Description

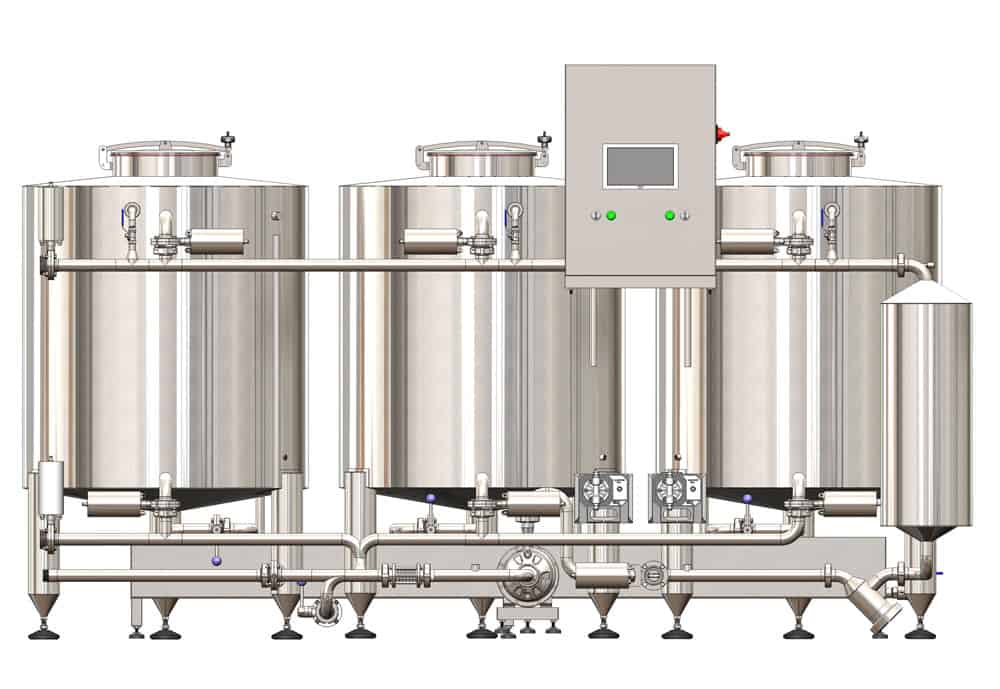

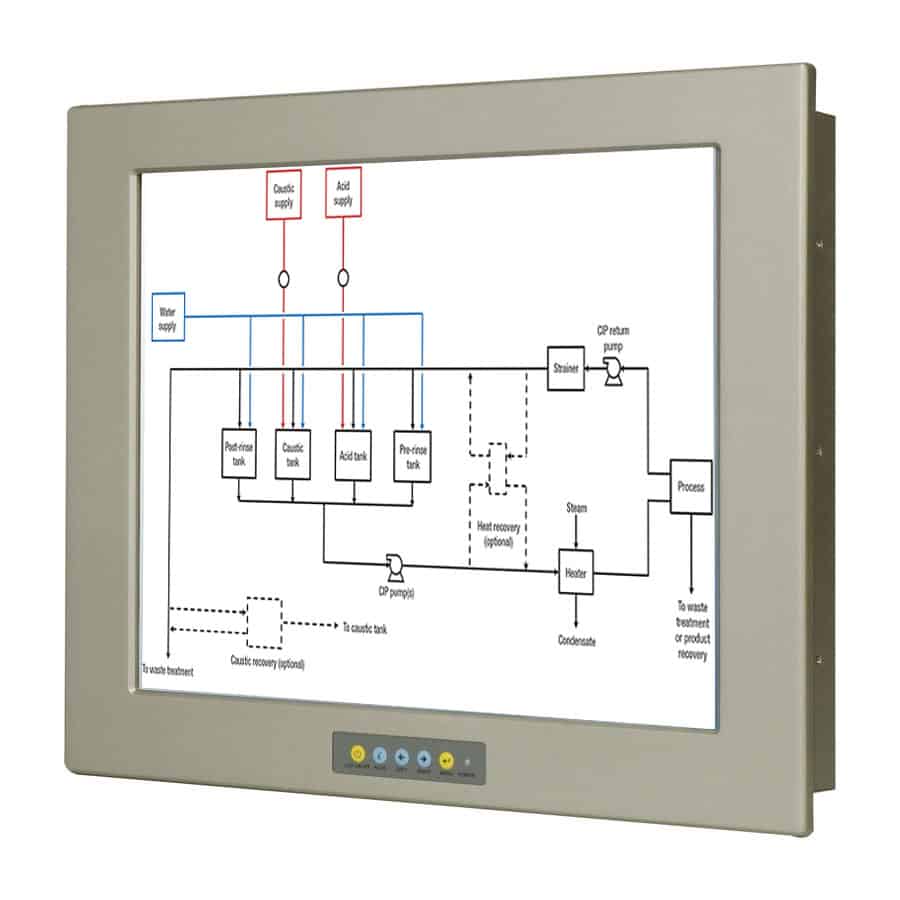

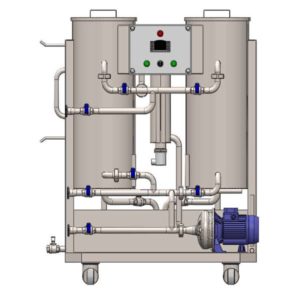

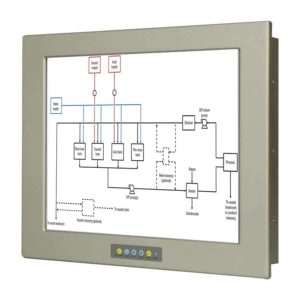

CIP-A503 is an automatic control system for the Cleaning In Place system CIP-503. The automatization includes all functions necessary to perfect cleaning and sanitation of all containers and optionally also pipes and hoses in a brewery using a special program, sensors, pneumatic valves and industrial computer with the touch display. This control system is compatible with the CIP-503 machine.

