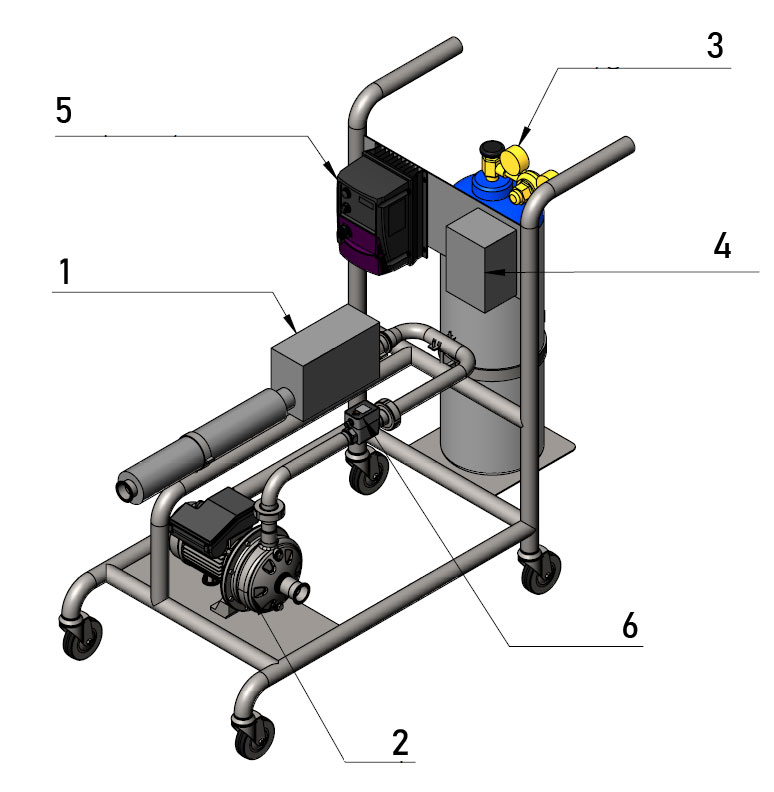

Description

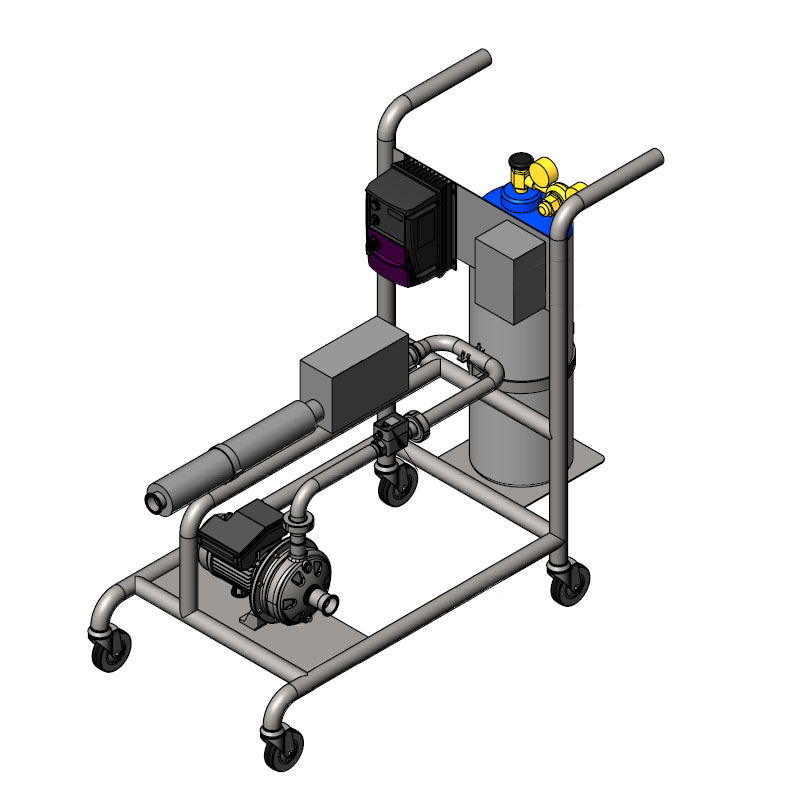

Compact solution of the flow-through beverage carbonizer (the in-line CO2 saturator) which consists of the CO2 in-line carbonator, the centrifugal pump, the holder of the pressure bottle with carbon dioxide. The machine can be optionally equipped with a frequency inverter (for the flow speed control) and a flow meter (for the flow measurement). All equipment is installed on a mobile stainless steel platform with wheels.

This carbonator is able to sature beverages with carbon dioxide up to value max. 6 g/l (beer, cider etc.)

