Description

Automatic gas steam-generator with power capacity 189 kW (from 125 to 250 kg of hot steam per hour), steam pressure in range from 1 to 5 bar

Automatic gas steam-generator, available power 189 kW – The production capacity from 125 to 250 kg of hot steam per hour. Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 5 bar.

This steam-generator is equipped with gas burner RIELLO RS 4DF MBZRDLE 412g – gas inlet pressure 2-36 kPa. The steam-generator shell is manufactured in accordance to the current PED regulations.

Produced in EU

Recommended usage :

- Heating of brewhouses – recomended for brewhouses with maximal usage volume from 1500 to 3000 liters per one brew

- Heating of hot water in heat water tanks – boilers

- Sterilization of vessels, pipes, hoses and food equipment or farmacy equipment by hot steam

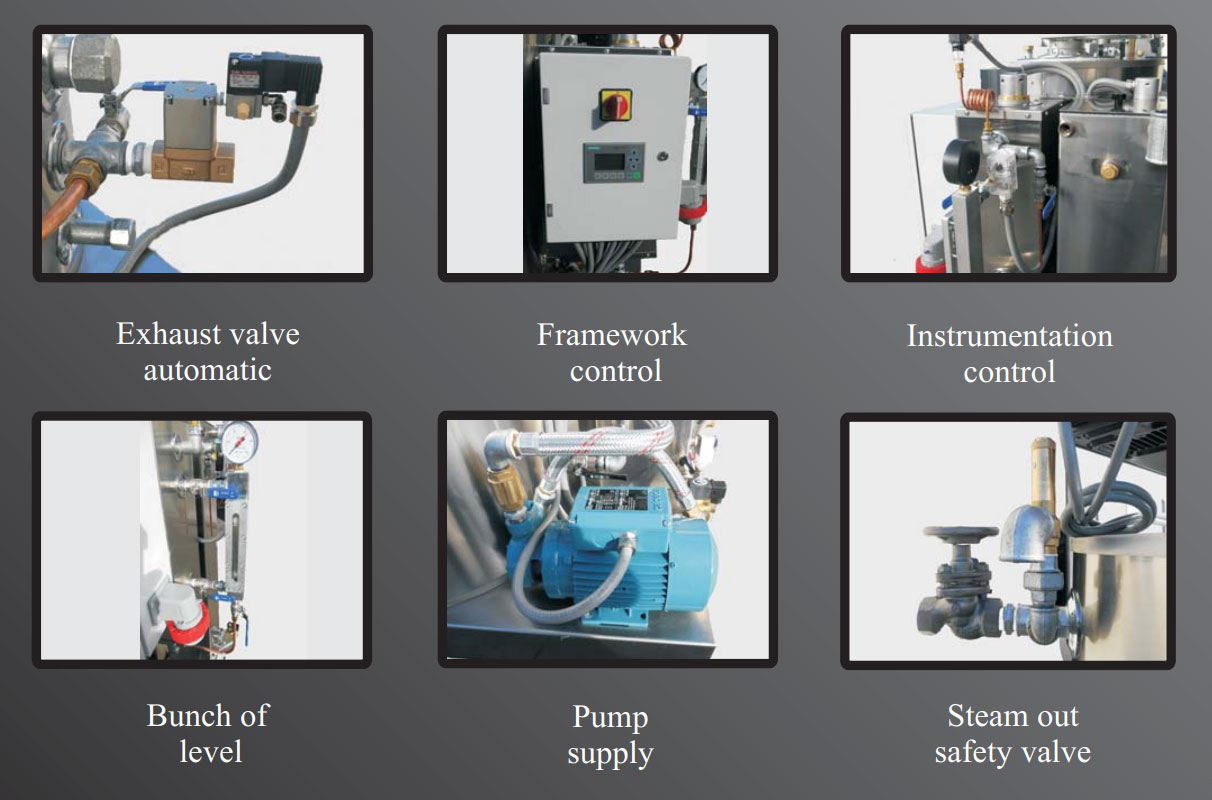

Standard accessories and properties (included in price) :

- Ready for use with common heating medium: natural gas, LPG or diesel (light fuel oil)

- Steel condensate recovery tank and all equipment for returned condensate reuse

- High temperature pump

- High efficiency burner – min. 92%

- Steel boiler

- Working ambient temperature : +5°C up to +80°C

Benefites :

- Easy connecting to the media (gas event. light fuel oil, water, electricity, steam exhaust, chimney, condensate outlet)

- Water tank with a pump, control the water level and temperature, incl.all valves, closing and locking components.

