Description

Manual rinsing and blowing machine for glass bottles

The bottle rinsing and blowing machine allows to rinse and to blow glass bottles and jars from inside, with sterile air and drinkable water. Two bottle rinsing positions, two bottle blowing positions.

Can be used with bottles of various shapes – range of volumes from 0.2 litres up to 2 litres.

Maximal bottle diameter: 120 mm.

Minimal bottle diameter: 30 mm.

Maximal bottle height: 400 mm.

Minimal bottle height: 180 mm.

CHARACTERISTICS:

- Dimensions: width 51 cm., length 58 cm., height 65 cm., weight 18 kg

- Stainless steel frame

- Water rinsing station with 2 nozzles

- Air-blowing station with 2 nozzles

- Water filtering assembly with 0,35 microns cartridge

- Filtering assembly for the compressed air

- No need of electric power connection

- Compressed air (or nitrogen) supply at pressure of 2 bar is required

- No need of change parts for standard bottles

- Productivity … depending on the operator experiences : 200 up to 600 bottles/hour

- Water consumption … water under pressure 2bar = 0.2 litres/bottle ( The water pump is not included).

- Air consumption … under pressure 2bar = 1 liter/bottle ( The air compressor is not included).

- Made to EC standards.

How the machine works :

Connection on media

The machine must be connected to a pure water supply with a pressure of 2-4 bar and to a compressed air (or nitrogen) supply with a pressure of 2 bar.

Water connection possible to normal water pipe, or on centrifugal pump can be used.

Used water drains under the machine to the floors.

Washing the bottles:

The operator places two bottles upside down on the two rinsing nozzles in the middle of the workbench and presses the bottles against the nozzles to start rinsing the bottles with pressure water. The bottle is rinsed as long as pressure is applied to the bottle.

Drying the bottles :

The operator places two bottles upside down on the two blow nozzles in the center of the workbench and presses the bottle against the nozzles to start drying the bottles with pressure air (or nitrogen). The bottle is blowed as long as pressure is applied to the bottle.

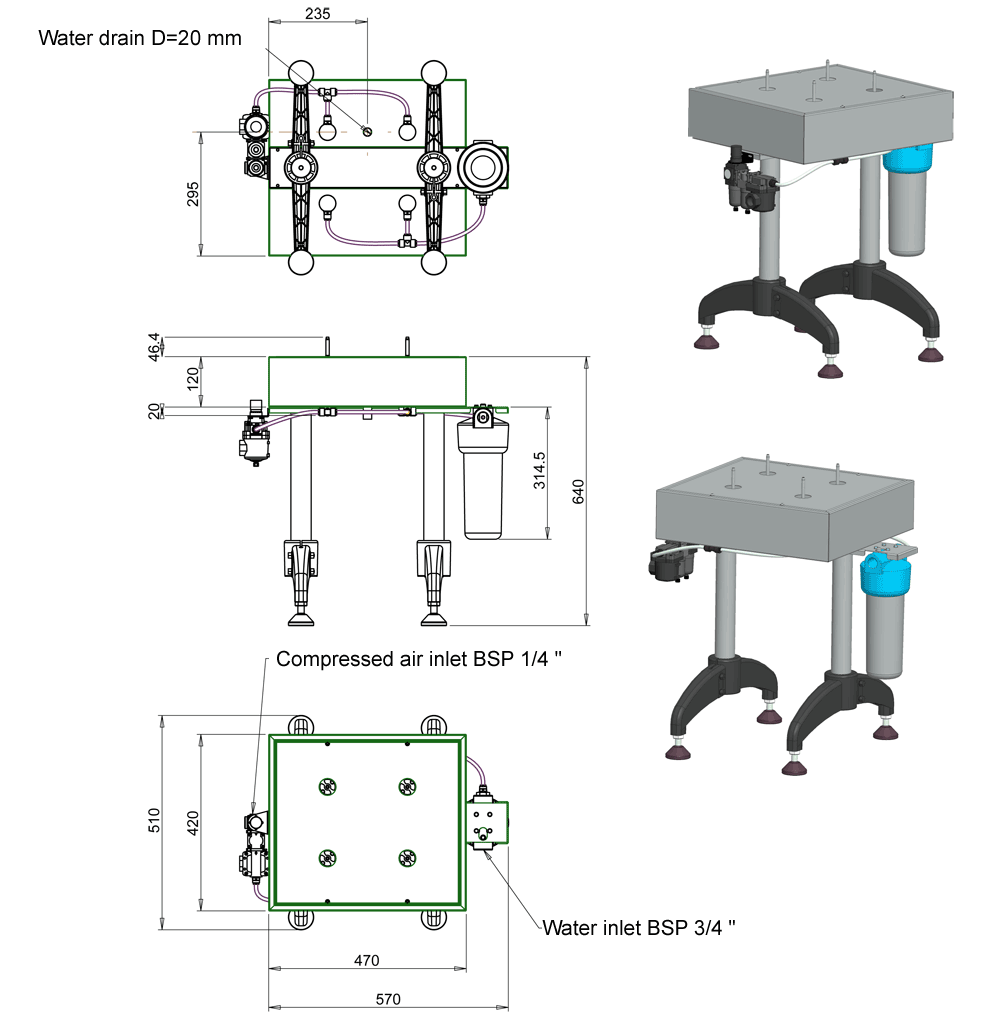

DESCRIPTION AND DIMENSIONS :

Frequently asked questions :

Can this machine also be used for used bottles? No, the BWB-M600 machine is not intended for washing used bottles – for this purpose we recommend purchasing a special washing machine for used dirty bottles.

What is the rinsing time of the bottles? It depends on how much are the bottles dirty. We recommend 3-6 seconds for each bottle if you rinse clean bottles.

How many bottles are sterilized at one time? The BWB-M600 has 4 nozzles: The user rinses 2 bottles at two primary nozzles, then he can let them dry the bottles inside with the secondary two nozzles with pressurized sterile air.

What are the recommended parameters of the air compressor to be connected to the machine? The machine is not equipped with an integrated air compressor. You have to connect an external oil-free air compressor. Pressure of air must be reduced to pressure 3-4 bar. We recommend to equippe the air compressore with at least 3-stage air filter including a carbon filter.

Pressure requirement 2.5 – 3.0 bars. The recommended oil-free air compressor would be with minimal power of 0.75 HP (0.65 kW) / 24L-50L.

How is the device controlled? The BWB-M600 has no commands. The machine rinses the bottles only when the user presses on the nozzles with the bottles neck.

Is the machine chemicaly cleanable ? Yes, the machine (excluding the air filter) can be sanitized with 2% lye and 2% acid 60°C.

Reviews

There are no reviews yet.