Description

The modular easy to assemble microbrewery kit MODULO CLASSIC 1002SSM-CF3000C with the brewhouse MODULO CLASSIC 1000 allows the production from 1000 to 4000 liters of beer per day. This configuration of the brewery includes set of tanks with production capacity up to 300.000 liters of top fermented beer or 180.000 liters of bottom fermented beer per year. Simple design with independent devices allows easy assembling by customer without our specialists. This configuration doesn´t include an assembly work – a customer ensures it himself according the assembly manual.

The modular easy to assemble microbrewery kit MODULO CLASSIC 1002SSM-CF3000C with the brewhouse MODULO CLASSIC 1000 allows the production from 1000 to 4000 liters of beer per day. This configuration of the brewery includes set of tanks with production capacity up to 300.000 liters of top fermented beer or 180.000 liters of bottom fermented beer per year. Simple design with independent devices allows easy assembling by customer without our specialists. This configuration doesn´t include an assembly work – a customer ensures it himself according the assembly manual.

Manual control of the boiling process, media and tanks with PLC controllers support.

Notice : This offer does not include any services that are necessary for delivery and instalation of the brewery (installation work, transport and accomodation of workers, transport of the brewery technology, start up, training of brewer …) We calculate them individividually for each project – only for your demand.

Modulo Classic = the modular microbrewery kit

Build yourself your own microbreweryfrom prefabricated modules within a few hours in a normal restaurant kitchen. The unique and inexpensive solution allowsthe gradual expansion of the brewerywithout a large investment, withoutdesigning, assembly teamandworkers. More about the modulo breweries …

Technical parameters :

Production capacity – daily :

- 1000 liters of beer wort per day – one batch within 12 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 2000 liters of beer wort per day – two batches within 24 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 3000 liters of beer wort per day – three batches within 24 hours – source raw materials are malt extract, hops, drinking water and brewer’s yeast

- 4000 liters of beer wort per day – four batches within 24 hours – source raw materials are malt extract, hops, drinking water and brewer’s yeast

Production capacity – yearly :

- Beer produced using the on surface fermentation method ……… 300.000 liters per year

- Beer produced using the under bottom fermentation method ….180.000 liters per year

Raw material :

- Classical raw materials : Malt + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

- Beer concentrates : Malt extract + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

- CO2 in pressure bottles (cylindres)

- Washing and sanitizing agents

Control system :

- Brewhouse – boiling equipment :

- valves and claps – manual control

- temperatures – PLC controllers

- motors, pumps – PLC controllers

- timing – manual control

- Tanks – fermentation, maturation, bright beer :

- temperatures – PLC controllers

- timing – manual control

- Media – hot water, ice water, wort cooling, glycol tank :

- temperatures – PLC controllers

- timing – manual control

Required space for building :

- Floor area min : 84 m2

- Room height min : 3.8 m

Electrical connection :

- Electrical socket : 400V 3ph / 50 Hz

- Electrical consumption : 101 kW

Heating system – brewhouse :

- Electric steam-generator

Cooling system :

- Cooling of wort : Drink Cold water + Ice cooling water

- Cooling of tanks : Ice cooling water (optionally glycol)

