Description

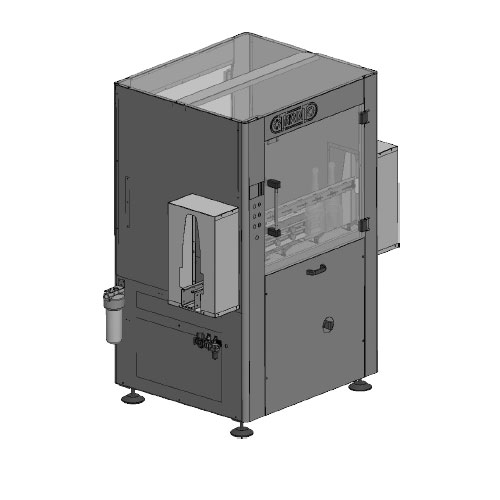

The automatic bottle blowing machine with independent loading and unloading of the bottles, works injection of micro-filtered air.

The machine is designed to quick drying the inside of wet bottles with filtered air, after their rinsing and before filling them with a beverage product.

The air is filtered using a filtering cartridge with nominal filtration rating 0.01μm (filtration efficiency: 99.9%) which is supplied with the machine.

Operation capacity is 1800 bottles per hour.

The machine is mounted on adjustable jointed feet, is manufactured in stainless steel AISI 304 and plastic components in conformity with the international directives.

Machine is designed to be inserted in the line (motor drive and idle wheel not supplied) or it can operate separatelly with manual loading and unloading the bottles.

Main parameters :

- AISI 304 quality stainless steel frame

- Bottle blowing station with 6 positions

- AISI 304 stainless steel water filtering assembly with 0.01 μm cartridge

- Blowing capacity : up to 1800 bottles per hour

- Installed power : 0.75 kW

- Standard voltage : 220V – 1ph – 50/60hz

- Weight : 350 kg

- Maximal bottle diameter : 100 mm

- Minimal bottle diameter : 45 mm

- Maximal bottle height : 380 mm

- Minimal bottle height : 115 mm

Working cycle description :

- Loading the bottles on the enter conveyor (manually or automatically optionally from the incomming conveyor)

- Automatic positioning of the bottles in the machine (6 positions)

- Clamping the bottles through double-acting suction cups

- Turnover of the bottles around the horizontal axis (6 bottles atthe same time)

- Blowing of the internal surface the bottles with filtered air

- Returning the bottles to starting position

- Releasing the bottles on the conveyor belt

- End of the working cycle

- Unloading the bottles from the output conveyor (manually or automatically optionally by the outgoing conveyor)

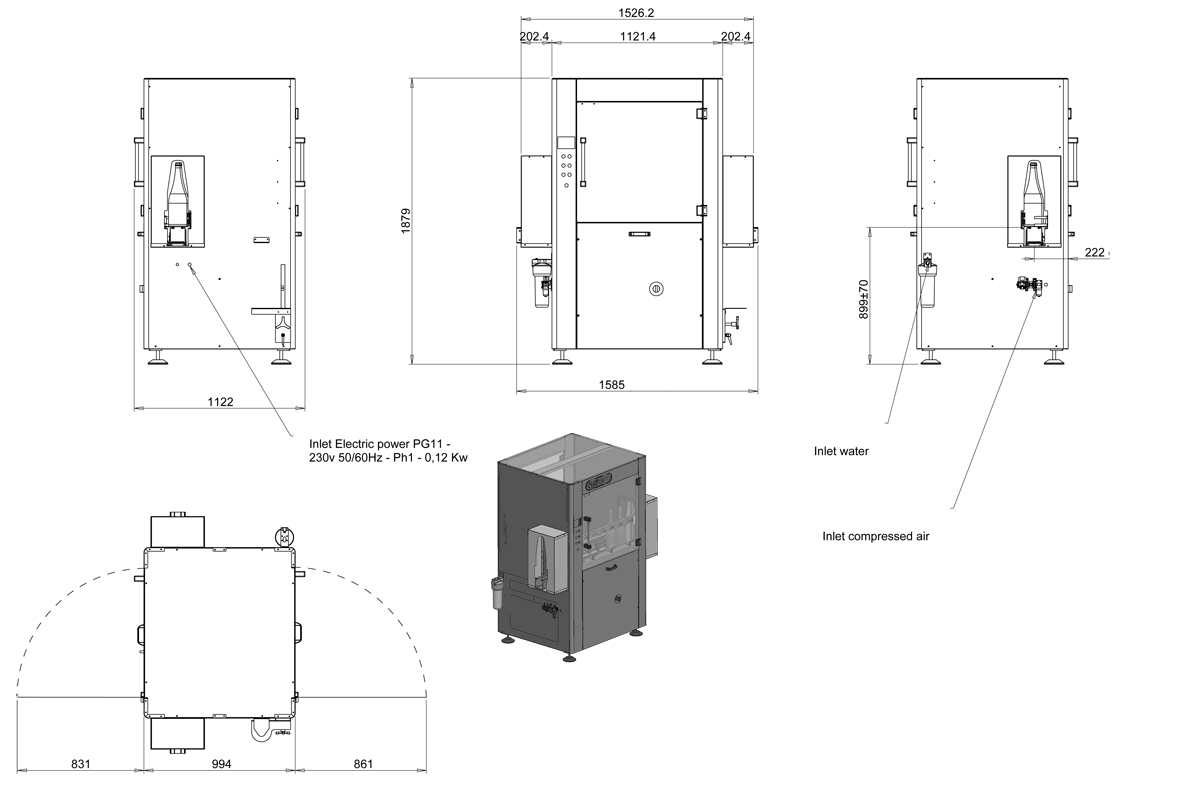

Machine dimensions :

