Description

Price-effective can filling and capping set for the smallest craft breweries. The set consists of :

- The CANNULAR/RAPT semi-automatic can filler

- The CANNULAR PRO benchtop can closure machine.

CRCBF-1 : CANNULAR/RAPT Semi-automatic Can and Bottle Filler

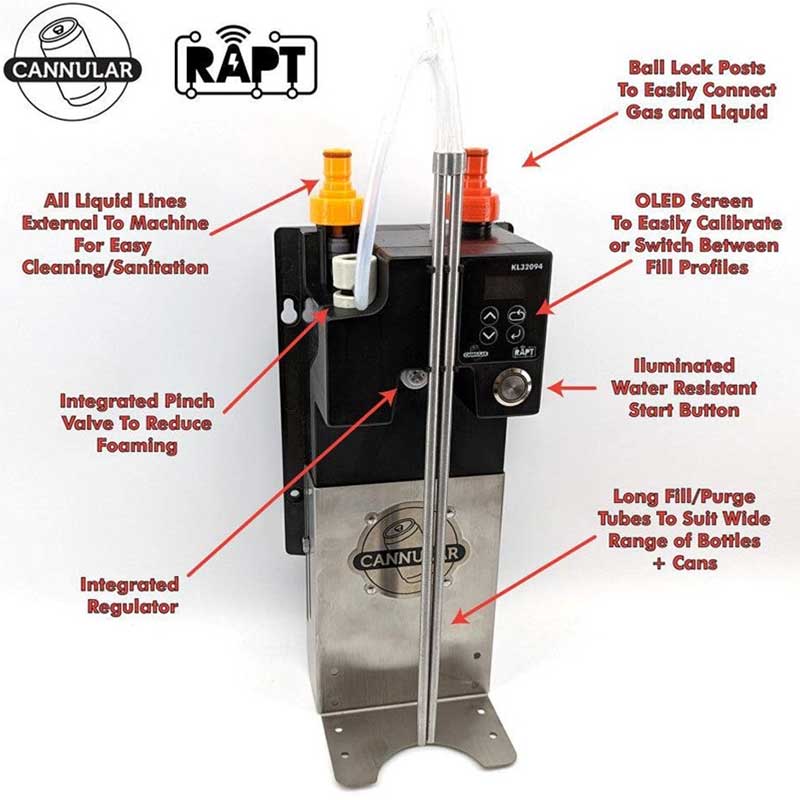

The CANNULAR/RAPT semi-automatic filler from Kegland is the ideal machine for filling beverages into cans and bottles. It is equipped with two adjustable stainless steel nozzles, which allow one nozzle to push the air out of the bottle/can with injected carbon dioxide and the other nozzle to fill the bottle/can exactly to the set level based on the measurements by the integrated pressure sensor.

The supply includes an AC 230V / DC 24V source for safe low-voltage power supply of the charger.

Fill any beverage into any bottle, can, jar or glass automatically with this Cannular Can and Bottle Filler.

Internet connection, RAPT compatibility . More easily instalable, sanitable and easier to use than similar filling machines of other competitors. For uncomparable lower price !!

Technical specifications:

- Power supply : Adapter Single Phase 230V / 50Hz to 24V

- Compact size of the machine

- Easy and quick installation and maintenance adjusting

- Made out of AISI 304 Stainless Steel and Plastic

- Tubes extend up to 15″ (381 mm) into can/bottles

- Total Height : 13″ (330 mm)

Attention : This machine is designed mainly for home non-commercial use or or use in the smallest brewpubs. It is not designed for continuous work many several hours a day in a big commercial brewery.

The set includes:

- Cannular Can and Bottle Filler x 1

- Stainless Steel Tubes – 15″ (381mm) x 2

- Plastic Ball Lock Caps (Red/Yellow) x 2

- Power Supply – 24V x 1 + Adapter Single Phase 230V / 50Hz to 24V

- Vinyl Tubing – 3/16″ (4.75mm) inner diameter X 1/4″ (6.35mm) outer diameter x 1′ (25.4mm)

- Silicone Tubing – 3/16″ (4.75mm) inner diameter X 5/16″ (7.93mm) outer diameter x 1′ (25.4mm)

Filling the cans :

Main advantages :

OLED Digital Display:

Allows easy calibration and monitoring of fill speed, number of cycles/fill, empty time and fill height. The display allows for immediate adjustments during filling.

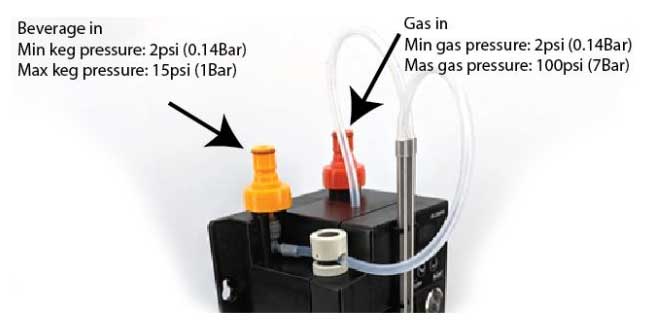

Integrated Ball Lock connectors:

Quick connection of beer and gas ball lock connectors.

