Description

High-performance removable agitator with motor 1.1 kW 3-phase 380-420V 50Hz made in stainless steel, designed to temporary sealed connection with the stainless steel tanks with capacity up to 60000 liters, to mixing low-viscosity media. Due to the moveable agitator shaft and the foldable propeller, it can be simply and quickly inserted into a filled container from the side, via a standard ball valve with the TriClamp DN50 2″ DIN 32676 (or Sanitary Screw Connection DIN 11851) connection, without leak liquid from the tank.

Fixed rotation speed, folding propeller blades. This equipment is not suitable with pressure tanks.

Special version – the agitator is equipped with the mobile stand and the frequency inverter.

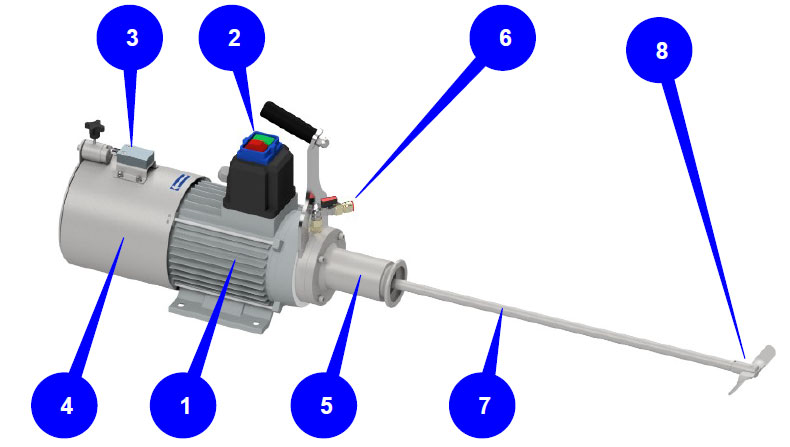

Description :

- Motor with integrated control panel

- START/STOP buttons

- Safety micro-switch

- Protective casing

- TriClamp for attachment to the tank, with mechanical seal

- Air release valve

- Extractable shaft

- Foldable propeller

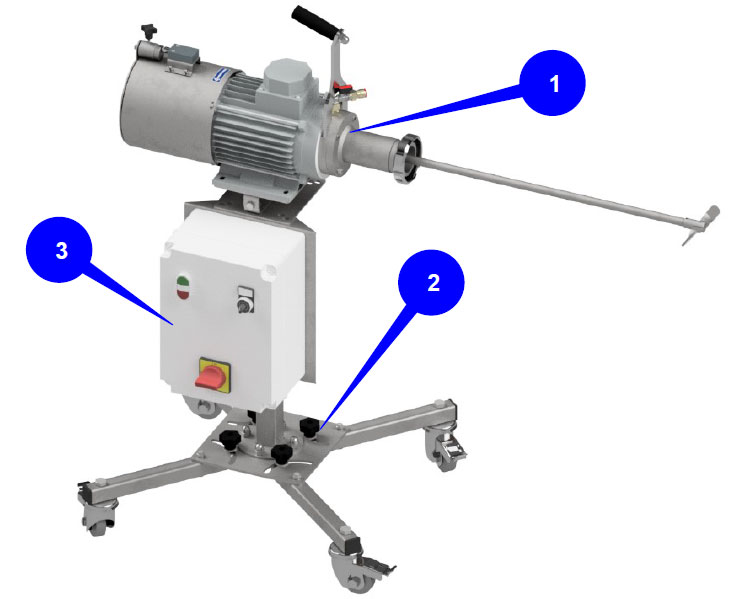

Agitator with the mobile stand and the frequency inverter :

- Agitator

- Height-adjustable stand (with either castors or feet)

- Control panel with the frequency inverter

Standard equipment and technical parameters :

- High-quality mechanical shaft seal

- Connector for joining with a tank : TriClamp 2″ (DIN 32676 TriClamp DN 50 / Disc Ø66mm.) or Sanitary Screw Connection DN 50 female (DIN 11851)

- Motor protection switch

- 10m power cable (Standard EU 3-phase 16A connector)

