Description

DAF3 Candle filter with diatomaceous earth for beer/cider filtration

with dosing equipment and internal auto-rinse . Recommended beer flow rate 1500-2400 liters per hour

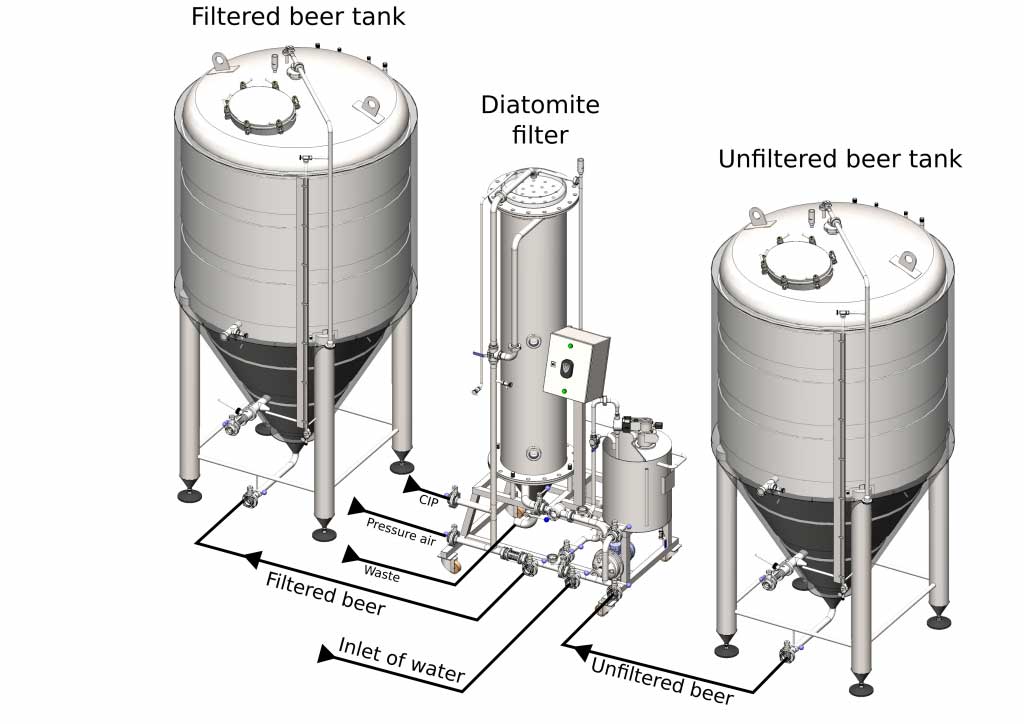

Beer filtration through the candle filter with kieselguhr is the most common solution of a filtration in a microbrewery of medium and large sizes . Beverage filtration is done through a layer from the filtration material that is flooded on the vertical filter candles . Candle filter with kieselguhr is characterized by high filtration efficiency . The most widely used filter medium is diatomaceous earth (kieselguhr). Depending on the composition of the filter layer different degrees of purity and flow of filtered liquid can be achieved . Ongoing diatomaceous earth dosage by a dosing pump keeps the filter still enough permeable . This allows to achieve high -capacity performance. Cleaning (regeneration ) of the filter is very easy and fast, without disassembling the pressured vessel

