Description

The CLC-4P2300 GreenLine is the compact water or glycol chiller with integrated 4 pumps, 4 thermosensors and 5 temperature regulators. This cooling unit is designed to cooling up to four beverage tanks. It can be used for cooling beer, ciders, freeze-drying wines or other beverages. Cooling power is 2300 W.

The CLC-4P2300 GreenLine is the compact water or glycol chiller with integrated 4 pumps, 4 thermosensors and 5 temperature regulators. This cooling unit is designed to cooling up to four beverage tanks. It can be used for cooling beer, ciders, freeze-drying wines or other beverages. Cooling power is 2300 W.

The machine is fitted with five digital thermostats and four water pumps. The first thermostat allows to control the temperature in a water bath. Next four thermostates is connected to external thermosensors and they are used to independent adjust the temperatures in four tanks with beverage.

The machine is fitted with five digital thermostats and four water pumps. The first thermostat allows to control the temperature in a water bath. Next four thermostates is connected to external thermosensors and they are used to independent adjust the temperatures in four tanks with beverage.

When the temperature in some changes, the dedicated circulation pump will automatically start. After reaching the desired temperature, the circulation pump automatically shuts off . Chilled water is then pumped into the heat exchanger.

This cooling unit is based on the successful design of the powerful cooler CLC-4P2300.

The CLC-4P2300 cooler stands out with its unique design, reliability, performance, simple operation and easy access during servicing operations. It is taking the advantages of the most popular series of water coolers CLC.

The materials used meet the highest hygiene standards and guarantee a smooth quiet operation and long life of this machine.

Technical parameters :

Power of the cooling compressor ….. 2300 W

Maximal cooling capacity … 200 liters To 0°C / Tk 45°C Δt 10°C

Full time cooling capacity … 180 liters To 0°C / Tk 45°C Δt 10°C

Ice bank capacity … 10-20 kg

Volume of the integrated glycol tank … 35 liters

Refrigerant … R290 (Green Line)

Electrical connection … 220-240V/ 50Hz

Consumption … 1380 W / 6A

Pump displacement … 12.0 m

Number of independent temperature regulators (for tanks) … 4pcs

Number of independent water pumps (for tanks) … 4pcs

Number of independent thermosensors (for tanks) … 4pcs

+ one regulation system for cooling water inside the cooler … 1pc

Length of the thermosensor cables … 4x 6 meters

4pcs of water output : JohnGuest 12.7 mm (1/2″) food hose

4pcs od water input : JohnGuest 12.7 mm (1/2″) food hose

Recommended for cooling up to 2000 liters of beer, wine, cider in 1-4 pcs of the insulated fermenters …

Notice : The power parameters are valid for ambient temperature from 0 to 25°C

Cooling capacity :