- Designed for tanks with capacity up to 35000 liters

- Motor 3-phase 380-420V 1.1 kW

- Fixed rotation speed of 920 rpm

- Weight 25 kg

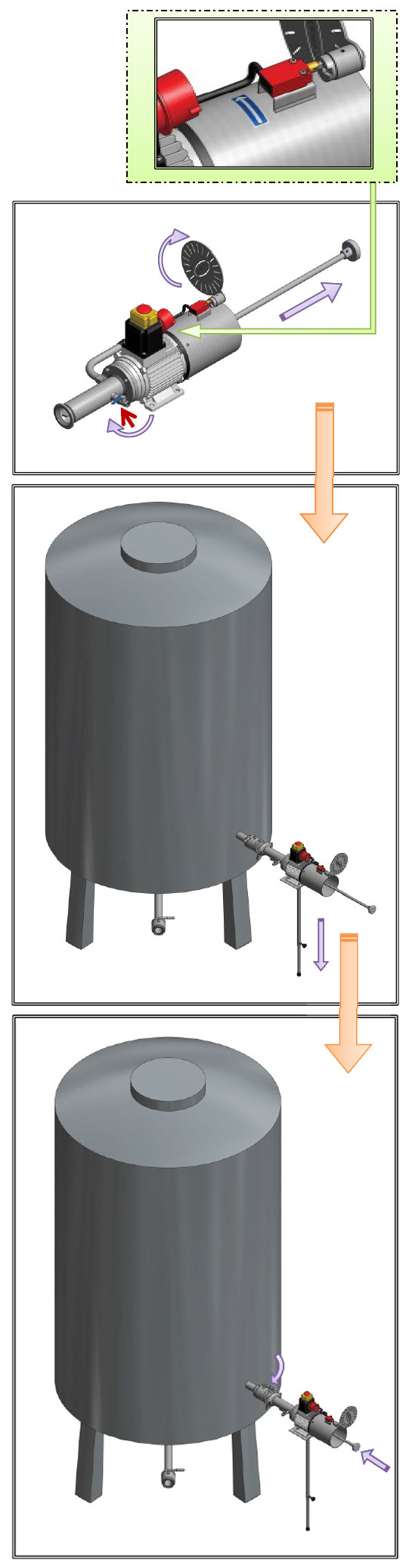

The procedure for fixing the agitator on the tank is very simple:

Thoroughly clean the propeller shaft and coupling tube, then proceed as follows:

- Check that the direction of rotation of the motor coincides with that indicated by the arrow

- Open the safety guard door

- Pull the shaft back until the propeller is retracted into the tube

- Close the air release valve

- Couple the agitator to the TriClamp DN50 connection pipe port on the tank (ball valve DN50)

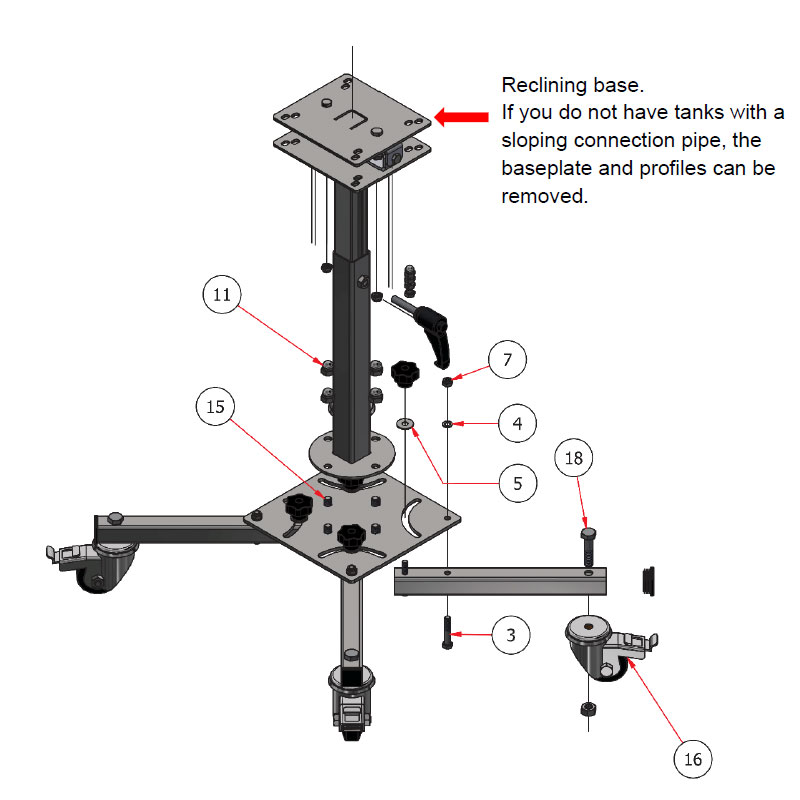

- If the agitator is equipped with a stand, adjust the height of the legs so that it is aligned with the TriClamp DN50 connection port

- Open the ball valve DN50, being careful because the pressure inside it could push the propeller shaft out

- Push the propeller shaft deeply into the tank

- Hook the pull pin of the rod onto the bronze pull bushing of the motor

- Close the crankcase door

To disconnect the removable mixing device, proceed as follows:

- Switch off the agitator using the stop button and disconnect the device from the power supply

- Open the crankcase door

- Release the traction coupling, taking care – the pressure in the tank could quickly push the propeller shaft out

- Pull out the propeller shaft to the extent necessary to close the balll valve

- Close the ball valve

- Open the pressure relief valve

- Disconnect the device from the tank (Unlock the clamp)

The stirrer connection port on side of the tank :

We offer the ball valve DN50 (2″) to safety connection of the mixing device with the tank :

BVB-2TC50 : Ball valve DN50 (full-flow) with connections : TriClamp / TriClamp (DIN 32676), stainless steel

Dimensions of the agitator and parameters :

| Model | Motor power | Voltage | Rotational speed | Propeller diameter | Wheeled stand | Shaft length | Weight |

| RAT-055FS | 0.55 kW | 1-phase 220-240V 50Hz | 875 rpm | 150 mm | no | 510 – 530 | 18 kg |

| RAT-075FS | 0.75 kW | 3-phase 380-420V 50Hz | 920 rpm | 150 mm | no | 510 – 530 | 22 kg |

| RAT-110FS | 1.10 kW | 3-phase 380-420V 50Hz | 920 rpm | 150 mm | no | 570 – 590 | 25 kg |

| RAT-110VS | 1.10 kW | 3-phase 380-420V 50Hz | 920 rpm | 150 mm | yes | 570 – 590 | 40 kg |

Reviews

There are no reviews yet.