Description

Microbrewery BREWMASTER BSB-502-CF750W with the brewhouse Brewmaster BM-500 and 4 pcs of cylindrical-conical tanks allows the production capacity up to 75.000 liters of top fermented beer or 45.000 liters of bottom fermented beer per year using only an infusion brewing method. A simple plug&brew design allows an assembling all microbrewery by customer and easy brewing. Patented brewhouse with PC support produces 500 liters of beer wort per one batch. No requirements for building reconstruction.

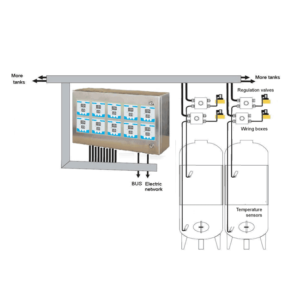

Manual or automatic control (if use the CellarMasterSW pack) of the brewing process, media and tanks with PLC controllers and PC Windows support.

Technical parameters :

Production capacity – daily :

- 500 liters of beer wort per day – one batch within 12 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 1000 liters of beer wort per day – two batches within 24 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 1500 liters of beer wort per day – three batches within 24 hours – source raw materials are malt extract, hops, drinking water and brewer’s yeast

Production capacity – yearly :

- Beer produced using the on surface fermentation method ……… 37.500 liters per year

- Beer produced using the under bottom fermentation method …. 22.500 liters per year

Raw material :

- Classical raw materials : Malt + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

- Beer concentrates : Malt extract + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

- CO2 in pressure bottles (cylindres)

- Washing and sanitizing agents

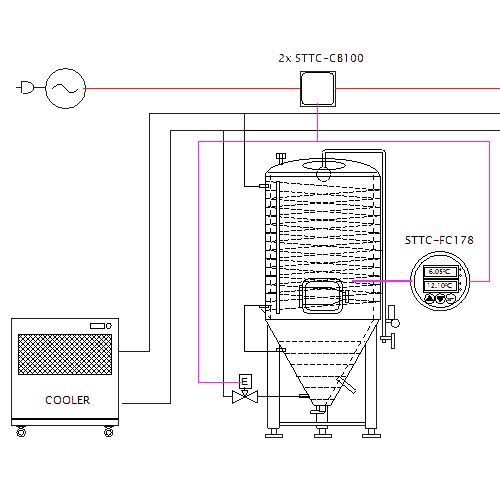

Control system :

- Brewhouse – boiling equipment :

- valves and claps – manual or automatic control with PCL support

- temperatures – manual or automatic control with PCL support

- motors, pumps – manual or automatic control with PCL support

- timing – manual or automatic control with PCL support

- Tanks – fermentation, maturation, bright beer :

- temperatures – manual control with PCL support

- timing – manual control

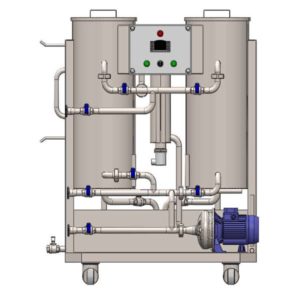

- Media – hot water, ice water, wort cooling, glycol tank :

- temperatures – manual control

- timing – manual control

Required space for building :

- Floor area min : 20 m2

- Room height min : 2.8 m

Electrical connection :

- Electrical socket : 400V 3ph / 50 Hz

- Electrical consumption : 32 kW

Heating system – brewhouse :

- Electric heating elements

Cooling system :

- Cooling of wort : Drink Cold water directly in the brewhouse and CCT tanks

- Cooling of tanks : Ice cooling water (optionally glycol)

BREWING PROCESS :

PROGRAMMING – Depending on the recipe, the BM-200 brewing system is programmed with the appropriate brewing times. The brewing process starts by switching over to automatic brewing. The control system guides the user through the various steps and executes the four brewing phases automatical

MASHING – Depending on the recipe and method, water is poured in and heated up to 38 °C. Then the malt pipe with the sieve inserts is put in position. Malt is poured between the sieve inserts. The malt pipe is fixed with bracket and drawbar.

MASHING / BREWING – The pump switches on. Due to the resulting water / wort circulation, he starch is extracted from the malt. The four brewing phases

are executed as programmed, for example as follows:

- Protein rest 55 °C, approximately 5 min

- Maltoserast 63 °C, approximately 30 min

- Saccrification rest 72 °C, approximately 20 min

- Saccrification rest 78 °C, approximately 10 min

LAUTERING – At the end of the four phases an acoustic signal sounds. The subsequent lautering process is quickly executed by simply removing the malt pipe. In the case of the BM-200 this is done by means of the lifting device. Allow to drain a few minutes and remove – if necessary, pour water through the malt (sparge) to achieve a better yield.

BOILING HOPS – With the lid open, the wort is boiled for 80 minutes with hops being added several times. The evaporated water is to be replaced by adding

fresh brewing water. The original gravity can be finally adjusted by adding or leaving out water. The drawbar on the Nanobeer serves as a level meter. At the end of the boiling phase, an acoustic signal sounds again.

COOLING WORT – After boiling, the wort is cooled as soon as possible to the fermentation temperature by a special wort cooler directly inside the brewhouse.

FERMENTATION / MATURATION PROCESS

– Immediately after the boiling of the wort the temperature of the wort is brought to the level of the fermentation temperature by a wort cooler or by a double jacket; the wort is also mixed with yeast and fermented in a suitably large tank (accessory).

CONSUMING – After several weeks of storage in bottles or in a maturing barrel (accessory), the well cooled beer can be consumed.

Recommended accessories :

1. BM-510 Additional cooker for the BREWMASTER BM-500

The additional cooker for use with the BREWMASTER BM-500 brewhouse. Both devices BM-500 and BM-510 are necessary for production of two batches of beer wort per one day. It is available for mashing during the second brew. The BM-510 cooker is fully realized in Stain steel AISI 304.

2. BMTM-500 Thermo sleeve for the BREWMASTER BM-500

BMTM-500 Thermo sleeve is a recommended accessory for the BREWMASTER BM-500 brewhouse and BM-510 additional kettle. This is used as jacket for insulation to speed up heating and saving energy. The thermo sleeve is also very recommended for use when is requirement for more than one brew cycle per day .

3. SBT2 – Set of brewing tools for Brewmaster breweries

Set of brewing tools for BREWMASTER and NANOBEER small breweries. This set includes :

- Hydrometer and support plastic cylinder – The hydrometer is basic measurement tool for measuring original gravity of wort and beer – this is important for calculation of the percentage of alcohol in the beer, cider or wine. This set includes a noncalibrated hydrometer with temperature correction and support plastic cylinder.

- Large malt shovel – for handy removing malt from the brewhouse after lautering process.

- Cleaning set – set of tools for easy cleaning of the brewhouse, tanks and hoses.

- Malt barrel – the plastic vessel for easy collecting of the milled malt under the malt mill

- Wooden mash paddle – for handy occasional agitation of wort during the brewing process

Reviews

There are no reviews yet.