Description

There is necessary to have enough of drinking hot water available during beer production process. Hot water is used for mixing malt mash in water in process production of wort, for showering of wort during the lautering process, for cleaning and sanitizing of the brewhouse and other vessels etc.

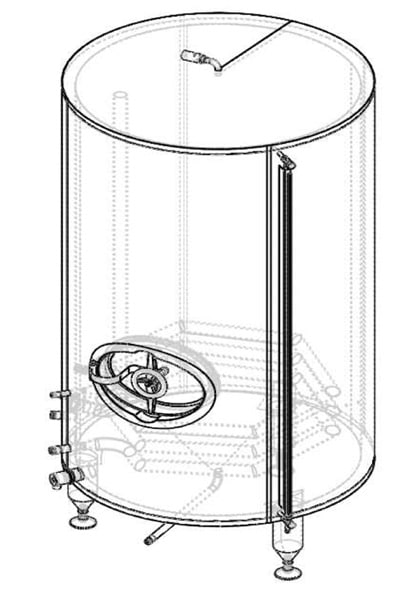

The hot water tank HWT-1500 (boiler) is equipped with a water pumping unit. It is designed for storage of 1500 liters preheated water from the first cooling stage and following heating up to 80°C. The container is made of material AISI 316L, DIN 17 349, AKV extra 2.

Four variants of heating system :

- SH – Steam heating system – water is heated with hot steam (requires an external hot steam generator). Includes the water pressure station.

- EH – Electric heating system – water is heated with electric heating spirals. Includes the water pressure station.

- BH – Both heating systems – both electric and steam heating (requires an external hot steam generator). Includes the water pressure station.

- NH – Without a heating system – only for storage of externally heated water without any own heating system

Parameters:

Parameters:

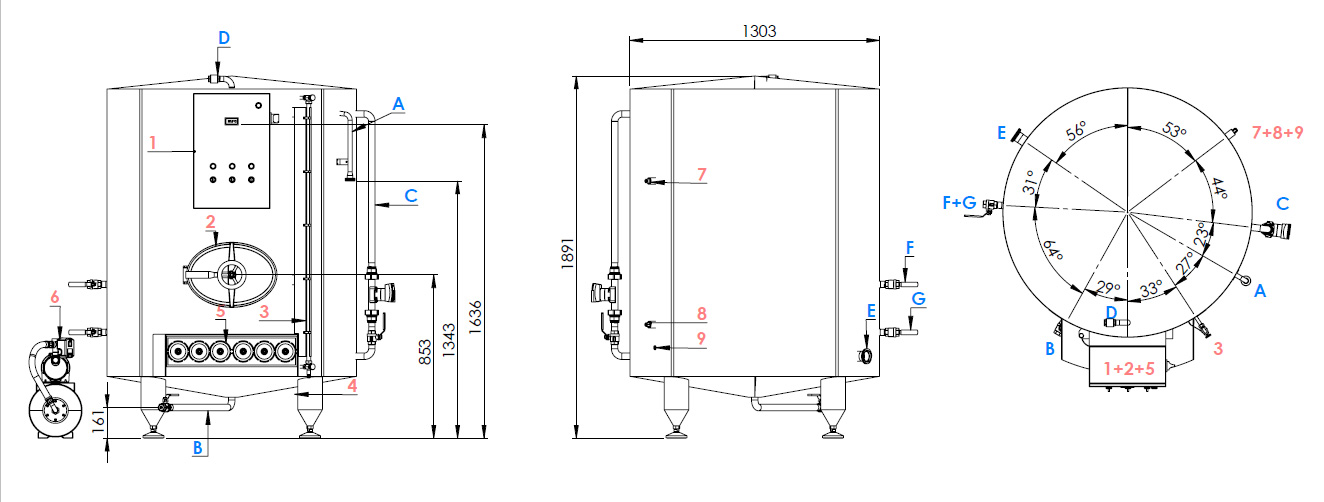

- Total capacity 1615 l

- Diameter with insulation 1303 mm

- Weight 118 kg

- Input power of heating element 3 500 W

- Input power of pumping unit 360W

- Overall height 1891 mm

Accessories:

- Oval manhole 340*420 mm

- Inlet and outlet armature DN 25

- Underpressure armature DN 25

- Overflow armature DN 25

- Float valve DN 25

- Expansion vessel 28 l

- Pump for water 95°C 360W, 230V, 50 Hz, Hmax 35

- Pressure switch of pump

- Armature for discharge into sewage DN 25

Electric switchboard and other equipment (valid for the BH combi version : steam and electric heating)

- Main switch 3ph 400V /50Hz 25A

- Circuit breaker of heater 3ph 400V /50Hz 25A

- Heating contactor 3ph 400V /50Hz 25A

- Digital regulator -15 -135°C Dixel XR20D

- Probe NTC

- Circuit breaker of regulator 230V 4A

- Motor starter 230V 1,5-4A

- 1pc of the electric heating element with input power 3500 W – the electric heater serves only to keeping of current temperature, not to main heating of water. Hot steam is main heating media to heating of water up.

