Description

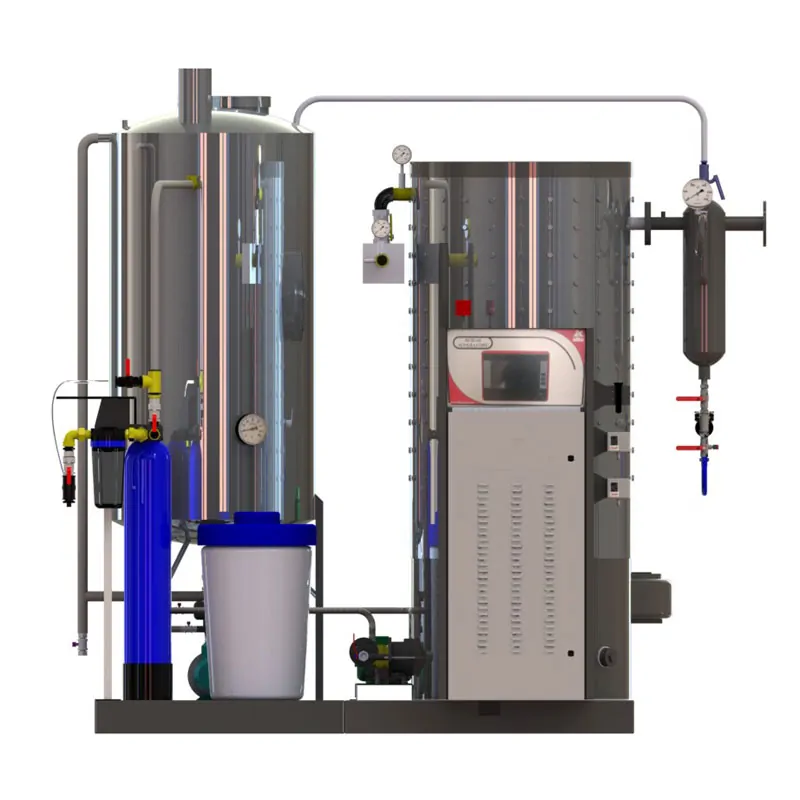

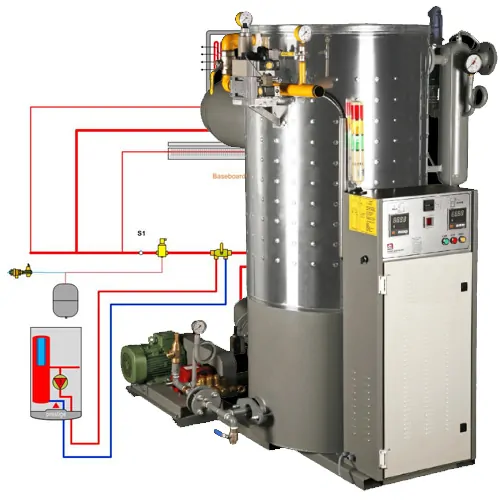

The compact fully equipped steam boiler room based on the GSG-500A gas steam generator with output capacity 349 kW which generates up to 500 kg of hot steam per hour at pressure of up to 16 bar.

The compact solution of a complete system which which includes the steam generator, the water/condensate supply tank, the water treatment system, the circulation pump, the by-pass system, all internal pipelines, electric switchbox and connections and all other necessary elements. The pre-installed compact system occupies less floor space, saves your time and money needed for the installation work. Its 100% safety allows you to place it into any environments. The machine complies with EU Directive 97/23 EC (PED) and Module H1, CE.

The high-quality european burners enables maximum energy gain from the GSG-500ACS steam generator supplied with natural gas or diesel together. Good access to all components guarantees easy maintenance of the machine.

Clean and safe chimney exhaust system which enables usage of the GSG-500ACS steam generator in every kind of building. Special multi-coil heating system enables maximum productivity in comparation with one-coil heating system.

The Digital Fault Indicator ensures fast and easy maintenance and saves time in locating any defect. All data is shown electronically and the system has an integrated self-protection for its electronics and safety parts. All Pressure, Control and Safety equipment is pre-installed.

