Description

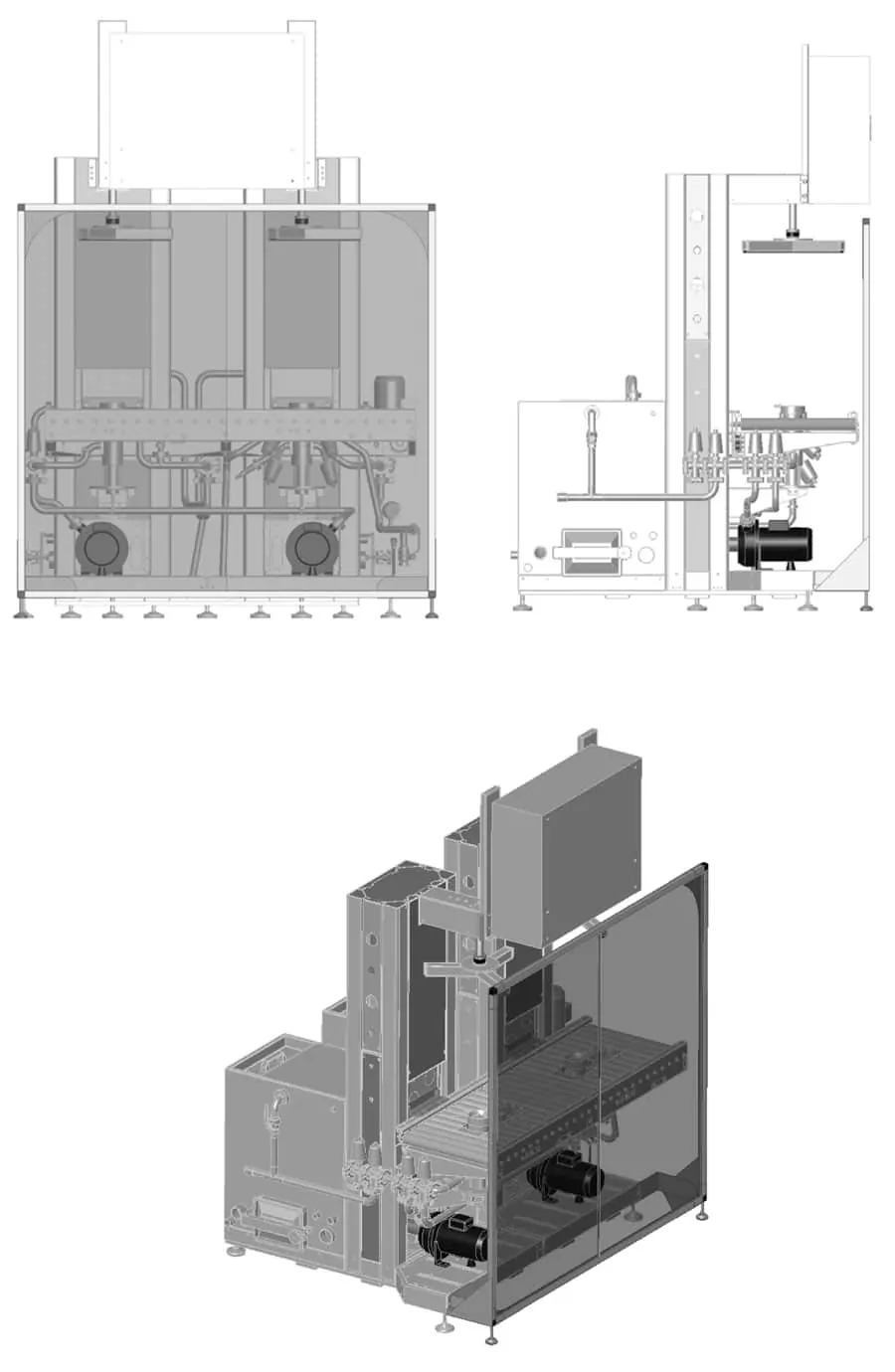

The KWFL-32 is full-automatic washing, sanitizing and filling line for kegs with volume from 10 liters to 50 liters.

Operating capacity : from 28 to 32 kegs per hour ( washing + filling cycles).

