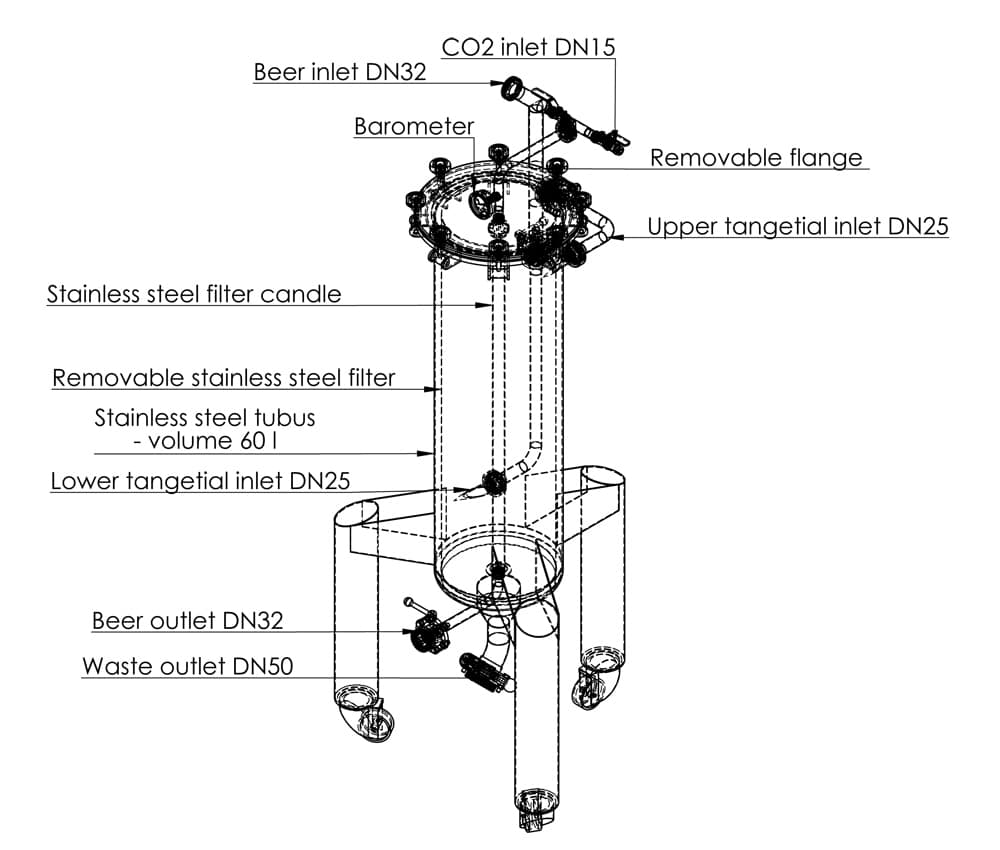

Description

The hop extractor – Dry hopping tank – is an equipment for extraction of aromatic active substances from hops into cold beer (dry hopping) – an infusion of hop extracts to finalized cold beer after finalizing the beer fermentation process. This equipment is used in the production of strongly bitter beer types, such as IPA (India Pale Ale). The capacity of the hop tank is 25 liters.

A cylindrical vessel on three legs with wheels. It is used to dissolve granulated hops in finished beer. It does not increase the bitterness of beer and it supports the special aroma of hops. Effective extraction of hops, a united and definable beer aroma, reduces the consumption of hops. This equipment is simply used and It can be easily integrated into the existing fermentation and filling.

Why to use the hop extractor?

- It emphasizes the aroma of hops in beer

- Sensitive and careful dissolution of hop pellets (type 45 and 90) in the cold beer

- Optimal extraction and increase in the proportion of essential oils in finished beer

- Fixed period of the extraction of hops

- Without heating, absence of agitators

- Excellent separation of extracted substances – it does not cause problems during a filtration