Main advantages :

- Completelly equipped steam boiler room, immediatelly ready to use.

- All components are installed and connected together on two steel platforms.

- Installation and start-up in the same day (if all outer connections are prepared before)

- Very compact space-save system.

- Corrosion inhibitor dosage station Polybetalux 1500 is included.

- Water treatment system to water softening is included.

- Supply tank for water and returned condensate is included.

- By-pass system is insluded.

- All internal pipe connections are included.

- All internal electric wire connection and the electric switchboard are included.

- The circulation pump is included.

- The automatic sludge draining system is included.

- No risk of explosion.

- High 92-94% efficiency.

- Production of high quality 99.5% dry steam.

- Steam is ready to use only in maximally 3 minutes after cold start.

- Working pressure of steam up to 16 bar.

- Steam output capacity of 500 kg/h.

- Very easy to use – minimal maintenance requirement.

- Environment friendly.

- Multi fuel system – intended to use with natural gas, LPG or diesel.

- Low electric energy consumption.

- High efficient ignition system with Riello or Weisshaupt burner.

- All body parts are electrostatic powder paint coated.

- 4-way coil system and servo-motor technology that regulates air-fuel flow for high productivity and efficiency.

- 24/7 technical support and direct spare parts supplies.

Recommended use :

- Food and beverage processing and production

- Heating of water

- CIP stations

- Steam cleaning

- Sterilization of vessels, pipes, hoses and food equipment or farmacy equipment

Standard and optional accessories :

| Item code : | Description : | Price : |

| Built-in accessories : | ||

| GSG-500A | Gas steam generator 349 kW | 500 kg/hr | 16bar | included |

| GSG-DCS | Automatic digital monitoring and control system based on the touch display and internal PLC computer | included |

| GSG-ASS | Automatic start system (the machine and hot steam will be ready to use in time you need) | included |

| GSG-500A-ST | Supply tank for water and returned condensate | included |

| GSG-500A-WT | Duplex water treatment system (necessary equipment if water for use with the machine is not very soft) | included |

| GSG-500A-CF | Compact thick steel frame for the steam generator and accessories, all internal connections (supply water/condensate tank, water treatment system, circulation pump, by-pass system) | included |

| GSG-ABSD | Automatic boiler sludge draining system (do not need an operator manual activities – the digital timer and the pneumatic valve are included) | included |

| Optional accessories : | ||

| GSG-500A-CT | Sludge water cooling tank (to avoid draining hot sludge water in sewerage) | € 1500,- |

| GSG-DBP | Special burner and the pump for use the steam generator with LPG or diesel (the light fuel oil) | € 750,- |

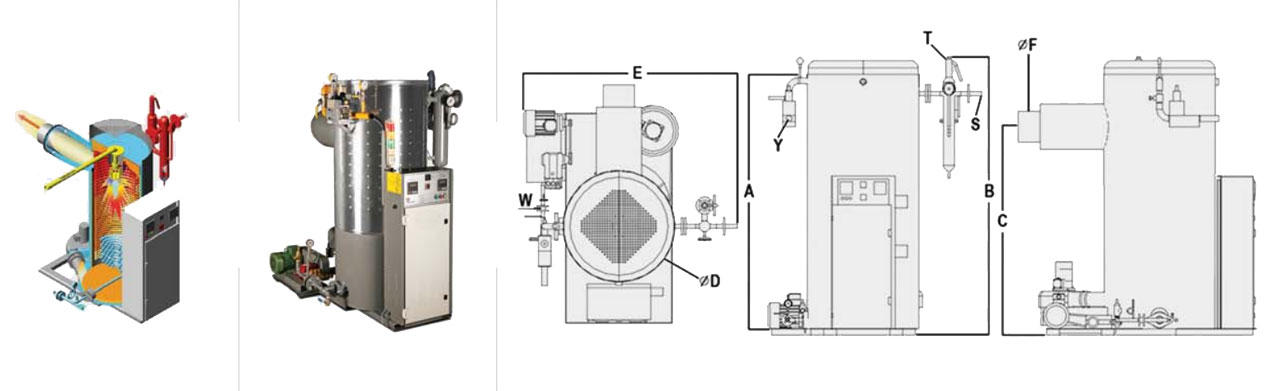

Dimensions and main parameters :