Values are valid for ambient temperature max. 25°C

| Water/glycol temperature | -4°C | 0°C | +4°C |

| Cooling capacity | 1.5 kW | 1.9 kW | 2.3 kW |

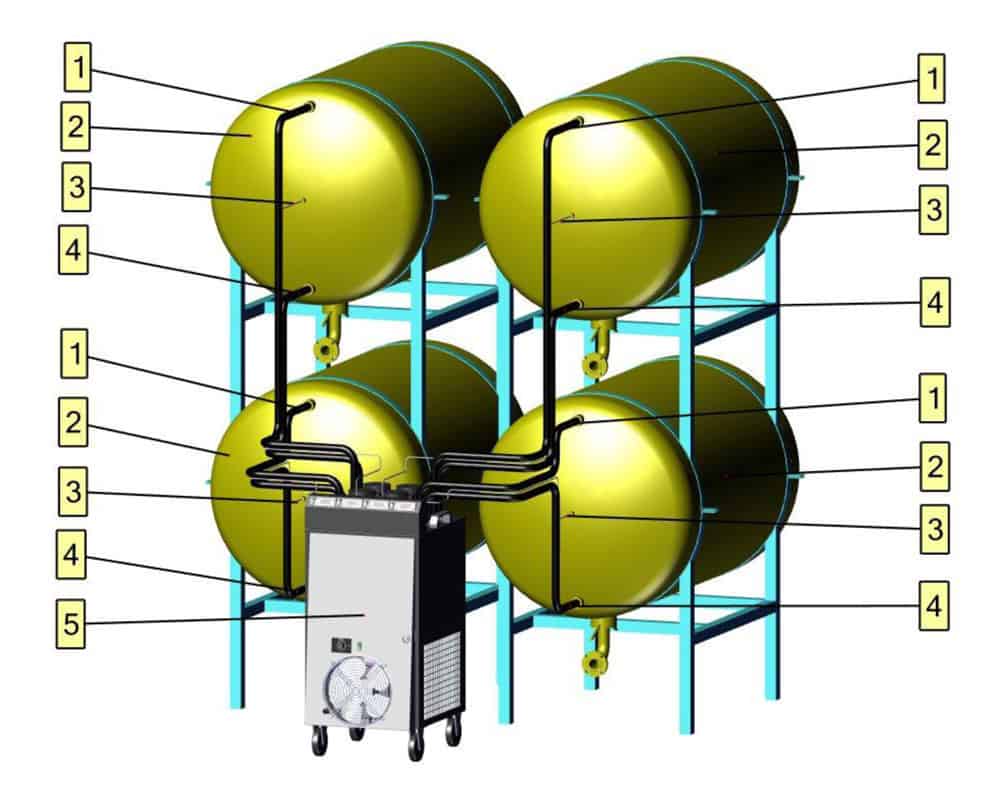

Description – connections and main parts of the cooler

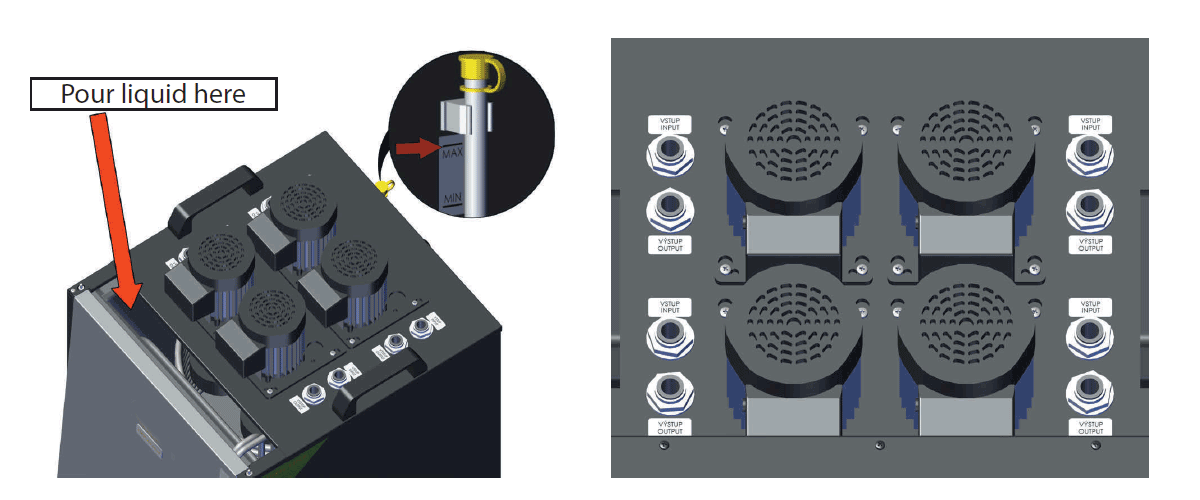

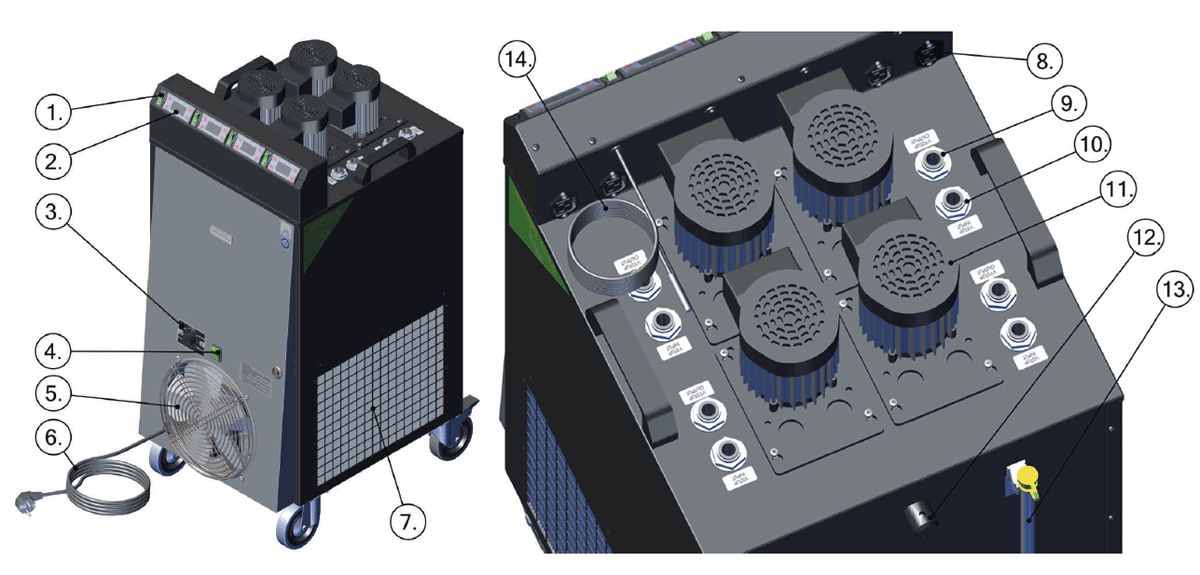

- Pump switch (4pcs)

- Digital thermostat for the pump (4pcs)

- Thermostat for the cooler (1pc – this sensor serves for regulation temperature of the cooling media inside the cooler)

- Power switch (on/off)

- Air fan

- Power cable (1ph 230V / 50Hz)

- Condenser

