Description

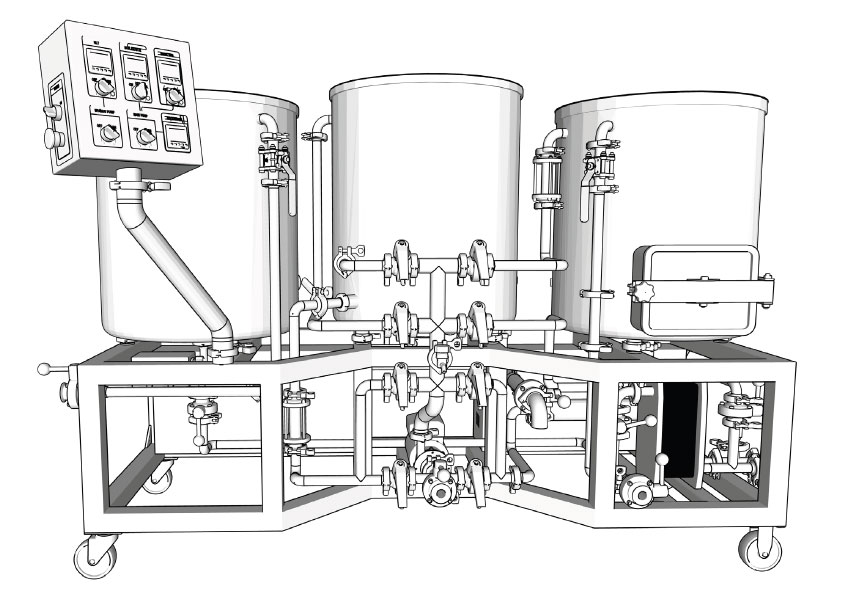

BREWTRION BT-100 is a compact wort brew machine

with production capacity 117 liters per batch and three special tanks

The BREWTRION BT-100 is the smallest “professional” brewery that is equipped with all what you need to effective beer production in small amount.

Although the BT-100 is a small machine for the production of wort, it, like large brewhouses, contains three separate special containers:

- Mashing tank

- Hot water tank (HLT)