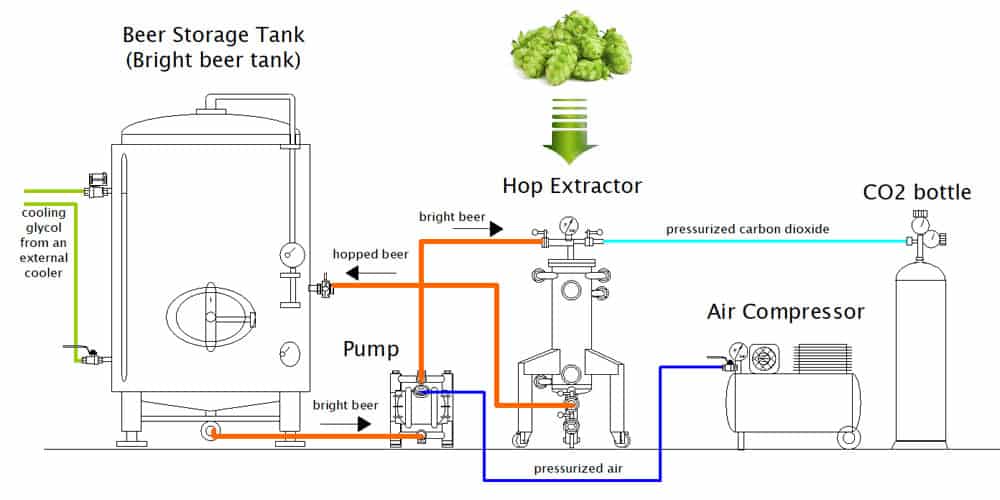

Scheme of the recommended connections and all needed equipment for the cold extraction of hop into beer

We recommend to use the hop extractor with a peristaltic or membrane pump. The process of dry hopping is optimally done when the entire volume of the beer tank flowed through the equipment – the hop extractor.

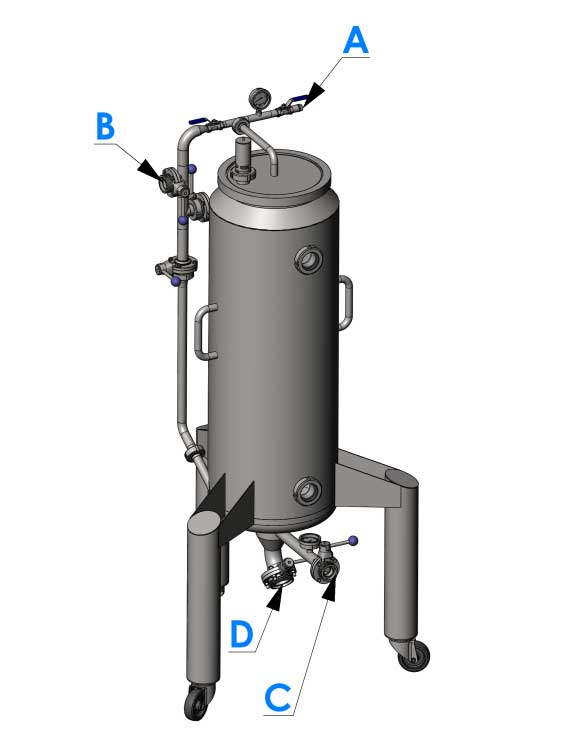

Connections :

| Connection : | Media : | Description : |

| A | Gas inlet | Inner thread BSP 1/2″ |

| B | Product inlet | DIN 11851 DN 32 (threaded neck) |

| C | Product outlet | DIN 11851 DN 32 (threaded neck) |

| D | Drain outlet | DIN 11851 DN 50 (threaded neck) |

How does it work:

- Firstly, open a top lid of the device (unscrew all screws).

- Fill with: hop pellets (20% of the total volume of the hop extractor) and close the top lid, tighten all screws of the lid.

- Connect a beer tank and the device with the membrane pump according to the picture above.

- Push air out – start to fill the device with beer and open the top CO2 inlet. The air will be pushed out through the opened valve. Close the top part when the device is full of beer.

- If the pressure in the tank of the device is too low, refill CO2 into the tank from the CO2 bottle.

- Open all valves in the circle. (Input and output: the device, input and output of the beer tank).

- Turn on the membrane pump (2 – 6 hours). The time of the extraction of hops depends on a volume of the beer tank.

- Push all beer – start to fill the device with CO2 and open a bottom HG outlet. Beer will be pushed out through the opened valve.

- Close all valves in the circle. (Input and output: the device, input and output of the beer tank)

- Reconnect the system, clean and disinfect the device, pump and hose.

- If the pressure in the tank is too low, refill CO2 into the tank from the CO2 bottle.

- Your beer is now ready.