- Pump power socket (4pcs – for easy replacement of damaged pump)

- Cooling water outlet (4pcs of the John Guest connectors for hoses with outer diameter 12.7 mm)

- Cooling water inlet (4pcs of the John Guest connectors for hoses with outer diameter 12.7 mm)

- Pump (4pcs)

- Overflow draining pipe (recommended to be inserted to the waste water can)

- Level indicator (drain)

- Temperature probe (4pcs to be inserted into the sensor well in the tank to be cooled)

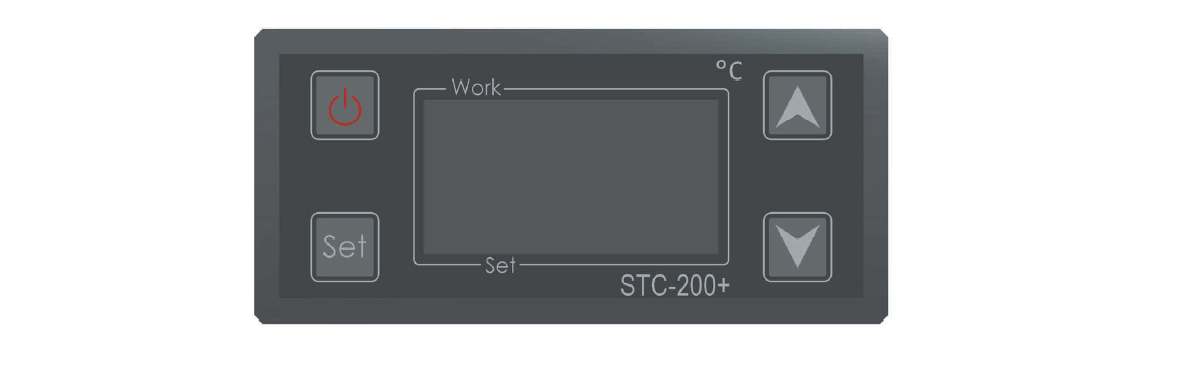

Control panel – four digital thermostats for displaying and setting temperatures in four tanks :

