Description

Price-effective set of equipment for bottle rinsing, drying, bottle filling, bottle capping, bottle labelling, for the smallest craft breweries with output capacity of up to 250 bottles per hour. This set is suitable to filling of non-carbonated beer into glass bottles after fermenting (beer natural carbonation takes place in the bottles stored in a cold place after the filling). This set is not designed to bottling of carbonated beer.

The set consists of :

- The FBW-12B fast bottle washer with 12 positions

- The FBD-12B fast bottle dryer with 2×12 positions

- The CANNULAR/RAPT semi-automatic can filler

- The CMB-M2 manual capping mechanism for bottles

- The BLM-PE180G Manual bottle labeler for round bottles

FBW-12B : Fast bottle washer with 12 positions

FBW-12B is an easy-use high-capacity bottle cleaning and sanitizing equipment with 12 positions for glass bottles that will cut your bottle washing time in half in comparation with manual bottle washing!

FBW-12B is an easy-use high-capacity bottle cleaning and sanitizing equipment with 12 positions for glass bottles that will cut your bottle washing time in half in comparation with manual bottle washing!

Already no scrubbing, no mess, no pile of empty bottles to wash and sanitize by hand ever again!

Cleaning and sanitizing your bottles has never been quicker nor easier. Load your bottles in to the rack , turn on the washer and let the powerful pump do all the work.

Attention : FBD-12B Fast bottle dryer with 2×12 positions is not included (recommended accessory)

CHARACTERISTICS:

- Engineered from high-density plastic

- Powerful CE certified pump

- Maximum water temperature 41°C

- Easy to assemble using just a Phillips head screwdriver (cross head)

- Fits a wide range of bottles (330-750 ml)

- Cleans/sanitizes 12 bottles at once

- Fast bottle dryer with 12/24 positions as optional equipment

- Maximal diameter of the bottles is 85 mm (distance between the axes of the nozzles is 82 mm)

You will need a rubber or plastic tub to place the fast bottle washer in; recommended size = 50 x 40 x 20 cm (the tub is not included)

Note: It is important to follow the installation instructions in the manual very carefully; product damage due to incorrect assembly will not be compensated.

FBD-12B : Fast bottle dryer with 2×12 positions

FBD-12B is an easy-use bottle rack for fast gravity drying of water cleaned bottles. It allows to dry up to 48pcs bottles in the same time. This is a recommended accessory for the FBW-12B Fast bottle washer with 12 positions.

This set contains 1 drip tray and 2 racks (each for 4×3=12 bottles with diameter up to 85mm).

This system can also be used for larger bottles, such as Champagne (D>85mm). In that case one rack can hold about 8 bottles.

- Suitable for 2x4x3=24 bottles up to 85 mm wide

- Stackable up to 6 layers

- Dishwasher safe

Easy packing the bottles into carton boxes :