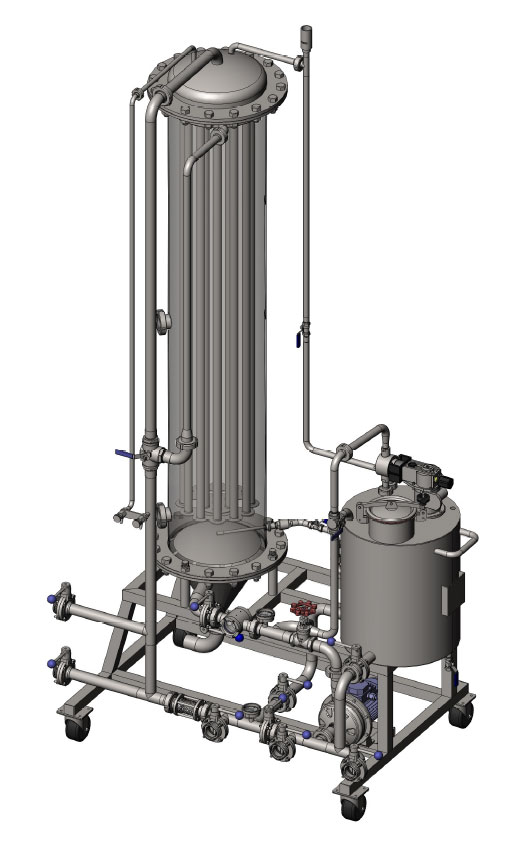

The filter is fitted as standard with the flow-through sight glass at both the inlet and outlet . It can be equipped with various level of automation. The filter is designed as a mobile device placed on travel wheels

The filter is fitted as standard with the flow-through sight glass at both the inlet and outlet . It can be equipped with various level of automation. The filter is designed as a mobile device placed on travel wheels

How works the filtration of beverages via the candle filters with diatomaceous earth ?

The layer of diatomaceous earth is applied to the support structure of the filter candle.

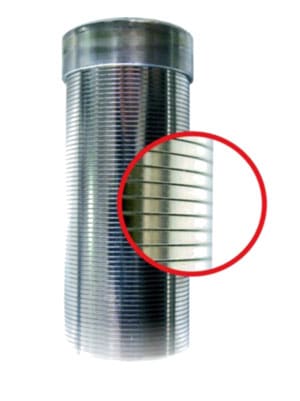

The candle is a cylindrical element that are made of stainless steel wire with trapezoidal special cross-section design, ensuring high deformation resistance and durability of these carriers.

Hence result a high filtration efficiency – the possibility of using filter for both coarse filtration and fine filtration – before a secondary micro-filtration that is provided on special microfilters.

Filtration by candle diatomaceous filter characterizes a very low cost filter material and very inexpensive operation.

IMPORTANT:

Filter performance depends mainly on the parameters of the filtered product – viscosity, amount and nature of the substances contained in the filtered product, on the type of filtration material,on the total filtration surface, and on pressure loss.

