Description

Price-effective can filling and capping set for the small-size professional breweries. Output capacity of 600-800 cans per hour.

The set consists of :

- 1pc of USAF4-800 : Semi-automatic counter-pressure bottle/cans filling machine (up to 800 pcs per hour).

- 2pcs of CSM-SA3 : ProKAN – the compact semi-automatic can seamer.

Recommended number of operators : 3 humans

- One operator – washing and loading empty cans

- Two operators – unloading and closing full cans

USAF4-800 : Semi-automatic counter-pressure bottle/cans filling machine (up to 800 pcs per hour)

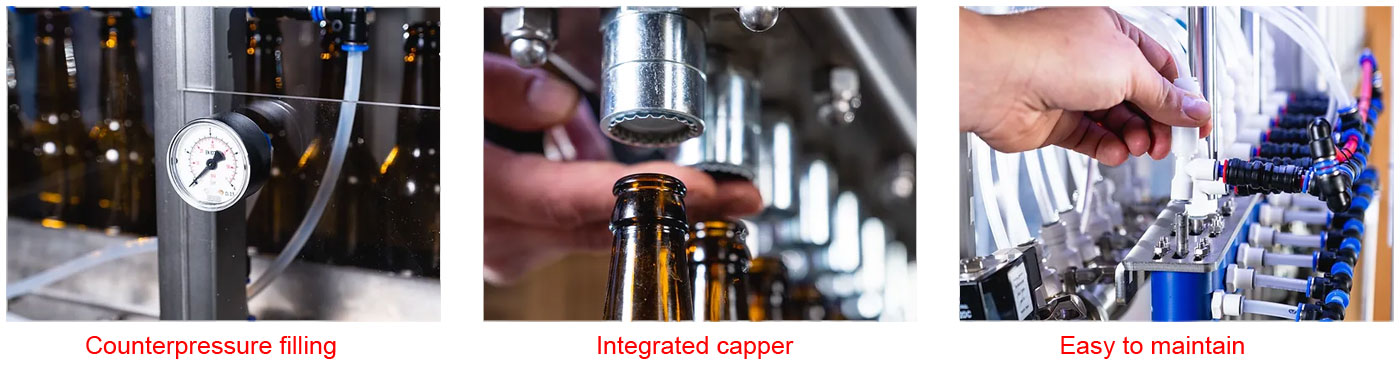

Universal semi-automatic four-head filling machine for glass bottles and cans with the filling capacity up to 800 containers per hour. The universal counter-pressure filling machine is ideally suited for beverage producers who do not want to be tied to one type of bottle or can. The configuration of the isobarical filling machine can be changed between different bottle sizes in 5 minutes and can be converted from filling the bottles to cans in 20 min.

We are an authorized sales partner of the European producer.

Technical specifications :

- Dimensions: 2150 x 800 x 2300mm (W x D x H)

