Description

The electric malt crusher 3x400V 14kW with wide hardened rollers designed for a preparation of malt grist with production capacity from 6000 to 8000 kg per hour. The MMR-900 roller mill is a device made for a crushing of grains. We recommend using this model for microbreweries with volume of the brewhouse up to 6000 liters.

ADVANTAGES:

- Special technical solution for the gentle squeezing of malt grain

- The structure of the final product can be changed and the machine meets a wide range of grain malt requirements

- Production of malt with a performance up to 10 tons per hour

WHAT IS THE PURPOSE OF THE MACHINE?

This machine is great for medium sized and small breweries with the required capacity. It usually works in cycles, but we also supply a small technological line with scales , hopper and drill.

We produce three variations of the MMR-900 mill :

- Malt mill MMR-900M – is designed to the gentle squeezing of malt grain before the wort boiling process (in breweries).

- Crimper MMR-900G – is designed to crushing of cleaned malt (for mixes and concentrates).

- Crumbler MMR-900P – is designed to crushing of granules (pellets).

Other uses are possible after consultation and approval of the manufacturer.

Prices are all the same (for these three variations).

Manufacturer’s declaration

The machine has been produced since 1995. Its compliance is certified with Czech Republic Act no. 22/1997 Sb. The machine is also certified by the Veterinary Office of the Czech Republic.

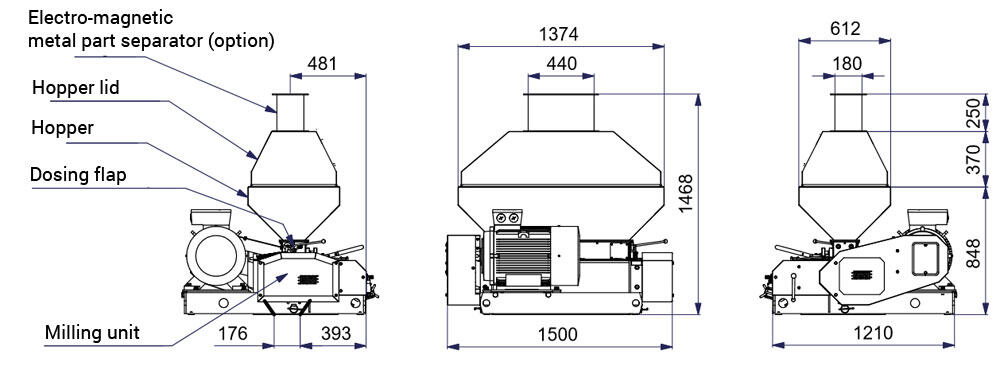

TECHNICAL DESCRIPTION :

The machine is composed of a feed hopper with a sliding inlet and a technological section.

The technological section is made up of welded steel into which the upper working rollers are inserted from above and fastened. One of the rollers runs, the other is driven. It is ensured that the axes of the working rollers remain parallel in all positions. Transfer of torque from the electric engine to the driving roller via V-belt pulleys is done on one side of the case. The driven roller (movable) is driven by gear wheels from the driving roller shaft at the other side of the case. This roller is rotating in the opposite way to the driving roller.

The crimper has a gear ratio 1:1, the grinder and the crumbler have ratio 1:2.

Main parameters :

Features |

Units |

Values |

| Working roller diameter | mm | 215.5 |

| Working roller length | mm | 900 |

| Dimensions : length x width x height | mm | 1500 x 1210 x 848 |

| Output and rated electromotor current: | ||

| 3x400V, 50Hz, 1466 RPM (grinder) | kW; A | 14.5; 25 |

| 3x400V, 50Hz, 719 RPM (crimper) | kW; A | 8.0; 18.8 |

| 3x400V, 50Hz, 1460 rot./min (crumbler) | kW; A | 9.0; 17,1 |

| Throughput (depending on feed fraction and engine output) | ||

| Malt mill MMR-900M | t/hour | 6 – 8 |

| Crimper MMR-900G | t/hour | 5 – 6 |

| Crumbler MMR-900P | t/hour | 14 – 20 |

| Working roller grooving | ||

| Recommended setting of the gap : | ||

| grinding: wheat, barley, oats | mm | 0.2 |

| grinding: maize, peas | mm | 0.5 |

| grinding for cattle and poultry | mm | 0.5 – 0.8 |

| crimping grain | mm | 0.2 – 0.6 |

| crumbling granules | mm | 0.4 – 0.7 |

| Minimum gap | mm | 0.1 |

| Maximum bounce | mm | 20 |

| Slide gate opening in the feeding hopper | mm | up to 50 |

| Weight (dependent on the engine used) | kg | 1387 |

Material

The machine is made of steel – grade 11 (with respect to functionality, endurance and weldability of the parts).

Rollers have special surface protection because their coatings are subject to considerable stress. All standardized parts are made of Czech origin.

The surface is protected by varnish.

Covers

The machine is designed to operate in a flammable dust environment with a maximum temperature of + 40 ° C and a minimum temperature of -20 ° C. Therefore, all electrical installations are manufactured with respect to this risk and meet the requirements of EN ISO. The machine also complies with air pollution regulation standards. The machine was designed to operate under mild climatic conditions and has an IP 54 rating.