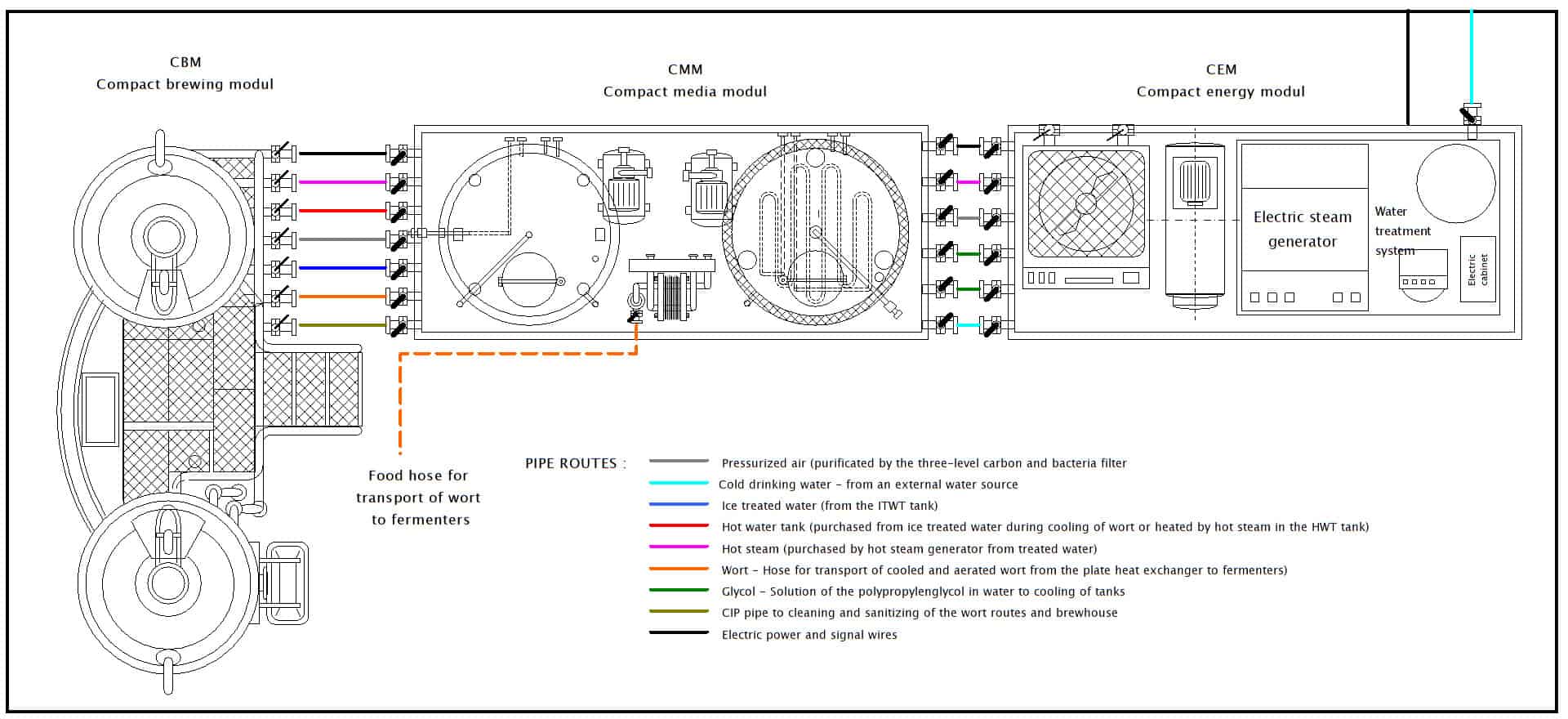

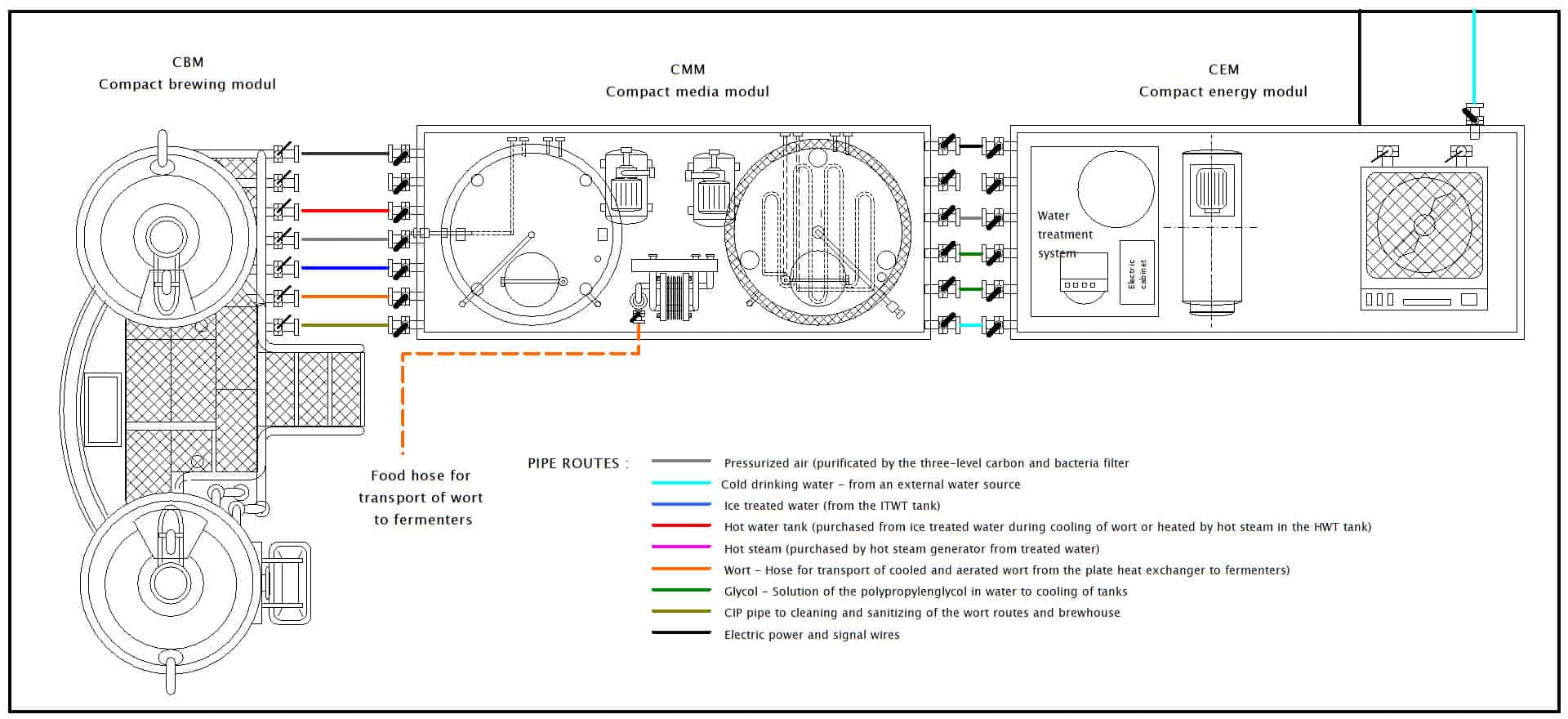

Scheme of the recommended Modulo wort brew systems :

