Description

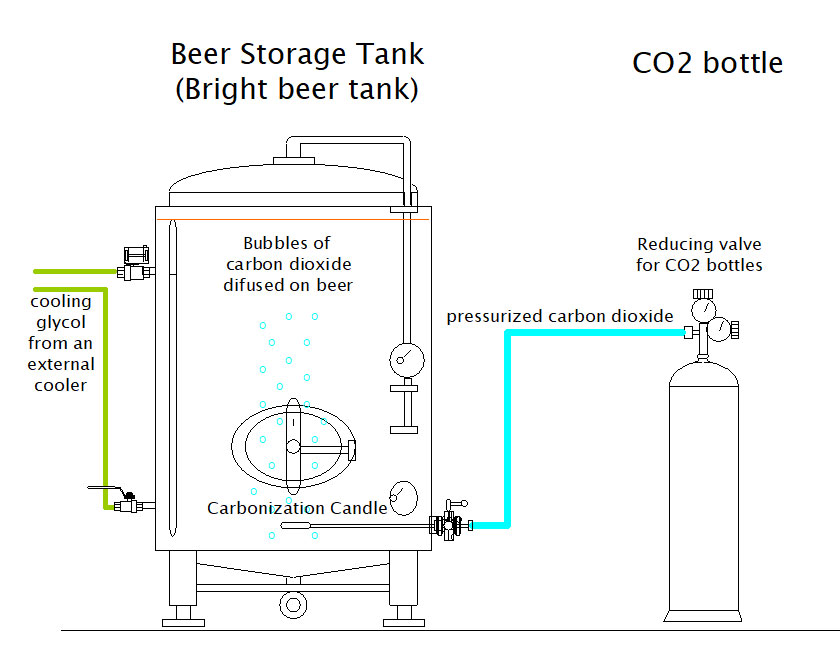

The candle with a porous stone for beverage tanks is designed for the saturation of the wort, beer, wine or cider by sterilized compressed oxygen, carbon dioxide, nitrogen or other technical gas, when the beverage is in the tank under pressure. The saturation of beverage is usually carried out before, during or after the fermentation or maturation process. The candle has to be removably built into the tank, the nozzle is connected to source of the pressurized gas. The porous stone is made from the sintered stainless steel carbide therefore it is easy sanitizable in the tank.

Maximal content of CO2 you can achieve in the tank using this candle is 5,6 g/l (pressure in tank 2.5 bar, temperature of beverage 0°C, time of carbonization > 2 days).

This type of the carbonization stone is compatible only with customized simplified pressure fermentors.The price includes a customization of the pressure tank for connection of the carbonization stone.

Attention : It is not possible to weld the connector onto the pressure tank additionally. The fermentation-maturation pressure tank has to be ordered, manufactured and delivered just with this connector according to demand of the customer.

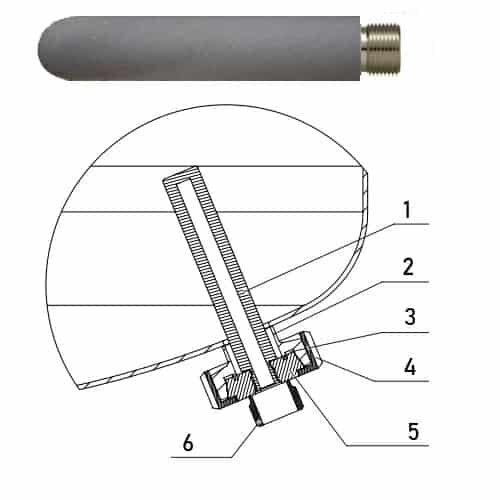

ACOS03-NW25/DN25 carbonization stone – the full turnkey solution includes :

- Carbonization porous stone made of sintred stainless steel with outer thread connection G 1/4″

- Connector NW25 / DN25 welded on the tank … it is not possible to weld the connector on the pressure tank additionally, the tank must be ordered with this connector

- Rubber gasket

- Nut (Dairy coupling DIN11851 NW25 / DN25)

- Tapered neck (Dairy coupling DIN11851 NW25 / DN25) with inner thread connection G 1/4″

- Pipe with outer thread connection G 3/4″

Compatibility only with these types of the fermentation-maturation tanks :

Cylindrically-conical fermentation and maturation tanks with the simplified construction

- CCT-SLP conical fermentation-maturation tanks 1.2 bar … Cylindrically-conical tanks for fermentation and maturation of beer, cider or wine. Simplified design, maximal pressure 1.2 bar, without insulation, with water (or glycol) cooling channels.

- CCT-SHP conical fermentation-maturation tanks 2.5 bar … Cylindrically-conical tanks for fermentation, maturation, storage, filtering and bottling of beer, cider or wine. Simplified design, maximal pressure 2.5 bar, without insulation, with water (or glycol) cooling channels.

Cylindrical fermentation and maturation tanks with the simplified construction

- FMT-SLP cylindrical fermentation-maturation tanks 1.2 bar … Cylindrical tanks for fermentation and maturation of beer, cider or wine. Simplified design, maximal pressure 1.2 bar, without insulation, with water (or glycol) cooling channels.

- FMT-SHP cylindrical fermentation-maturation tanks 2.5 bar … Cylindrical tanks for fermentation and maturation of beer, cider or wine. Simplified design, maximal pressure 2.5 bar, without insulation, with water (or glycol) cooling channels.

Simple beer carbonization system – connections :

Reviews

There are no reviews yet.