- Wort boiling tank – wort kettle

Heating and temperature control system

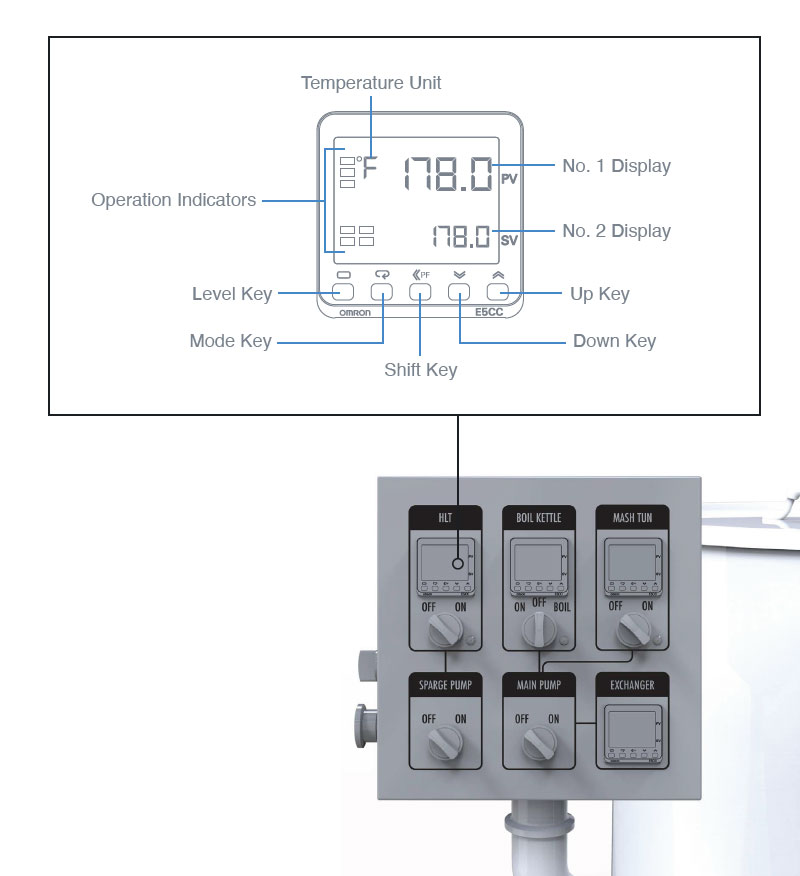

The heating, measure and control system based on simple computer enable the brewer precise control over each step, temperature and phase of the beer production process. At the core of that objective are independent heating elements for each vessel, allowing the user to choose the perfect temperatures for each step and to sustain the optimal temperature in the boil tanks. The computer always precisiously regulates temperature via the proportional heat control system.

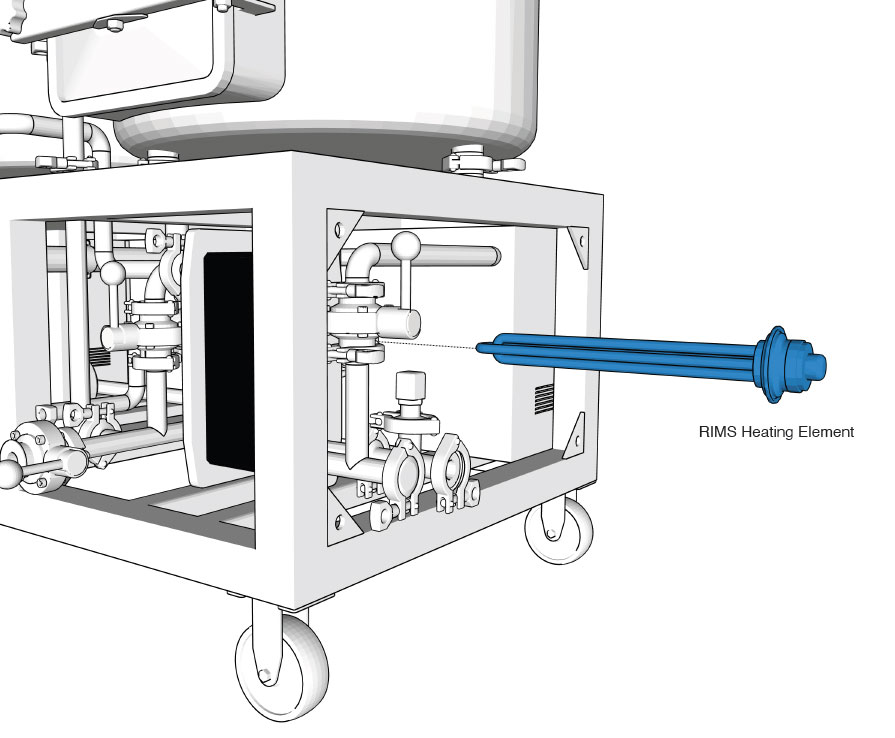

Patented internal heater

The brewhouse has a custom center-mounted element which serves to efficient wort production. Convection forces the wort up from the bottom of the kettle through the central tube, where the wort is then quickly heated and dispersed. Yielding is increased with wort circulation, volatile compounds boiling off more efficiently, and greater hops utilization.

Patented valve tree and central frame

Keeping the brewer´s experiences in mind, the valve tree was designed, which is the key design feature of this system. Placing all the critical process valves in one central location makes every brew day intuitive and enjoyable. The control panel is a scaled down version of control panels from the larger professional brewhouses. The entire brewhouse is built upon a network of welded and fully sanitizabled TriClamp connections. The integral stainless steel piping matched with a fully welded frame connects all parts of the unprecedented compact brewhouse.