I. SH – Steam heating system (click on the picture to enlarge)

II. Electric-oil heating system (click on the picture to enlarge)

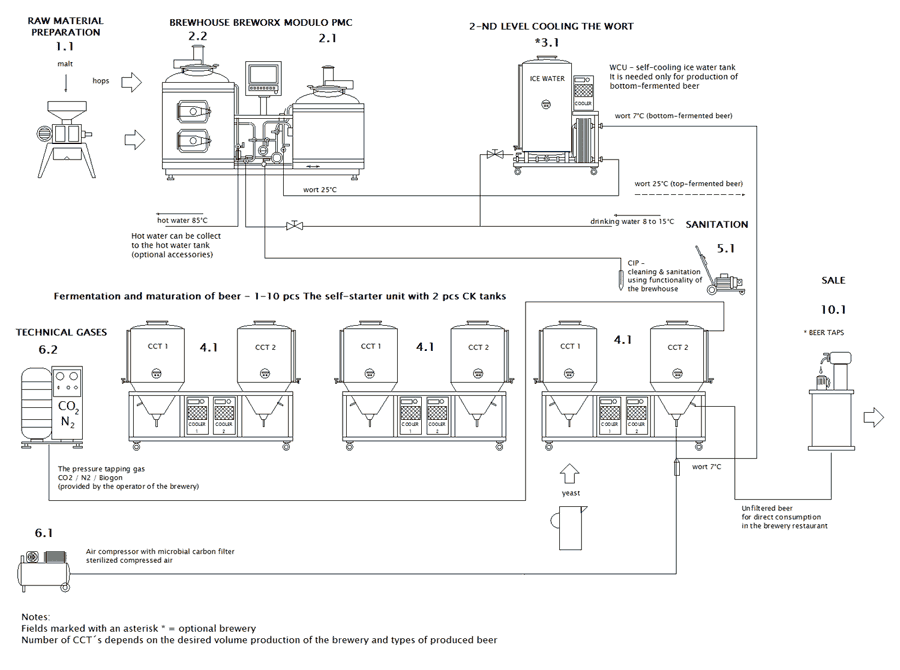

Scheme of the Modulo Classic microbrewery

I. Basic configuration :

1. Preparation of the ingredients: 1.1 malt grinder 2. Wort production: 2.1 Brewhouse: mash-wort pan 2.2 Brewhouse: kombi tank – lauter tub / whirlpool tub, 3. Water management system, 3.1 WCU-Cooler and storage tank for ice water to cool down the wort, 4. Fermentation and maturation of beer: 4.1 Fermentation tanks (CCT) with integrated cooler, 5. Sanitation: 5.1 Mobile CIP pump, 6. Industrial gases: 6.1 Air Compressor with carbon filters, 6.2 N2 generator / cylinder with CO2, 7. Yeast storage system: 7.1 Can for storing yeast 10. Sale of beer: 10.1 * Taproom at the brewery restaurant.

II. Expanded configuration :

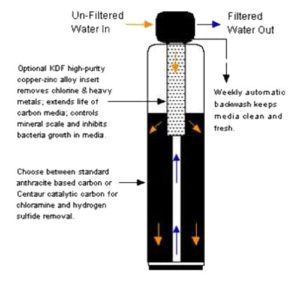

1. Preparation of the ingredients: 1.1 malt grinder 2. Wort production: 2.1 Brewhouse: mash-wort pan 2.2 Brewhouse: kombi tank – lauter tub / whirlpool tub, 3. Water management system, 3.1 and 3.2 WCU-HWT unit – Cooler and storage tank for ice water to cool down the wort and storage tank for heat water, 3.3 Equipment for the treatment of drinking water, 4. Fermentation and maturation of beer: 4.1 Fermentation tanks (CCT) with integrated cooler, 5. Sanitation: 5.1 Mobile CIP pump, 5.2 CIP station,, 6. Industrial gases: 6.1 Air Compressor with carbon filters, 6.2 N2 generator / cylinder with CO2, 7. Yeast storage system: 7.1 Yeast tanks®enerators for storing of yeast, 9. Filtration of beer: 9.1 *Primary and secondary beer filter, 10. Sale of beer: 10.1 * Taproom in the brewery restaurant, 10.2 *Distribution of beer in packages 10.3 *Washer and filler for kegs

More informations about MODULO:

-

Detailed description of microbreweries MODULO … Why choose this solution ?

-

Extend the brewery system MODULO on the production of CIDER! How to do … ?

-

Technical specifications of microbreweries MODULO …

-

Components of the modular microbreweries MODULO – description and prices …

-

Typical configurations of microbrewery sets MODULO – description and prices …

-

Description of the brewing process – How to brew beer with microbrewery MODULO …

Reviews

There are no reviews yet.