- Weight: 210 KG

- Stainless steel frame

- Stainless valves with EPDM seal

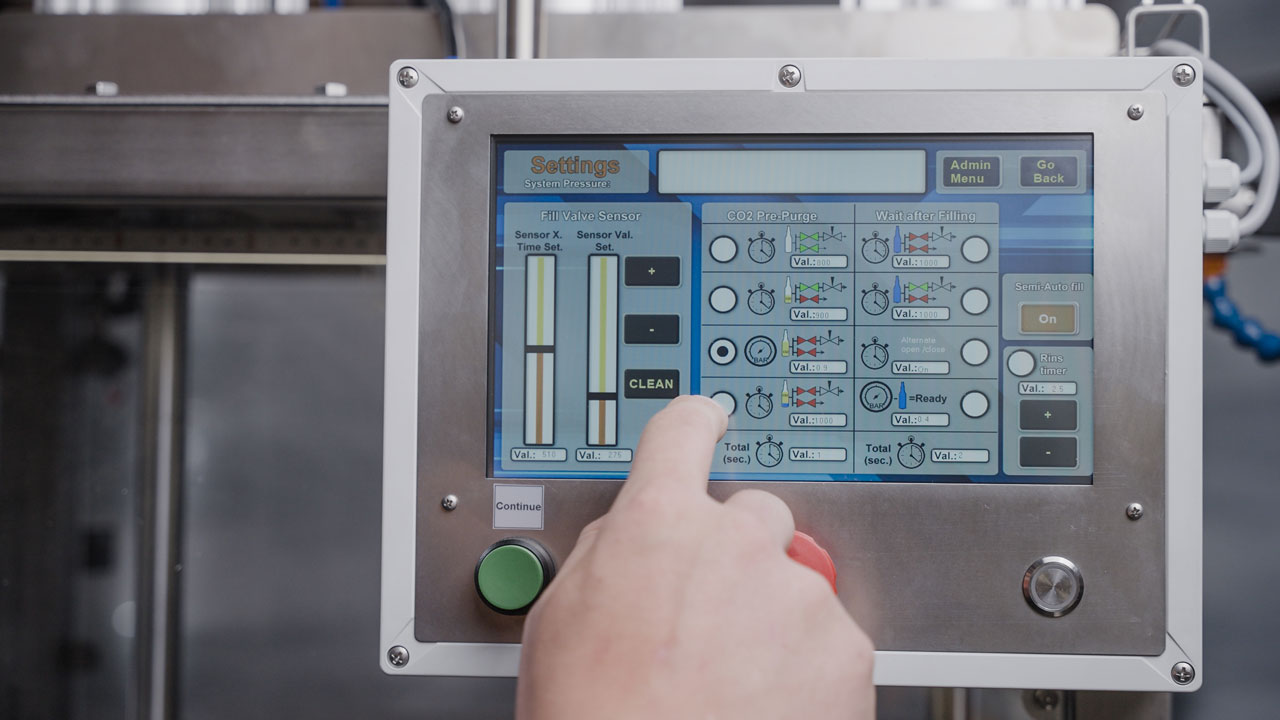

- 10” waterproof touchscreen

- The Arduino PRO PLC controller with lifetime updates.

- Power supply : 110 ~ 230V / 50-60Hz @ 6A maximal input power

- Beverage input : DIN 32676 (TriClamp) 1,5” / DN40

- Compressed air input : 8mm hose (John Guest quick coupler) @ pressure 8 bar max

- C02 input: 8mm hose (John Guest quick coupler)

- Number of the bottle/can rinsing positions : 12

- Number of the bottle/can filling heads : 4

- Number of the bottle/can capping heads : 4

- Output capacity with one operator : 250-500 bottles/cans per hour (depends on foamicity of a beverage)

- Output capacity with two operators : 400-800 bottles/cans per hour (depends on foamicity of a beverage)

How the machine works :

The universal filler comes standardly with a manual rinser for 12 bottles/cans. Filling starts with this rinser. A user places manually bottles/cans in the rack and presses the start button. Water or chemical sanitizer sprays into the bottles/cans for the set time. The pump for the water or chemical sanitizer is not included in the machine.

The bottles/cans are manually then placed in special trays which correspond in size to the diameter of the bottle / can. The trays bring the bottles and cans under the filling heads and then under the capping heads.

At the end the bottles/cans are slid towards the user after which the bottles and cans can be manually removed from the trays.

Optional equipment and services :

| Item code : | Description : | Price : |

| USAF4-CFH | Can filling set (parts for the cleaning and the filling the cans). A machine for seaming the cans with lids is not included in this set. | € 2200,- |

| USAF4-FFS | The Carbon Dioxide Fast Flush System (we recommend it to extending the shelf life of the drink) | € 825,- |

| USAF4-LWH | Large wheels (outdoor suitable) | € 550,- |

| USAF4-OCF | Set of replaceable parts for each next bottle/can format (a set for one bottle/can format is in basic price) | € 600,- |

| USAF4-OCC | Bottle/can output conveyor 500mm (necessary for connection with an input of another machine – for example a bottle labelling machine) | € 1500,- |

| USAF4-SEK | Service kit (basic set of recommended spare parts – cables, sensors and one filling head) | € 385,- |

| USAF4-INS | Installation service on place (available only in Europe) – this service is not necessary because we provide our remote support for the installation by a customer | € 900,- / day |

| USAF4-TRA | Packing and transport (valid only for transport to EU countries) – price depends on a destination and a required configuration | € 800-2000,- |

Delivery time : 3-4 months after the order and the 1st after down payment.

Warranty: 2 years full warranty – excluding wear parts.

Machines to closure the cans with lids :

CSM-SA1 : CANNULAR PRO – the compact semi-automatic can seamer (for the smallest breweries)

The Cannular Pro is one of the most compact and easy to use benchtop can closure machines around. A single operator can seam/seal the cans in under 5 seconds meaning this compact machine is suitable for small breweries or brewpubs doing small production runs.

Attention : This machine is not suitable with the B64 can ends.

UCS-300 : CAN ULTRA SEAMER – Compact manual/electric can capping machine (250-300 cans per hour)

The CAN ULTRA SEAMER is a machine designed to manual capping beverage aluminium cans after filling. The machine is compatible with CDL or B64 type aluminium can lids (depending on the model).

The CAN ULTRA SEAMER supports standard sizes (330ml and 500ml) and the SLEEK (330ml). The machine is operated manually using levers, rotation of a can is ensured electrically. That offers great control for each can seaming cycle.

CSM-SA3 : ProKAN – the compact semi-automatic can seamer (for professional use in small breweries)

The ProKAN is the smallest and lightest automatic can seaming machine in the world designed for professional use in the beverage industry. Fully automatic seaming function for can sizes: CDL/B64 200, 200S, 250, 250S, 330, 375, 500, 550 a 1000 ml.

Fully automatic seaming function for can sizes: CDL/B64 200, 200S, 250, 250S, 330, 375, 500, 550 a 1000 ml