Description

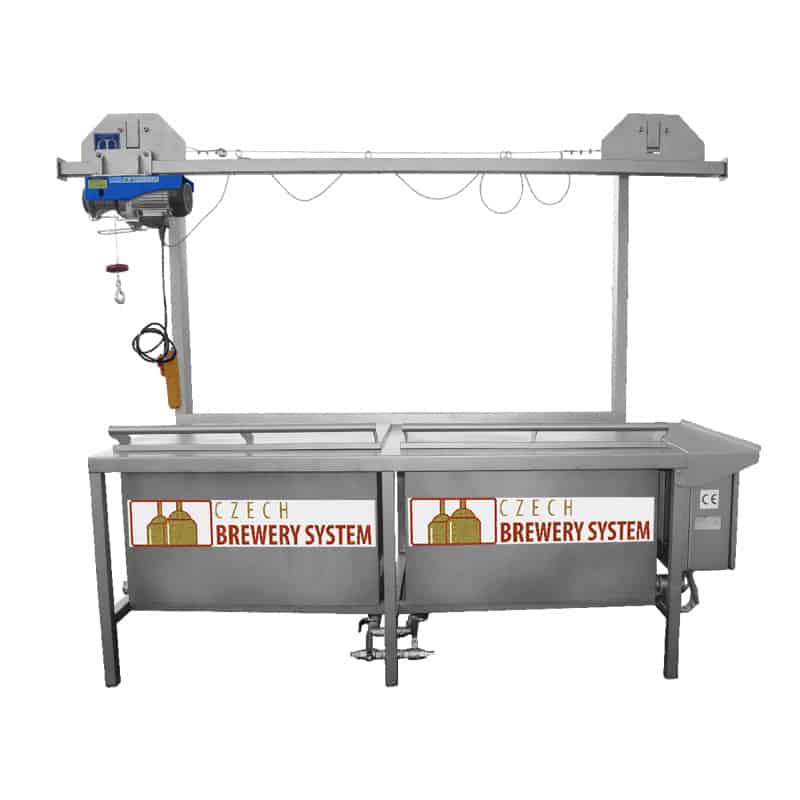

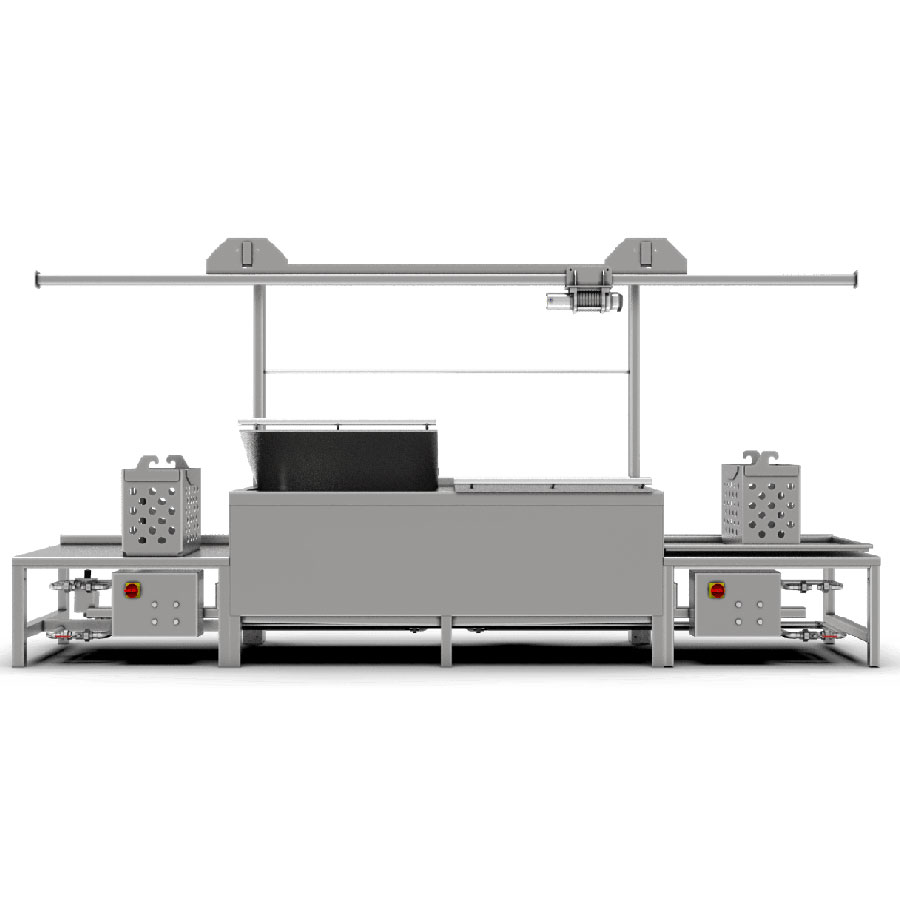

Perfect solution for the small to medium sized beer or cider producers. The PBA-400MG is a water bath-based pasteuriser that uses an electrically heated water system to heating of filled and closed bottles to the desired pateurisation temperature. Pasteurizing capacity up to 400pcs of 1-liter bottles per hour (two batches per 200 bottles). Real capacity depends on the bottles shape and their volume.

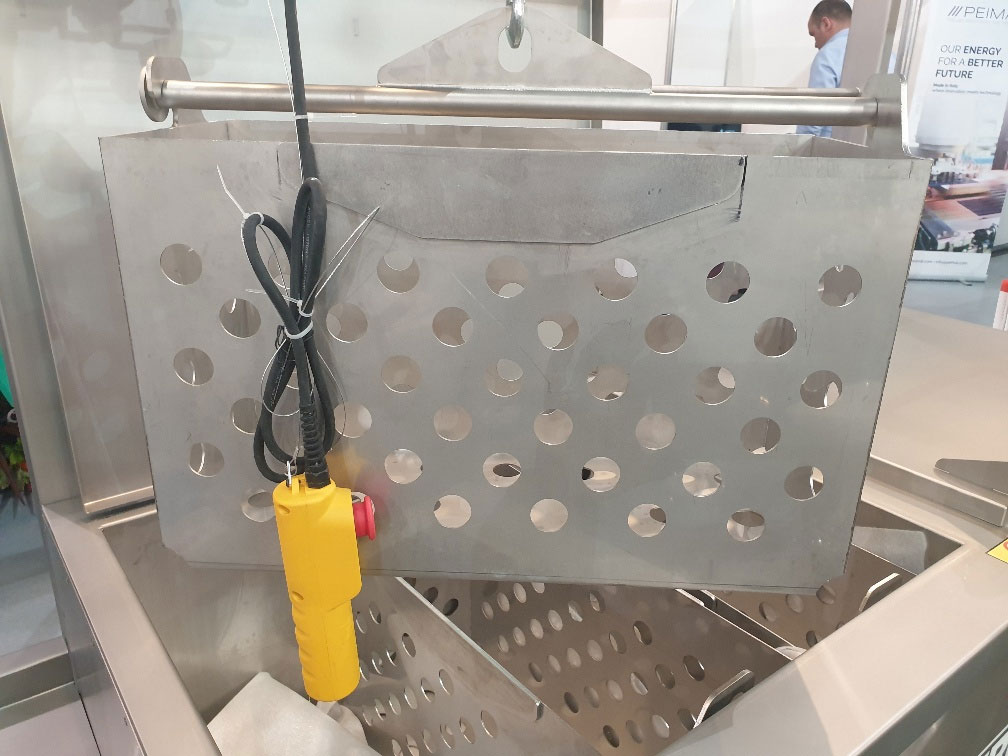

The PBA-400MG pasteuriser is an ideal solution for pasteurising of cold-filled bottles. It has a capacity of 2x 200 liters (approximately 200pcs x 1 litre bottles per batch or greater capacity for smaller bottles). The bottles are manually placed into steel box and then they are dived in the hot water bath (using the crane integrated). You can set the pasteurisation temperature and time via a digital display. Then bottles are moved from the hot water bath into the second bath with cold water that cools the bottles to final temperature. The pasteurize process is semiautomatically controlled.

The second bath can be used either for the cooling the bottles after the heating or as the secondary heating bath without the cooling cycle.

The set includes :

- Pasteurizer with two baths (2x 200 liters)

- 6pcs of the steel submersible boxes for bottles

- Lifting electric motor crane with guide rail for easy handling with the steel boxes

- One bath equipped with the heating spirals

- Digital thermostat / Optionaly PLC + touch LCD

Heating spirals (in one bath) :

- Standard : 3x 9kW = 27kW / Necessary circuit breaker of 40A / 3-phase 400V

- Optionaly : 3x 6kW = 18kW / Necessary circuit breaker of 32A / 3-phase 400V

The bath is insulated on all side walls and on the bottom.

