Description

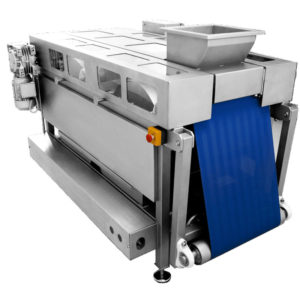

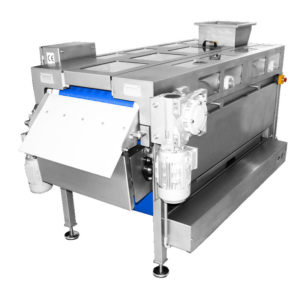

A combi multifunction machine includes two functionalities in one compact block : the fruit-rinser with rotable brushes and the fruit-crusher. Production capacity is from 1500 up to 2000 kg of fruits (apples, pears …) per hour. Fruit is washed in the hopper with water and cleaned with rotable brushes. Then fruit goes to the crusher using the transportation belt. During the must production, the machine is designed to the rinsing and crushing of apples, pears or other fruit into small pieces, from which subsequently the fruit-press squeezes the fruit juice which is the starting intermediate for the production of fruit must or cider. Made in European Union.

Main advantages and properties :

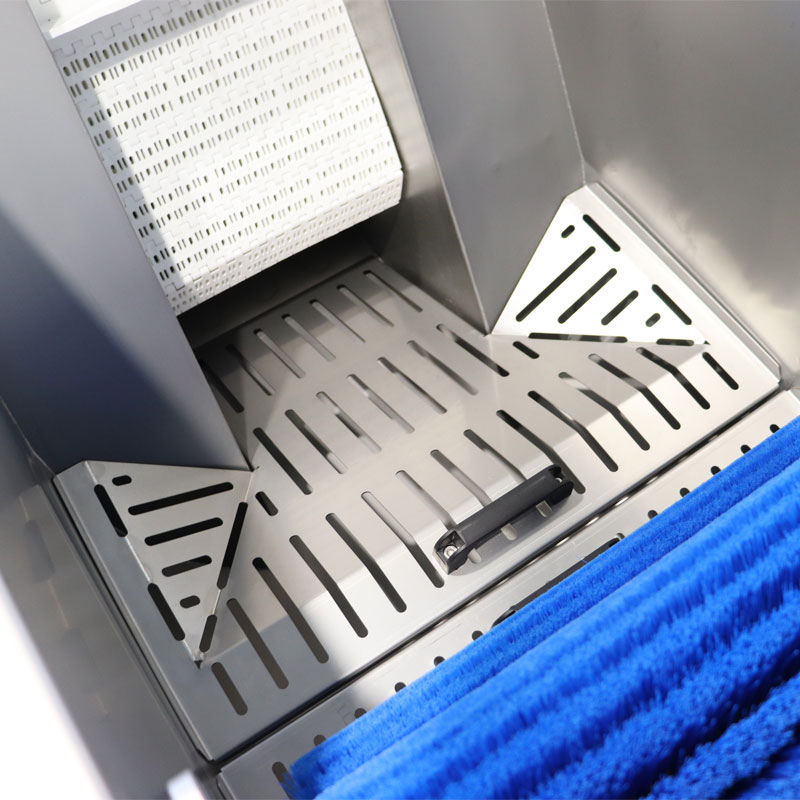

- The bottom is tilted, so it will providing a significantly better drainage.

- Turnable control panel grants side-free operation.

- The touchscreen display can be folded to both sides without tools or assembly.

- Foldable input table for reducing the gross dimensions for transportation. When it is folded inside, stone-fruits can go straight to the water tub avoiding the brushes.

- The grinder screen is available with two different, choosable hole diameters. After the screen is removed, it can be repositioned upside down, thus switching to a screen with a different hole diameter.

- Grinder can be missed by a by-pass slide when processing stone-fruits

- Water circulation system with the filter

Built-in Schneider PLC panel with the following functions:

- Working hour counter

- Elevator controls – speed and grinder

- Brush control

- Error log

- Notifications for the operator about maintenance according to the working hours

Optional:

- Remote access (internet connection needed)

- Adaptive water valve – fresh water spray only works when the elevator is working. When the elevator stops, the water also stops.

- Stop and go system for beltpress

- Stronger fruit grinder motor (3 kW instead of 2.2 kW) – recommended for hard fruit

New design :

Technical description :

– Capacity from 1500kg up to 2000kg per hour (apples, pears)

– Made of stainless steel AISI 304 / 1.4301

– Equipped with adjustable feet

– Central control cabinet

– Steppless speed control

– Optional rudeness of crushing

– Electric consumption 4 kW / 10 A

– Electrical connection 16A 3F 400V / 50 Hz

– IP65 electrical control box

– Machine complies with EU guidelines

– Minimal maintenance

– Belt speed infinitely adjustable

– Easy to handle

– Easy to clean

– Swivel grinder

– Noise emission: 60-70 dB

– Equipped with 4 counter-rotating brushes for intensive washing

– Washing container size: 280 L

– Water requirement: 100-200 L/h (depending on the settings)