CRCBF-1 : CANNULAR/RAPT Semi-automatic bottle filler

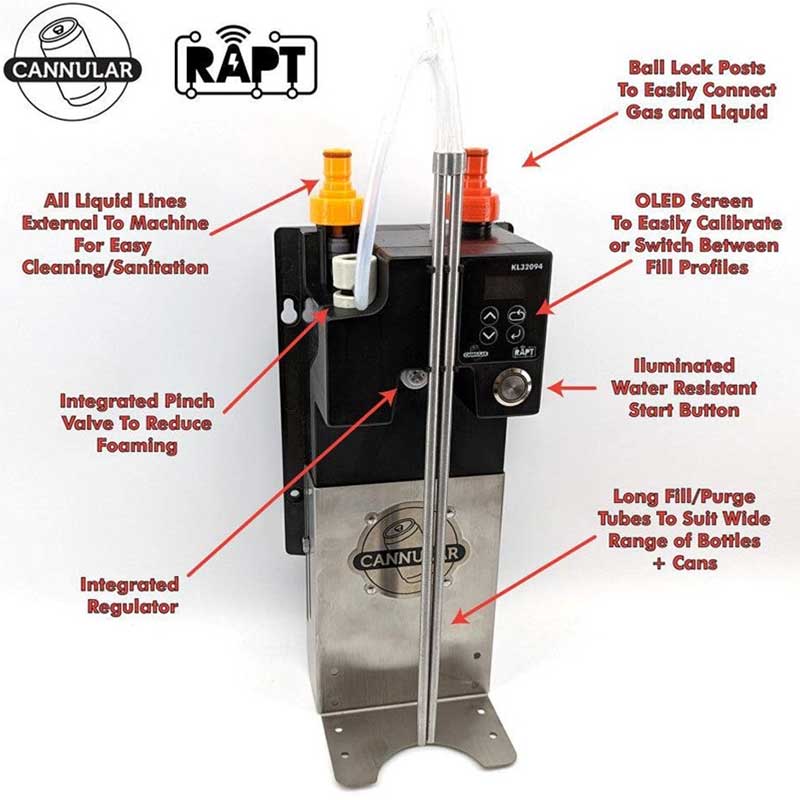

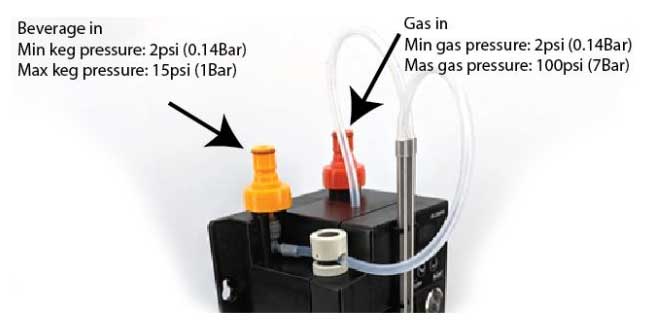

The CANNULAR/RAPT semi-automatic filler from Kegland is the ideal machine for filling beverages into cans and bottles. It is equipped with two adjustable stainless steel nozzles, which allow one nozzle to push the air out of the bottle/can with injected carbon dioxide and the other nozzle to fill the bottle/can exactly to the set level based on the measurements by the integrated pressure sensor.

The supply includes an AC 230V / DC 24V source for safe low-voltage power supply of the charger.

Fill any beverage into any bottle, can, jar or glass automatically with this Cannular Can and Bottle Filler.

Internet connection, RAPT compatibility . More easily instalable, sanitable and easier to use than similar filling machines of other competitors. For uncomparable lower price !!

Technical specifications:

- Power supply : Adapter Single Phase 230V / 50Hz to 24V

- Compact size of the machine

- Easy and quick installation and maintenance adjusting

- Made out of AISI 304 Stainless Steel and Plastic

- Tubes extend up to 15″ (381 mm) into can/bottles

- Total Height : 13″ (330 mm)

Attention : This machine is designed mainly for home non-commercial use or or use in the smallest brewpubs. It is not designed for continuous work many several hours a day in a big commercial brewery.

The set includes:

- Cannular Can and Bottle Filler x 1

- Stainless Steel Tubes – 15″ (381mm) x 2

- Plastic Ball Lock Caps (Red/Yellow) x 2

- Power Supply – 24V x 1 + Adapter Single Phase 230V / 50Hz to 24V

- Vinyl Tubing – 3/16″ (4.75mm) inner diameter X 1/4″ (6.35mm) outer diameter x 1′ (25.4mm)

- Silicone Tubing – 3/16″ (4.75mm) inner diameter X 5/16″ (7.93mm) outer diameter x 1′ (25.4mm)

Filling the cans :

Main advantages :

OLED Digital Display:

Allows easy calibration and monitoring of fill speed, number of cycles/fill, empty time and fill height. The display allows for immediate adjustments during filling.

Integrated Ball Lock connectors:

Quick connection of beer and gas ball lock connectors.

Integrated Pinch valve:

Allows easy removal of the beer hose for cleaning.

Integrated regulator:

Allows you to connect a gas hose without the risk of damaging the device with a high-pressure gas source.

Multi-purpose design:

Long stainless steel filling jets and adjustable height make the device suitable for bottles up to 30 cm high and cans up to 27 cm high. It can be used for both still and sparkling drinks.

Filling profiles:

Possibility to save preset filling profiles for different containers. Synchronization with the RAPT.io portal allows easy sharing and creating of profiles on different devices.

