Description

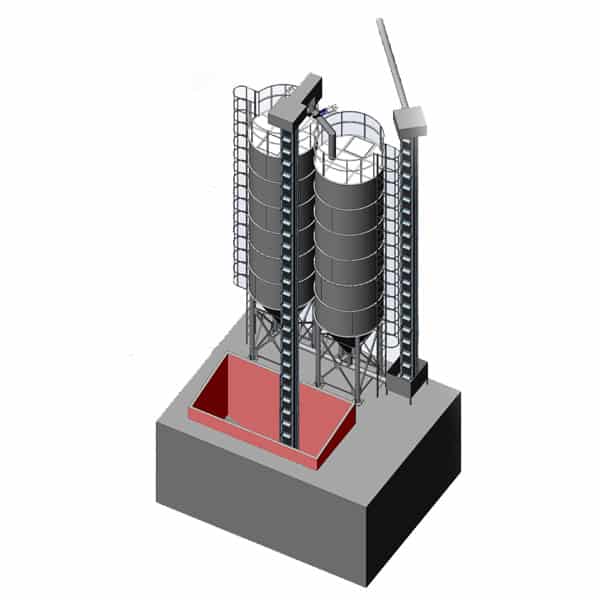

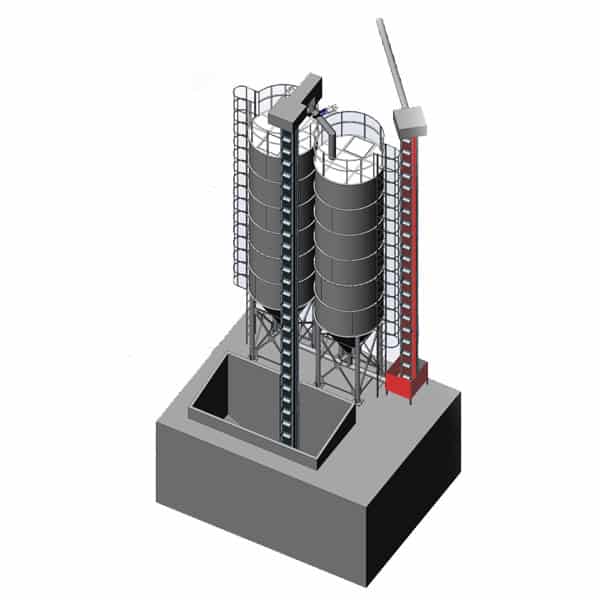

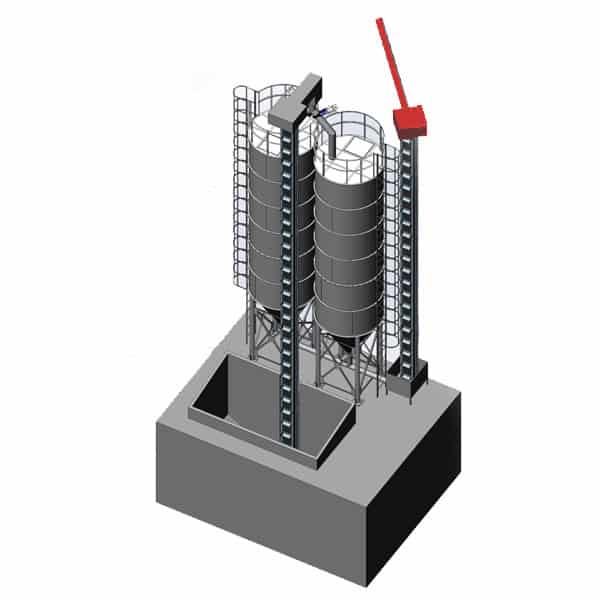

The MSS-40 malt storage silo is fully equipped system for storage and dose malt for medium-large breweries.

The system consists of these subsystems :

- Hopper for incoming malt

- Primary bucket conveyor for malt above the both silos

- Distribution pipe manifolds with flap above both malt silos

- Silos for storage malt … 2x 40 m3

- Screw conveyor for transport of malt from hopper placed under the silos to the input hopper of the secondary bucket conveyor

- Secondary bucket conveyor for transport of malt from lower screw conveyor under the both silos to the upper screw conveyor above the malt mill

- Screw conveyor for transport of malt from upper hopper above the silo to the brewery to the hopper above the malt milling machine.

- Automatic control system

- Steel construction, connection elements, pipe and electric system

1. Hopper for incoming malt

Stainless steel stack with a capacity of 8 tons of malt.

Stainless steel stack with a capacity of 8 tons of malt.

For installing the basket for incoming malt is required readiness of the concrete base and engineer nets ensured by customer before the installation work.

