Description

The candle with a porous stone for beverage tanks is designed for the saturation of the wort, beer, wine or cider by sterilized compressed oxygen, carbon dioxide, nitrogen or other technical gas, when the beverage is in the tank under pressure. The saturation of beverage is usually carried out before, during or after the fermentation or maturation process. The candle has to be removably built into the tank, the nozzle is connected to source of the pressurized gas. Usually one or more candles is installed on each tank. The porous stone is made from the sintered stainless steel carbide therefore it is easy sanitizable in the tank.

Maximal content of CO2 you can achieve in the tank using this candle is 6,8 g/l (pressure in tank 2.8 bar, temperature of beverage 0°C, time of carbonization > 2 days).

Parameters of the carbonation stone : |

|

| Material | Sintered stainless steel carbide |

| Pore size | < 15 µm (maximally) |

| Pore density | 2x 104 pores / 1 cm2 |

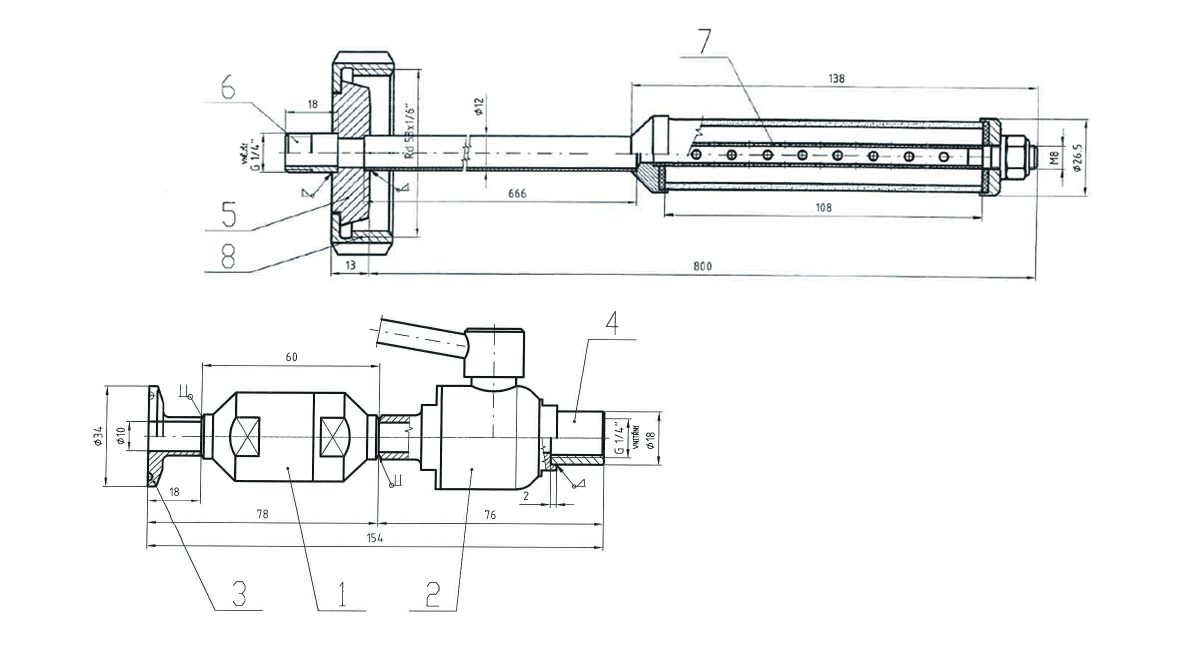

ACOS-02 with connection DIN 11851 (Dairy Coupling)

Description :

- Non-return flap DN 10

- Ball valve DN 10 1/4″

- Gas input – connection DIN 32676 TriClamp D=34mm / DN 10

- Pipe with inner thread G 1/4″

- Connection DIN 11851 DN32 (or DN40) – to join with a tank

- Pipe with outer thread G 1/4″

- Porous stone made of sintered stainless steel (for outgoing bubles of carbon dioxide, nitrogen, oxygen …)