The automatic control system includes :

I. Hardware

- PLC processor unit – standard : Siemens Simatic S1200 with expansion cards

- Control panel with the touch LCD Weintek 10“

- Pneumatic valves – full set

- Thermo sensors – PT100

- Conductivity sensor – LDL210

- Pressure sensors – PBT-SICK 0-10 Bar

- Level indicators – SF141

- Induction flow meter – COMAC CAL FLOW 38

- Frequency speed controllers for pumps – Invertek 2,2kW

- Emergency stop button

- Pneumatic valve terminal – IMI Norgren 12×2

- Pneumatic valves – AISI 316l DN 40 IMI Norgren / ASX Camozzi DN 15 AISI 316L

- Dosing pumps – BLACK STONE B2-10-2 10.8L/h

II. Software

- Automatic keeping of the sanitizing solution level

- Automatic rinsing cycle

- Automatic cleaning cycle

- Automatic venting when sanitizing solutions circulate

- Automatic flushing-through of the pipe system

- Automatic cleaning and sanitizing of the pipes and hoses (optionally)

- Sensing and checking the quality of the sanitizing solution

- Automatic temperature keeping

- Automatic neutralization of the sanitizing solution

- Automatic washing of the CIP station

- Remote access

III. Documentation

- Declaration of conformity

- Protocol about all tests

Designed only for :

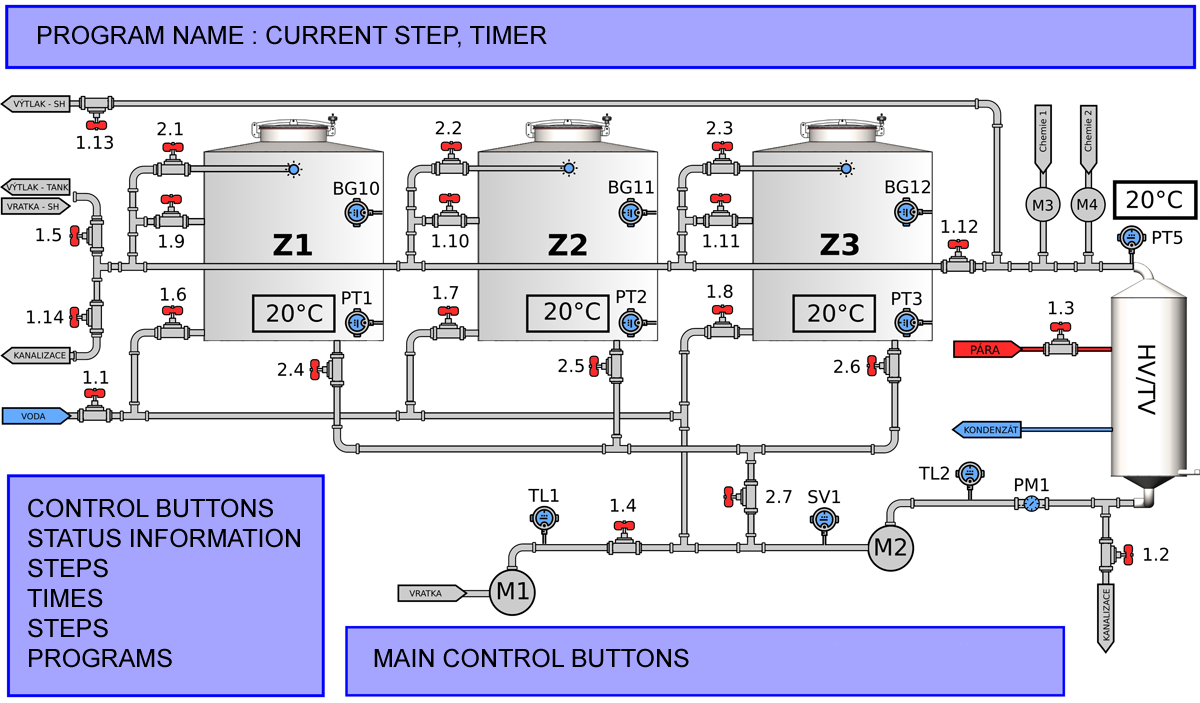

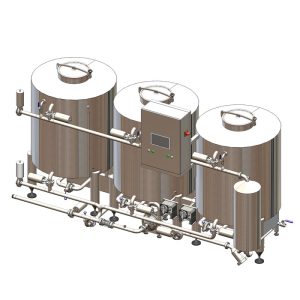

CIP-503SA with the automatic control system and the steam heating system – visualization :

Reviews

There are no reviews yet.