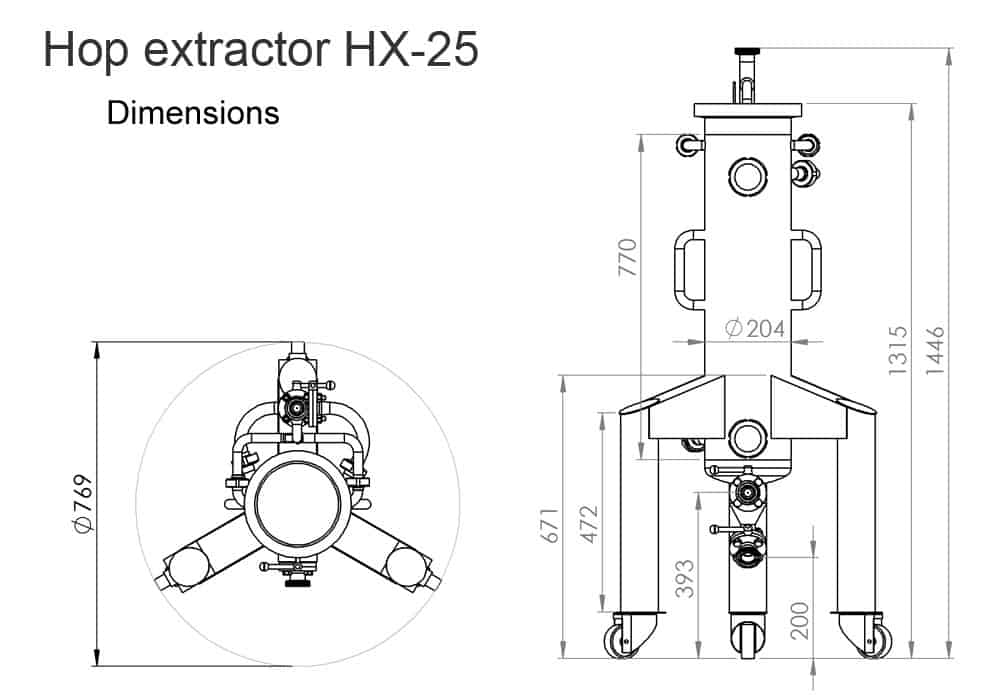

Technical parameters :

- Height of the tank … 770 mm

- Total height … 1446 mm

- Width …. 600 mm

- Diameter … 204 mm

- Weight … 42 kg

- Total volume of the container … 26 liters

- Filling capacity … 8.5 liters of dry hops

- Designed for use with beer tanks up to 1000 liters

- Special permeable candle made of stainless steel.

- Simple sanitation when connected to CIP station

- Material – stainless steel AISI 304

Legal restriction : This product is not available for customers in Germany and USA.

Recommended accessories :

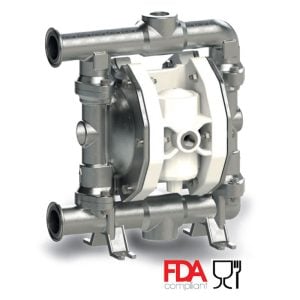

Pneumatic stainless steel diagphragm pump

A membrane pump for the beer circulation

A membrane pump for the beer circulation

Pneumatic stainless steel diaphragm pump for feedeng beer or cider to the filler, hop extractor or other equipment for product finishing. This device works without electrical consumption – it needs only pressure air and a pressure reduction valve. Minimalized mechanical impact on beer.

Features and benefits

- Adjustable flow rate and head via air pressure.

- 100% tested after final assembly regarding deadheading, priming, and sealing.

- Efficient air distribution design: low air consumption.

- Special air system: lube-free, non-stall, non-freeze, designed to operate at low noise levels.

- Suitabe for use in hazardous areas or areas with high humidity.

- Fully submersible.

- Dry-running without damaging the pump or system.

- Pump restart without any problems.

- Pumping against closed discharge without any pump damage. A diaphragm pump will stop if discharge will be closed (1:1 ratio between air and discharge pressure).

- fficient performance: high flow rates through optimal casings designs.

- Portable and compact for multi-location use, optionally available with trolley.

- Different connection possibilities through different suction and discharge ports.

- Bolted construction prevents any leakage and assures maximum safety

- Easily and quickly to maintain without the need of any special tools

Reviews

There are no reviews yet.