Milled false bottom & Grains output door

In none of our professional brewhouses will you find a punched false bottom. This is valid for this small brewhouse as well. The precisious milled sieve (false bottom) allows for a faster wort filtration, clearer run-off, and mitigates the risk of a stuck malt sparge. The grain-output door above the sieve allows for quick and easy clean-up of the filtration tank. No more hassle scooping grain from the top of a mashing tank.

Key Features:

- Fully sanitable hard piping with the patented valve tree

- Milled filtration sieve (false bottom) with grain-output door for easy removal of used grains

- Wort boiling tank with central wort pick-up tube to drain the clear wort after boiling

- Electric heating elements for heated tank, temperature measure and control system

- On frame mounted sanitary pumps and plate heat exchanger for wort cooling

Other features:

- 3 heating elements (wort boiling tank, mashing tank and Recirculating infusion mash system)

- Tangential whirlpool inlet

- Stainless steel pipping throughout with valve tree

- Perlick sampling valve

- Detachable CIP arm

- Combo inlet for water

- Proportional heating control with Omron PID Controllers combined with dynamic voltage adjustability

- Main control panel for all operations with heated tanks and heat exchanger temperature read-outs

- Pump control switches

- Dual cart mounted electrical service panels

- Fully assembled compact machine, ready to brewing

Specifications:

- Final batch volume … 100-117 l

- Foam space … 20% height of the tanks

- Wall thickness … 2.5 mm

- Inner surface finish … 2B ; matte appearance and bright defect-free finish

- Process piping … 1”

- Butterfly valves, pipe sight glass, and TC gaskets … 1”

- Heat exchanger surface area … 1 m²

- Measurements (w x h x d): 74″ x 52″ x 40″ (1,980 x 1,321 x 1,016 m)

- Power supply : 3ph 380-400 V / 32 A

Control panel :

The BREWTRION BT-100 Brewhouse is controlled by way of the centralized control panel located nearest the hot liquid tank.

The control panel allows the operator to:

• Monitoring the vessel temperatures

• Monitoring the temperature of wort exiting the heat exchanger

• Toggling the heating elements ON/OFF

• Programming the temperature set values for switching heating elements ON/OFF

• Toggling the pumps ON/OFF

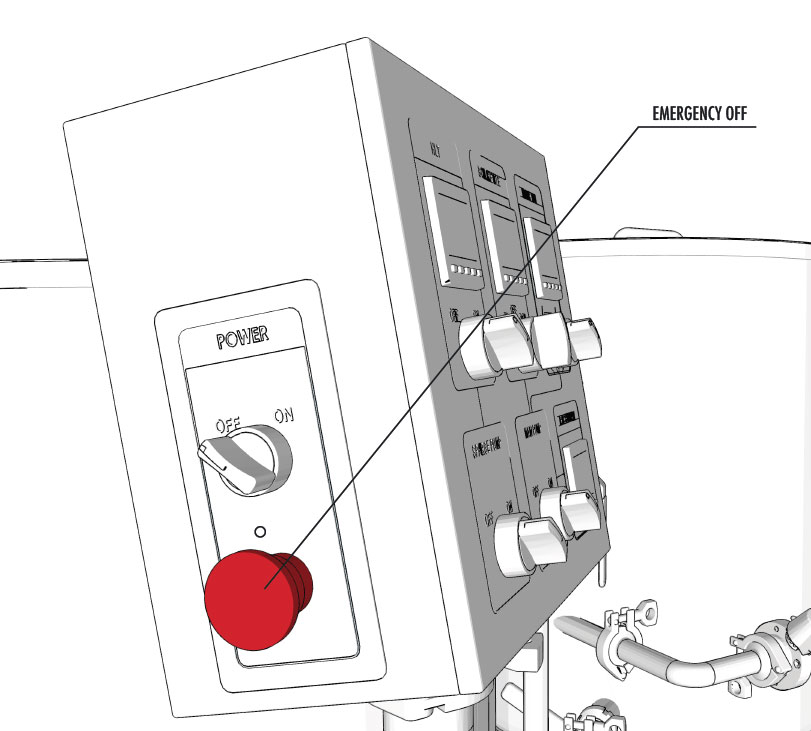

The switch for toggling the control panel ON/OFF is located on the left side of the control panel box.

