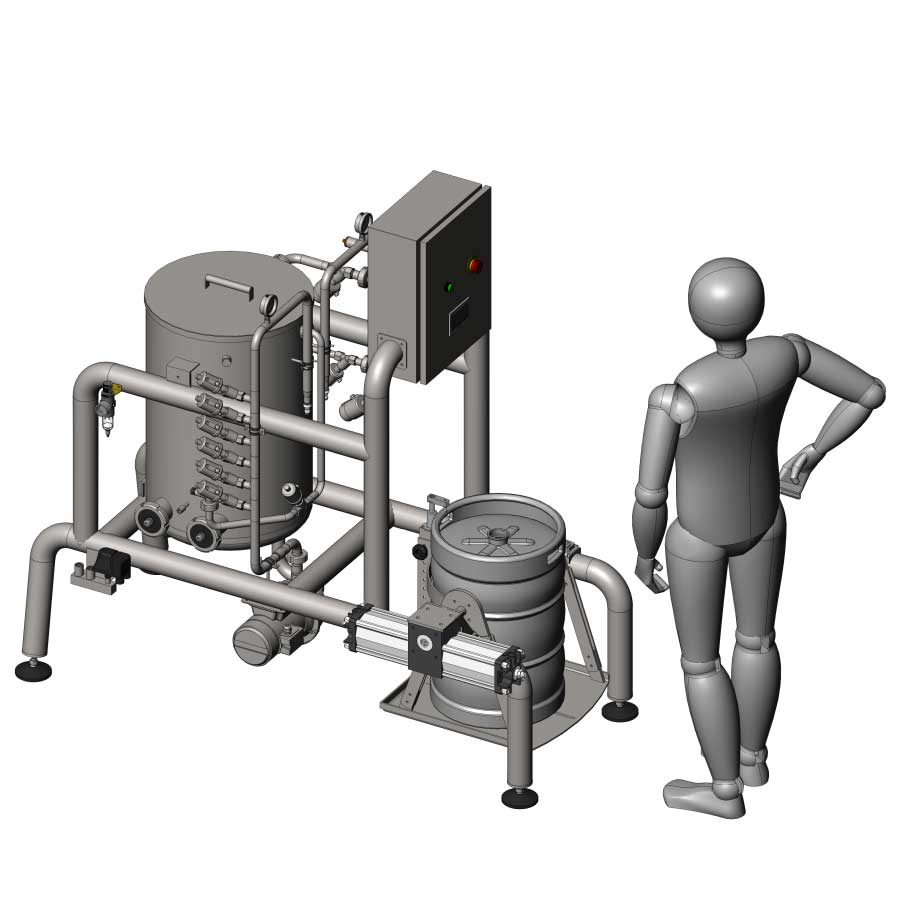

| Width / mm / | 850 | |

| Depth / mm / | 2000 | |

| Height / mm / | 1800 | |

| Weight /kg/ | 150 | |

| Average delivery time / months / (after first advance payment) | 2 | |

| Material | AISI 304 |

Recommended set of spare parts … price € 1200,-

The set includes :

- 2 pcs x electric heating spiral …. € 82,- / pc

- 2 pcs x gasket for EBARA CDX pump … € 120,- / pc

- 1 pc x pneumatic valve …. € 270,- / pc

- 2 sets x hoses and couplings …. € 120,- / set

- 2 sets x filling head for kegs …. € 140,- / set

Recommended accessories :

Conductivity sensor … € 1300,-

The IFM LDL220 conductivity sensor (measure range of 0.1 – 1 000 mS/cm ) for monitoring of current condition of the chemical solutions. The conductivity of chemical solutions is displayed on the PLC display.

MESG-06S : Micro electric steam generator 6kW 0.5bar (8 kg/h) … € 1090,-

The steam generator is necessary for the final keg sterilization after the chemical cleaning. The price includes also a hose connection between the keg washing machine and the steam generator.

Powerful steam generator with heating capacity of 6 kW for extra heavy continuous load operation. These robust models in a stainless steel case have exceptional steam generating capabilities thanks to the unique Teflon technology on the heating spirals. Output capacity is up to 8 kg of steam per hour at pressure 0.5 bar and temperature 111°C.

ACO-350-200OF : Oil-free air compressor 21.0 m3/h (350 l/min) with pressure tank 200 liters

Since air is also used in the individual steps of sanitation, it is necessary that this air be sterile, free of moisture and not contain any residues of solid particles or oils that have escaped into the air distribution system from the compressor.

Piston air compressor of the oil-free Pro Line Zero series. Machine output 350 l/min (21.0 m3/h) at 3 kW, power supply 3-phase 400V/50Hz. Compact lightweight oil-free piston air compressor with direct drive with a maximum air pressure of 10 bar and an air pressure tank with a volume of 200 liters. Automatic run control using Condor’s superior pressure switch. Minimal machine maintenance.

AFS6-B700-38F : Extended 6-stage sterile air filtration set 0.005 µm FUTURA – 300 L/min (3/8″)

6-stage air filtration set FUTURA 1/4″ with maximal capacity of 300 liters per minute. Recommended air filtration set to use in the food industry.

The set consists of these air filters :

- AF-DF1038 : Dust filter 1000 l/min (3/8″)

- AD-RDL3512F : OMEGA Air Dryer – 583 l/min (1/2″)

- AF-FV14F : Air prefilter 0.3 µm FUTURA – 2200 L/min (1/4″)

- AF-FX14F : Air microfilter 0.01 µm FUTURA – 300 L/min (1/4″)

- AF-FA14F : Air filter with active carbon 0.005 µm FUTURA – 700 L/min (1/4″)

- AF-DF1038 : Dust filter 1000 l/min (3/8″)