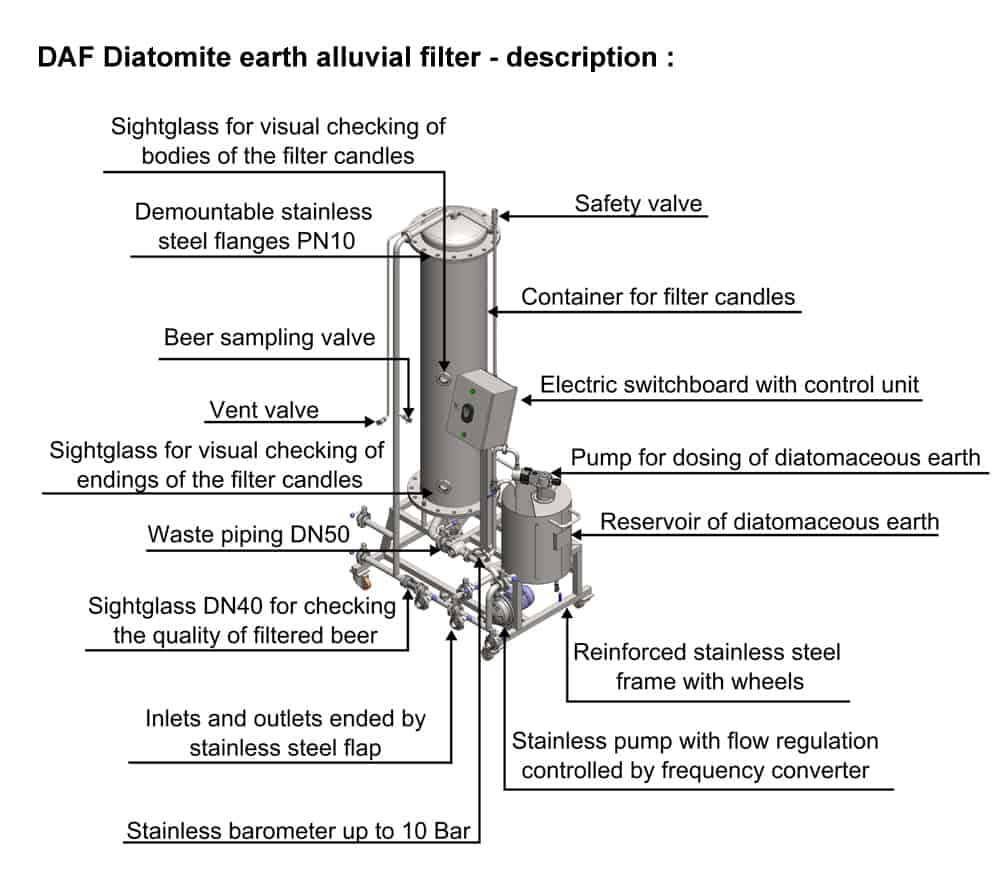

Description of the DAF3 filter:

DAF3, the candle kieselguhr filter is placed on a rigid frame provided with castor wheels for easy relocation. It is used in beer filtration using of alluvial filter (diatomaceous earth) to the vertical filter candles. The filter is fitted with a metering pump which supplies the kieselguhr at regular doses, which ensures a continuous throughput of the filter candles. For visual inspection of filtered beer and filter components, are the most important sites of the filter fitted with sight glasses. The container for the filter candles is constructed using pressure PN10 flanges for easy disassembling.

The main benefits of this type candle filter with diatomaceous earth :

- high filtration efficiency

- easy filter maintenance in terms of sanitation

- large number of filter cartridges provide high capacity power

- filter mobility

- simple operation

- small cost of consumables – diatomaceous earth

- using both primary and secondary filtration – choice of diatomaceous as a filtering material

- stable flow filtration performance – it does not decrease until fully clogging of the filter layer

- quick and easy cleaning (regeneration) of the filter without removing the device

- the possibility of automatized operation

Technical description

Technical description

- Filtration area of the candle ….. 3.0 m2

- Filtration area after alluvial of the diatomaceous earth ….. 3.6 m2

- Capacity of filter body ….. 140 l

- Capacity of diatomaceous earth batch ….. 68 l

- Maximum operating pressure ….. 6 bar

- Maximum operating temperature ….. 80°C

- Minimum operating temperature ….. 0°C

- Quantity of diatomaceous earth batch ….. 20 kg

- Recommended flow (beer) ….. from 15 to 22 hl per hour

- Max. capacity for one filter cycle :

- dosing of diatomaceous earth 100 g … 170 hl

- dosing of diatomaceous earth 150 g … 113 hl

- Input / output flaps (mm) ….. DN 40 / DIN 11851

- Waste drainage flap (mm) ….. DN 50 / DIN 11851

- Sampling valves (mm) ….. DN 10 / DIN 11851

- Safety valves 6 bar (mm) ….. DN 20

- Pressure gauge 0-10 bar (mm) ….. DN 10

- Integrated dosage of diatomaceous earth … yes

- Integrated internal auto-flushing … yes

- Integrated buffer tank … not available

- Filter housing – removable using screws

- Filter housing is mounted helical filter candles (diameter coiled wire, trapezoidal or circular), adjustable pressure valve, sight glass, devices for mixing of diatomaceous earth

- Storage vessel equipped with metering pump with variable dose and stirrer, dosing pipe fitted with a three-way valve, adjustable pressure valve and pressure pulses compensator

- Circulating centrifugal pump EBARA CD 120/20

- Frequency inverter for the pump rotation speed control

- Dosing pump HB 43ACC96

- Filtering candles :