These dimensions and descriptions are valid for the basic version of the steam generator without the optional accessories (not for the fully equipped steam boiler room on the frame).

| Pipe connection | Description |

| F | Chimney (waste vapour outlet) |

| S | Steam outlet |

| Y | Gas inlet |

| W | Water inlet |

| T | Safety valve |

| Dimensions / Connections |

A | B | C | D | E | F | S | Y | W | T |

| GSG model | mm | mm | mm | mm | mm | mm | inches | inches | inches | inches |

| GSG-150A | 1435 | 1500 | 1035 | 575 | 1200 | 190 | 1/2″ | 1″ | 1/2″ | 3/4″ |

| GSG-350A | 1700 | 1800 | 1350 | 710 | 1250 | 230 | 1″ | 1″ | 3/4″ | 3/4″ |

| GSG-500A | 1700 | 1800 | 1350 | 710 | 1250 | 230 | 1″ | 1 1/4″ | 3/4″ | 3/4″ |

| GSG-750A | 1900 | 2000 | 1510 | 810 | 1420 | 310 | 1 1/4″ | 1 1/4″ | 3/4″ | 1″ |

| GSG-1000A | 2150 | 2250 | 1760 | 860 | 1650 | 310 | 1 1/4″ | 1 1/2″ | 1″ | 1 1/4″ |

| GSG-1500A | 2150 | 2350 | 1850 | 1000 | 1800 | 350 | 1 1/2″ | 2″ | 1″ | 1 1/4″ |

| Parameters | Capacity | Capacity | Capacity | Weight | Counter pressure | Input power | Noise level |

| GSG model | kg / h | kCal / h | kW | kg | mbar | kW | dB |

| GSG-150A | 150 | 90000 | 104.65 | 280 | 1.3 | 1.67 | 70.0 |

| GSG-350A | 350 | 210000 | 244.18 | 480 | 1.7 | 2.42 | 73.0 |

| GSG-500A | 500 | 300000 | 348.83 | 480 | 1.7 | 2.42 | 74.0 |

| GSG-750A | 750 | 450000 | 523.25 | 925 | 2.0 | 3.37 | 75.5 |

| GSG-1000A | 1000 | 600000 | 697.67 | 1200 | 2.3 | 4.07 | 77.0 |

| GSG-1500A | 1500 | 900000 | 1046.51 | 1750 | 3.1 | 6.57 | 77.0 |

| Parameters | Maximal steam pressure |

Boiler volume |

Heat exchange area |

Electric supply connection | Natural gas consumption | LPG consumption | Diesel consumption |