- Steam production within a few minutes

- Automatic boiler sludge draining system

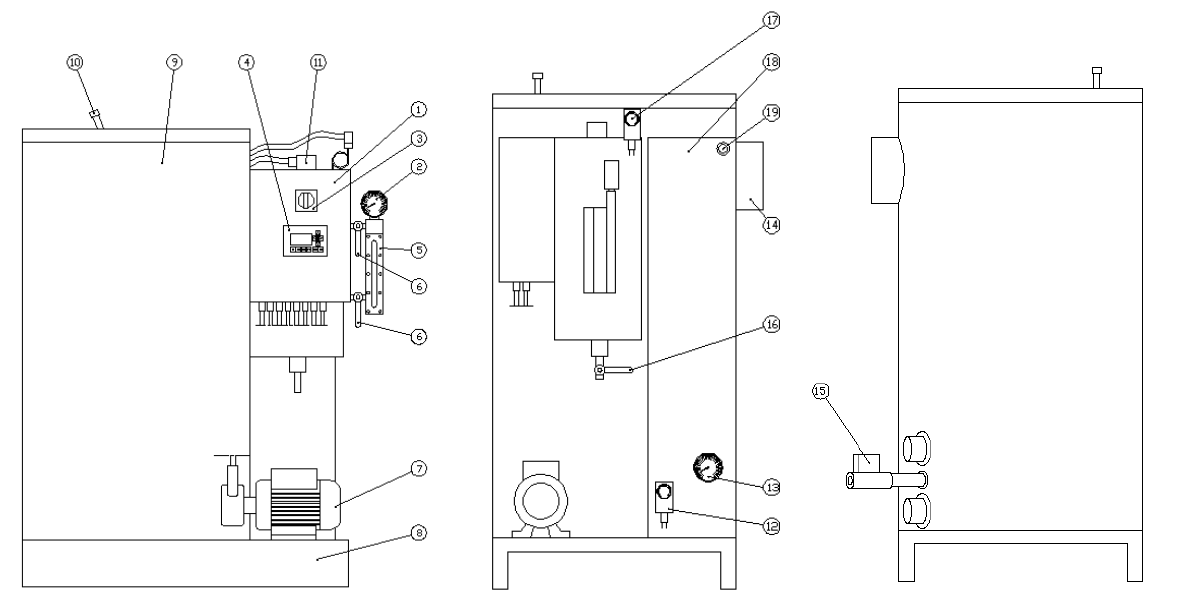

Description of main parts :

- Electric switchboard

- Manometer

- Main switch (on/off)

- Control panel

- Water level indicator

- Valves to closure of the level indicator

- Pump

- Basic frame

- Boiler body

- Inspection pipe

- Level probes

- Thermostat

- Thermometer

- Outlet of the exhaust fan

- Blowdown valve

- Boiler discharge valve

- Pressure relief valve

- Water reservoir

- Water overflow drain outlet

Technical parameters :

