Description

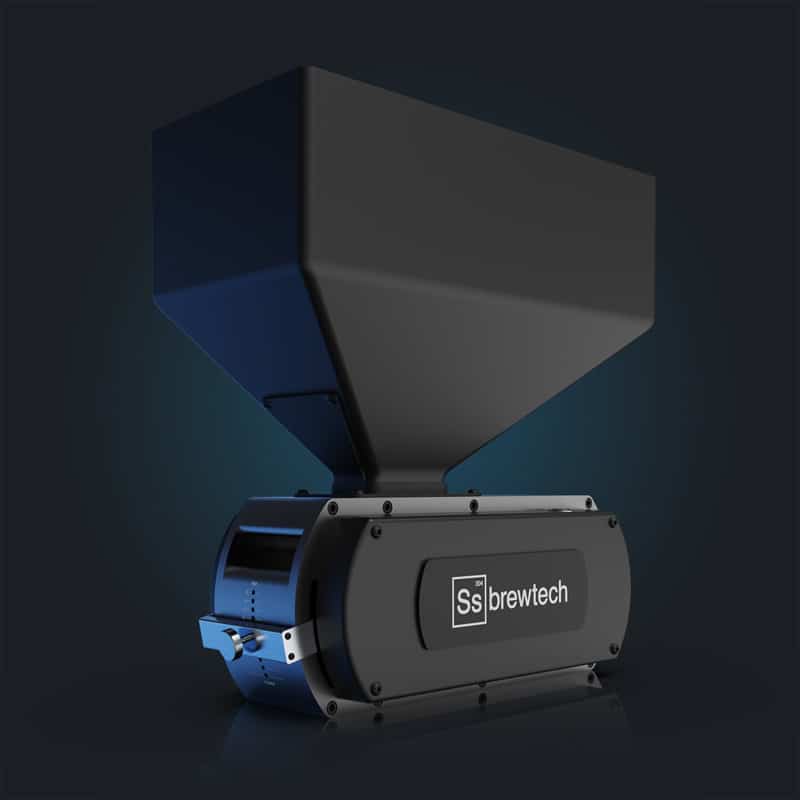

Brewtech malt grain mill – with production capacity up 160 kg (350lb) per hour, for fine squeezing malt grains before beer brewing.

High quality of all materials of the electrical mill for preparation of malt grist from malted grains, fluted rollers, tool-less gap adjustment and differential speed rollers are just a few features that set this malt grind mill the best choice for the beer brewing in microbreweries.

We recommend this model of mill for microbreweries (with a volume of the brewhouse wort machine up to 600L.)

Technical description and features :

- Capacity of production : 160 kg of malt grist per hour

- Two rollers with differential speed

- Adjustable distance between rollers

- High torque DC motor

- Leveraged gear reduction system

- Aluminum pulleys and high inertia rollers

- Easy work with all wheat and rye malts

- Power supply : 1-phase 230V/50Hz 16A

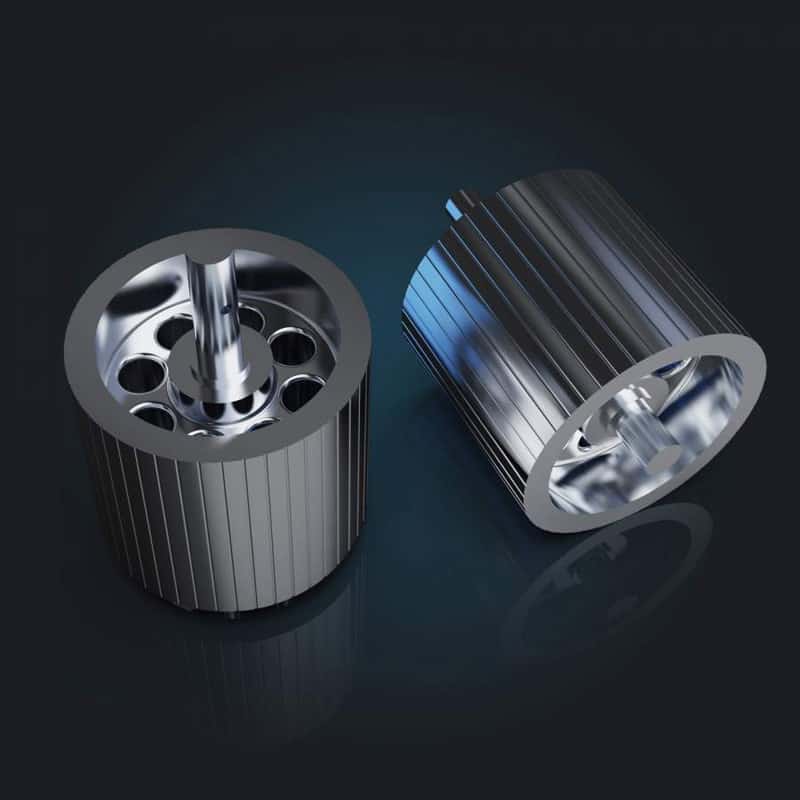

Differential speed rollers

This mill is designed specifically for processing malt. The key feature are the two rollers inside of this specially developed mill, both driven by the built-in motor, that are designed to rotate at different speeds.

If you’re brewing beer then you don’t want to crush the grains. It’s preferable to crack the endosperm in several places, then sheer off the husk and keeping the grains mostly intact. Construction of this mill maximizes efficiency of the malt grains preparation before brewing beer.

Machinery fluted stainless steel rollers

Machinery fluted stainless steel rollers

Other malt grain crushers that are designed to pulverize grain, are often equipped with hardened steel knurled rollers, whereas the Ss Brewtech Grain Mill is equipped with fluted rollers that are cast in solid 304 stainless steel, weighing a robust 3.4 kg.

