Description

COM-16 Central Oxygenation Manager

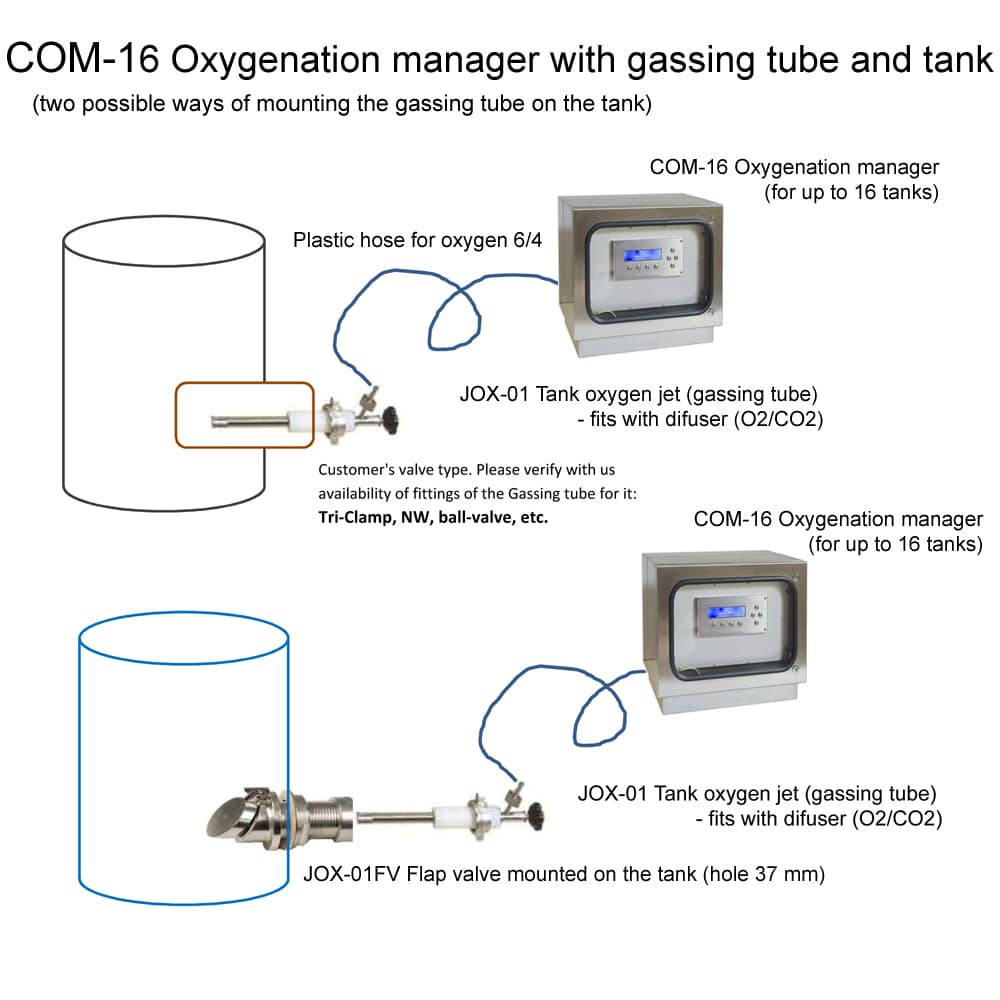

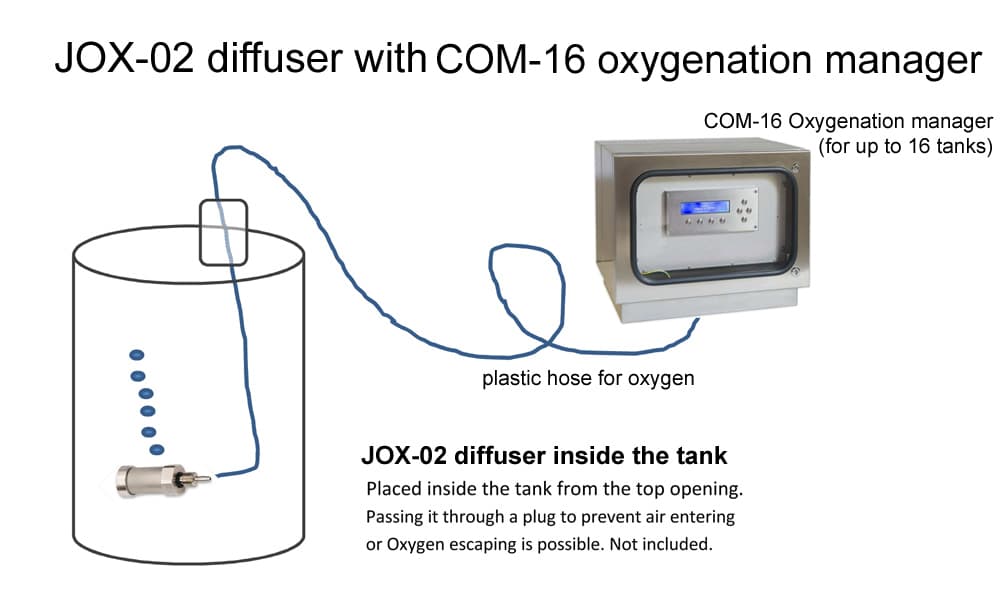

COM-16 is the central control cabinet for managing oxygenation up to 16 Tanks, Cascadable. The OxyBox controls up to 16 jets for oxygenation or aeration of beverages. Compatible with the ACOS-02 oxygenation stone , JOX-01 oxygenation jet or JOX-02 oxygenation diffuser

The COM-16 is designed for the application of oxygen in gas form to must and wine. They can be applied in both Micro- and Macro-oxygenation. The COM-16 is portable with hanging possibility.

The COM-16 is designed for the application of oxygen in gas form to must and wine. They can be applied in both Micro- and Macro-oxygenation. The COM-16 is portable with hanging possibility.

The COM-16 can apply smaller doses of Oxygen , but it is therefore extremely exact. The COM-16 is optimal for micro-oxygenation, and for macro-oxygenation of smaller tanks.

The COM-16 units are equipped with sensitive sensors from the medical technology, thanks to which they are free from the influence of entry and exit pressure (height of must or wine). The unit reacts automatically and continuously to changing environmental conditions. Integrated temperature measurement function allows the setting of operation within a temperature range (requires the temperature-sensor kit).

Wine, cider or beer oxygenation improves a quality of fermentation.

Inside view to the COM-16 Central Oxygenation Manager (with 4pcs of COM-1M modules)

What is Micro-Macro Oxygenation ?

MACRO-OXYGENATION – during the beginning of the fermentation: Stengthens the yeast cells and their re-gernationed cells. Every brewer, cidermaker or winemaker fears a stuck fermentation due to weakening of the yeast cells. Macro-ox at this stage contributes to the development of strong yeast cells that can carry the fermentation well to a complete ending. Helps to stabilize the color of red wine and taste of beer.

MICRO-OXYGENATION – after the fermentation: Improves wine aroma and flavor assimilating aging in a barrel, with more control over the Oxygen amounts. The oxygen binds the Tanins