| Type | GSG-AV250 / ANFRA A.V.250 |

| Steam production capacity | 250 kg/h |

| Steam output power capacity | 189 kW |

| Steam output power capacity | 162500 kcal |

| Steam output pressure | 5 bar |

| Gas consumption (light fuel oil) | 19.0 m³/h |

| Diesel consumption | 16.2 kg/h |

| LPG consumption | 13.5 kg/h |

| LPG consumption | 6.0 m³/h |

| Electric power supply | 400V / 3phase + N / 50 Hz / 1.50 kVA |

| Steam output connection | GAS 1 inch |

| Waste vapour outlet (chimney connection diameter) | 200 mm |

| Pressure of waste vapour | 3.5 bar |

| Net weight | 430 kg |

| Jet length of the gas burner | 200/250 mm |

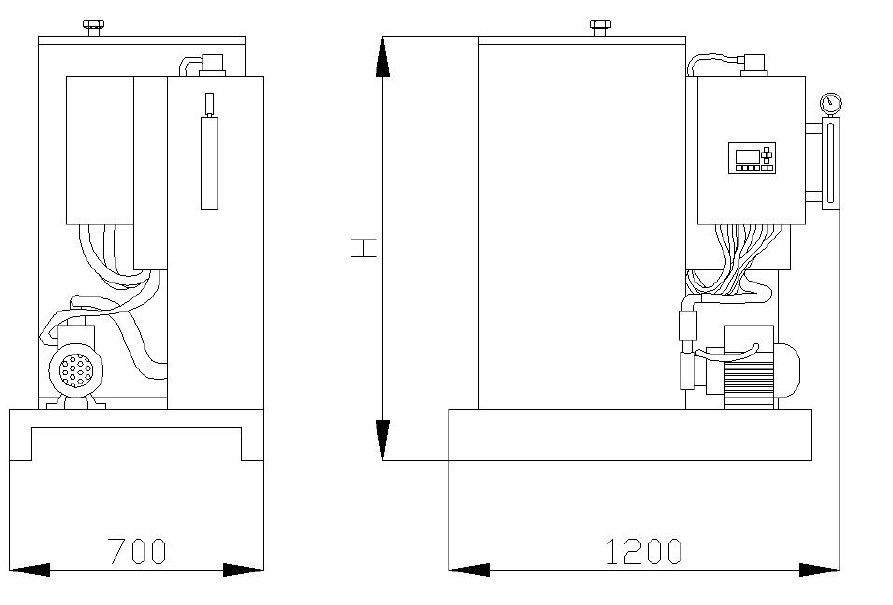

| Height (without the gas burner) | 1670 mm |

| Width | 1200 mm |

| Depth | 700 mm |

Outer dimensions :

| Model | GSG-AV50 | GSG-AV100 | GSG-AV150 | GSG-AV200 | GSG-AV250 | GSG-AV300 | GSG-AV350 |

| height (mm) | 1130 | 1130 | 1400 | 1400 | 1670 | 1670 | 1670 |

Optional accessories (for surcharge) :

| Item code : | Description : | Price : |

| GSG-ASS | Automatic start system (the machine and hot steam will be ready to use in time you need) | in price |

| GSG-ABSD | Automatic boiler sludge draining system (do not need an operator manual activities – the digital timer and the pneumatic valve are included) | in price |

| GSG-STPH | Supply tank pre-heating (ensures quick start of the steam production) | On demand |

| GSG-ETCP | External LCD touch control panel (secondary LCD control panel for placing anywhere – 24V supply and FTP cable between the steam generator and the external LCD panel are required) | On demand |

| GSG-SOHS | System for over heating the steam (over heates the outgoing steam to temperature up to 180°C on 5 bar pressure) | On demand |

| GSG-ECON | Economizer (waste heat is used for pre-heating of water – the efficiency is 5% higher – up to 98% ) | On demand |

| GSG-DBP | Special burner and the pump for use the steam generator with diesel (the light fuel oil) | On demand |

| GSG-350A-CT | Cooling tank for the boiler sludge draining system | On demand |

| WTS-MX120 | Water treatment simple system (necessary equipment if water for use with the machine is not absolutelly soft) | On demand |

| WTS-SG3 | Water treatment duplex system (necessary equipment if water for use with the machine is not absolutelly soft) | WTS-SG3 page |

| SSFS-MX44 | Complete set of stainless steel accessories for achieve pure steam (culinary quality) for 1″ steam pipe line | SSFS-MX44 page |

Instalation : Installation and assembling of the gas steam-generator performs each specialist company authorized for installation of gas appliances. The customer receives detailed installation instructions in the manual.

Warranty : 12 months

Delivery time : from 3 days to 6 weeks (according store status)

Certificates: CE + PED 97/23/CE

Reviews

There are no reviews yet.