Parameters: (can be modified by the project)

- Length 3,000 mm

- Width 2 500 mm

- Height 2 500 mm

- Bottom drain DN200

- Total volume 18.75 m3

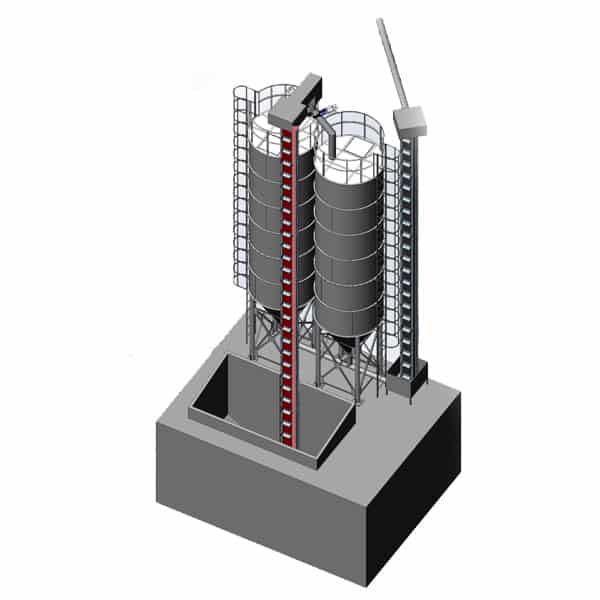

2. Primary bucket conveyor for malt above the both silos

The bucket conveyor located between the hopper for the incoming malt and the malt storage silos is used to transfer malt to distribution pipe-manifolds above both malt storage silos.

The bucket conveyor located between the hopper for the incoming malt and the malt storage silos is used to transfer malt to distribution pipe-manifolds above both malt storage silos.

Parameters: (can be modified by the project)

- The length of the bucket conveyor is about 14 meters

- Transport capacity of the bucket conveyor is 3 500 kg / hr

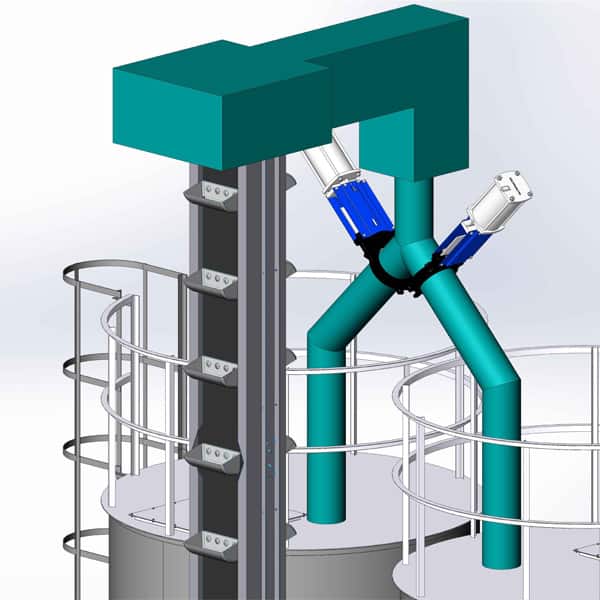

3. Distribution pipe manifolds with flap above both malt silos

The pipe system with the electricaly controled flap for distribution of malt incoming from the bucket conveyor, to the separated malt storage silos.