| GSG model | bar | liters | m2 | V / Hz | m3 / h | m3 / h | kg / h |

| GSG-150A | 16 | 13 | 4.5 | 3ph 400 / 50 | 10.9 | 4.5 | 9.2 |

| GSG-350A | 16 | 38 | 7.7 | 3ph 400 / 50 | 25.4 | 10.1 | 21.5 |

| GSG-500A | 16 | 38 | 7.7 | 3ph 400 / 50 | 36.2 | 14.5 | 30.6 |

| GSG-750A | 16 | 59 | 11.0 | 3ph 400 / 50 | 54.4 | 22.2 | 47.9 |

| GSG-1000A | 16 | 87 | 14.5 | 3ph 400 / 50 | 72.5 | 29.0 | 61.3 |

| GSG-1500A | 16 | 334 | 26.0 | 3ph 400 / 50 | 108.7 | 43.0 | 92.0 |

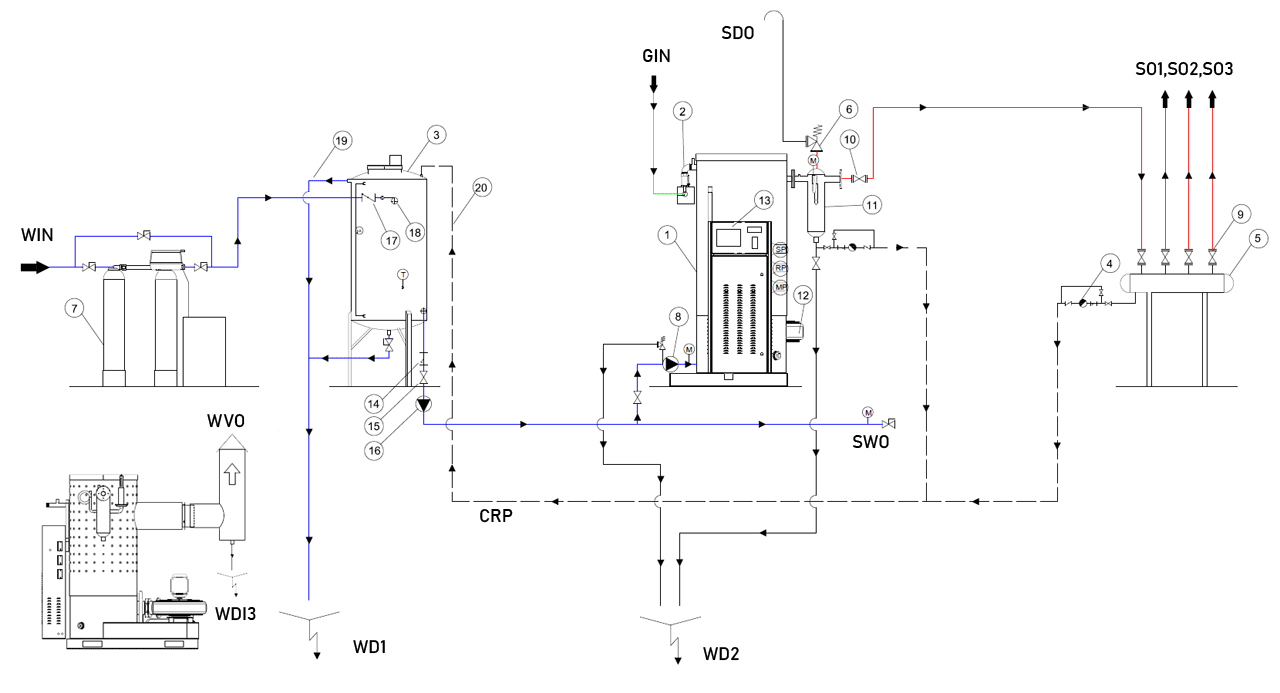

Flowchart

This flowchart describes all components, connections and elements which are included in the complete steam boiler room system.

( The steam manifold is not insluded in the steam boiler room … items no. 5, 9 )

Description :

| Item | Description | Item | Description | Item | Description |

| LG | Level gauge | 1 | Steam generator | 11 | Steam separator |

| MP | Maximum pressure switch | 2 | Fuel inlet multiblock | 12 | Ventilator |

| RP | 1st stage pressure switch | 3 | Water/Condensate tank | 13 | Electric control panel |

| SP | Safety pressure switch | 4 | By-pass system | 14 | Y-filter |

| T | Thermometer | 5 | Steam collector | 15 | Ball valve |

| M | Manometer | 6 | Safety valve | 16 | Booster Pump |

| WIN | Water inlet | 7 | Water treatment system | 17 | Check valve |

| GIN | Gas inlet | 8 | Feed pump | 18 | Float |

| S01 … S03 | Steam outputs | 9 | Ball valve | 19 | Overflow |

| WD1 .. WD3 | Water outlet (sewer) | 10 | Steam outlet valve | 20 | Condensate return |

| SDO | Water outlet (outside) | WVO | Waste vapour outlet (Chimney) | SWO | Sludge water outlet |

Instalation : Installation and assembling of the gas steam-generator performs each specialist company authorized for installation of gas appliances. The customer receives all detailed instructions in the English installation/operation manual.

Warranty : 12 months

Delivery time : from 3 to 12 weeks (according to current stock status)

Certificates: CE + PED 97/23 EC

Reviews

There are no reviews yet.