– Water connection: ¾” quick coupling

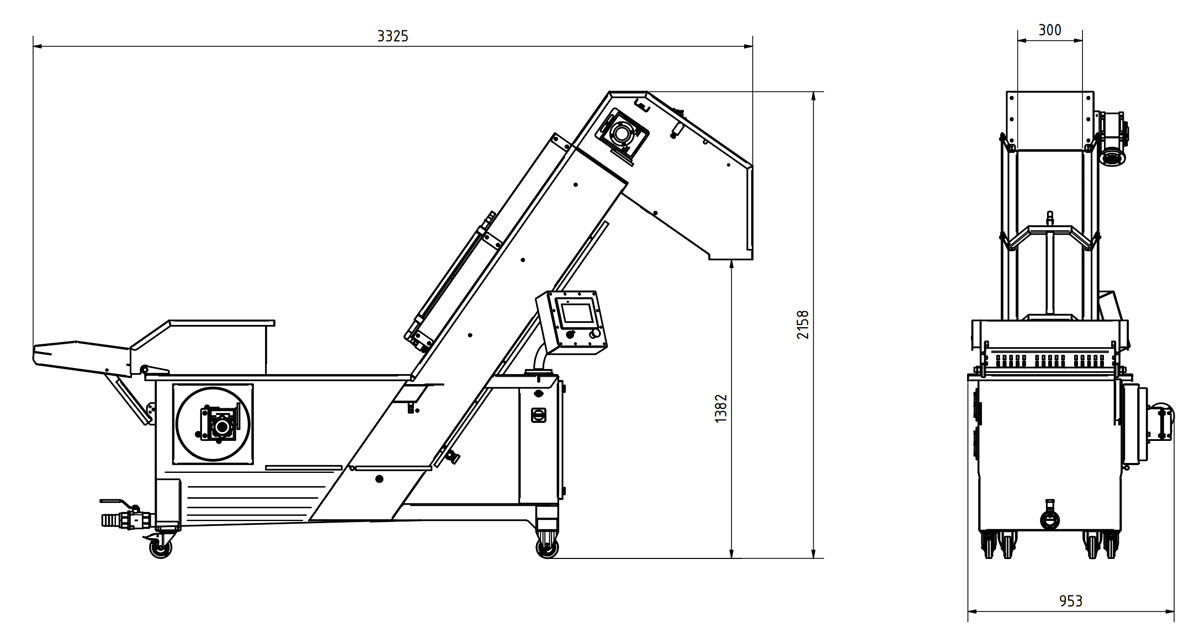

Dimensions :

– Receive opening height … 910 mm

– Output height … 1280 mm

– Length … 3325 mm

– Width …. 953 mm

– Height … 2158 mm

– Weight … 290 kg

Dimensions for transport : 3350mm x 1000mm x 2350mm / 310 kg

Hose connections on the machine :

| Description (purpose) | Hose connection on the machine | Intended for |

| Filling the tank with water | Gardena quick connector 3/4″ male | Hose 3/4″ with the Gardena quick connector 1/2″ female |

| Water spray inlet | Gardena quick connector 3/4″ male | Hose 3/4″ with the Gardena quick connector 1/2″ female |

| Water overflow outlet | Hose nipple 1 1/4″ | Hose 1 1/4″ |

| Waste water outlet | Hose nipple 2″ | Hose 2″ |

The machine is delivered with the standard 15mm sieve. Optionaly available sieves : 5-8-10-15 mm (for demand).

Optional equipment :

| Code | Description | Price |

| FWBC-ECL | Electrical cabinet on the left side (standard position is on the right side) | € 100,- |

| FWBC-SGS | Stop & Go system (membrane sensor and switch that allow to operate the fruit washer-grinder and the beltpress together ) | € 890,- |

| FWBC-ABW | Air blowing into the washing water for more intense fruit washing | € 1990,- |

| FWBC-AKN | Air knife for intensive drying of the fruit on the conveyor | € 1990,- |

| FWBC-AWV | Adaptive water valve for regulation of water consumption | € 290,- |

| FWBC-DPP | Doser for a pack press | € 890,- |

| FWBC-CPF | Circulating pump and filter for washing water | € 1990,- |

| FWBC-SCO | Silicone cover on the fruit output | € 350,- |

| FWBC-SDO | Sliding door for the output with end-switch, that allows the dosing of fruit mash from the fruit grinder safely to the belt press | € 350,- |

| FWBC-EPM | Elevation paddle module (spare part) | € 35,- |

| FWBC-ELM | Elevation link module (spare part) | € 26,- |

| FWBC-EPI | Elevation pin between modules (spare part) | € 11,- |

| FWBC-ELV | Elevation change (non-standard height of the fruit input and output for request) / price for each 100 mm | € 350,- |

| FWBC-CPM | Conveyor paddle module | € 35,- |

| FWBC-CLM | Conveyor link module | € 26,- |

| FWBC-CRP | Conveyor removable pin between modules | € 11,- |

| FWBC-SBW | Spare brush for the washing module (full set) | € 890,- |

| FWBC-SHG | Spare hammer for the fruit grinder | € 490,- |

| FWBC-BCA | Bearing for the conveyor axis | € 110,- |

| FWBC-FIN | Frequency inverter for variable speed of the conveyor | € 790,- |

| FWBC-SFG | Sieve for grinder (with chooseable hole diameters 5-8-10-15 mm) | € 49,- |

| FWBC-M30 | Stronger motor (3 kW instead of 2.2 kW) | € 750,- |

Video

Reviews

There are no reviews yet.