Description

Microbrewery BREWORX CLASSIC 602M-3600 with the brewhouse BREWORX CLASSIC 600 allows the production from 600 to 2400 liters of beer per day. This configuration of the brewery includes set of tanks with production capacity up to 360.000 liters of top fermented beer or 216.000 liters of bottom fermented beer per year. Professional design of the brewhouse predetermines this brewery for luxury interiors of pubs, restaurants or hotels.

Manual control of the boiling process, media and tanks with PLC controllers support.

Notice : This offer does not include any services that are necessary for delivery and instalation of the brewery (installation work, transport and accomodation of workers, transport of the brewery technology, start up, training of brewer …) We calculate them individividually for each project – only for your demand.

Technical parameters :

Production capacity – daily :

- 600 liters of beer wort per day – one batch for 24 hour – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 1200 liters of beer wort per day – two batches within 24 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 1800 liters of beer wort per day – three batches for 24 hour – source raw materials are malt extract, hops, drinking water and brewer’s yeast

- 2400 liters of beer wort per day – four batches within 24 hours – source raw materials are malt extract, hops, drinking water and brewer’s yeast

Production capacity – yearly :

- Beer produced using the on surface fermentation method ……… 360 000 liters per year

- Beer produced using the under bottom fermentation method … 216 000 liters per year

Raw material :

- Classical raw materials : Malt + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

- Beer concentrates : Malt extract + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

- CO2 in pressure bottles (cylindres)

- Washing and sanitizing agents

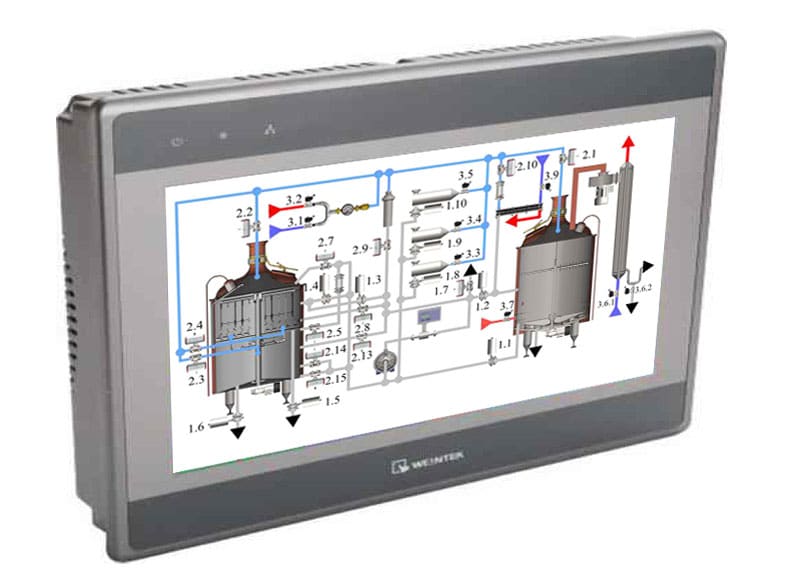

Control system :

- Brewhouse – boiling equipment :

- valves and claps – manual control

- temperatures – PLC controllers

- motors, pumps – PLC controllers

- timing – manual control

- Tanks – fermentation, maturation, bright beer :

- temperatures – PLC controllers

- timing – manual control

- Media – hot water, ice water, wort cooling, glycol tank :

- temperatures – PLC controllers

- timing – manual control

Required space for building :

- Floor area min : from 69 to 95 m2

- Room height min : 3.2 m

Electrical connection :

- Electrical socket : 400V 3ph / 50 Hz

- Electrical consumption :

- for the brewery with the electric steam-generator or electric heating elements … 75 kW

- for the brewery with the gas steam-generator … 41 kW

Brewhouse heating system – options :

- Electric heating elements

- Electric steam-generator – recomended

- Gas steam-generator

Cooling system :

- Cooling of wort : Drink Cold water + Ice cooling water

- Cooling of tanks : Ice cooling water (optionally glycol)

CONTROL SYSTEM FOR BREWERY BREWORX CLASSIC

I . Control system MC (manual control):

I . Control system MC (manual control):

Manually controlled brewhouse with simple button control panel what contains basic control and measuring elements. Manually controled pipe transfers, motors, pumps and temperatures. Timing and steps are controlled by a brewmaster.

II . Control system AC (automatic control) :

Automatic controlled brewhouse with computer support and most of the operation controlled by computer according to selected program in central control panel. Control panel is designed with touchscreen on which the brewmaster selects a recipe and starts program what controls the production process. Brewmaster controls and makes a laboratory tests, ensures preparation of raw materials and brewhouse for the process.

Reviews

There are no reviews yet.