- Pipe hot steam exchanger – an external hot steam generator is required to heating of water (not included)

Electric switchboard and other equipment (valid for the EH version : only electric heating)

- Main switch 3ph 400V /50Hz 25A

- Circuit breaker of heater 3ph 400V /50Hz 25A

- Heating contactor 3ph 400V /50Hz 25A

- Digital regulator -15 -135°C Dixel XR20D

- Probe NTC

- Circuit breaker of regulator 230V 4A

- Motor starter 230V 1,5-4A

- 3 pcs of the electric heating element with input power 6000 W (total 18000 W) – the electric heater serves to heating of water in the tank

- Optionaly : 6 pcs of the electric heating element with input power 6000 W = 36kW

- Without the steam heat exchanger

Electric switchboard and other equipment (valid for the NH version : without heating system)

- This version is only passive water boiler

- Without electric switchboard

- Without thermo sensors

- Without water pressure station

- Without thermo regulators

- Without electric heating elements

- Without the steam heat exchanger

Warranties:

- Tank 1570 l 36 months

- Pump 24 months

- Armatures 36 months

- Expansion vessel 24 months

- Electric switchboard 24 months

- Heating element 24 months

- Float valve 36 months

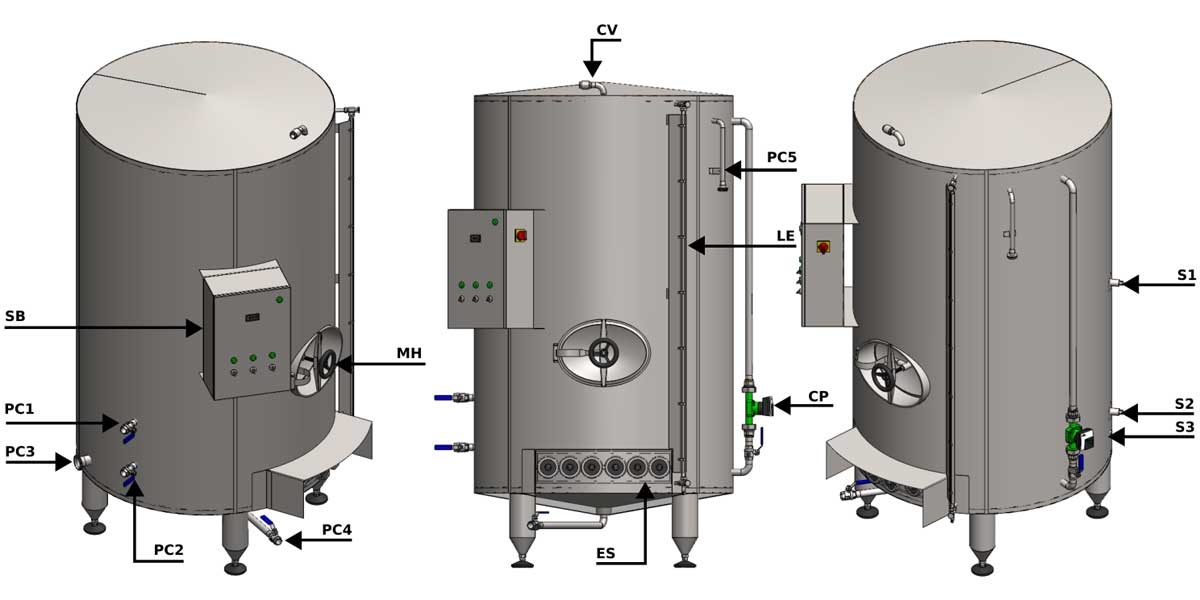

Description of the HWT-1500EH36 : Hot water tank with the electric heating system 6x 6kW (total 36 kW)

|

PC1 |

Pipe connection for water inlet |

Pipe DN32 – connection G1“ |

|

PC2 |

Pipe connection for pump suction |

Pipe DN32 – connection G1“ |

|

PC3 |

Pipe for overflowing |

Pipe DN50 – connection DIN11851 |

|

PC4 |

Vessel drain |

Pepi DN32 – connection G1“ |

|

PC5 |

Pipe connection for sanitation |

Pipe DN32 – connection DIN11851 |

|

S1 |

Socket for level sensor G1/2“ |

Sensor not included (MAVE) |

|

S2 |

Socket for level sensor G1/2“ |

Sensor not included (MAVE) |

|

S3 |

Thermal sensor G3/8“ |

PT100 |

|

SB |

Switchboard |

Unit control |

|

MH |

Manhole 321x456mm |

– |

|

ES |

Electric spirals – heating elements |

6 x 6kW |

|

CV |

Checkvalve |

Regulation presure while draining |

|

CP |

Circulation pump |

Homogenizing the hot water |

|

LE |

Level indicator |

– |

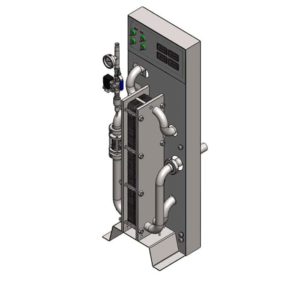

The Waterworks

The waterworks is always a part of the hot water tank delivery.

A water station is a device that ensures that hot water is available at the required pressure (usually 4 bar) at the outlet of the tank. From the point of view of the powered equipment, the hot water tank therefore appears as a standard water supply connection with a supply of pressurized hot water.

Dimensions :

Scheme of the hot water system in the Breworx breweries :

Reviews

There are no reviews yet.