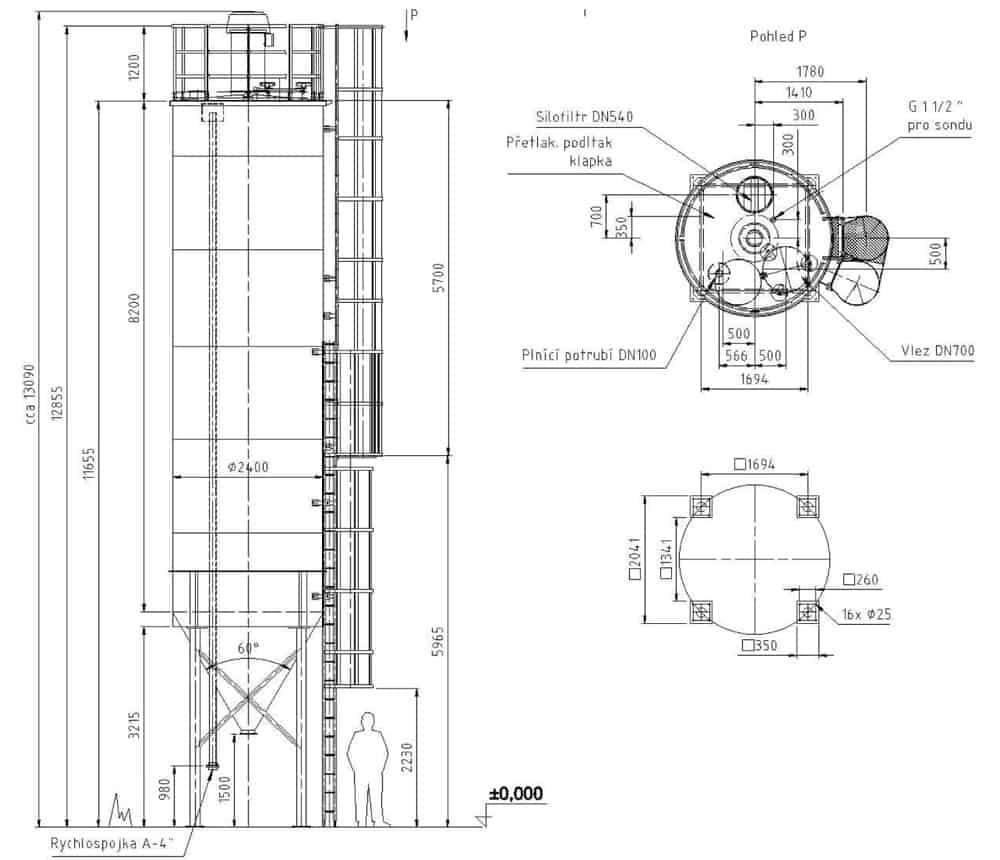

4. Silos for storage malt … 2x 40 m3

Set of two malt storage silos 2 x 40 m3 consists of :

- Two malt storage tanks for storage malt, each with useful volume of 40 m3

- The silos are delivered completely welded

- Outlet of malt from silos in height 1200 mm

- Tubular base frame

- 1 outlet ladder

- 3 pieces of service-maintenance footbridge

- Each silo equipped with anti-explosive membranes

- At every silo is mounted dust filter in the normal version

- Material Standard S 235 JR steel with common outer surface finish painted outside, inside the food paint applied.

- Pressureless tanks … maximal working overpressure 0.2 bar

- Diameter 2400 mm

- Height of the cylindrical part 8200 mm

- Total height 12900 mm

- 60 ° discharge port with opening and outlet DN 250

- 1pc of manhole DN 700 in the lid

- 1pc of filling pipes DN 100 inside the tank

- 1pc of pipe port for the air filter

- 1pc of pipe port for the overpressure and vacuum safety valve

- 2 pcs of pipe port for the level indicator probe

- 4pcs of pipe port with flange for anti-explosive membrane in the shell

- Silo base – 4 legs with fixing pipes

- Outlet height 1500 mm

- Anchor plates for anchoring on a concrete foundation

- Safety railing along the outer perimeter of the lid

- Quick-coupling piping type A with lid on the chain

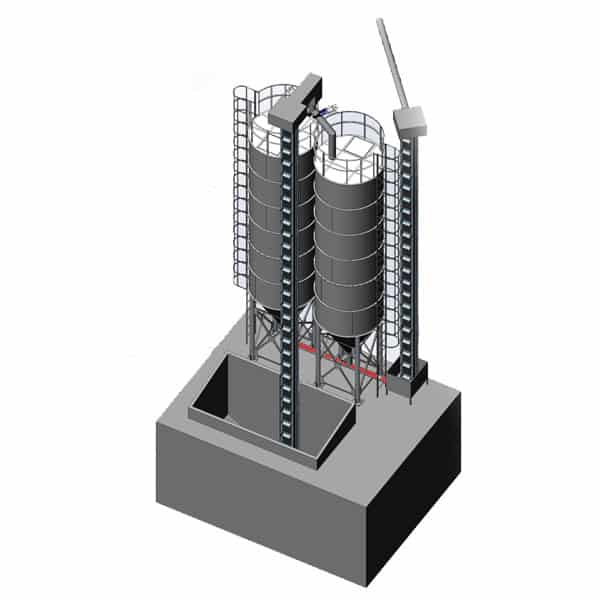

5. Screw conveyor for transport of malt from hopper placed under the silos to the input hopper of the secondary bucket conveyor

The screw conveyor located between the hopper under silos for the transport of malt to the lower hopper of the secondary bucket conveyor.

Parameters: (can be modified by the project)

- The length of the bucket conveyor is about 7 meters

- Transport capacity of the bucket conveyor is 1 000 kg / hr

6. Secondary bucket conveyor for transport of malt from lower screw conveyor under the both silos to the upper screw conveyor above the malt mill

The bucket conveyor located between the lower hopper under silos for the transport of malt from the malt storage silos to the hopper of the upper screw conveyor.

Parameters: (can be modified by the project)

- The length of the bucket conveyor is about 14 meters

- Transport capacity of the bucket conveyor is 3 500 kg / hr

7. Screw conveyor for transport of malt from upper hopper above the silo to the brewery to the hopper above the malt milling machine.

The screw conveyor located between the hopper under silos for the transport of malt to the lower hopper of the secondary bucket conveyor.

Parameters: (can be modified by the project)

- The length of the bucket conveyor is about 7 meters

- Transport capacity of the bucket conveyor is 1 000 kg / hr

8. Automatic control system

Hardware and software to automatic or manual control of the full silo system.

9. Steel construction , connection elements, pipe and electric system

Basic frame and supporting construction, ladders, safety elements.

Dimensions :

Technical specifications :

Reviews

There are no reviews yet.