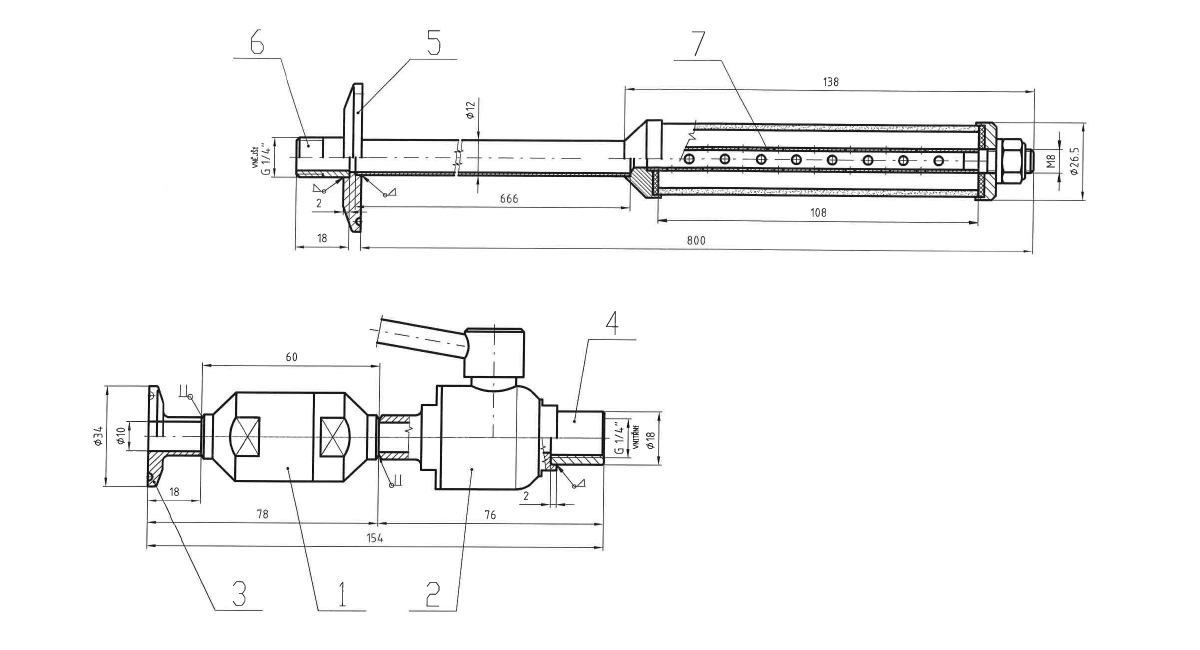

ACOS-02 with connection DIN 32676 (TriClamp)

Description :

- Non-return flap DN 10

- Ball valve DN 10 1/4″

- Gas input – connection DIN 32676 TriClamp D=34mm / DN 10

- Pipe with inner thread G 1/4″

- Connection DIN 32676 DN32 (or DN40) – to join with a tank

- Pipe with outer thread G 1/4″

- Porous stone made of sintered stainless steel (for outgoing bubles of carbon dioxide, nitrogen, oxygen …)

ACOS02-DN1040TC is also used as an optional accessory of the CCT-M cylindrical-conical tank system – position MTS-CC1 in the scheme of the tank.

