Description

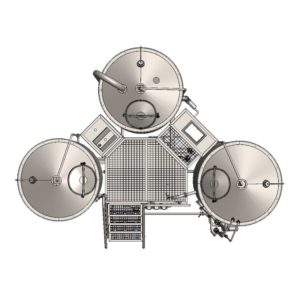

The smaller-size wort brew machine that is intended for easy preparation 100-130L of beer wort in one batch using the infusion brewing method. Practical and easy beer production device to use for all home brewers. Our brew machine BREWMASTER BM-100 with use of some simplified wort fermentors permits to prepare a good hand crafted beer, using fresh products according to any kind of recipe. The wort brew machine is produced of stainless steel. Maximal malt quantity 21.0 kg per batch. The wort brew machine is fully produced of stainless steel AISI 304.

130 liters of produced wort is sufficient volume to produce around 100 liters of beer after finish the fermentation and maturation process.

BREWMASTER BM-100 produces 100 up to 130 liters of hopped wort per one batch

The new Brewmaster 100 Liter brewhouse is a wort brewing system for brewing approximaly 100-120 liters of beer and offers the advantage that no crane or lifting device is required for filtering wort. The installation is therefore completely flexible and the complete wort brewing process can also be carried out alone.

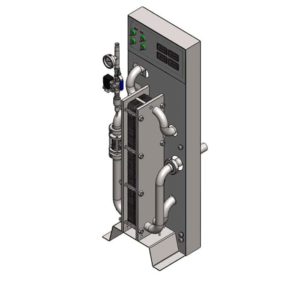

The brewhouse comes with a stainless steel frame on castors, the controls are easily accessible and can be adjusted in height and inclination.

The pumping device supplied makes it easy to pump wort into a fermentation tank after the brewing process.

The Braumeister is located at a very convenient height with a favorable height-to-width ratio, making its cleaning a breeze.

New design since 2025 :

Technical parameters and equipment:

- Heating coil: 3x 2000W heating power

- Pump: 3x 27W – speed adjustable

- Power connection: 400V (fuse protection min. 16A)

- Total connection: 7kW

- Cooling: approx. 0.6m2 double jacket surface, with ice water approx. 50 min at 25°C

- New fully automatic brewing control with touchscreen

- Heating coil: 3x 2000W heating power

- Pump: 3x 27W – speed adjustable

- Power connection: 400V (fuse protection min. 16A)

- Total power connection: 7kW

- Cooling: approx. 0.6m2 double jacket surface, with ice water approx. 50 min at 25°C

- New fully automatic brewing control with touchscreen

- Max. Malt quantity: 21kg

- Latest touch screen control system

- Brewing guide – display of exact quantities and ingredients during the brewing process

- Highly accurate temperature measurement

- Assistance during the brewing process

- Flexibly adjustable pump pauses

- Integrated Wifi module for software updates “over the air” and recipe synchronisation

- Integrated ingredient database

- Timer function – for delayed brewing start

- Data from tilt hydrometers can also be read into the fermentation programme

- IP 65 – high water resistance

- 5″ touchscreen

- Other outputs: 24V and CAN for future additions

- Max. malt quantity: 21 kg – distributed over 3 malt pipes

- Made of stainless steel incl. frame on castors

- Adjustable control

- Brewing volume 100-120 litres of finished beer (normal beer) = approx. 130 litres of wort

- Max. Malt quantity 21kg – distributed over 3 malt pipes

- incl. double jacket for cooling

- incl. pumping device for pumping out the wort

- Weight : 70 kg

- Weight in transport : 100 kg

Benefits :

- Very easy to use, clean and maintain.

- In support of the brewing unit, we can supply a wide range of accessories (hop filters, passive or cooled cylindric and conic fermentation tanks, cooling heat exchangers, ..) which will guide you into a brewing of perfect your own beers !

- It is an ideal solution for small craft breweries, pubs, agritourisms, catering institutes and for any activities which wants to offer their own craft beer to their customers.

Pipe connections :

- Rear cooling jacket connections BSPP 1″ male (2x)

- Outlet tap 1″ vertical downwards with disc valve DIN 11851 DN25

Dimensions

- Diameter: 90 cm

- Height: 110 cm

- Wooden crate: 120 x 120 x 125 cm (length x width x height)

- Shipping weight: 100 kg

Video :

Beer fermentation/maturation process :

Immediately after end of the boiling of the wort the temperature of the wort is brought to the level of the fermentation temperature by a wort cooler or by a double jacket; the wort is also mixed with yeast and fermented in a suitably large fermentation tank (optional accessory).

Primary beer fermentation

For the primary beer fermentation you can use simple plastic or stainless steel fermentation vessels equipped with the air lock.

>> Recommended vessels for the primary beer fermentation …

Secondary beer fermentation – maturation

For the beer maturation you can use the stainless steel fermentors fully equipped for semi-professional the beer production process.