Noise

The noise value done by the machine is 86 dB(A) – crimper and 81 dB(A) – grinder. The noise values were measured at a distance of 1 m from the machine at a height of 1.5 m in place for the attending worker.

Why choose just this malt mill?

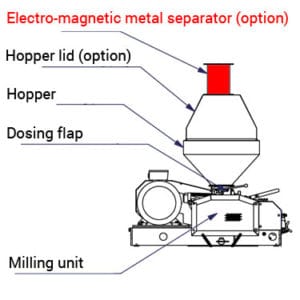

1. Hopper and protection against dirt

The capacity of the hopper corresponds to the capacity of the machine. The hopper is equipped with a sophisticated protective mechanism that regulates the amount of processed raw material. In the event of a sudden increase in the gap between the rolls as a result of ingress of lumps of malt or undesirable impurities this mechanism works as a quick shutter. The peak parameters of the hardness of the cylinders can not be achieved practically without increasing the brittleness of the surfaces of the rollers. Therefore, it is necessary to protect these cylinders against metallic and mineral impurities larger in size, which will not keeped by the grid in the hopper. For this case, all MMR machines are equipped with unique mechanisms for the immediate safe divergence off of the adjustable cylinder when the dirt is going through. This makes the hard object between the rollers pass without damaging the surface of the cylinder shell. Simultaneously with the safety moving of the cylinders, the supply of material from the hopper to the cylinders is closed, and thus there is no way to let the contamined raw material to go through out up to the wort brew machine.

2. Stable and precision gearbox with cylinders

The basis of trouble-free operation is a rigid and precisely designed main case with the gearbox and drive, in which two horizontal working cylinders are mounted. The correct operation is ensured by proven gears and a reliable mechanism that changes the position of one of the cylinders depending on the momentary load and thus the size of the gap between cylinders, and ensures always safe rolling-off of both cylinders without danger of their damage.

3. Cured cylinders

The very long life of the cylinders is achieved by the use of special high quality steel as well as by combining several process techniques for the surface coating of the cylinders. As a result, the abrasive wear of the cylinders is several times smaller than how it is usual in cylinders made of the finest cast iron, cast steel or hardened steel cylinders used by other world manufacturers.

4. Guaranteed parallelism between the axes of both cylinders.

Malt milling machines of most manufacturers in the world, which are based on the independent mounting of the two roller bearings of the movable cylinder, can not ensure the ideal parallelism of the two cylinders and thus the same size of the gap between rollers on entire length. In MMR machines, the movable cylinder forms a rigid system that prevents the axis of the moving cylinder deflecting from a precisely defined position.

5. Reliable gearbox

The torque from the electric motor to the drive roller shaft is transmited by belts. The driven adjustable roller is driven from the drive roller by gear wheels. One gear wheel is made of special mass. Such a gear has a high service life, proven by long-term load of our machines at many our customers. The transmission gear does not require lubrication and has a low noise level.

6. Various installation options

Machines are most commonly used on their own, but they are rarely as part of production lines. Handling and loading raw material into the hopper is performed manually, or to eliminate physical strain and time saving, the machine may be placed under the hopper outlet or the screw conveyor from room with store of malt is inserted into the hopper from upside. The milled malt is discharged to the suspended bag or to a screw conveyor connected to dosing, mixing, transport, storage of malt scrap. Otherwise the milled malt may been falling directly into the wort machine.

7. Simple and maintenance-free operation

All controls are available from one side of the machine. During operation, it is only necessary to regulate the milling fineness setting and the amount of incomming raw material feeded from the hopper. The machine placed on bagging stand requires the operator to manually handle both empty and filled bags, fixing of bags under machine, and keep control of the fill rate. Few necessary maintenance tasks is to be done only when replacing the damaged rolled up rollers.

RECOMMENDED ACCESSORIES :

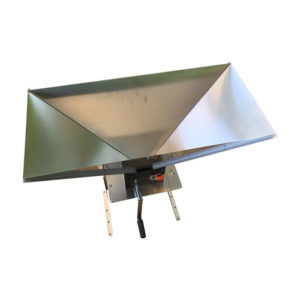

- Hopper lid – This optional part is intended to use with a screw conveyor (as a reductor between screw conveyor and mill). The lid enlarges a space for accumulation of malt above the sieve, prevents dust leakage during the malt squeezing process. This part must be used always when the electro-magnet is used.

- Electromagnetic separator of metal parts – The optional accessory for the malt mill for increase the purity of malt squeezing process. Its function is the separation of metal parts from milled malt above rollers.

- Control panel – The power cabinet with all electric signal, control and power elements designed to powering and control fo the machine. The control panel has to be placed on the wall near of the machine.

Optional part |

Price |

| Hopper lid | included in price |

| Electromagnetic separator of metal parts EMPS-6 | € 1139,- |

| Control panel – switchboard | € 2590,- |

| Dosing turniquets | € 9212,- |

Spare parts |

Price |

| 2 pcs roller shell – 107 05 02 01 | € 6300,- |

| 2 pcs complete roller (with roller shafts and hubs) – 107 05 02 00 | € 8600,- |

| 2 pcs TITAN modified rollers (longer lifetime) | € 1700,- |

All prices are ExWorks.

Reviews

There are no reviews yet.