Optional equipment :

Code |

Description |

PBA-400MG-SV : short version |

PBA-400MG-LV : long version |

| PBA-400MG-SST | Steel tables for temporary putting and easy handling with the boxes | € 395,- / pc | 2 pcs included |

| PBA-400MG-ECT | Extended crane track with overlaps above both table | € 400,- / meter | Included in price |

| PBA-400MG-SHS | One bath is equipped with the heating system :

3 x 9 kW = 27 kW / Necessary circuit breaker of 40A / 3-phase 400V Optionaly : 3 x 6 kW = 18 kW / Necessary circuit breaker of 32A / 3-phase 400V |

Included in price | Included in price |

| PBA-400MG-DHS | Both baths are equipped with the heating system : 2 x (3 x 9 kW) = 54 kW) / Necessary circuit breaker of 80A / 3-phase 400V. Optionaly : 2x (3 x 6 kW) = 36 kW / Necessary circuit breaker of 63A / 3-phase 400V |

€ 950,- / set | € 990,- / set |

| PBA-400MG-BBA | Additional steel submersible boxes for bottles | € 750,- / pc | € 750,- / pc |

| PBA-400MG-WC1 | Water circulation system with the pump (for one tank) – to achieve the same temperature of water in all volume of the tank | € 340,- / set | € 340,- / set |

| PBA-400MG-WC2 | Water circulation system with the pump (for both tanks) – to achieve the same temperature of water in all volume of the tank | € 640,- / set | € 640,- / set |

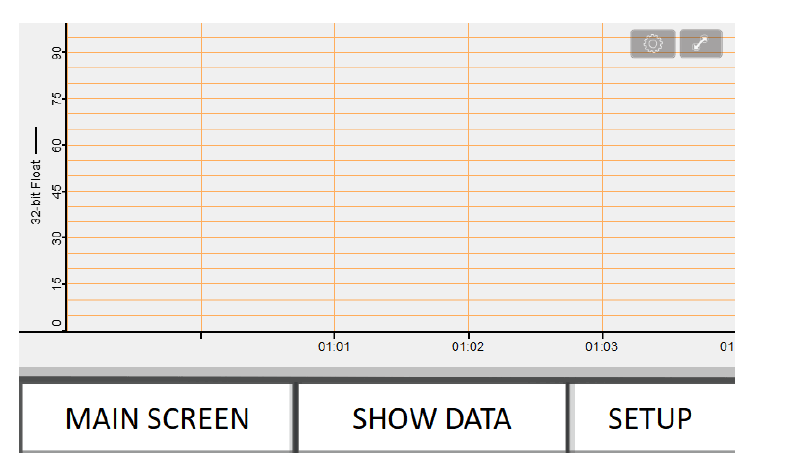

| PBA-400MG-PLC | PLC with a touch screen for programming the temperature pasteurization curve (temperature course over time) and recording the actual temperature course in a log for later comparison and archiving of the record. | € 1985,- / set | € 1985,- / set |

| PBA-400MG-HS6 | Spare heating spiral 6kW (Recommended spare part ). The heating spirals are a consumption material without warranty. | € 195,- / pc | € 195,- / pc |

| PBA-400MG-HS9 | Spare heating spiral 9kW (Recommended spare part ). The heating spirals are a consumption material without warranty. | € 225,- / pc | € 225,- / pc |

Short version without the stainless steel tables and with one heated bath:

Long version with two stainless steel tables, the extended crane track and two heated baths :

(note : only one bath is equipped with the heating system in the basic price of the long version. See the price table)