Main equipment :

- Flow-through beverage carbonation unit (CFR-125PRO CARBO PRO-INOX-PLUS)

- Centrifugal pump 1800W

- Pressure reduce valve for CO2 + pressure bottle holder (the pressure bottle with carbon dioxide is not included in price)

- Electric switch box

- Frequency inverter – to the pump rotation speed control (only in the S/F versions)

- Flow meter – to beverage flow speed displaying (only in the F version)

Centrifugal pump EBARA CDX 200/25 (3-phase 230/400V / 50 Hz) 1800W

The stainless steel mobile centrifugal pump 1800W for transport beverages between containers, beverage filtraton, cleaning and sanitizing the tanks and pipes.

CFR-125PRO : Flow-through compact carbon dioxide beverage saturator 400-12500L/hr (up to 6g/L)

The CFR-125PRO CARBO PRO-INOX-PLUS is a fully automatic flow-through compact carbon dioxide saturator for beverages with capacity of 400 up to 12500 liters per hour. Material : All parts in contact with beverage are made of stainless steel AISI-304.

The main advantages of the Carbo technology

-

- Dosage is shut on and off automatically with the switching of the pump

- No electrical connections required (purely mechanical controls)

- Proportional gas metering (dosage adapts automatically to the current flow of beverage)

- Can be installed at bottling station or in front of filter

- Exact an reproducible dosage of carbon dioxide

- Highly efficient equals lower CO2 consumption

- Compact structure, therefore adaptable to on-site requirements

- Simple and safe operation

- The carbonator is also available in stainless steel model upon request

- We would be pleased to advice you can on the use of our carbonizing technology for the exact dosage of CO2 in the creation of sparkling wines, beer, cider, lemonades or sparkling water.

Special properties and equipment of the CFR-125PRO CARBO PRO-INOX-PLUS version :

- The injector box, the injector, non-return valve and all parts in contact with beverage are made of stainless steel

- Fully automatic regulation with pre-selective adjustment and analog display to grant reproducibility of adjustment.

- Complete delivery with hose connections (DIN 11851 DN25, DN32, DN40 / BSM threads / TriClamp / TriClover etc.)

- CO2-measuring and CO2 pressure reducing device included

- Stainless steel fittings DN 40 male, adapter for other fittings included

- May be chemically cleaned with CIP (all parts in contact with beverage are made of stainless steel 1.4404 = AISI 316L)

- One injector is included (by requirements of a customer) :

| Available injectors | Flow capacity |

| injector 0.6 (Stainless steel Pro-Inox-Plus) | 400 – 600 l/h |

| injector 1.1 (Stainless steel Pro-Inox-Plus) | 700 – 1.100 l/h |

| injector 1.4 (Stainless steel Pro-Inox-Plus) | 950 – 1.400 l/h |

| injector 2.0 (Stainless steel Pro-Inox-Plus) | 1.300 – 2.000 l/h |

| injector 2.5 (Stainless steel Pro-Inox-Plus) | 1.700 – 2.500 l/h |

| injector 3.0 (Stainless steel Pro-Inox-Plus) | 2.000 – 3.000 l/h |

| injector 4.0 (Stainless steel Pro-Inox-Plus) | 2.500 – 4.000 l/h |

| injector 5.0 (Stainless steel Pro-Inox-Plus) | 3.500 – 5.000 l/h |

| injector 6.0 (Stainless steel Pro-Inox-Plus) | 4.000 – 6.000 l/h |

| injector 6.5 (Stainless steel Pro-Inox-Plus) | 4.500 – 6.500 l/h |

| injector 7.0 (Stainless steel Pro-Inox-Plus) | 5.000 – 7.500 l/h |

| injector 8.0 (Stainless steel Pro-Inox-Plus) | 5.500 – 8.500 l/h |

| injector 9.0 (Stainless steel Pro-Inox-Plus) | 6.500 – 9.500 l/h |

| injector 12.5 (Stainless steel Pro-Inox-Plus) | 8.500 – 12.500 l/h |

| Optionally : Additional injector (type DeLuxe Stainless steel) | € 1490,- |

Cleaning restrictions for the CFR-125PRO CARBO PRO-INOX-PLUS version :

- No restrictions – can be cleaned with hot water and chemically, can be sterilized with hot steam