Thanks to its shearing action less stress is placed on the roller to effectively process the grain. Fluting the rollers enhance their capacity to process the malt grains without their damaging.

Furthermore, the profile of the rollers has been completely rethought. While most small malt grain crushers rely on a small, 3,8-5 cm diameter roller, Ss Brewtech has emulated the design of large production mills and increased the diameter of the roller to 10 cm.

This design increases the rotating mass, and stores rotational energy, which ultimately helps to smooth abrupt changes in rotational speed. Furthermore, the entrance angle is less acute with a larger roller, resulting in additional mechanical advantage and this is gentle for malt grains.

Precision gap adjustment

Eleven points of adjustment ranging from 0.5 to 2.0 mm open up a wide range settings of the gap between both rollers for all kinds of malt products. Gap adjustment is tool-less and it can easily be made without any disassembly.

Aluminum case

The two-piece aluminum case promotes structural rigidity resulting in a more precise degree of roller alignment. This is important to retaining consistent roller gap settings.

Furthermore, the two-piece construction isolates the motor and rollers in separate chambers, preventing the motor and drivetrain from accumulating dust and debris. All rotational pulleys and rollers have their own dedicated fully sealed ball bearings for low drag and long life.

Hopper capacity of 11.3 kg

The malt grain mill includes a custom tooled 4 mm thick ABS hopper that is both structurally strong and lightweight. The hopper hold up to 11.3 kg of grain at a time.

The machine has been tested at processing roughly 160 kg per hour of barley malt. Which is approximately a 25kg bag with malt every 8 mins, making it perfect for brewing batch sizes from 19 liters (5 gallons) up to 800 liters (5 bbl).

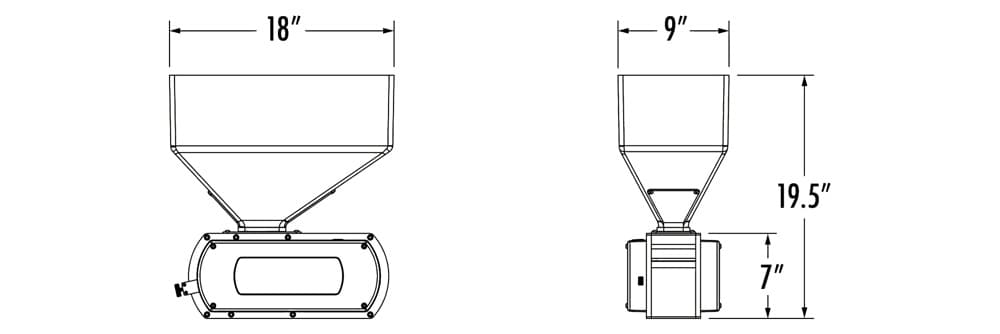

Dimensions :

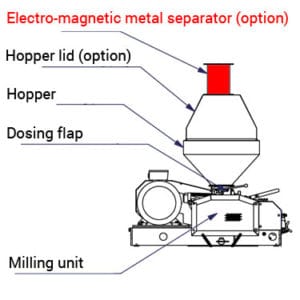

Optional accessory :

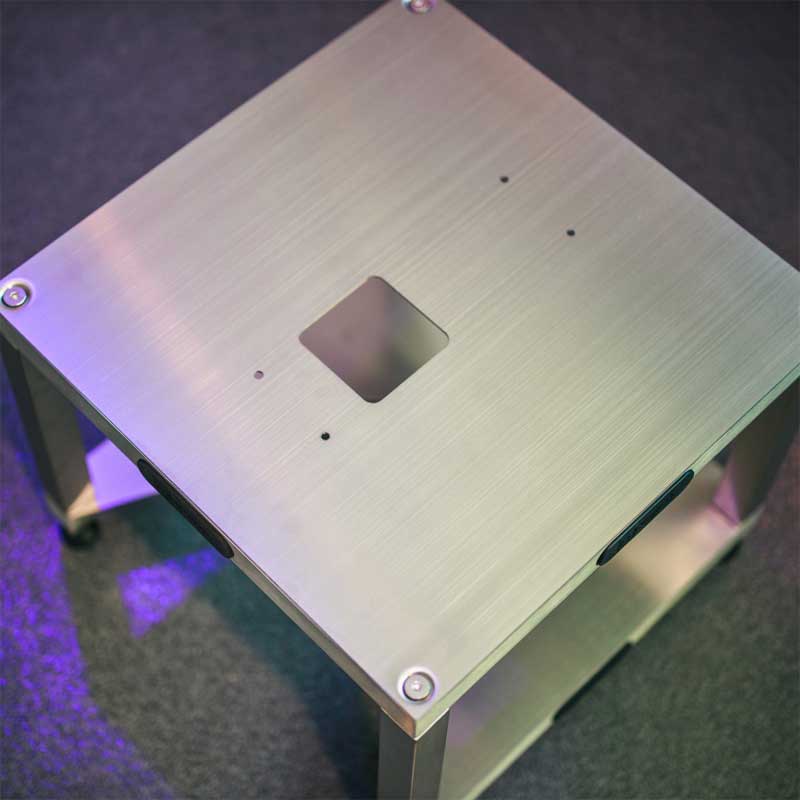

Stainless steel stand for the MM-160BT malt grain mill

Designed especially for the MM-160BT Malt grain mill .

The top plate has precision machined mounting holes, as well as a grain chute port.

The removable bottom plate is designed to easily align a standard five gallon (23 liters) bucket commonly used in grain transfer for home and nano breweries.

- Material : AISI 304 stainless steel

- Dimensions : Approximately 50,8 x 50,8 x 43,18 cm

Videos :

Reviews

There are no reviews yet.