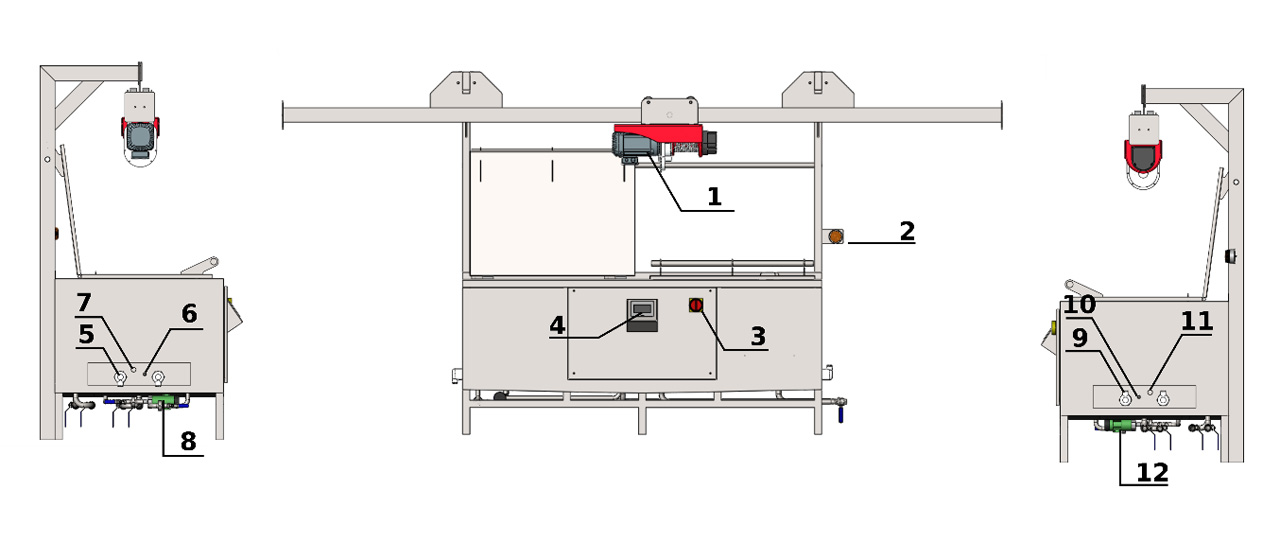

Description of main components :

| Pos. | Description : | Function / Parameters : |

| 1 | Lifting winch | 1000W / 300kg |

| 2 | Beacon | Strobe + siren (Optionaly – only in the PLC version) |

| 3 | Cam switch | Main switch |

| 4 | HMI | Standard version : Digital thermostat / PLC version : Touch LCD (Optionaly) |

| 5 | Preheating tank – electric heating elements | 2 x 6kW 3×230 V / 50Hz (Optional equipment / Double heating system) |

| 6 | Preheating tank temperature sensor | PT100 |

| 7 | Preheating tank level switch | Safety element against burning of spirals |

| 8 | Preheating tank circulation pump | Homogenization of preheating water (Optional equipment) |

| 9 | Pasteurizing tank – electric heating elements | 3 x 9kW 400V / 50Hz (Optionaly 3x 6kW 400V) |

| 10 | Pasteurizing tank temperature sensor | PT100 |

| 11 | Pasteurizing tank level switch | Safety element against burning of spirals |

| 12 | Pasteurizing tank circulation pump | Homogenization of hot water (Optional equipment) / 20 Watts |

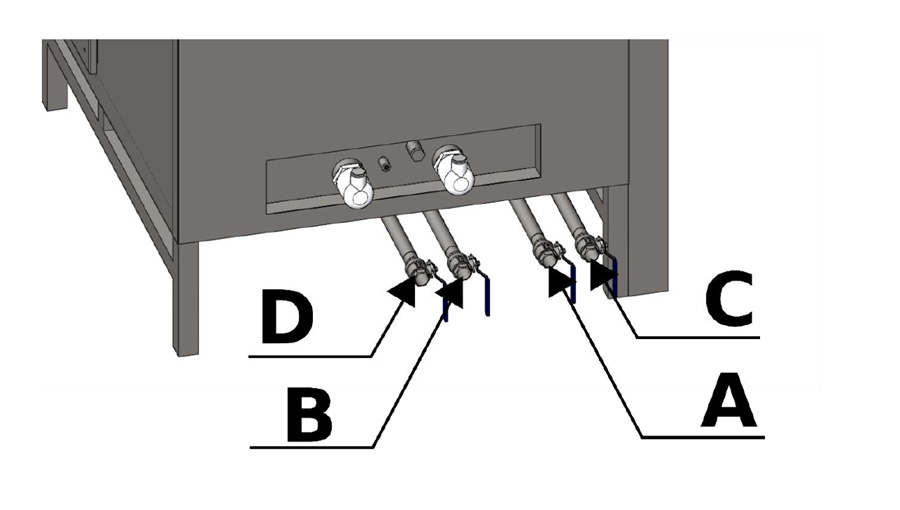

Pipe connections :

| Pos. | Description : | Parameters : |

| A | Filling the preheating tank | Internal thread BSP G3/4“ |

| B | Preheating tank drain pipe | Internal thread BSP G3/4“ |

| C | Filling the pasteurization tank | Internal thread BSP G3/4“ |

| D | Pasteurization tank drain pipe | Internal thread BSP G3/4“ |

Key Features:

- All stainless steel construction

- Programmable pasteurisation temperature and time via a digital display panel

Specification:

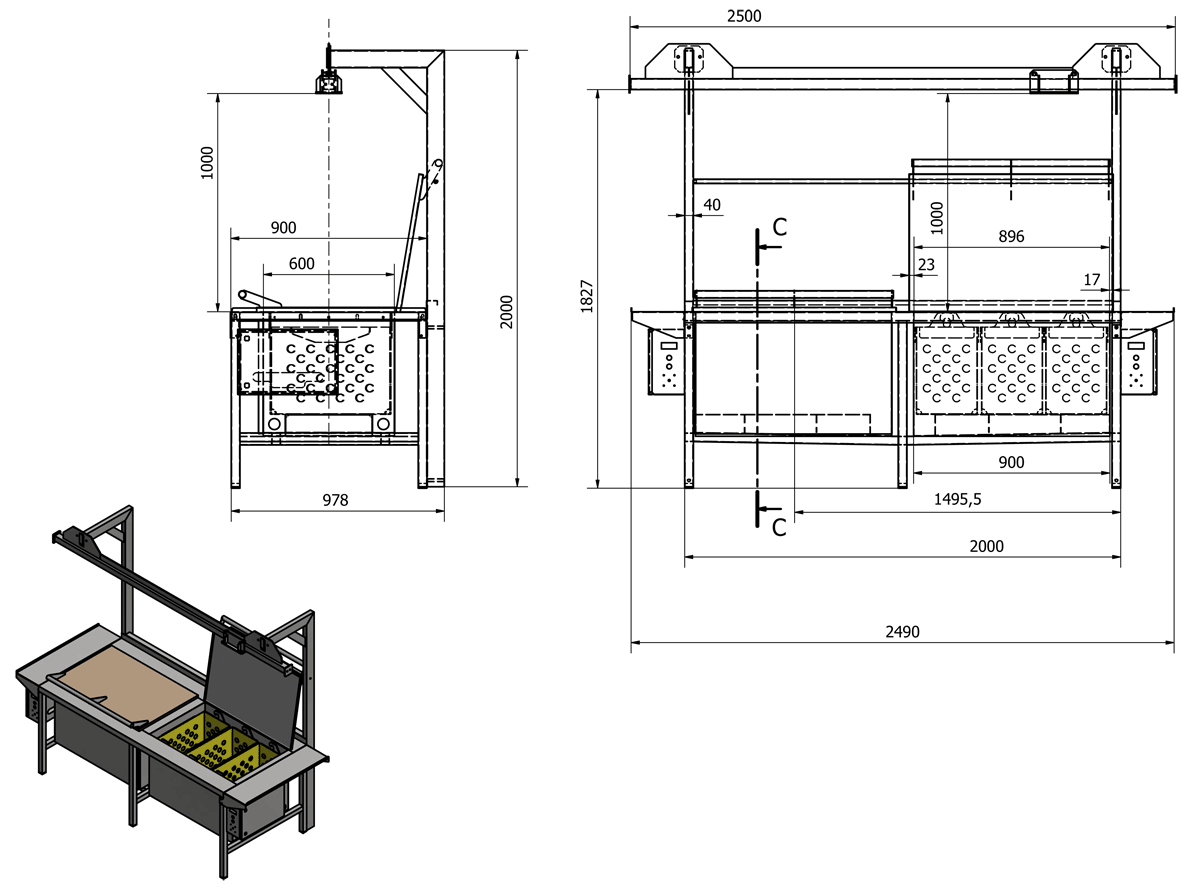

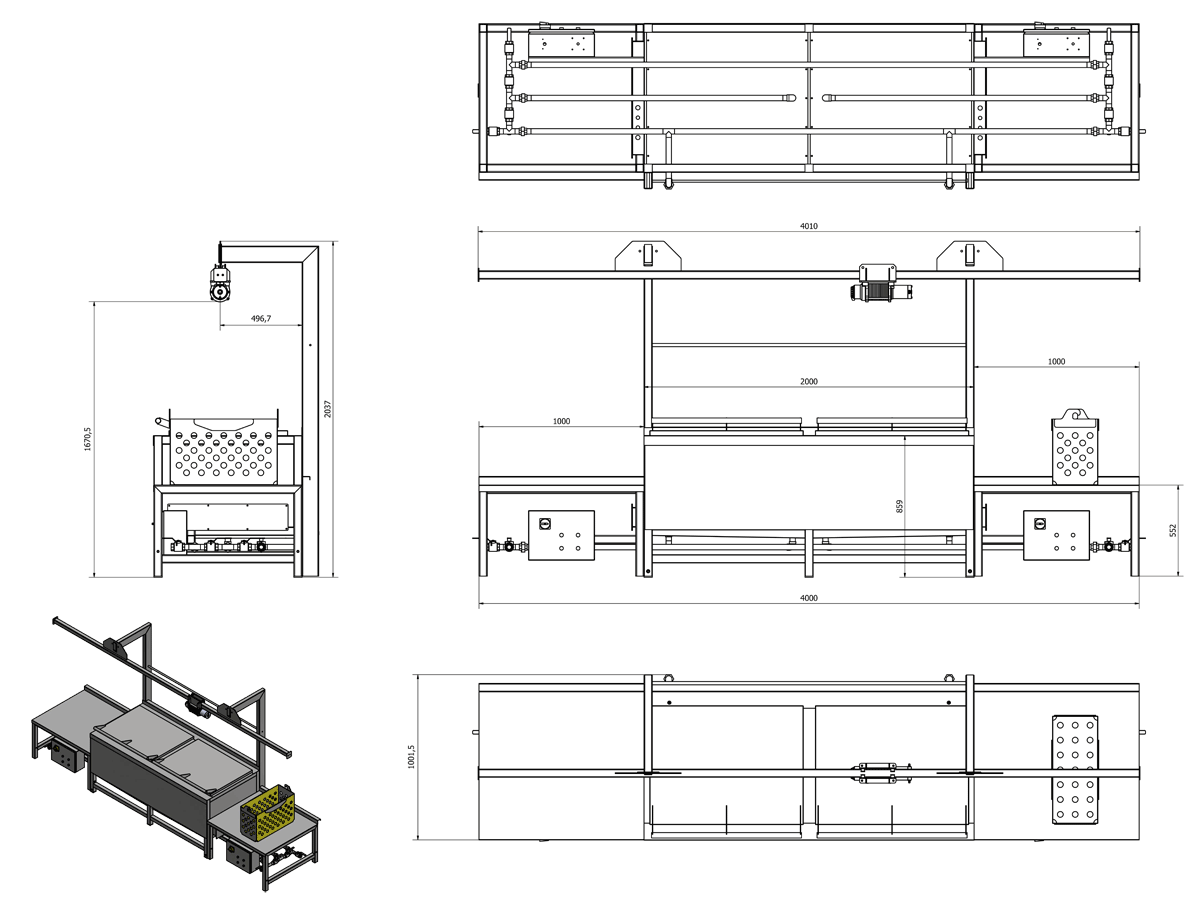

| Dimensions – the short version (mm) | Assembled machine :

length … 2510 mm Transporting dimensions : length … 2500 mm weight: 400kg + 40kg (pallet) = 440 kg |