Displaying Set Temperature:

1. Short-press the SET button. The display will show the set value.

2. To return the display to the current temperature, again short-press the SET button or wait 5s.

Changing Set Temperature:

1. Hold the SET button for more than 2 s.

2. The set temperature will be displayed and the °C indicator will begin flashing.

3. The set temperature can be changed by pressing or (within 10 s).

4. The newly set temperature can be saved by pressing the SET button again or automatically by waiting 10 s.

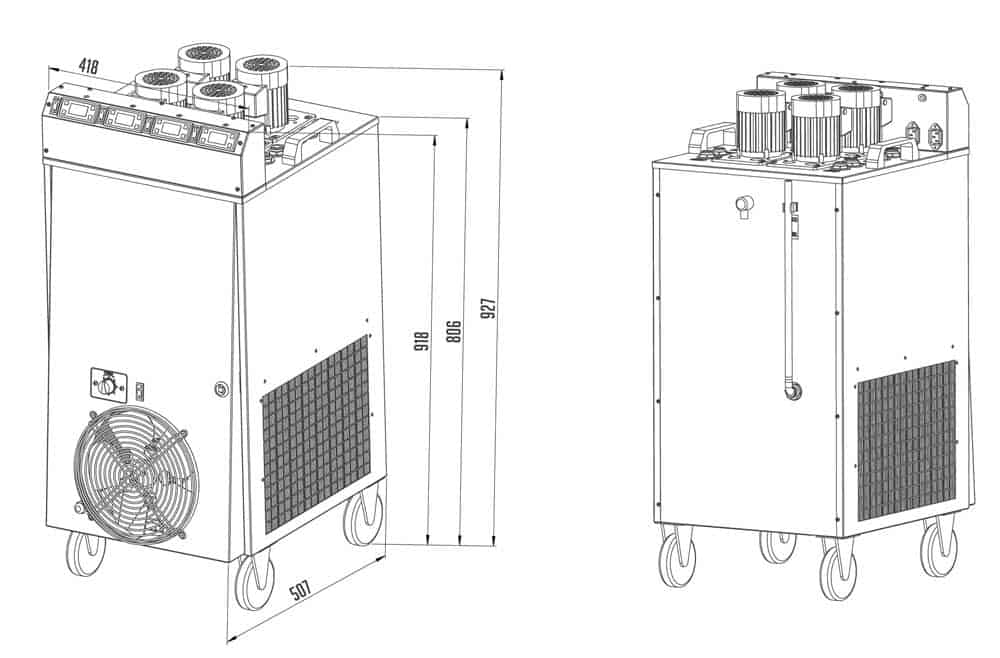

Dimensions :

Dimensions … 420x520x930 mm

On pallette …1200x800x1100 mm

Weight … 70 kg

Recommended application :

We use this type of the liquid cooler for cooling up to 4 pcs of the beer tanks (or also wine tanks, cider tanks) with smallest capacities (Stainless steel fermenters with capacity from 50 to 1000 liters ).

For this application you need not any else equipment (regulation valves, controllers, sensors etc.)