Integrated Pinch valve:

Allows easy removal of the beer hose for cleaning.

Integrated regulator:

Allows you to connect a gas hose without the risk of damaging the device with a high-pressure gas source.

Multi-purpose design:

Long stainless steel filling jets and adjustable height make the device suitable for bottles up to 30 cm high and cans up to 27 cm high. It can be used for both still and sparkling drinks.

Filling profiles:

Possibility to save preset filling profiles for different containers. Synchronization with the RAPT.io portal allows easy sharing and creating of profiles on different devices.

WiFi connection:

Monitors output capacity in cans per minute (CPM), filling speed and temperature (with external probe). Records information to monitor device and employee performance.

On-Wall Mounted Design:

Allows for easy wall mounting, making it easy to fill cans and bottles from the bottom of the unit. Especially designed for quick installation and to be simply used in restaurants, pubs, outdoor drink stalls etc.

Quick start manual

Quick start manual to download is here

CSM-SA1 : CANNULAR PRO – the compact semi-automatic can seamer

The Cannular Pro is one of the most compact and easy to use benchtop can closure machines around. A single operator can seam/seal the cans in under 5 seconds meaning this compact machine is suitable for small breweries or brewpubs doing small production runs.

Beer in cans has some important advantages as opposed to beer in bottles: less risk of oxidation and 100% protected from light, so no lightstruck off-flavour due to UV rays penetrating the beer.

Beer in cans has some important advantages as opposed to beer in bottles: less risk of oxidation and 100% protected from light, so no lightstruck off-flavour due to UV rays penetrating the beer.

Thanks to its favourable price-quality ratio, the Cannular Pro is the choice for both advanced hobby brewers as well as commercial micro breweries. Every can is claosed in a few seconds already. What’s more, cans offer endless possibilities for personalisation. The compact Cannular Pro machine is also extremely easy to use.

Technical parameters :

Voltage: 24V (12amps)

Power: 250W

Rated Speed : 3300 RPM

Gearbox Ratio: 9.8 : 1

Power Plug: Anderson Type 40A

Can Height: 45-170mm

Can Diameter: 35-75mm

Type of the can end : Standard CDL202 connection

Dimensions (L x W x H): 41 x 25 x 54 cm

The machine is suitable to closing of standard beverage aluminium cans with volume of 0.33L or 0.50L, with can ends CDL202. Other formats of can ends are not supported. Delivered with head for EU cans 0.33L and 0.50L.

Compatible cans :

Without the sleeve :

ACN33N : Aluminium Can For Drinks 330 ml STANDARD, silver, with CDL 202 lid (small aperture)

ACN33B : Aluminium Can For Drinks 330 ml STANDARD, black, with CDL 202 lid (small aperture)

ACN50N : Aluminium Can For Drinks 500 ml STANDARD, silver, with CDL 202 lid (small aperture)

ACN50B : Aluminium Can For Drinks 500 ml STANDARD, black, with CDL 202 lid (small aperture)

With the sleeve :

ACS33N : Aluminium Can For Drinks 330 ml STANDARD, silver, sleeved, with CDL 202 lid (small aperture)

ACS50N : Aluminium Can For Drinks 500 ml STANDARD, silver, sleeved, with CDL 202 lid (small aperture)

Uncompatible cans :

All other can formats.

ATTENTION:

Attention : This machine is designed for small breweries or brewpubs doing small production runs. It is not designed for continuous work many several hours a day in a big commercial brewery.

We are not responsible for incompatibility with non-standard cans. When you use other cans, for example with Visy/CDLE 202 ends from the Ardagh Group, you will need the separately available Visy chuck.

Please note:

When you receive your Cannular the rollers have been set and tested at the factory. They should not need adjustment for 100,000 cans. The table, however, comes unadjusted and getting it set up correctly is very important to getting a proper seal of cans. Producer´s test show that a 0.4 mm (0.015″) actual overlap is all that is needed to seal to 90 PSI (6.2 bar). The proper table tension takes a little practice and expect to waste a few cans getting it dialled in.

The Cannular Pro machine is delivered with :

The original power adapter 24 V

The Cannular Pro can closing machine is delivered with an original power adapter (1phase 230V/50Hz to 24 V) and . This power adapter is optimised for the Cannular Pro and is sufficiently powerful and safe to use in wet environments, without the risk of electrocution (only safety voltage 24 V is in output).

Videos :

How to set up the CANNULAR/RAPT can filling machine before the first use :

First look on the CANNULAR/RAPT :

How to use the CANNULAR PRO can capping machine :