- Number elements ….. 18 pcs

- Diameter ….. 30 mm

- Filter grid ….. 60/80 μm

- Material ….. stainless steel AISI 316

- Hydraulic connection with pipe fittings – closing butterfly valve, control valve, sampling valve, vent valves, sight flow illuminated, indicative mechanical flowmeter

- Electrical installation in a stainless steel cabinet

- Installation unit on mobile frame

- Outer surface finish is grinding and brushing

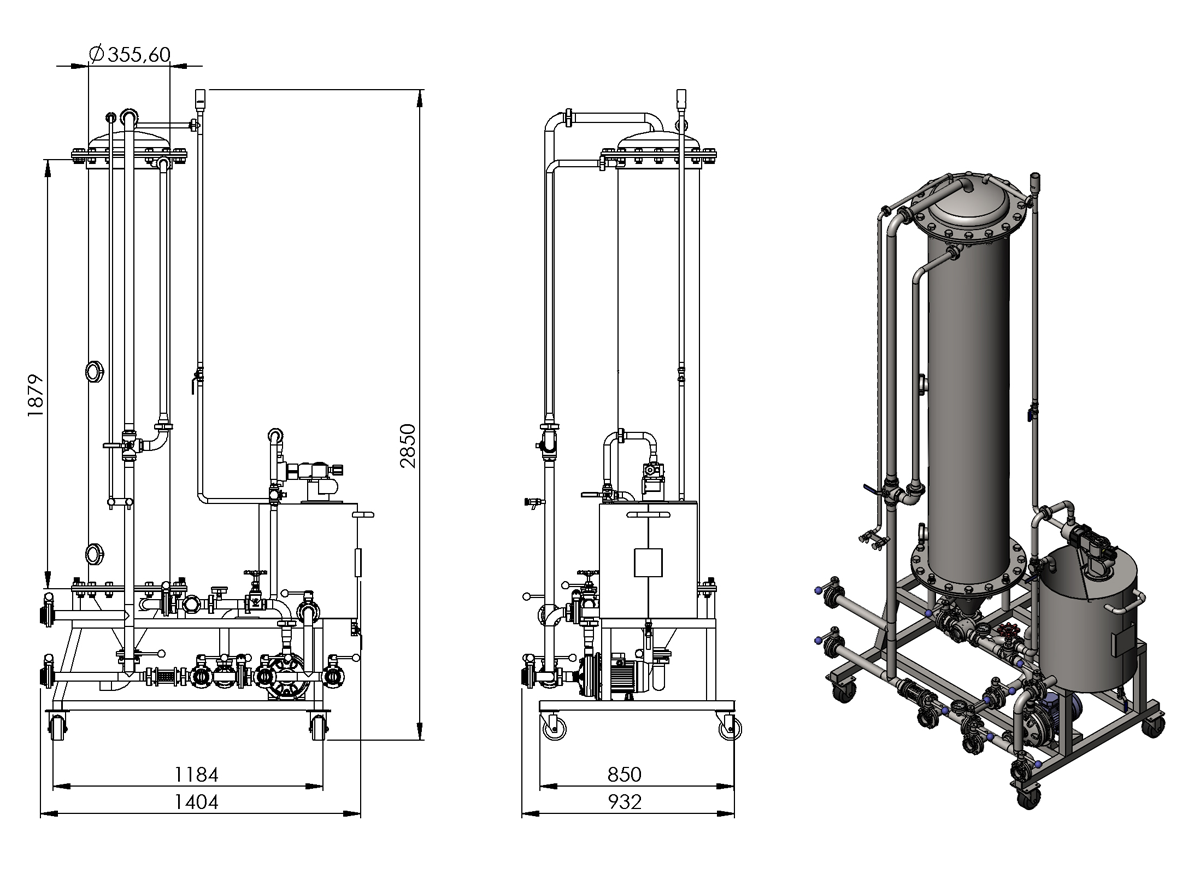

- Dimensions :

- Height …… 2850 mm

- Length ….. 1450 mm

- Width …… 900 mm

- Weight without media …… 350 kg

- Material ….. stainless steel 1.4301 / AISI316

Cleaning of the filter

Rinsing of the candles : it is carried out easy via the water backflow through the filter, without disassembling of the filter or pressure vessel.