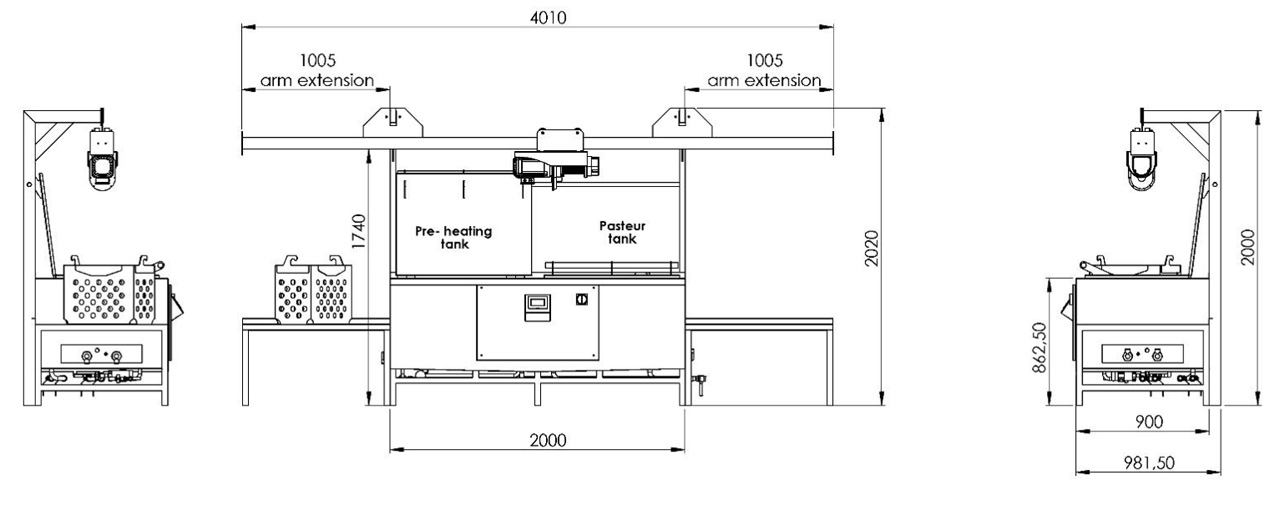

| Dimensions – the long version (mm) | Assembled machine :

length … 4010 mm Transporting dimensions : length … 2500 mm weight: 460kg + 40kg (pallet) = 500 kg |

| Capacity | Up to 400 one litre bottles per hour (two batches per 200 bottles 1L)