For the filling and washing of stainless steel kegs : a range of machines designed and made with special care paid to hygiene and available in different sizes and models.

The entire structure of the machine and the parts that are contact with the liquid are entirely made out of AISI 304 stainless steel. The filling head was conceived with careful detail to exclude any type of contact with air on the part of the product being worked and to ensure a filling that’s completely sterile.

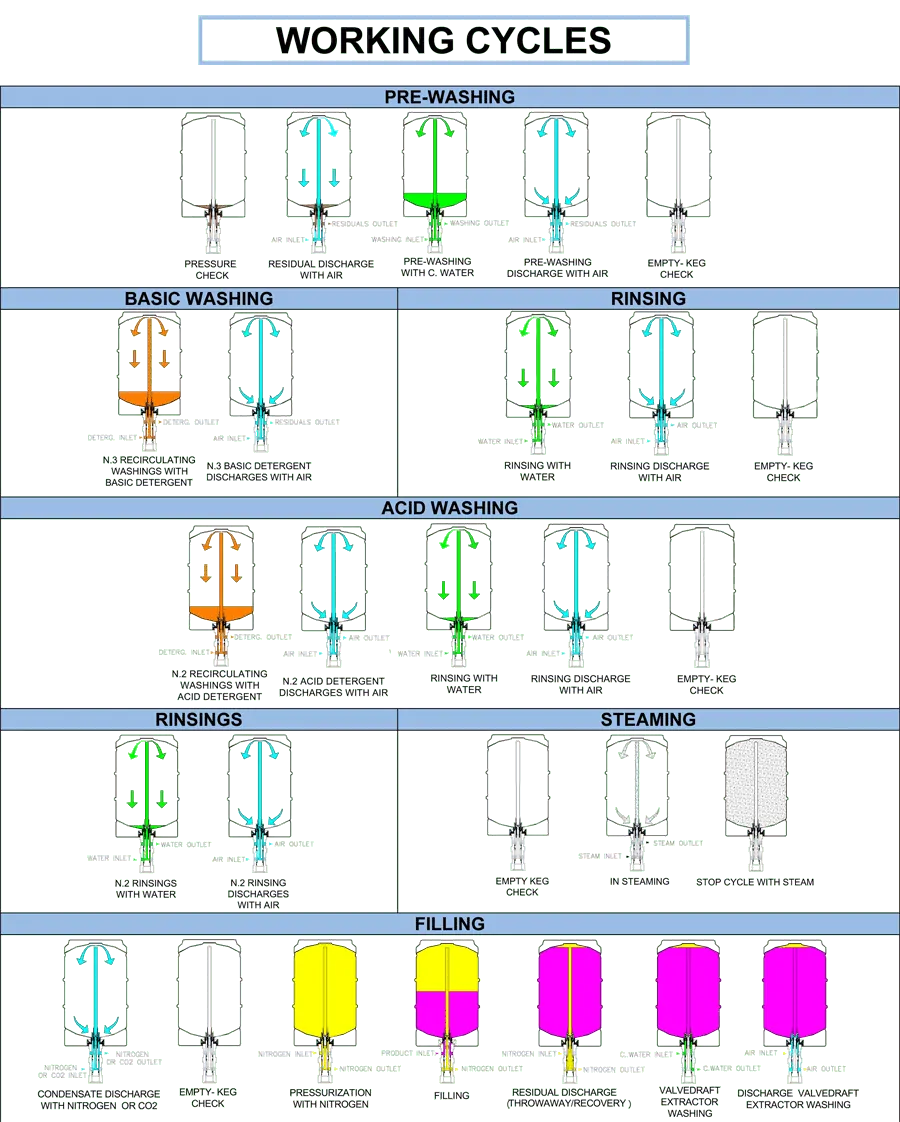

The washing systems were conceived to ensure:

- A good cleaning

- The checking and monitoring of the rinsing phase

- At the end of every work phase, the checking for the absence of liquid in the kegs, thus confirming the impossibility of unwanted rackings so as to be able to provide the assurance that the discharge phase has occurred.

