Description

The PPM-DR is a portable measuring device designed for recording temperature curves and for measuring the pasteurization effect (in pasteurizing units) during pasteurization of beer, cider, lemonades and soft drinks. The device can also be used as a recorder of any other temperatures in a defined time period, e.g. during mashing, main fermentation, post-fermentation, room temperatures in warehouses, etc.

It is possible to use the measuring device also for working calibration of immersion, shower, tunnel and steam pasteurizers to be used with different bottle/can formats and different drinks.

Delivery time : Usualy 6-9 weeks.

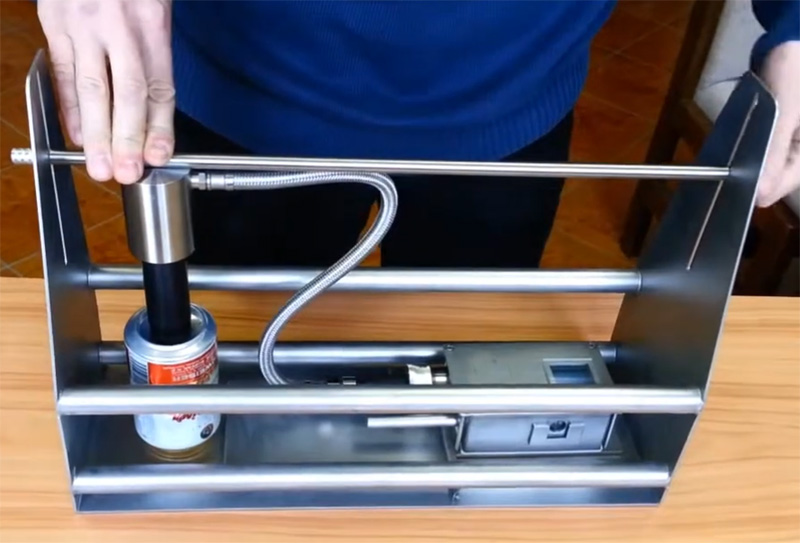

Measuring of pasteurizing a beverage in the can :

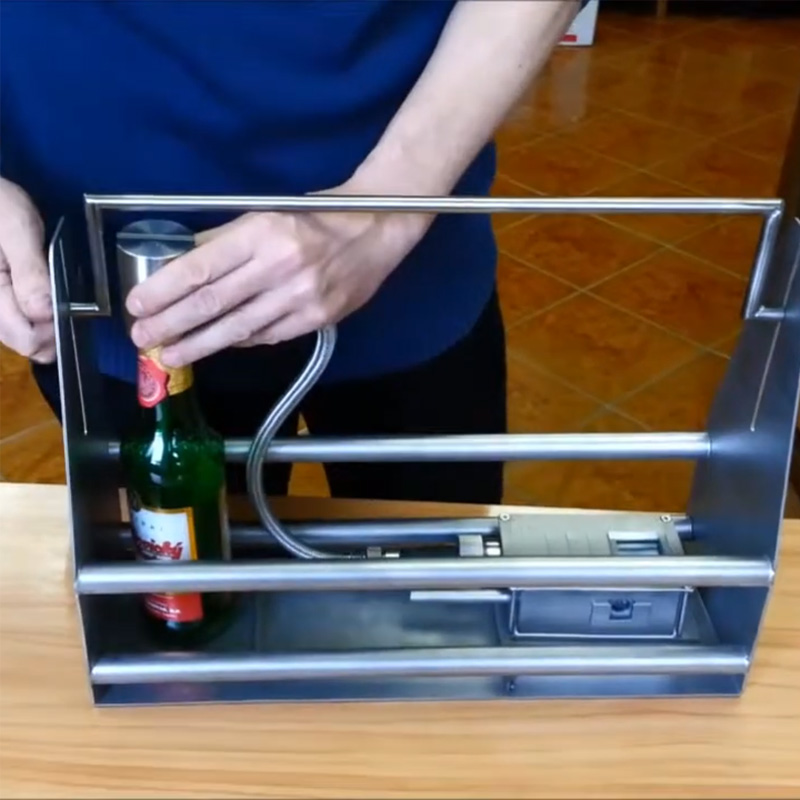

Measuring of pasteurizing a beverage in the glass bottle :

How the measuring takes place ?

The measuring device consists of two temperature probes and a measuring microcomputer. One temperature probe measures the temperature of the beer in a bottle or can. The second temperature probe controls the temperature of the shower water or water fog that heats the bottles.

The measuring microcomputer is located in a waterproof and temperature resist case. The length of the temperature probe is chosen so that the measurement point is at a height of approximately 10 mm to 30 mm from the bottom of the bottle or can, which is the place that heats up the slowest.