Each tank is volume of 270 liters (three baskets with bottles or cans) |

| Material | AISI 304 Stainless steel |

| Insulation | 40mm XPS |

| Electrical supply | 400V / 42 kW three phases 50 Hz / IP65 protection / Cable 5×10 CYKY / Circuit breaker 3x 63 A |

| Heating Power | Preheating tank : 12 kW / Pasteurizing tank : 27 kW / Total : 39 kW |

| Maximal temperature | 80°C |

| Weight (with both full tanks) | Approximaly 1200 kg + weight of bottles or cans |

Dimensions of the pasteuriser without the stainess steel tables (the short version) :

Dimensions of the pasteuriser with two stainless steel tables and the extended crane track (the long version) :

Dimensions of the steel submersible box for bottles :

Specifications of the pasteurizer with the automatic control system based on the Siemens PLC

Following information are valid only if the PLC is required.

Touch LCD panel (HMI) :

Pasteurization process control (preheating + heating) :

This manual is intended for the PBA-400MG water-bath based pasteuriser in configuration where the left tank is intended for product preheating and the right tank is intended for product pasteurization. The automatic pasteurization process is divided into the following separate processes.

1. First, the product is placed in stainless steel baskets and immersed in the left tank. In this tank, the product is preheated to the recommended temperature of 40°C. The operator sets the target water temperature in the preheating tank and starts heating the water using the “PRE-HEAT TANK HEAT” button. As soon as the water temperature in the preheating tank reaches the set temperature, the pasteurization process itself can be continued.

2. In the second tank, the operator heats the water to the desired pasteurization temperature. The water temperature is set on the screen and the water heating is started by pressing the “PASTEUR-TANK HEAT” button. As soon as the target temperature is reached, the heating coils are disconnected. If the temperature drops below the set limit (possibility of setting the so-called hysteresis), the heating process is restarted.

3. The product pasteurization process itself follows. The product is pulled out of the left preheating tank by a winch and lowered into the right pasteurization tank. A temperature sensor is placed in one of the cans or bottles. The operator sets the desired product temperature and the time for which the product is to be pasteurized on the HMI. As soon as the actual product temperature reaches the set product temperature, the timer starts. After the set time has elapsed – the end of pasteurization – a message appears on the display stating that the process has ended, the warning light flashes and the siren is turned on to alert the operator that pasteurization is complete.

Warning system :

- After the pasteurization process is completed, the program is coded to trigger a warning beacon, which signals both with light flashes and an acoustic siren.

- The light flashes are permanent in the program and cannot be turned off in any way.

- The siren can be permanently turned off using the rotary switch on the cabinet door.

- If necessary, the sound of the siren can be changed using the enclosed manual and the volume can be increased or decreased.

Program description :

