Description

Manual sterilizing machine for glass bottles

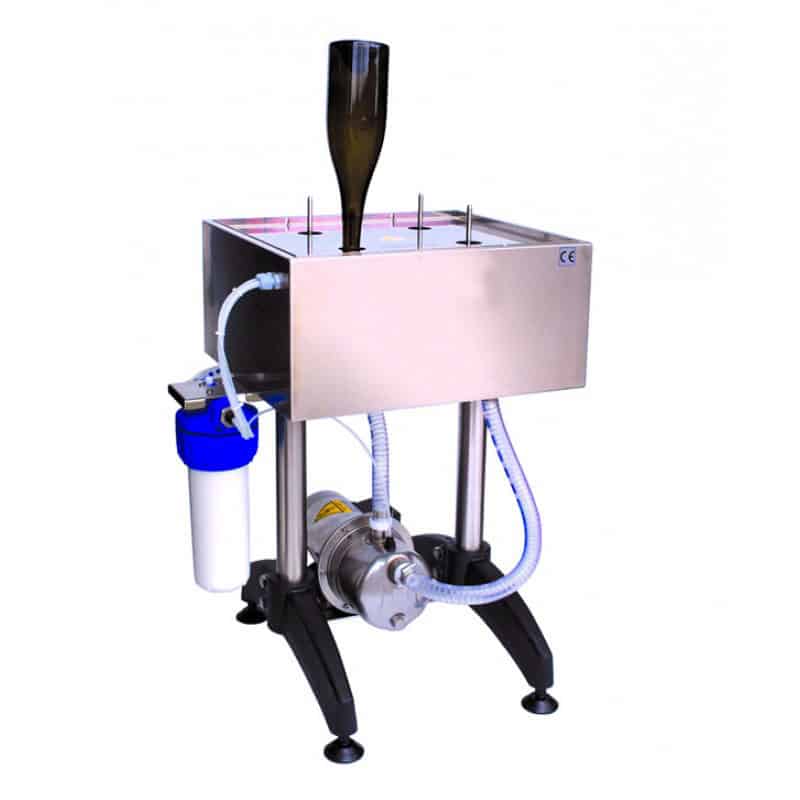

The bottle sterilizing machine allows to rinse glass bottles and jars from inside with an alcohol based sterilizing solution. Four positions for bottles to be sterilized.

Can be used with bottles of various shapes – range of volumes from 0.2 litres up to 2 litres.

- Maximal bottle diameter: 120 mm.

- Minimal bottle diameter: 30 mm.

- Maximal bottle height: 400 mm.

- Minimal bottle height: 180 mm.

Main properties :

-

- Productivity … depending on the operator experiences : 200 up to 600 bottles/hour.

- Sterilizing solution consumption … 0 liters/bottle – the sterilizing solution is recycled using the pump.

- Stainless steel centrifugal pump for recycling of sanitizing solution.

- Dimensions: width 51 cm, length 47 cm, height 65 cm, weight 25 kg.

- Made to EC standards.

Frequently asked questions :

Can this machine also be used for used bottles? No, the BWC-M600 machine is not intended for washing used bottles – for this purpose we recommend purchasing a special washing machine for used dirty bottles.

What is the rinsing time of the bottles? Since the bottles are clean, then 3-6 seconds are usually enough to sterilize the bottle.

How many bottles are sterilized at one time? The BWC-M600 has 4 nozzles: The operator rinses 2 bottles at two nozzles. A second operator can use next two nozzles to achieve higher capacity.

What is the volume of the sterilization solution container? 20 litres

How is the device controlled? The BWC-M600 machine has no commands. The machine rinses the bottles only when the user presses on the nozzles with the bottles neck.

Is the machine chemicaly cleanable ? Yes, the machine (excluding the air filter) can be sanitized with 2% lye and 2% acid 60°C.

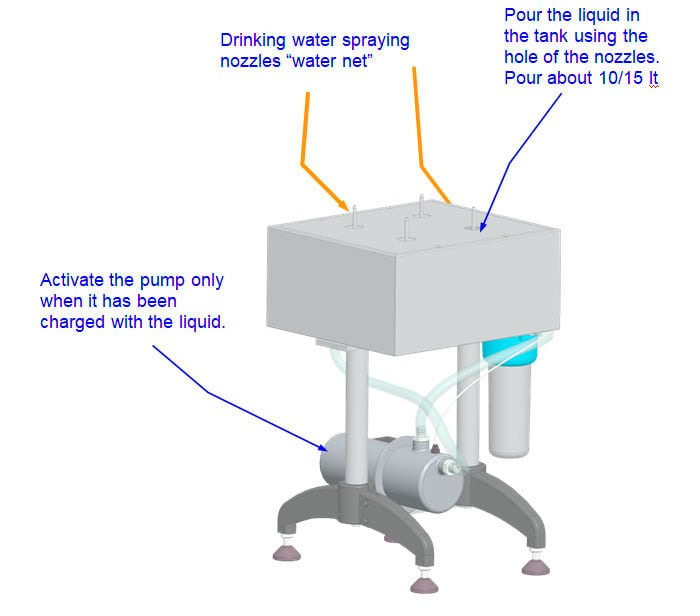

Main components :

WATER FILTER

The water filter assembly is including a micro-filtering cartridge of 0,45 μm (supplied apart in the machine package).

NOZZLES

The machines has 4 nozzles to rinse the bottles with the chemical solution.

CENTRIFUGAL PUMP

Operation process :

1. Check that the water supply connection has been carried on properly.

2. Check that the compressed air supply connection has been carried on properly.

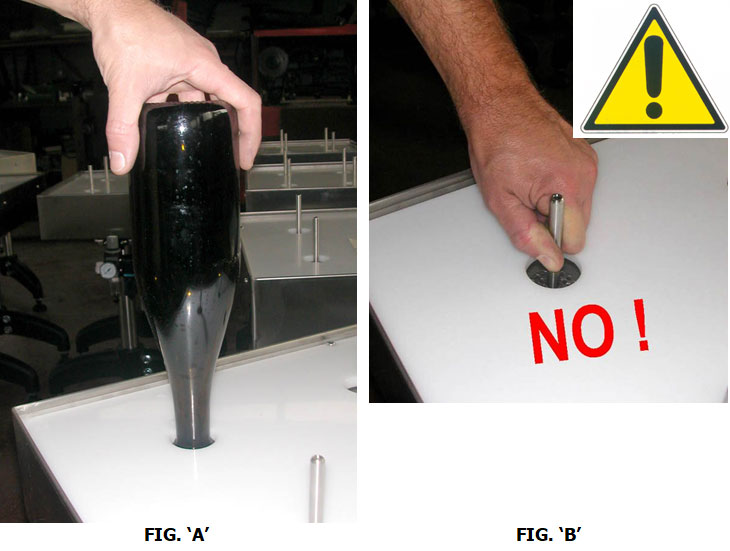

3. Load the bottle manually on the spraying nozzle, as shown on fig. ‘A’

4. Push down the bottle without excessive pressure, until the water / air jet comes out from the jet

5. Release the bottle after a few seconds

ATTENTION : NEVER PRESS THE NOZZLES MANUALLY, AS SHOWN ON FIG. ‘B’ – THE PRESENCE OF WATER / AIR UNDER PRESSURE COULD CAUSE SERIOUS INJURY ON YOUR FACE.

Reviews

There are no reviews yet.