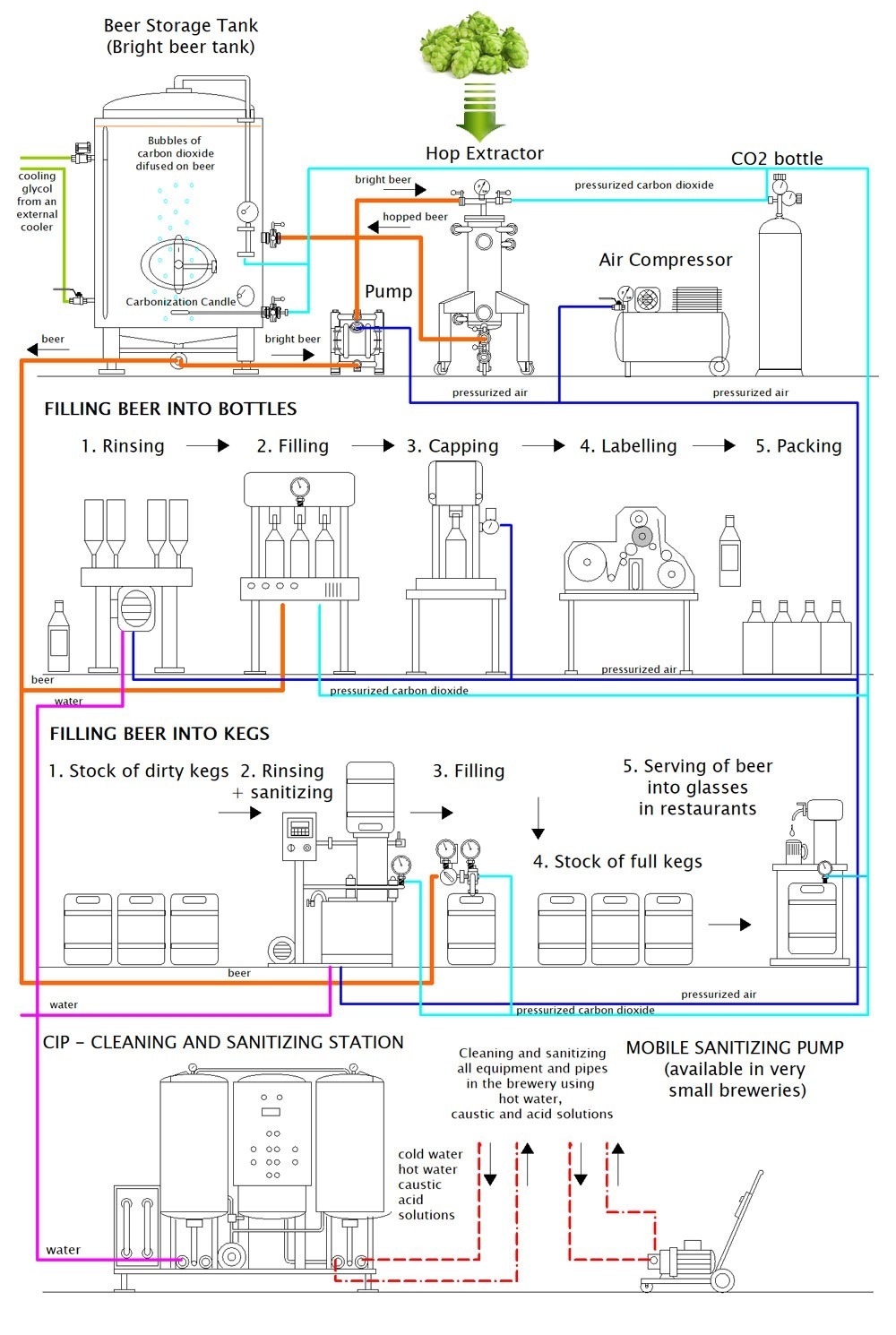

Simple beer carbonization system – connections :

The ACOS02-DN1040TC carbonization candle includes :

The ACOS02-DN1040TC carbonization candle includes :

- Cylindrical stone produced of sanitizable porous material – sintered stainless steel AISI 304 with pore size 15μm

- Pipe ⌀12mm DN 10 / NW 10 with drilled holes inside the stone with screw and nut for fixing the stone on the pipe.

- Ball valve DN 10 / NW 10

- One way valve to avoid flowing the product outside from the tank DN 10 / NW 10

- Throat DIN 32676 “Tri Clamp” ⌀50.5mm or DIN 11851 “DairyCouping” with inner diameter DN 32 or DN 40 welded on the tank side of the ball valve.

- Throat DIN 32676 “Tri Clamp” ⌀34mm DN 10 / NW 10 welded on the out side of the one way valve – for connection of the hose from the gas source. May be replaced with G-threat.

- Pipe DN 10 / NW 10 – its length (including three segments) depends on the dimensions of the tank – standard length is 800 mm

- Sealing for DIN 32676 “Tri Clamp” ⌀50.5mm – for the tank side connection (only for DIN 32676 versions)

- Sleeve-ring for DIN 32676 “Tri Clamp” ⌀50.5mm – for the tank side connection (only for DIN 32676 versions)

- Sealing for DIN 32676 “Tri Clamp” ⌀34mm – for the hose side connection (only for DIN 32676 versions)

- Sleeve-ring for DIN 32676 “Tri Clamp” ⌀34mm – for the hose side connection (only for DIN 32676 versions)

- Material – body and pipes : Stainless steel AISI 304

- Material – stone : Sintered stainless steel AISI 304 with pore size 15μm

- Input : Triclamp or other (by requirement of customer)

- Pipe : DN10 or other (by requirement of customer) – custom price for other diameters

Recommended accessories to be ordered with the carbonation candle

(For version with the DIN32676 TriClamp connections – the parts are not included)

The gasket and the clamp for TriClamp connection system DIN 32676

We recommend : Fully equipped set for carbonization of beer, cold extraction of hops in beer, filling of beer into bottles and kegs

Equip your brewery with all devices you need to sale good beer to customers …

For more informations visit this category …

Reviews

There are no reviews yet.