Other optional accessories :

| Description | Price |

| BR-PHCE : Photocell at the exit | € 250,- |

| BR-ADCO : Additional bottle conveyor 100×100 mm (example : 500mm at the inlet of the rinser + 500mm at the outlet of the rinser = 1 meter) | € 700,- / meter |

| BR-MDIW : Motor drive and idle wheel | € 650,- |

| BR-FHC60U : 60μm filtering cartridge with a housing made of AISI316L stanless steel | € 73,00 |

| BR-SST : Stainless steel tank made of AISI316L stanless steel | € 250,00 |

| BR-BIRT800 : Rotating bottle accumulation table at inlet (Ø800 mm) | € 2350,00 |

| BR-BORT800 : Rotating bottle accumulation table at outlet (Ø800 mm) – with the speed variator and motor | € 4500,00 |

| BR-ANDS : Automatic Nitrogen Dosing Station ( designed to blow nitrogen into empty bottles before filling) | € 3700,00 |

| BR-ANDS-ISC : Additional inlet screw for the Automatic Nitrogen Dosing Station (to enlarge of the bottle feeding mechanism) | € 250,00 |

| BR-ANDS-FRI : Frequency Inverter for the Automatic Nitrogen Dosing Station (to allow speed change with a potenciometer) | € 580,00 |

| BR-ANDS-PHC : Photocell at the inlet for the Automatic Nitrogen Dosing Station | € 250,00 |

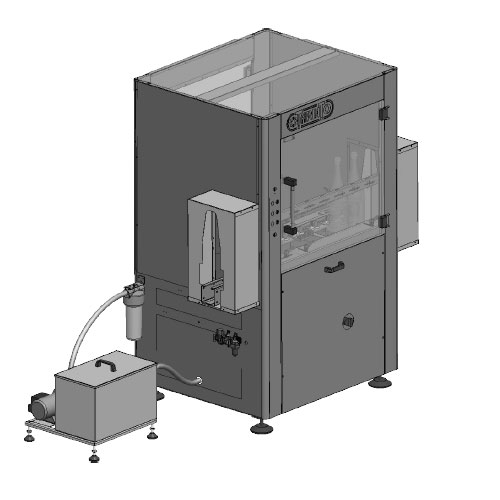

Automatic Nitrogen Dosing Station ( designed to blow nitrogen into empty bottles)

This optional automatic nitrogen dosing station is a free-standing module including a conveyor frame, easy to be installed at the infeed of a bottling line.

This optional automatic nitrogen dosing station is a free-standing module including a conveyor frame, easy to be installed at the infeed of a bottling line.

The unit is designed to blow nitrogen into empty bottles before filling, reducing the contact between the product (wine or oil) and the air, to get lower oxygen pick-up.

The infeed screw is selecting the incoming bottles under the dosing nozzle.

‘No bottle – no blow’ system to inject the nitrogen only with presence of a bottle.

The blowing time is depending on the speed of the line, with a maximum working output of 1500 bph.

The standard conveyor section is 100×100 mm, its length is 500mm.

The height of the dosing head is adjustable by a handwheel, to cover bottles height range of 150 – 400mm.

Technical Specifications :

- Control panel with push-buttons

- Standard Voltage 220V – 1ph – 50Hz.

- Fixed working speed, adjustment by frequency inverter on option.

- Photocell for bottles-jam control at outfeed

- Output : 1.500 bph

- Min. bottles sizes : diam. 55 x h.150 mm

- Max. bottles sizes : diam. 115 x h. 400 mm

Sales conditions :

| Delivery terms : | EX- WORKS our plant |

| Lead time : | 5 months (August excluded) from the order / deposit payment / samples of the bottles delivery.

Delivery terms are not binding but approximative. Delay on delivery terms not allows the right on order annulation or on price reduction or on damage refund. |

| Packing : | Packing fee is not included:

– surcharge for normal wooden pallete (shipping by a truck) : 110,00 € – surcharge for heat treated wooden box (for over sea shipping) : 550,00 € |

| Payment : | 50% when is ordered

50% before delivery |

| Warranty : | The warranty has duration of 12 months from the date of purchasing. Remote support considering a daily working shift between 8:00 – 16:00 of CET. On-site services are not included. A customer must disassembly the machine, diagnose and find a bad part, send the bad part to the producer with use our remote help. Then the producer send a spare part to the customer. |

| Installation : | The installation and commissioning are not included in price of the machine, only for demand. A customer pays all related cost of technician € 650,00 / day (flight, hotel, meals not included, at buyer’s charge). |

| What is not included in price : | All connections necessary for the machine operation (electric, pneumatic, water discharge…), to be performed by authorized personnel following the local safety laws; any works which will be necessary to install the machine in your production plant; anything else not mentioned in this present offer. |

| Offer validity : | 60 days from the present date |

| Other questions : | We remind you that we are at your disposal for a deeper examination of the technical and economical details of this offer. |

Reviews

There are no reviews yet.