Additionally, an Emergency Stop (E-Stop) switch is located just beneath the main power switch. In the event of an emergency, press the E-Stop in to quickly kill power to the entire system. Twist the E-Stop clockwise to release.

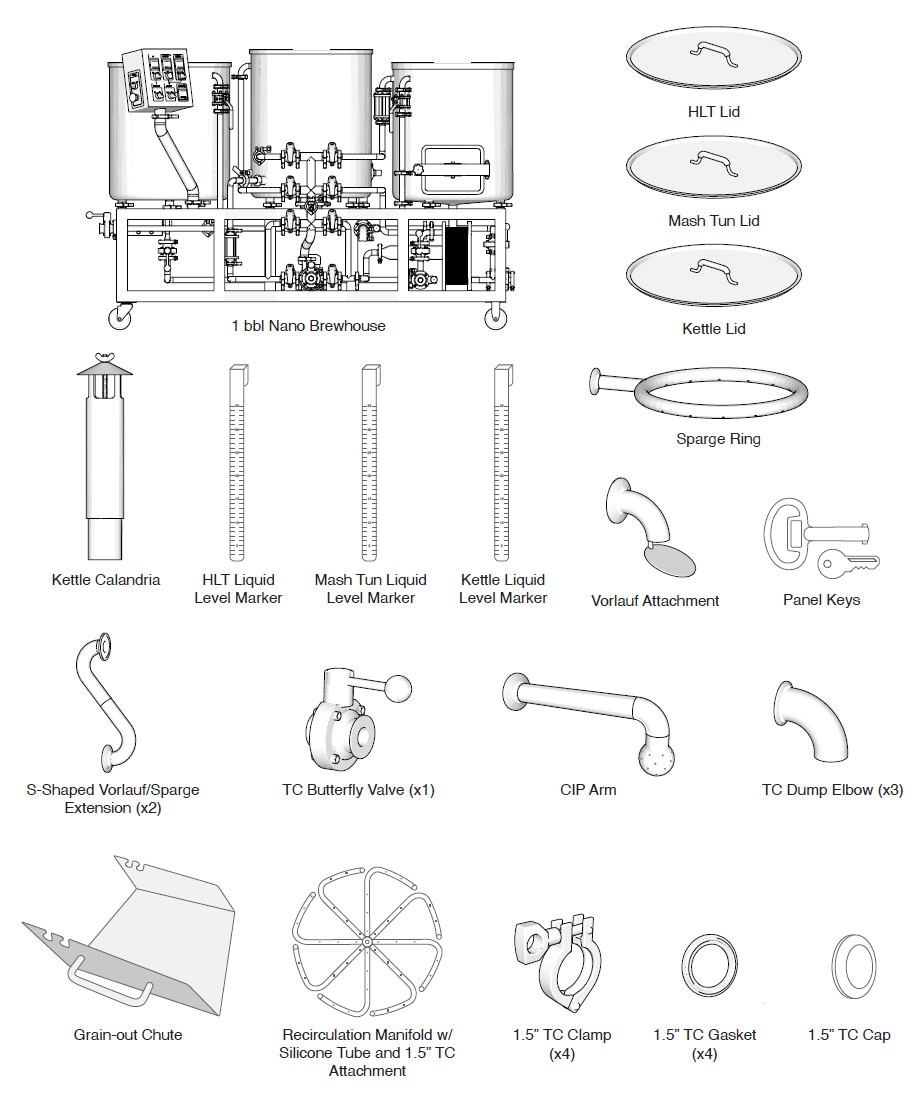

What is in the crate :

This product is made in China, designed and certified in USA. This version is designed and certified especially for European market. Will be delivered with the CE certificate.

Warranty 6 months. On-site services are not included.

Reviews

There are no reviews yet.