WiFi connection:

Monitors output capacity in cans per minute (CPM), filling speed and temperature (with external probe). Records information to monitor device and employee performance.

On-Wall Mounted Design:

Allows for easy wall mounting, making it easy to fill cans and bottles from the bottom of the unit. Especially designed for quick installation and to be simply used in restaurants, pubs, outdoor drink stalls etc.

Quick start manual

Quick start manual to download is here

Manual bottle capping machine (with a single head) for crown caps

Heavy and sturdy tabletop model of the bottle capping mechanism for continuous use. Manually controlled. Included two heads for crown caps with diameters 29 mm and 26 mm.

• Simple manual mechanism to closing of bottles by crown caps

• Cap tens of bottles per hour

• A massive steel body

This heavy duty commercial manual capping mechanism is ideal when you have not a pressure air supply and a need to close a small quantity of bottles of the same height.

CHARACTERISTICS:

This manual capping mechanism enables you to seal bottles in an ergonomic way. The CMB-M2 model excels in its price range, thanks to the following essential features:

- Enlarged stamp around the magnet reduces risk of dimples in the caps

- Specially designed nickel-treated capping head ensures perfect crimp of the crown cap

- Steel piston with reinforced, durable spring for easy bottle release: no more any stuck bottles

- It comes with two 26 mm and 29 mm heads

- Easily adjustable in height for bottles up to 38 cm

- It can be quickly mounted to a flat workstation by means of 4 screws

- Three years warranty

Spare parts :

Replacement crowning head 26mm … 25 Eur

Replacement crowning head 29mm … 25 Eur

BLM-PE180G : Manual bottle labeler for round bottles (180-300 bottles per hour) without the stamp

The manual bottle labelling machine with handwell is perfect for use with cylindrical bottles with smooth surface and diameter of 50 to 120 mm. Operation capacity is 3 – 5 bottles per minute (180-300 bottles per hour), depending on the operator’s speed and skills. It is suitable to labelling round wine bottles, champagne bottles or beer bottles and cylindrical jars and cans.

The BLM-PE180G machine is suitable for attaching square, rectangular, circular or oval labels on the front or back side of the bottle.

The bottle labeller is made of polyethylene PE500 which is widely used for components in food machinery, it’s water proof and easy to clean.

Main properties :

- The manual bottle labelling system works by just turn the handwell.

- The machine strictly follows the latest European directives in terms of safety

- Easy positioning of the label roll and paper passage thanks to the mechanical systems studied by us

- A large range of feasible diameters of the bottles

- Possibility of customization through the optional expanding kits

The manual bottle labelling system works by just turn the handwell. With just one simple and light movement the label sticks to the container desired.

This machine is designed to stick labels on the cylindrical bottles or containers with a diameter between 50 mm and 120 mm. It is perfect for containers of glass, jars, plastic, cans or for other cylindrical object with smooth surface. Adapt the labeller to the different types of containers is very easy and quick thanks to the particular regulation system. The simple handwell allows you a simple but efficient process of the bottle labelling. The bottle labeller is made of polyethylene PE500, widely use for components in food machinery, it’s waterproof and easy to clean.

Technical parameters :

- Fully manually operated equipment

- Productivity : 3-5 bottles / min (180-300 bottles per hour)

- Construction material – Polyethylene PE500

- Rolls covering – Gray rubber

- Screws – Inox steel

- Weight : 11.2 kg

- Dimensions : 315 x 500 x 255 mm

Parameters of compatible bottles :

- Min. cylinder diameter: 50 mm

- Max. cylinder diameter: 120 mm

- Compatibility with bottles of square shapes: No

- Compatibility with bottles of round shape: Yes

Parameters of compatible labels :

- Label winding: external (out)

- Minimum tape width: 20 mm

- Max. tape width: 165 mm

- Min. label length: 20 mm

- Max. label length: 200 mm

- Inside diameter of reel: 76 mm

- Max. outer diameter of label roll: 250 mm

Accessories available for the bottle labeller :

- Manual number stamp for labels (date/batch)

- Stand for narrow label rolls

- Kit for second label placement

- Manual label sorter

… prices of the optional accessories on demand