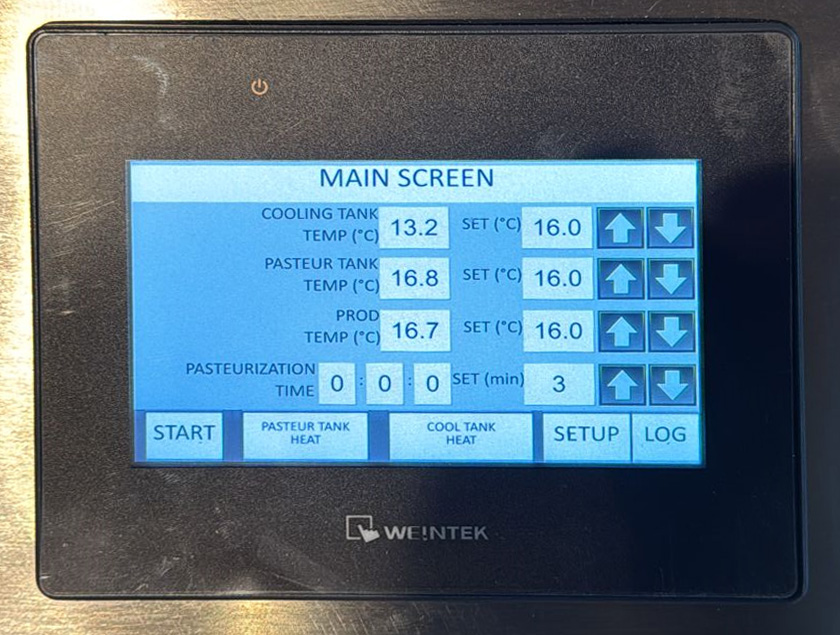

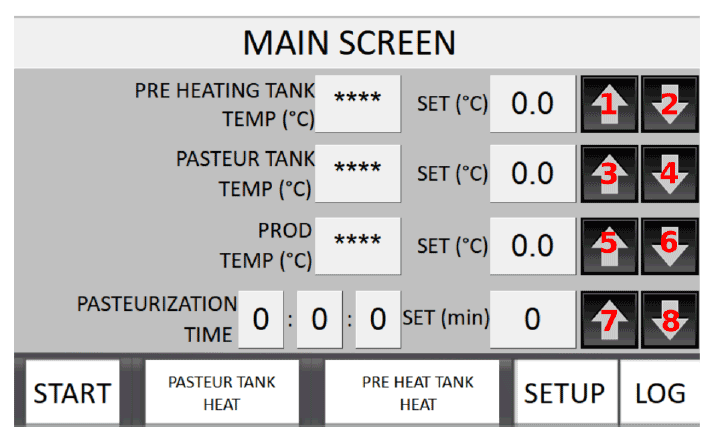

After turning the cam switch on the distributor, the initial screen will be displayed on the HMI panel – MAIN SCREEN

- Use the arrows (1 + 2) to set the target temperature of the preheating water in 0.5 °C increments

- Use the arrows (3 + 4) to set the target temperature of the pasteurization water in 0.5 °C increments

- Use the arrows (5 + 6) to set the target product temperature in 0.5 °C increments

- Use the arrows (7 + 8) to set the pasteurization time

- Press the PASTEUR-TANK HEAT button to start the automatic process of heating the pasteurization water in tank number 2

- Press the PRE-HEAT TANK HEAT button to start the automatic process of heating the preheating water in tank number 1

- Press the START button to start the automatic pasteurization process

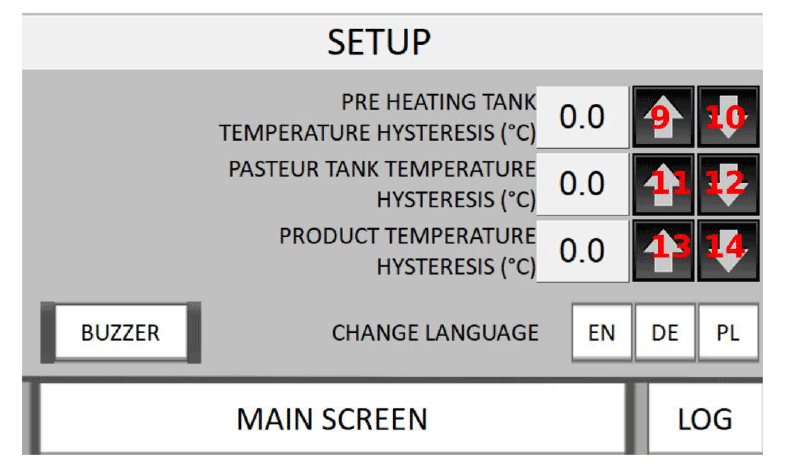

- Press the SETUP button to switch to the new SETUP screen

- Press the LOG button to switch to the new graph screen

- Use the arrows (9 + 10) to set the hysteresis of the preheating water temperature in 0.5 °C steps

- Use the arrows (11 + 12) to set the hysteresis of the pasteurization water temperature in 0.5 °C steps

- Use the arrows (13 + 14) to set the hysteresis of the product temperature in 0.5 °C steps

- Press the EN button to switch the language to ENGLISH

- Press the DE button to switch the language to GERMAN

- Press the PL button to switch the language to POLISH

- Press the MAIN SCREEN button to switch to the MAIN SCREEN screen

- Press the LOG button to switch to the graph screen

- Press the MAIN SCREEN button to switch to the MAIN SCREEN screen

- Press the SHOW DATA button to switch to the data screen

- Press the SETUP button to switch to the new SETUP screen

Dimensions :

Reviews

There are no reviews yet.