Description

The CDCH-SR11 is a compact flow-through cooler and heater of liquids and beverages, also known in some countries as Ultra-Cooler. It has a built-in spiral tube in tube heat exchanger, with automatic controls of the unit itself. It can either to cool – or when in reverse – also to heat the medium. It can control the temperature in a specific tank that you connect to it (adding a pump) for several hours or days, for example – for wine or cider stabilization. Intended also for carbonized beverages under pressure because the heat exchanger is closed. It cools wine, fruit must, apple cider, water in the inner pipe and in the surrounding pipe is the coolant which is gas (Freon). It’s using for wine cooling and heating, but also for cider, cooling down sparkling wine or cider before bottling etc. The cooling power is from 18500 W to 34000 W (from 25.15 to 46.22 HP). This cooling-heating unit is designed for indoor or covered outdoor use. The main advantages are very easy instalation without team of cooling specialists. It is produced with 3-phase (EU/USA). Designed in Germany.

The CDCH-SR machines are mobile direct-cooling and heating units, available in various sizes. The CDCH-SR consists of a cooling aggregate in the upper part and a heat exchanger in the lower part. Both are mounted inside a stainless steel frame equipped with wheels. The CDCH-SR was specifically developed for applications in the wine and cider industry. The CDCH-SR is designed to treat any substance from destalked-grapes to wine/cider or water. These units are the ideal solution for vintners or cider producers who require the option to heat their beverage as well as to cool it.

The casing and cover as well as all parts that come in contact with the treated medium are made of stainless steel. The ventilation grills are lacquered in black. Due to its four wheels this unit is easy to movable. This allows the vintner to cool or to heat even single tanks or other containers, as required, without the expenditure in any fixed pipe system installation. For example: starting of a fermentation by heating the beverage in the fermentation tank.

The cooling units from the CDCH-SR series are the economical answer to requirements of small and medium wineries. The CDCH-SR is to treat grapes in every processing state (must, apple cider, grapes, sparkling wine, wine or water). Due to its direct treatment of the medium, the CDCH-SR offers the most efficient way for cooling or heating of beverages.

The CDCH-SR chillers and heaters are available in sizes and capacities from 7 – 86 kW.

The mobile and flexible solution

CHARACTERISTICS

- Frigorific circuit with hermetic compressor and high efficiency counter flow evaporator

- Stainless steel chassis with wheels

- Minimum installation effort

- All parts that come in contact with the treated medium are made of stainless steel

- Temperature control by electronic thermostat with digital display

- Anti-freeze safety devices

- Control of an external pump by the SR’s control panel

- Low polluting refrigerant R 407 C Minimum / maximum ambient temperature: +5°C / +32°C

APPLICATIONS

- Direct cooling or heating of must at a clearing or at the beginning of fermentation

- Wine stabilizing to tartaric-crystals removal

- Biological reduction of acids

- Regulation of fermentation temperature

- Storage of wine until bottling

- Applications in the sparkling-wine or cider industry

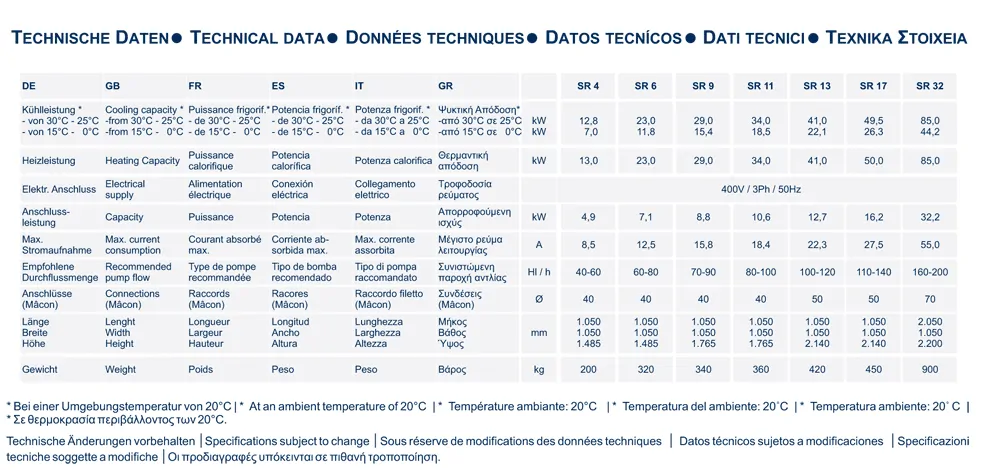

Technical Details

Available in seven models: SR 4 / 6 / 9 / 11 / 13 / 17 / 32

Cooling capacity: 12,8 – 85,0 KW (11,008 – 73,100kcal)

Heating capacity: 14,0 – 85,0 KW (12,040 – 73,100kcal)

Electrical connection: 400V/3Ph/50Hz (other options by inquiry)

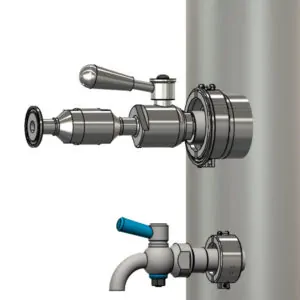

Connection (thread) type: Macon

Optional accessories :

Pipe Adapters

Adapters (connections) for integration of the CDCH cooling unit to your fixed pipe system are available on request.

Notice :

Prices of the chillers for USA electric standard are available on demand.

Reviews

There are no reviews yet.