Blasting silt with a compressed air : The filtration cake is blasted out from the filter housing and then it is subsequently pushed out from the candle by compressed air – all done via the opening and closing of valves, without a disassembling of the filter or pressure vessel.

Drawings

Recommended filtration material

Filtration performance can often be improved by combining the BECOGUR diatomaceous earth with additives:

BECOLITETM – Filtration beads (perlite),

BECOCELTM – Filtration cellulose fibers,

BECOFLOC® – Additional filter additives.

Optional equipment :

| Code | Description | Price |

| DAF3-AFCS | Automatic flow control system for the DAF3 Kieselguhr filter | € 2850,- |

FCD/DAF filters

FCD filters - Filtration cycle time / hours/ when the flow 5hl/hour/m3 - (without preparing the filter for the filtration and sanitation)| Tank volume / FCD filter type | FCD(B)1 DAF1 | FCD(B)2 DAF2 | FCD(B)3 DAF3 | FCD(B)5 DAF5 | FCD(B)7 DAF8 | FCD(B)10 | FCD(B)15 |

|---|---|---|---|---|---|---|---|

| 5 HL | 1 | ||||||

| 10 HL | 2 | 1 | |||||

| 15 HL | 3 | 1,5 | |||||

| 20 HL | 4 | 2 | 1,33 | ||||

| 30 HL | 6 | 3 | 2 | ||||

| 40 HL | 8 | 4 | 2,67 | ||||

| 50 HL | 5 | 3,33 | |||||

| 60 HL | 6 | 4 | |||||

| 70 HL | 7 | 4,67 | |||||

| 80 HL | 8 | 5,33 | 3,2 | ||||

| 90 HL | 6 | 3,6 | |||||

| 100 HL | 6,67 | 4 | |||||

| 120 HL | 8 | 4,8 | 3,43 | ||||

| 140 HL | 5,6 | 4 | |||||

| 160 HL | 6,4 | 4,57 | |||||

| 180 HL | 7,2 | 5,15 | 3,6 | ||||

| 200 HL | 8 | 7,14 | 4 | ||||

| 250 HL | 8,57 | 5 | |||||

| 300 HL | 6 | 4 | |||||

| 350 HL | 7 | 4,66 | |||||

| 400 HL | 8 | 5,33 | |||||

| Filter area / m2 / | 1 | 2 | 3 | 5 | 7 | 10 | 15 |

| Filtration area with kieselguhr / m2 / | 1,2 | 2,4 | 3,6 | 6 | 8,4 | 12 | 18 |

| Active sludge space / l / | 23,5 | 47 | 70 | 110 | 163 | 224 | 350 |

| Recommended flow - beer /hl per hour/ | 4 to 8 | 8 to 16 | 12 to 24 | 20 to 40 | 28 to 56 | 40 to 80 | 60 to 120 |

| - dosing of diatomaceous earth 100 g / hl | 55 | 110 | 170 | 265 | 400 | 540 | 850 |

| - dosing of diatomaceous earth 150 g / hl | 36 | 72 | 113 | 176 | 266 | 360 | 560 |

| Input / output fitting (mm) | DN 25 | DN 25 | DN 32 | DN 32/40 | DN 40 | DN 50 | DN 50 |

| Integrated dosage of diatomaceous earth | yes | yes | yes | yes | yes | yes | yes |

| Integrated internal auto-flushing | yes | yes | yes | yes | yes | yes | yes |

| Integrated buffer tank | (only FCDB) | (only FCDB) | (only FCDB) | (only FCDB) | (only FCDB) | (only FCDB) | (only FCDB) |

Reviews

There are no reviews yet.