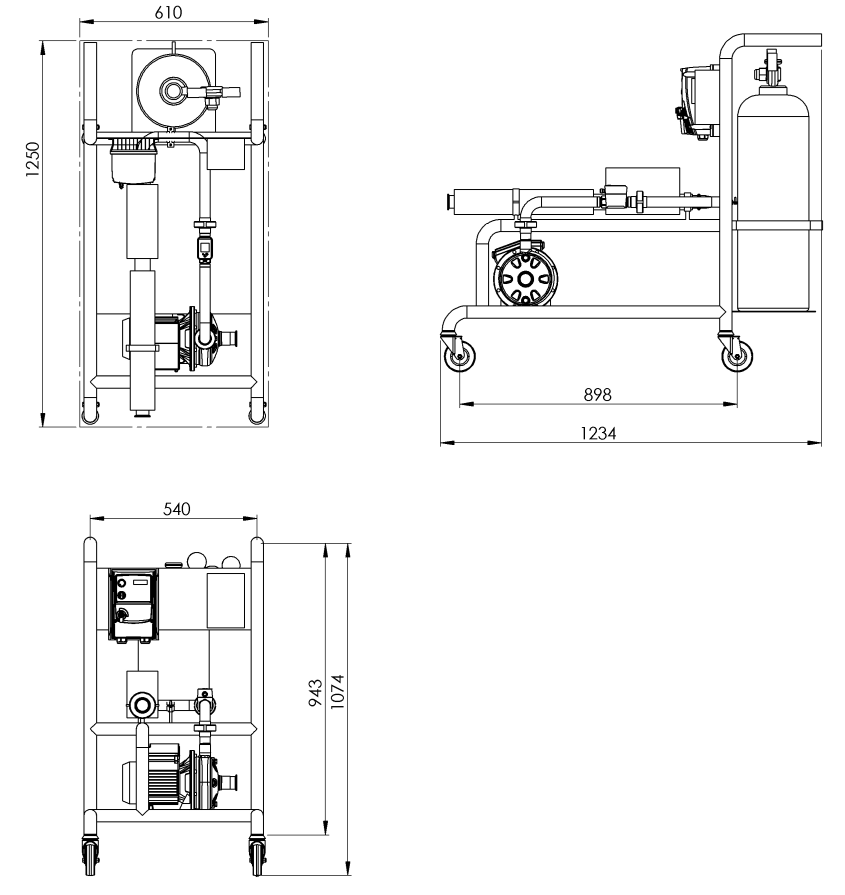

Dimensions of the compact mobile unit:

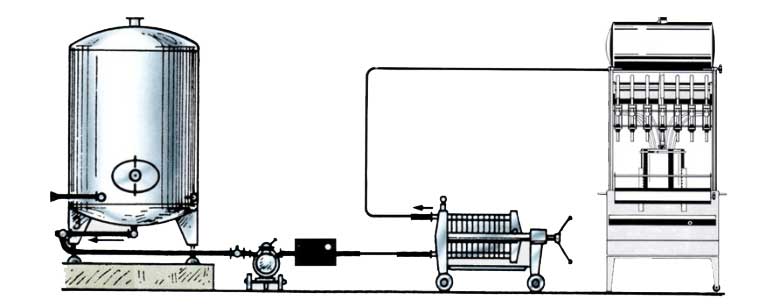

Recommended connection of the carbonizer in the bottling system

When a beverage is carbonated immediatelly before its bottling :

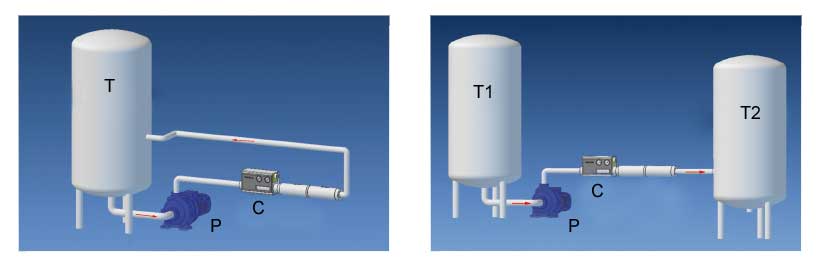

When a beverage is carbonated in a pressure tank :

T …. pressure tank

T1 … source pressure tank

T2 … target pressure tank

P … beverage pump (recommended is a pump with the flow rate control)

C … Flow-through compact beverage saturator (CARBO)

Model / technical details

| Processor model | CFR-20PC | CFR-30SS | CFR-125PC | CFR-125SS | CFR-125PRO | CFR-125DLX | CFR-300PC | CFR-300SS |

| Maximal CO2 dosage (g/l) | 1,8 | 1,8 | 1,8 | 1,8 | 6,0 | 11,0 | 1,8 | 1,8 |

| Max. flow performance (l/h) – see the injector table | 2.000 | 3.000 | 12.500 | 12.500 | 12.500 | 12.500 | 30.000 | 30.000 |

| Pressure loss at min./max. performance (bar) | 0,7 / 2,0 | 0,7 / 2,0 | 0,7 / 2,0 | 0,7 / 2,0 | 0,7 / 2,0 | 0,7 / 2,0 | 0,7 / 2,0 | 0,7 / 2,0 |

| Max. CO2 pressure (bar) | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 |

| Max. pressure in beverage (bar) | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Dimensions (L x H x D) (cm) | 30 x 14 x 10 | 30 x 14 x 10 | 30 x 16 x 10 | 30 x 16 x 10 | 30 x 16 x 10 | 30 x 16 x 10 | 30 x 16 x 10 | 30 x 16 x 10 |

| Weight (kg) | 5,5 | 6,5 | 7,1 | 7,6 | 7,6 | 7,6 | 8,5 | 9,3 |

| Material of the parts in contact with beverage | AISI 316L | AISI 316L | AISI 316L | AISI 316L | AISI 316L | AISI 316L | AISI 316L | AISI 316L |

Reviews

There are no reviews yet.