The systems are fitted for the connection with a steam-generator for hot sterilization of the containers. The command and control parts are positioned in a watertight control board and electronically managed thanks to the use of a PLC. Our valves for the controlling of the washing and filling cycles are made out of turned-ingot stainless steel and, thanks to their perfect internal finishing, allow for easy washing and sterilization, thereby preventing filth and grime from settling. In addition, the special solid steel structure guarantees excellent resistance to wear and minimizes the need for ordinary maintenance operations.

Technical specifications

Keg filling range 10-50 l

Product handled Wine and similar liquids

Washing heads 1

Filling heads 1

Liter counter accuracy ± 0.20%

Average filling accuracy ± 1.5%

Accident-prevention protection Barriers with stop blocks

Sanitization – sterilization Water-chemical-Steam

PRODUCTION

Max. hourly keg production 20/30 l 32

Max. hourly keg production 50 l 28

CONSTRUCTION MATERIALS

Construction material Aisi 304 L stainless steel

Material in contact with the liquid Aisi 304/316L stainless steel & EPDM/PTFE/Silicone

DIMENSIONS AND WEIGHT

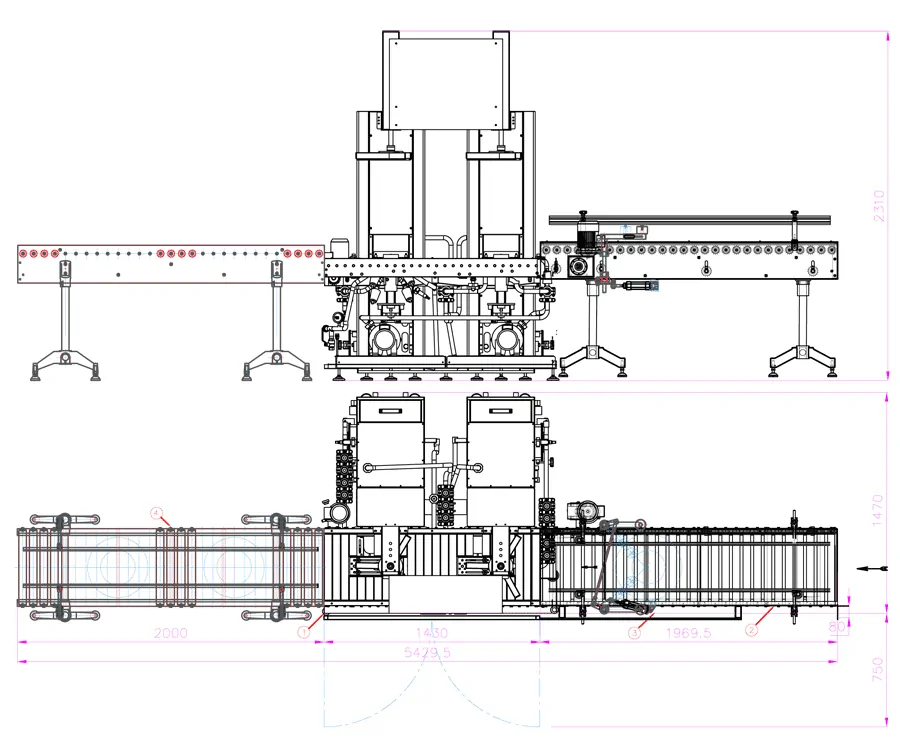

Height of the work table (mm) 870

Dimensions WxDxH (mm) 5500x1600x2350

Weight (Kg) 770

ELECTRICITY

Power of the filler (kW) 1.5

Power of the resistances (kW) if present 4.5

Number of phases 3/pe

Voltage (Volt AC) 400

Frequency (Hz) 50

CONSUMPTION

Max. liquid flow rate (l/h) 3600

Product Pressure (bar) 2-2.5

Air pressure (bar) 6

Air consumption (N l/min) 367

Nitrogen pressure (bar) 6

Nitrogen consumption (N l/min) 134

Water pressure (bar) 3

Water flow rate (liters/hour) 800

Heating steam (kg/h) 24

Sterilization steam (kg/h) 18

CONNECTIONS

Product DN 25

Compressed air ⅜” slide valve

Nitrogen ⅜” gas

Detergent-heating steam ½” gas

Sterilization steam ½” gas

Water ¾” gas

Electricity supply 3P+T 16A

Reviews

There are no reviews yet.