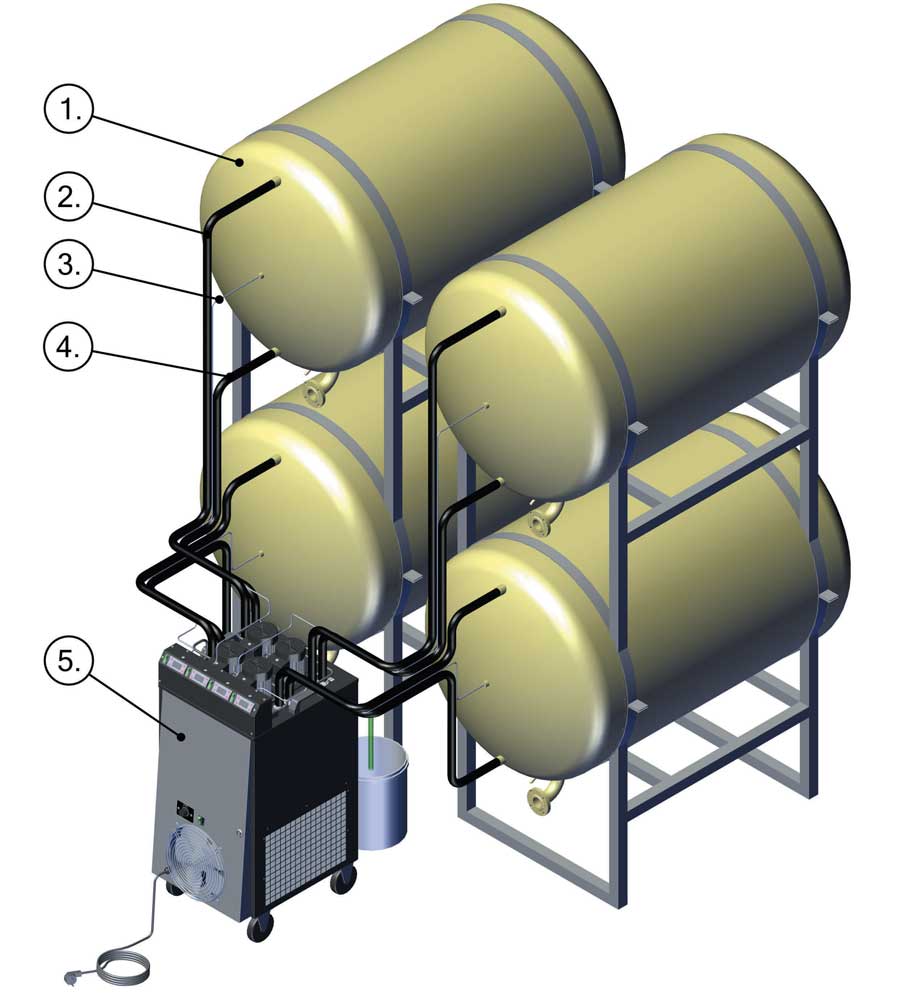

How the cooler is to be connected to the tanks ?

- Tank to be cooled (must be equipped with the cooling jacket or the submersible cooling exchanger)

- Cooling media hose – input to the tank (with outer diameter 12.7 mm)

- Thermo sensor (inserted in the sensor well)

- Cooling media hose – input to the tank – return from the tank (with outer diameter 12.7 mm)

- The CLC-4P2300 cooling unit

See the example fermentation systema equipped with the CLC-4P2300 GreenLine cooler …

FUIC-SLP1C-4x500CCT – Fermentation & maturation self-cooled unit 4×500/625 liters … more info

CFSCT1-4xCCT100SLP – Complete fermentation set with 4pcs of CCT-SLP 120 liters, direct cooling … more info

Connections of the cooler with the beverage tanks

- Hose with diameter 12.7mm with PUR insulation : Input from the cooler to double-shell tank

- Double-shell tank with beverage to be cooled

- Temperature probe 6m

- Hose with diameter 12.7mm with PUR insulation : Output from the double-shell tank to the cooler

- CLC-4P2300 Compact Liquid Cooler 2.3 kW with 4 pumps

Reviews

There are no reviews yet.