The pasteurization process monitor is equipped with an internal memory in which the measured temperatures are periodically stored. After the measurement, these measured temperatures are transferred via the RS232 or USB connection cable from the internal memory of the pasteurization monitor to the PC or the notebook, where the measured values are processed and evaluated using the supplied evaluation software.

The pasteurization process monitor is powered by a 3.6 V lithium battery (size AA), which is easily replaceable. The measurement is switched on and off by placing a magnet on the case of the pasteurization monitor, or the pasteurization monitor can be switched on and off software-wise from the PC.

Technical parameters:

- Pasteurization unit measurement range: 0 to 1000 PU

- Standard temperature range: -15° to +70°C

- Special temperature range (only on customer request): -15° to +85°C

- Pasteurizing units calculation: 1 PU/min at 60 deg. C

- Z (for yeast culture): 6.94 (can be changed)

- Temperature measurement accuracy: +/- 0.1 deg. C

- Temperature measurement period: 10 sec (can be changed)

- Power supply: Lithium batteries 3.6 V (size AA)

- Battery life: min. 2 years

- Dimensions : H x W x D : 400 x 130 x 300 mm

- Weight : 3 kg

The evaluation program provides the following options:

- Works under WINDOWS 10, WINDOWS 8, WINDOWS 7, 2000, XP, Vista operating systems

- Transfer of data from the pasteurization monitor to a PC

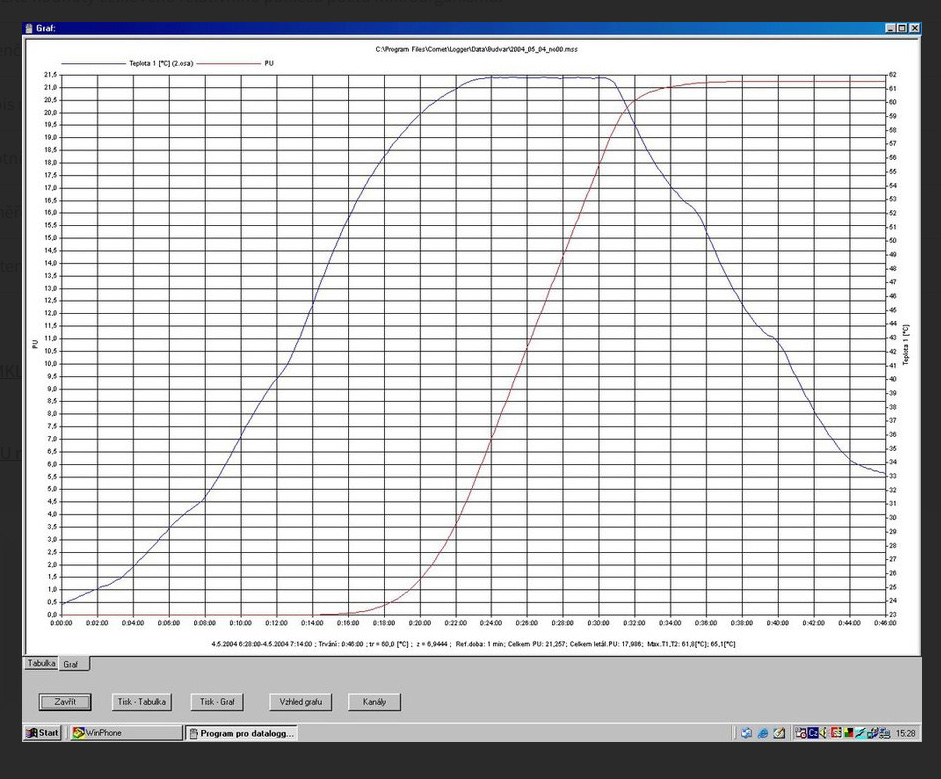

- Graphic display of temperature curves and pasteurization curves

- Graphic display of the curve of assigned lethal rates of biological killing of microorganisms

- Calculation of total pasteurization units

- Calculation of instantaneous values of the total lethal effect

- Calculation of the instantaneous value of the total relative decrease in the number of microorganisms

- Calculation of the reference proportion of sensory damage to beer by pasteurization

- Table listing of measured values

- Printing of the temperature curve, pasteurization curve and table values on a printer

- Archiving of measured data on the computer disk – Reloading of saved data from the disk and displaying on the computer display, or printing on a printer

Range of supply:

- Measuring device with the display, the integrated temperature sensor and built-in memory

- Two different exchangeable external temperature sensors (for bottles / for cans)

- Data cable for the connection of the measuring unit with a PC computer

- Magnet for start/stop of the pasteurizing process monitor

- User’s guide

Reviews

There are no reviews yet.