(Phenols) stabilizing the color of the wine and giving it a fuller flavor and mouth-feel.

Wine Oxygenation can improves beer quality.

MACRO- OXYGENATION – during the beginning of the fermentation beer, cider or wine: Has the same beneficial effect on the yeast as in wine .

JET-OXYGENATION (CLIQUAGE) – A jet (spurt) of Oxygen into the tank at the beginning of the fermentation for similar effect as the Maco-Ox. Quantity controlled manualy by operator.

How it works ? Why to use the oxygenation process in the brewery / cideria ?

Macro- Oxygenation – during the beginning of the fermentation: Has the same beneficial effect on the yeast as in wine (see here above).

Macro- Oxygenation is done only in the beginning of the fermentation to strengthen the yeast when the start to multiply. Yeast consume oxygen and sugar as nourishment, and produce alcohol and heat. As long as there is oxygen in the tank – they will multiply aerobically and regenerate larger and stronger cells which can bring the fermentation to a better finish. The risk of the yeast cells getting tired and not finishing the fermentation complete is drastically reduced.

Yeast that do not get extra dosage of oxygen, very soon consume all the oxygen in the tank, and begin to multiply un-aerobically. The regenerated cells are smaller and weaker. At the same time they start producing alcohol which is a poison to them, so the regeneration is slower and weaker in the presence of alcohol without added oxygen.

The amounts of oxygen are up to the brewer himself to decide according to his experience, brew-batch size, type of beer and yeast he is using.

What do you need for use the beverage oxygenation process ?

-

JOX-01 oxygenation jet , JOX-02 oxygenation diffuser or ACOS-02 oxygenation stone for each tank …from 1 to 16 pcs

-

(optionaly) JOX-01FV Flap valve …for each tank

-

COM-16 Cabinet – this case for installation up to 16 COM-1M modules, Cascadable … 1 or more pcs cascaded

-

COM-1M Module for COM-16 cabinet … 1 pc for each tank (up to 16 modules for one COM-16 cabinet)

Reviews

There are no reviews yet.