Description

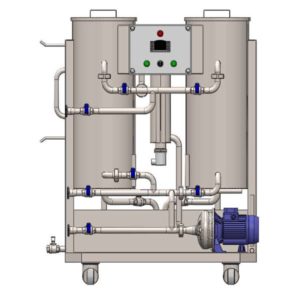

FMT-SLP-1000H is the simplified low-pressure beverage round-bottom tank with usable volume 1000 liters and total volume 1150 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 1.2bar, noninsulated, with water(or glycol) cooling channels.

The tank is completely made in Germany.

This offer and price includes the tank which is equipped with the most common equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories”

Main features:

- Pressure arched top bottom : NW 400

- Safety valve mounted on top layer

- Type plate for the identification of the container

- Multi use connection: nozzle NW 25 DIN 11851 welded on the top arched bottom – intended for T-adapter to the connection of carbon dioxide valve and adjustable pressure valve or sprayhead holder NW 10 for a cleaning of the tank.

- Threaded neck for connection of the sample valve NW 10 DIN 11851

- Temperature measuring-welded threaded connector NW 10 DIN 11851

- Pure product drain outlet 1″ ET

- Sediment / yeast drain outlet 1″ ET

- Double jacket 2 x 1″ ET

Advantages :

- The tank is designed for both fermenting and maturating (under pressure) larger quantities of beer (or cider, wine).

- Material : Stainless steel AISI 304

- The special 3D inner surface facilitates cleaning

- With double cooling jacket at the tank cylinder for the easy automatically water cooling during the maturation and fermentation process

- Made in compliance with the guidelines for pressure equipment PED 2014/68/EU including approval from Germany’s Technical Inspection Agency (TÜV)

- The double cooling jacket is equipped with two threaded necks to connection of a water cooler.

- The tank stands stably and safely on three legs.

- Several useful available accessories for expanding of the tank.

Dimensions

| Usable volume [liters] | 1000 |

| Total volume [liters] | 1150 |

| Total height [mm] | 1740 |

| Total diameter [mm] | 820 |

| Weight of empty tank [kg] | 85 |

| Weight of full tank [kg] | 710 |

Standard properties, design and equipment

| Maximal allowed overpressure | 1.2 bar |

| PED 2014/68/EU certificate | yes |

| Germany’s Technical Inspection Agency (TÜV) certificate | yes |

| Inner surface – surface quality of the stainless steel sheets | 3D |

| Inner surface – roughness of the welds | Ra<0.8μm |

| Cooling channels (double jackets) | yes |

| Insulation of the tank | optionally |

| Pressure arched top bottom NW400 | yes |

| Safety overpressure valve mounted on top arched bottom | yes |

| Type plate for the identification of the container | yes |

| Multi use connection: nozzle NW 25 DIN 11851 moulded on top layer. It is prepared to mounting of the T-adapter for the connection of carbon dioxide valve and plug apparatus or sprayhead holder NW 10 for cleaning >> See optional accessories bellow … | yes |

| Double jacket cooling channel in/out 2x 1″ ET | yes |

| Nozzle for sample cock NW10 DIN11851 >> See optional accessories bellow … | yes |

| Threaded thermometer socket NW10 – To mounting of the thermometer or the temperature sensor of the control system. See more about it … | yes |

| Pure product drain outlet 1″ ET | yes |

| Sediment / yeast drain outlet 1″ ET | yes |

| Stable legs [pcs] | 3 pcs |

| Automatic temperature control system >> See optional accessories bellow … | optionally |

Recommended use

| Usable for the fermentation process | yes |

| Usable for the maturation process | yes |

| Usable for the storage of the finished product | yes |

| Usable for the non-pressure product flotation | yes |

| Usable for the product clearing under pressure | yes |

| Usable for the product filtration under pressure | no |

| Usable for manual filling of the product into kegs | yes |

| Usable for manual filling of the product into bottles | yes |

| Usable for machinery filling of the product into kegs | no |

| Usable for machinery filling of the product into bottles | no |

Example accessories (included in this configuration)

Optional accessories (for surcharge)

How to choose the right type of CCT ?

| Type of CCT | CCT-SNP | CCT-SLP | CCT-SHP |

|---|---|---|---|

| Maximal adjustable pressure in the tank | 0.0 bar | 1.2 bar | 2.5 bar |

| Usable for the fermentation process | yes | yes | yes |

| Usable for the maturation process | no | yes | yes |

| Usable for the storage of the finished product | no | yes | yes |

| Usable for the non-pressure product flotation | yes | yes | yes |

| Usable for the product clearing under pressure | no | yes | yes |

| Usable for the product filtration under pressure | no | no | yes |

| Usable for manual filling of the product into kegs | no | yes | yes |

| Usable for manual filling of the product into bottles | no | yes | yes |

| Usable for machinery filling of the product into kegs | no | no | yes |

| Usable for machinery filling of the product into bottles | no | no | yes |

Our recommendation:

If you are comparing our prices with competitors, please always make sure that any other manufacturer guarantees the same quality as our company offers.

T-adapter

T-adapter

Stainless steel ball valve 1″

Stainless steel ball valve 1″ Stainless steel drain valve 1″

Stainless steel drain valve 1″

Thermometer analog NW10

Thermometer analog NW10 CIP sanitizing nozzle

CIP sanitizing nozzle Water (glycol) cooler for one single tank

Water (glycol) cooler for one single tank

Temperature measuring and control system

Temperature measuring and control system Compact temperature controller for one tank

Compact temperature controller for one tank