>> Pressure tanks for the secondary beer fermentation …

>> Complete sets with one fermentor for the secondary beer fermentation …

>> Complete sets with more fermentors for the secondary beer fermentation …

Consuming :

After several weeks of conditioning beer in bottles or in a pressure beer maturation tank (optional accessory), the well cooled beer can be consumed.

Available accessories :

1. HBA-BM100 : BREWMASTER Wi-Fi mobile interface

The wireless internet module

- for the supervision of the brewing process within the wireless local area network via wireless internet router

- for the update of the BREWMASTER BM-200 control system to the latest software (firmware)

- network standard: IEEE 802.11 b/g/n

- software for update: PC with installed Windows 7 OS or newer version

2. BMTM-200 : Termo-sleeve for the BREWMASTER BM-200

BMTM-200 Termo-sleeve is a recommended accessory for the BREWMASTER BM-200 wort brew machine. This accessory is intended for insulation of the boiling vessel to speed up heating, speed of each brew batch and saving energy. The termo-sleeve is also very recommended for use when is requirement for more than one brew cycle per day – in this case we recommend to use the fermentation-maturation tanks with volume equal total volume of daily produced wort.

3. SBT2 : Set of brewing tools for the BREWMASTER breweries

Set of brewing tools for BREWMASTER . This set includes :

- Hydrometer and sampling plastic cylinder – Hydrometer is a basic measurement tool for measuring the percentage of alcohol in the beer produced. This set includes a noncalibrated hydrometer with temperature correction and support plastic cylinder.

- Large shovel – for handy removing malt from the wort-boiling machine after the wort filtration process.

- Cleaning set – set of tools for easy cleaning of the wort-boiling machine, tanks and hoses.

- Malt barrel – the plastic vessel for easy collecting of the milled malt under the malt milling machine

- Wooden mash paddle – for handy occasional mixing of wort during the brewing process

4. MM-80 : Mill of malt grains

Machine for fine squeezing of malt grains without damaging the outer parts of grain, with production capacity from 60 to 80 kg per hour.

5. FUIC-SLP1C-2x200CCT Compact beer fermentation unit 2×200/240 liters 1.2bar

The beer fermentation and maturation unit, BREWORX MODULO FUIC-SLP1C-2x200CCT, is the independent mobile block with two cylindrically-conical tanks 2x 200 liters (total capacity 2×240 liters). This SLP version of FUIC has a simplified construction design without insulation and with the adjustable low-pressure range from 0 to 1.2bar. The FUIC unit includes everything what is necessary for the main fermentation of beer, maturation of beer, storage and preparation of beer for handy bottling and dispensing process.

The BREWORX MODULO FUIC-SLP1C-2x200CCT consists of these components :

- 2 pcs of CCT-SLP 200 liters (usable volume) / 240 liters (total volume) – noninsulated cylindrically-conical tanks, the cylindrical part is cooled by water or glycol, pressure 0 – 1.2bar

- 1 pc of the compact water/glycol chiller 2300 W with four independent temperature regulators and pumps.

- System for measurement and control of temperatures and circulation of coolant

- All pipes and hoses for cooling system – elements for connecting between cooler and tanks

- Supporting frame with adjustable legs or wheels with an aretation

6. CFSCT1-1xCCT200SNP-3xFMT200SLP : Complete beer fermentation set with 1xCCT-SNP 240 liters and 3xFMT-SLP 240 liters

The complete beer fermentation set. This set CFSCT1-1xCCT200SNP-3xFMT200SLP includes all equipment necessary for professional production of beer using the fermentation and maturation of wort using the fermentation and maturation process. The set consists of 1 pc of non-pressure cylindrically-conical tank 240 liters (for the primary fermentation) and 3 pcs of the pressure cylindrical tanks 240 liters (for the secondary fermentation). The set includes one dedicated compact water/glycol cooler with the integrated digital temperature control system and all sensors, hoses, wires and fittings.

The set CFSCT1-1xCCT200SNP-3xFMT200SLP consists of :

- 1 pc of the CCT-SNP-200DE simplified non-insulated cylindrically-conical fermentation tank 200 liters (total capacity 240 liters) with one cooling zone – the special container for the pressureless primary beer fermentation – for the primary fermentation

- 3 pcs of the FMT-SLP-200H simplified non-insulated cylindrical fermentation tank 200 liters (total capacity 240 liters) with one cooling zone – the special container for both beer fermentation and maturation under pressure max. 1.2bar – for the secondary fermentation

- 1pc of the compact water/glycol chiller 2300 W with four independent digital temperature regulators, four temperature sensors, foru pumps

- Hoses and fittings to connection between cooler and tank.

- Installation manual

Reviews

There are no reviews yet.